Bosch Tronic TR4500T 50 EB Installation guide

- Category

- Water heaters & boilers

- Type

- Installation guide

This manual is also suitable for

User and Installation manual

Electrical storage water tank

Tronic

TR4500T 30|50|80|100|120|150 EB

6 720 884 457 (2018/02) DK-(en)

2

Index

Tronic – 6 720 884 457 (2018/02)

Index

1 Key to symbols and safety instructions . . . . . . . . . . 3

1.1 Key to symbols . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Security Measures . . . . . . . . . . . . . . . . . . . . . 3

2 Technical Characteristics and dimensions . . . . . . . 6

2.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Type overview . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Appliance Description . . . . . . . . . . . . . . . . . . 6

2.4 Anticorrosion protection . . . . . . . . . . . . . . . . 6

2.5 Accessories (included in the appliance

packaging) . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.6 Technical specifications . . . . . . . . . . . . . . . . 7

2.7 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.8 Electrical wiring diagram . . . . . . . . . . . . . . . 9

3 Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1 Transport, storage and recycling

regulations . . . . . . . . . . . . . . . . . . . . . . . . . 10

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.1 Important notes . . . . . . . . . . . . . . . . . . . . . . 10

5.2 Siting the appliance . . . . . . . . . . . . . . . . . . . 10

5.3 Wall mounting . . . . . . . . . . . . . . . . . . . . . . . 11

5.4 Water connection . . . . . . . . . . . . . . . . . . . . 11

5.5 Electrical connections . . . . . . . . . . . . . . . . . 13

5.6 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6 Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.1 Turning the appliance on/off . . . . . . . . . . . 15

6.2 Operating the heater – manual setting . . . 15

6.3 Operation of the heater in

the "BOOST" mode . . . . . . . . . . . . . . . . . . . 15

6.4 The Anti-Legionella Function . . . . . . . . . . . 15

6.5 Emptying the appliance . . . . . . . . . . . . . . . 16

7 Environment / disposal . . . . . . . . . . . . . . . . . . . . . . . 16

8 Inspection/Maintenance . . . . . . . . . . . . . . . . . . . . . 17

8.1 User information . . . . . . . . . . . . . . . . . . . . . 17

8.1.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8.1.2 Safety valve verification . . . . . . . . . . . . . . . 17

8.1.3 Safety valve . . . . . . . . . . . . . . . . . . . . . . . . . 17

8.1.4 Maintenance and repair . . . . . . . . . . . . . . . 17

8.2 Periodic maintenance work . . . . . . . . . . . . 17

8.2.1 Functionality verification . . . . . . . . . . . . . . 17

8.2.2 Magnesium Anode . . . . . . . . . . . . . . . . . . . . 17

8.2.3 Periodic cleaning . . . . . . . . . . . . . . . . . . . . . 18

8.2.4 Long standing - non working

(more than 3 months) . . . . . . . . . . . . . . . . .18

8.3 Required actions after any maintenance

work has been carried out . . . . . . . . . . . . . .18

9 Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

9.1 Indication of errors . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3

Key to symbols and safety instructions

Tronic – 6 720 884 457 (2018/02)

1 Key to symbols and safety instructions

1.1 Key to symbols

Warnings

The following keywords are defined and can be used in this

document:

• NOTICE indicates a situation that could result in damage to

property or equipment.

• CAUTION indicates a situation that could result in minor to

medium injury.

• WARNING indicates a situation that could result in severe

injury or death.

• DANGER indicates a situation that will result in severe

injury or death.

Important information

Additional symbols

1.2 Security Measures

Installation

▶ Installation must only be carried out

by an authorised service.

▶ IEC 60364-7-701 must be observed

when installing the appliance and or

electrical accessories.

▶ The appliance must be installed in a

room free from the risk of frost.

▶ First connect the appliance

hydraulically and fill with water, then

connect the power supply.

▶ During the installation isolate the

appliance from the power supply.

