12

5. Disengage the parking brake:

a. Fully push DOWN on the brake pedal.

b. Push IN the parking brake control.

c. Release the brake pedal.

6. Push down on the speed control pedal to move forward.

Release the pedal to stop.

Note:The further down the pedal is pushed the faster the

tractor will move.

7. To stop the tractor, release the speed control pedals, set

the parking brake, and stop the engine. SeeStop Tractor

and Engine.

Automatic Controlled Traction (ACT)

Automatic Controlled Traction (ACT) applies a preset amount

of torque to both rear wheels even if one starts to slip. A

transmission without ACT will lose traction completely if one

rear wheel starts to slip. This preset torque is just enough to

give additional traction, and still let the wheels turn at different

speeds in a tight turn without damage to the lawn.

Under certain circumstances, the ACT system limit can be

exceeded, and one of the rear tires may slip. For example, if

you turn up a hill, when you accelerate. This is normal. If you

start to lose traction, do not speed up. Instead, slow to stop,

straighten the steering wheel, and slowly accelerate. Stopping

the tractor lets the transmission get more traction.

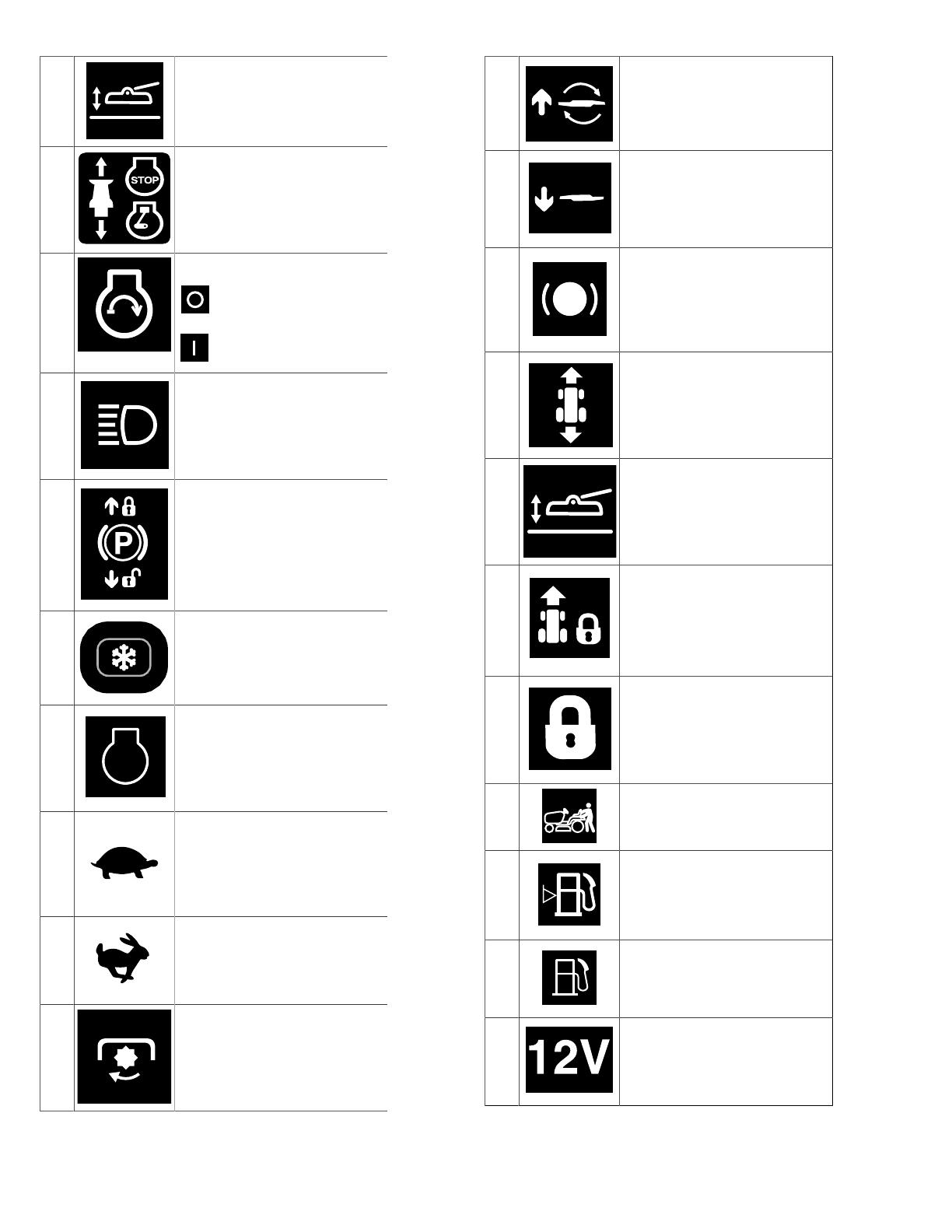

Cruise Control

To engage:

• Push down on the cruise control lever (S, Figure3) until

the desired speed is reached.

To disengage:

• Pull back on the cruise control lever or push the brake

pedal (P).