▶ In a closed, pressurised system of

installation, it is obligatory to install a

safety valve on the inlet pipe with a

rated pressure of 0.6 MPa (6 bar),

0.9 MPa (9 bar) or 1.0 MPa (10 bar)

(see the label), which prevents the

elevation of pressure in the boiler by

more than 0.1 MPa (1 bar) above the

rated pressure.

▶ Water may drip from the outlet

opening of the safety valve, so the

outlet opening should be set to

atmospheric pressure.

▶ The outlet of the safety valve should

be installed facing downwards and in

a non-freezing area.

▶ To ensure proper functioning of the

safety valve, the user should perform

regular controls to remove limescale

and make sure the safety valve is not

blocked.

Warnings in this document are identified by

a warning triangle printed against a grey

background.

Keywords at the start of a warning indicate

the type and seriousness of the ensuing risk

if measures to prevent the risk are not taken.

This symbol indicates important information

where there is no risk to people or property.

Symbol Explanation

▶ Step in an action sequence

Cross-reference to another part of the document

•List entry

– List entry (second level)

Table 1

4

Key to symbols and safety instructions

Tronic – 6 720 884 457 (2018/02)

Installation and conversion

▶ Only permit an authorised service to

install this appliance.

▶ Do not install a stop valve between

the water heater and the safety valve,

because it will impair the pressure

protection of the heater!

▶ Before connecting it to the power

supply, the water heater must be

filled with water!

▶ The heater is equipped with an

additional thermal cut-off for

protection in case of failure of the

operating thermostat. In this case,

however, the temperature of the

water in the heater can reach up to

130 °C according to the safety

standards. During the water supply

installation, the possibility of

temperature overloads should be

taken into account.

▶ If the heater is to be disconnected

from the power supply, please drain

any water from the heater to prevent

freezing.

▶ Water can be drained from the heater

through the boiler inlet pipe. For this

purpose it is advisable to install a T-

element with an outlet valve between

the inlet pipe and safety valve.

▶ Never obstruct the safety valve outlet.

▶ During the heat-up, water may be

expelled from the safety valve.

Maintenance

▶ Only authorised technicians are

permitted to service this appliance.

▶ Isolate the appliance from its power

supply before commencing any

maintenance work on the appliance.

▶ Customers are responsible for the

safety and environmental

compatibility of the appliance as well

as its maintenance.

▶ Use only original spare parts.

▶ To ensure compliance with all safety

requirements, a defective power

cable may only be replaced by an

authorised service.

▶ Please do not try to fix any defects of

the water heater on your own. Call the

nearest authorised service provider.

Instructing the customer (for the

installer)

▶ Instruct the customer in the function

and operation of this appliance.

▶ It is the responsibility of customers to

carry out regular maintenance and

inspections.

▶ The appliance must be serviced

annually.

▶ Inform customers that they must not

carry out any modifications or

repairs.

Safety of electrical appliances for

domestic use and similar purposes

The following requirements apply in

accordance with EN 60335-1 in order to

5

Key to symbols and safety instructions

Tronic – 6 720 884 457 (2018/02)

prevent hazards from occurring when

using electrical appliances:

“This appliance can be used by children

of 8 years and older, as well as by people

with reduced physical, sensory or

mental capabilities or lacking in

experience and knowledge, if they are

supervised and have been given

instruction in the safe use of the

appliance and understand the resulting

dangers. Children must not play with the

appliance. Cleaning and user

maintenance must not be performed by

children without supervision.”

“If the power cable is damaged, it must

be replaced by the manufacturer, its

customer service department or a

similarly qualified person, so that risks

are avoided.”

6

Technical Characteristics and dimensions

Tronic – 6 720 884 457 (2018/02)

2 Technical Characteristics and

dimensions

2.1 Intended use

The appliance was designed to heat and store DHW. Comply

with all regulations and standards related to drinking water

applicable in the country.

Using the appliance for any other purpose will be considered

incorrect use. Bosch accepts no liability for any damage

resulting from such use.

2.2 Type overview

[TR] Tronic

[4500] Version

[T] Tank

[30] Capacity (liters)

[E] Electronic

[B] Bottom connections

2.3 Appliance Description

• Steel-glassed tank in conformity with the European

regulations

• Tank designed and built to withstand high pressures

• Exterior material: steel sheeting and / or plastic

• Easy handling

• Insulating material: polyurethane without CFC

• Anticorrosion protection: magnesium anode.

2.4 Anticorrosion protection

The inside of the tank is lined with homogeneous glass enamel,

completely neutral with regards to compatibility and contact

with potable water. This lining is neutral with regard to the use

with potable water. The existence of a magnesium anode

provides additional anticorrosion protection.

2.5 Accessories (included in the appliance

packaging)

Fig. 1

[1] Bracket

Water characteristics Unit

Water hardness, min. ppm

grain/US gallon

°dH

120

7.2

6.7

pH, min. – max. 6.5 – 9.5

Conductivity, min. – max. μS/cm 130 – 1500

Table 2 Water characteristics

TR 4500 T 30 E B

TR 4500 T 50 E B

TR 4500 T 80 E B

TR 4500 T 100 E B

TR 4500 T 120 E B

TR 4500 T 150 E B

Table 3

7

Technical Characteristics and dimensions

Tronic – 6 720 884 457 (2018/02)

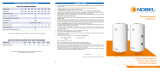

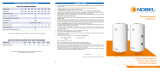

2.6 Technical specifications

This appliance meets the requirements specified by the

European Directives 2014/35/EC and 2014/30/EC.

Technical characteristics Unit TR4500 30 TR4500 50 TR4500 80 TR4500

100

TR4500

120

TR4500

150

General characteristics

Declared load profile S M M L L XL

Energy efficiency class

1)

1) EU Regulation 812/2013; EN 50440

B CCCCC

Water heating energy efficiency

(wh)

1)

[%) 33,5 37,2 36,9 38,1 37,4 38,1

Annual electricity consumption

1)

[kWh] 550 1382 1393 2687 2739 4399

Daily electricity consumption

2)

2) EN 50440

[kWh] 2,626 6,425 6,490 12,410 12,715 20,322

Thermostat temperature settings 60 °C

Value of “smart” 0 0 0 0 0 0

Volume [l] 29,1 48,3 78,0 97,3 118,1 147,1

Quantity of mixed water at 40 °С

V40

2)

[l] - 66 116 137 172 225

Sound power level indoors db(A) 15 15 15 15 15 15

Water details

Working pressure [MPa

(bar)]

1,0 (10)

Net Weight (empty) kg 19 28 34 39 44 50

Weight when full kg 49 78 114 139 164 200

Anti-corrosion of tank enamelled & Mg Anode

Water connections Pol. G3/4

Electrical characteristics

Power of electrical heater [W] 4200 6000

Number and power of heating

elements

[W] 6 x -700 6 x -1000

Voltage VAC 1/N/PE 230V~; 50Hz

3/N/PE 400V~; 50Hz

Protection class I

Type of protection IP 24

Heating time at 230V

from 10 °C to 65 °C

0 h 59 m 1 h 38 m 2 h 37 m 3 h 16 m 3 h 55 m 4 h 54m

Heating time at 400V

from 10 °C to 65 °C

0 h 59 m 1 h 38 m 2 h 37 m 3 h 16 m 3 h 55 m 4 h 54m

Table 4 Technical characteristics

8

Technical Characteristics and dimensions

Tronic – 6 720 884 457 (2018/02)

2.7 Dimensions

Fig. 2 Dimensions in mm (Vertical installation on a wall)

Appliance A B C D E F G

30... 510 310 235 70 110 180 420

50... 610 400 240 100 100 260 500

80... 830 600 260 100 100 360 500

100... 975 750 255 100 100 510 500

120... 1130 900 260 100 100 510 500

150... 1345 1100 275 100 100 510 500

Table 5

9

Technical Characteristics and dimensions

Tronic – 6 720 884 457 (2018/02)

2.8 Electrical wiring diagram

Fig. 3 Electric circuit diagram (30L heater)

[1] Connection terminal

[2] Electronic regulator

[3] Relay

[4] Thermal cut-out

[5] Electric heating elements (6x700W)

[L1] Live conductor

[L2] Live conductor

[L3] Live conductor

[N] Neutral conductor

[PE] Earthing conductor

Fig. 4 Electric circuit diagram (50L - 150L heaters)

[1] Connection terminal

[2] Electronic regulator

[3] Relay

[4] Thermal cut-out

[5] Electric heating elements (6x1000W)

[L1] Live conductor

[L2] Live conductor

[L3] Live conductor

[N] Neutral conductor

[PE] Earthing conductor

CAUTION: Electric shock!

▶ Before any intervention into the interior

of the water heater, disconnect it from

the power supply network! This

intervention may only be performed by a

trained professional!

10

Regulations

Tronic – 6 720 884 457 (2018/02)

3Regulations

The country’s regulations currently in force must be fulfilled for

the installation of the electric appliances.

4 Transport

▶ Do not drop the appliance.

▶ Remove the appliance from the packaging only at the place

of installation.

4.1 Transport, storage and recycling regulations

• The equipment should be stored in protected areas against

negative temperatures.

• Whenever applicable, the EU 2002/96/EC directive

imposed and the differentiated collection / gathering of

used electrical and electronic equipment.

5 Installation

5.1 Important notes

The water heater shall be installed as close as possible to the

outlets. When installing the water heater in a room with a

bathtub or shower, take into account the requirements defined

in IEC Standard 60364-7-701 (VDE 0100, Part 701).

It has to be fitted to the wall using appropriate wall screws with

a minimum diameter of 8 mm. A wall with a poor load-bearing

capacity must be properly reinforced where the heater will be

installed. The water heater may only be fixed upon the wall

vertically.

To facilitate future service interventions, you are advised to

install the heater in accordance with the installation

measurements.

5.2 Siting the appliance

Dispositions relative to the place of installation

• Comply with country-specific requirements

• Never install the appliance above a heat source.

• Never install the appliance in rooms where the ambient

temperature can fall below 0 °C.

• Install the appliance near the most frequently used draw-

off point to keep energy losses and waiting times to a

minimum.

• Install the appliance in a room that permits the replacement

of the magnesium anode, and necessary maintenance

procedures.

Protection areas 1 and2

▶ Do not install in protection areas 1 and 2.

▶ Install the appliance outside the protection areas at a

distance greater than 60 cm, of the bath.

Installation, power connection and

commissioning must only be carried out by a

service approved for such work by the local

entities.

CAUTION:

▶ Do not drop the appliance.

▶ Remove the appliance from the

packaging only at the place of

installation.

▶ Wherever applicable, comply with the

IEC 60364-7-701 norm on installing the

appliance and / or any electric

accessories.

▶ Chose a sufficiently robust wall to

support the appliance with the tank full

( see tab. 5).

CAUTION: Damage to the heating elements!

▶ Firstly connect all the water connections

and fill the appliance.

▶ Connect the appliance to the electric

point, assuring connection to earth.

CAUTION:

▶ Chose a sufficiently robust wall to

support the appliance with the tank full

( Tab. 4).

CAUTION:

▶ Make sure that the appliance is

connected to the DB board (electrical

board) with a connection to the earth

cable.

11

Installation

Tronic – 6 720 884 457 (2018/02)

Fig. 5 Protection areas

5.3 Wall mounting

Vertical installation

Fig. 6 Vertical installation

5.4 Water connection

The water heater connections for the inlet and outlet of water

are colour-coded. The inlet of cold water is marked with blue

colour, while the hot water outlet is marked with red colour.

The water heater can be connected to the water supply in two

ways. The closed-circuit pressure system enables several

points of use, while the open-circuit gravity system enables a

single point of use only. The mixer taps must also be installed in

accordance with the selected installation mode.

▶ Identify the piping for hot and cold water, in order to avoid

a possible swop (Fig. 7).

Fig. 7

[1] Cold water inlet (right hand side)

[2] Hot water outlet (left hand side)

In a closed, pressurized system ( Fig. 8) pressurised mix

taps should be used at the outlet points. To ensure safe

operation of the heater a safety valve should be installed on the

inlet pipe to prevent elevation of pressure for more than 0.1

MPa (1 bar) above the nominal pressure. The outlet opening on

the safety valve must be equipped with an outlet for

atmospheric pressure. The heating of water in the heater

causes the pressure in the tank to increase to the level set by

the safety valve. As the water cannot return to the water supply

system, this can result in dripping from the outlet of the safety

valve. The drip can be piped to the drain by installing a catching

unit just below the safety valve. The drain installed below the

CAUTION: Appliance fall!

▶ Use sleeves and hooks (according with

the type of wall) to fix the bracket that

can hold the appliance with the tank full.

CAUTION: Damage to appliance

connections through contact corrosion!

▶ Use galvanized insulators in your water

connections. These will avoid galvanic

electric currents between the hydraulic

link metals and, consequently corrosion

of these.

225 cm

6 720 612 659-13.3TT

22 11

60 cm

60 cm

NOTICE: Material damage!

▶ Install a filter at the water inlet in areas

where the water contains particles or

sediments.

It is recommended:

▶ to purge the system before appliance

installation, the existence of sand can

cause a reduction in flow or even cause a

total obstruction.

12

Installation

Tronic – 6 720 884 457 (2018/02)

safety valve outlet must be piped down vertically and placed in

an environment that is free from the onset of freezing

conditions.

To avoid water dripping from the safety valve, an expansion

tank should be installed on the inlet pipe of the heater with the

capacity of at least 5% of the heater volume.

To ensure proper operation of the safety valve, periodical

inspections must be carried out to remove limescale and make

sure the safety valve is not blocked. To check the valve, open

the outlet of the safety valve by turning the handle or

unscrewing the nut of the valve (depending on the type of the

valve). The valve is operating properly if the water comes out of

the nozzle when the outlet is open.

An open-circuit, non-pressurised system (Fig. 9) requires the

installation of a non-return valve at the water inlet to prevent

water draining out from the tank in the event of the water

supply running dry. This installation mode requires the use of

an instantaneous mixing tap.

As the heating of water expands its volume, this causes the tap

to drip. The dripping cannot be stopped by tightening it further;

on the contrary, the tightening can only damage the tap.

▶ Use the appropriate connection accessories to do the

hydraulic connection to the appliance.

Fig. 8 Closed (pressure) system

[1] Pressure mixer taps

[2] Expansion tank

[3] Safety valve

[a] Test valve

[b] Non-return valve

[4] Funnel with outlet connection

[5] Checking fitting

[6] Pressure reduction valve

[7] Test valve

[H] Cold water

[T] Hot water

Fig. 9 Open (non-pressure) system

[7] Test valve

[8] Non-return valve

[9] Low pressure mixer tap

[H] Cold water

[T] Hot water

The heater can be connected to the domestic water supply

network without a pressure-reducing valve if the pressure in

the network is lower than the nominal pressure. If the pressure

in the network exceeds the nominal pressure, a pressure-

reducing valve must be installed.

In the case of freezing:

▶ Switch off the appliance.

▶Purge the appliance ( Chapter 6.5).

Safety valve

No closing valve may be built-in between the

water heater and return safety valve,

because with it the pressure protection

would be impeded!

DANGER:

▶ Install a safety valve at the water inlet of

the appliance (Fig. 8).

NOTICE:

NEVER OBSTRUCT THE PURGE OUTLET OF

THE SAFETY VALVE.

Never install any accessory between the

safety valve and the cold-water inlet (right

hands side) of the appliance.

13

Installation

Tronic – 6 720 884 457 (2018/02)

5.5 Electrical connections

All adjusting devices, verification and safety mechanisms were

submitted to a rigorous test in factory and are ready to work.

Before connecting to the power supply network,

▶ Install a power supply cord in the water heater, with a min.

diameter of 1.5 mm2 (H05VV-F 5G 1.5 mm2). To do this,

the protective plate must be removed from the water

heater.

In the electrical installation, please install a disconnect switch

to separate all poles from the power supply network in

accordance with the national regulations.

Fig. 10 Removing the protective cover

If the pressure at the cold water inlet is

superior to that of 80% of the maximum

pressure of the appliance at, ie: 6,4 bar:

▶ Install a reducing valve (Fig. 8).

The safety valve will trigger every time the

water pressure in the appliance exceeds 6,4

bar. A facility for draining the expelled water

must be provided.

DANGER:

By electrical discharge!

▶ Before working on the electrical

components, firstly cut the power,

(fuse, circuit breaker or other).

CAUTION:

Electrical protection!

▶ The appliance should dispose of an

independent connection to the DB

board (electric board), protected by a

30 mA differential circuit breaker and

earthing.

The electrical connection must be realized in

accordance with the current country laws

regarding electrical installations.

14

Installation

Tronic – 6 720 884 457 (2018/02)

5.6 Start-up

When filling the heater for the first time, the tap for the hot

water on the mixing tap must be opened. When the heater is

filled with water, the water starts to run through the outlet pipe

of the mixing tap.

Before start-up,

▶ Verify that the appliance has been correctly installed and

assembled.

▶ Open the water inlet valves.

▶ Open all the hot water taps in order to ensure all the air is

out of the connections.

▶ Control the tightness of all the connections and ensure that

the appliance fills to its full capacity.

▶ Connect the appliance to the electric current.

▶ Inform the customer of any user information of the

appliance and handling.

Before connecting it to the power supply, the

water heater must be filled with water.

15

Use

Tronic – 6 720 884 457 (2018/02)

6Use

After it has been connected to the water and power supply grid,

the heater is ready to be used. When connected to the power

supply, the heater runs in standby mode. In the standby mode,

the heater maintains the water temperature of 10 °C.

Fig. 11 User interface

[1] Display of the set/actual temperature of water in the

heater, signalisation of errors

[2] On/Off button, temperature setting

[3] "BOOST" mode indicator

[4] On/Off button for the "BOOST" mode

6.1 Turning the appliance on/off

Turn on

▶ Hold the button (fig. 11, [2]) for about 3 seconds.

Standby

▶ Hold the button (fig. 11, [2]) for about 3 seconds, the

heater goes into standby.

Turn off

▶ Unplug the appliance.

6.2 Operating the heater – manual setting

To set the temperature,

▶ Press button (fig. 11, [2]) until you get the desired

temperature level (preset temperature level is 57 °C).

Once the maximum level ,

▶ Press the button (fig. 11, [2]).

The temperature returns to the first setting .

We recommend the setting. This setting is the most

energy-efficient. The temperature of water is about 57 °C,

while limescale production and heat loss will be smaller than in

case of higher temperature settings.

The temperature of water in the heater is indicated on the

display (fig. 11, [1]).

If the heater will not be used for a longer period of time, please

protect its contents from freezing by setting the temperature to

the position. At this setting, the heater will maintain the

temperature of water at about 10 °C.

6.3 Operation of the heater in the "BOOST" mode

This mode is useful when you need a large quantity of hot water

immediately. In the "BOOST" mode the heater uses the main

heating elements as well as auxiliary heating elements to heat

water quickly.

You can choose between one-time or constant activation of the

"BOOST" mode.

For one-time activation,

▶ Press button [4] shortly.

The heater’s operation in the "BOOST" mode is indicated

by control light [3], which remains on until the water in the

heater is heated to the set temperature.

For constant operation of the "BOOST" mode,

▶ Hold button [4] for 3 seconds.

The heater’s operation in the "BOOST" mode is indicated

by control light [3]. The "BOOST" mode can be turned off

by pressing button [4].

6.4 The Anti-Legionella Function

If the water in the heater does not reach 65 °C for 14

consecutive days, the anti-legionella function heats the water

to 70 °C and maintains this temperature for 120 minutes.

CAUTION: The first start-up of the appliance

must be carried out by an authorized

technician, which will provide the user with

all the necessary information to the best

working and handling of the device.

Symbol Description

Freeze protection, temperature about 10 °C

Water temperature about 35 °C

Water temperature about 57 °C

Water temperature about 75 °C

Table 6 Control panel symbols

16

Environment / disposal

Tronic – 6 720 884 457 (2018/02)

6.5 Emptying the appliance

▶ Unplug the appliance from the power supply.

▶ Switch off the water cutting valve and open a hot water tap.

▶ Open the safety valve (Fig. 12).

▶ Wait until the appliance is completely empty.

Fig. 12 Manual activation of the safety valve

Refill the appliance

When refilling the heater with water it is recommended to open

the warm water tap on the mixing tap and let the water run for

at least two minutes through the outlet pipe (the water stream

should be steady, medium strength, about as thick as a pencil).

7 Environment / disposal

Environmental protection is a fundamental corporate strategy

of the Bosch Group.

The quality of our products, their efficiency and environmental

safety are all of equal importance to us and all environmental

protection legislation and regulations are strictly observed.

We use the best possible technology and materials for

protecting the environment taking into account of economic

considerations.

Packaging

We participate in the recycling programmes of the countries in

which our products are sold to ensure optimum recycling.

All of our packaging materials are environmentally friendly and

can be recycled.

Old electrical and electronic appliances

Electrical or electronic devices that are no

longer serviceable must be collected

separately and sent for environmentally

compatible recycling (in accordance with the

European Waste Electrical and Electronic

Equipment Directive).

To dispose of old electrical or electronic

devices, you should use the return and

collection systems put in place in the country

concerned.

DANGER: Burn risk!

Open a hot water tap to and verify the

temperature of the water in the appliance

before opening the safety valve.

▶ Wait until the water temperature

decreases in order to avoid burns or any

other damage.

6720643873-06.1V

17

Inspection/Maintenance

Tronic – 6 720 884 457 (2018/02)

8 Inspection/Maintenance

8.1 User information

8.1.1 Cleaning

▶ Never use abrasive, corrosive or solvent cleaning

detergents.

▶ Use a soft cloth and mild detergent intended for cleaning

smooth varnished surfaces.

▶

8.1.2 Safety valve verification

▶ Verify that the water is expelled during the heating process

through the safety purge valve.

▶ Never obstruct the safety purge valve outlet.

8.1.3 Safety valve

▶ Manually open the safety valve at least once a month (Fig.

12).

8.1.4 Maintenance and repair

▶ It is the responsibility of the client to regularly call out

technical assistance or an authorized technician to perform

periodic maintenance.

8.2 Periodic maintenance work

With regular service inspections you will ensure faultless

functioning and long life of the heater.

1. Tank corrosion warranty applies only if all the prescribed

regular inspections of the protective anode wear have been

made.

2. The period between regular inspections should not be

longer than stated in the terms and conditions.

3. Inspections should be carried out by authorised service

providers that will record each inspection on the warranty

statement of the product.

4. Upon inspection the service provider will inspect the

amount of wear on the anti-corrosion anode and, if

necessary, clean the limescale that accumulates

depending on the quality, quantity and temperature of the

water inside the heater.

5. The service provider will also recommend the date for the

next inspection depending on the condition of the heater.

6. With regular service inspections you will ensure faultless

functioning and long life of the heater.

▶ Only make use of genuine replacement parts.

▶ Order the replacement parts in accordance with the parts

catalogue for the appliance.

▶ When carrying out maintenance work change the

disassembled joints and replace these with new ones.

8.2.1 Functionality verification

▶ Verify the good working order of all the elements.

8.2.2 Magnesium Anode

Maintenance must only be carried out by an

authorized technician.

WARNING:

Water leakage!

▶ Turn off all electric current.

▶ Turn off the water cut off valve

(Fig. 8).

WARNING:

▶ Ensure the purging of the water does not

cause any damage to persons or goods.

WARNING:

Do not attempt to fix any defects of the

heater by yourself:

▶ Call the nearest authorised service

company.

WARNING:

Before carrying out any maintenance work:

▶ Turn off all electric current.

▶ Turn off the water cut off valve

(Fig. 8).

CAUTION: Damages to the glass enamel!

Never clean the enamel interior of the

appliance with decalcifying agents. The

magnesium anode ensures anti corrosion

protection. There is no need for alternative

products for the protection of the enamel.

This appliance disposes of an anti-corrosion

magnesium anode in the inside.

18

Inspection/Maintenance

Tronic – 6 720 884 457 (2018/02)

▶ Switch off the circuit breaker feeding the appliance.

▶ Before starting, verify that the appliance is disconnected

from the electric current.

▶ Completely drain the appliance ( section 6.5).

▶ Remove the lid of the appliance, by unscrewing the fixing

screws.

▶ Unscrew the flange fastening nut.

▶ Disconnect the connecting cables to the thermostat [1].

▶ Remove the flange [2].

▶ Verify the magnesium anode and replace it if necessary.

Fig. 13 Access and identifying internal components

[1] Fastening screw

[2] Flange

[3] Magnesium anode

8.2.3 Periodic cleaning

▶ Turn off all hot water taps.

▶ Inform all residents of the danger of burns.

▶ Position the thermostat on the maximum position (

Fig. 11).

▶ Wait until the indicator turns off.

▶ Open all the hot water taps, starting with the nearest one to

the furthest one from the appliance, and purge all the hot

water from inside the appliance, at least 3 minutes.

▶ Turn off all the hot water taps, and position the thermostat

on the normal working position.

8.2.4 Long standing - non working (more than 3 months)

▶ Switch off the electric current to the appliance.

▶ Drain the appliance completely.

▶ Fill the appliance until the water comes out from all the hot

water taps.

▶ Turn on the appliance to the electric current.

8.3 Required actions after any maintenance work

has been carried out

▶ Refasten and check the fastness of all the water

connections.

▶ Turn on the appliance.

WARNING:

It is forbidden to operate the appliance

without an installed magnesium anode.

WARNING:

The magnesium anode needs to be tested

every second year and replaced if

necessary, failing to do so will result in the

termination of the warranty. The appliance

without this type of protection will not be

covered by the manufactures warranty.

2

672087523-07.1V

1

3

DANGER: Burn risk!

During the periodic cleaning process the hot

water may cause serious burns.

▶ Carry out this operation outside working

hours.

After a long period of inactivity you should

change the water inside the appliance (more

than 3 months).

19

Problems

Tronic – 6 720 884 457 (2018/02)

9Problems

9.1 Indication of errors

In case of error, control lights start to flash on the display

(fig. 11[1]).

In the following diagram there are some solutions described for

possible problems / errors.

DANGER:

Assembly, maintenance and repairs should

only be carried out by authorized

technicians.

Error Error description Signalization Solution

E1 Temperature sensor error Repeated 2x quick pulse of the control

light on the display ( fig. 11, [1]).

▶ Call service (heater out of order).

E5 Overheating

(temperature > 90 °C)

Repeated 3x quick pulse of the control

light on the display (fig. 11, [1]).

The error is automatically deleted when

the temperature drops below the set value.

Should the error repeat,

▶ Call the service company.

E44 Dry start Repeated 4x quick pulse of the control

light on the display (fig. 11, [1]).

Fill the heater with water. The error is

deleted by switching off the heater or by

holding button ( 11, [2]) for 3 seconds.

Table 7

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

Bosch Tronic TR4500T 50 EB Installation guide

- Category

- Water heaters & boilers

- Type

- Installation guide

- This manual is also suitable for

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

Other documents

-

Gorenje GB 120 Instructions Manual

-

Unical HP 300S Installation guide

Unical HP 300S Installation guide

-

Atlantic VERTIGO 841258 Operating instructions

-

Inalsa PSG 25GL User manual

-

Gorenje TG 100 N Installation Instructions Manual

-

Vox WHSM35-50-65-80-100 User manual

-

Nobel ELECTRIC WATER HEATERS User manual

Nobel ELECTRIC WATER HEATERS User manual

-

Aspes ATE81D Owner's manual

-

Aspes ATE51 Owner's manual

-

clage SX 50 Operating instructions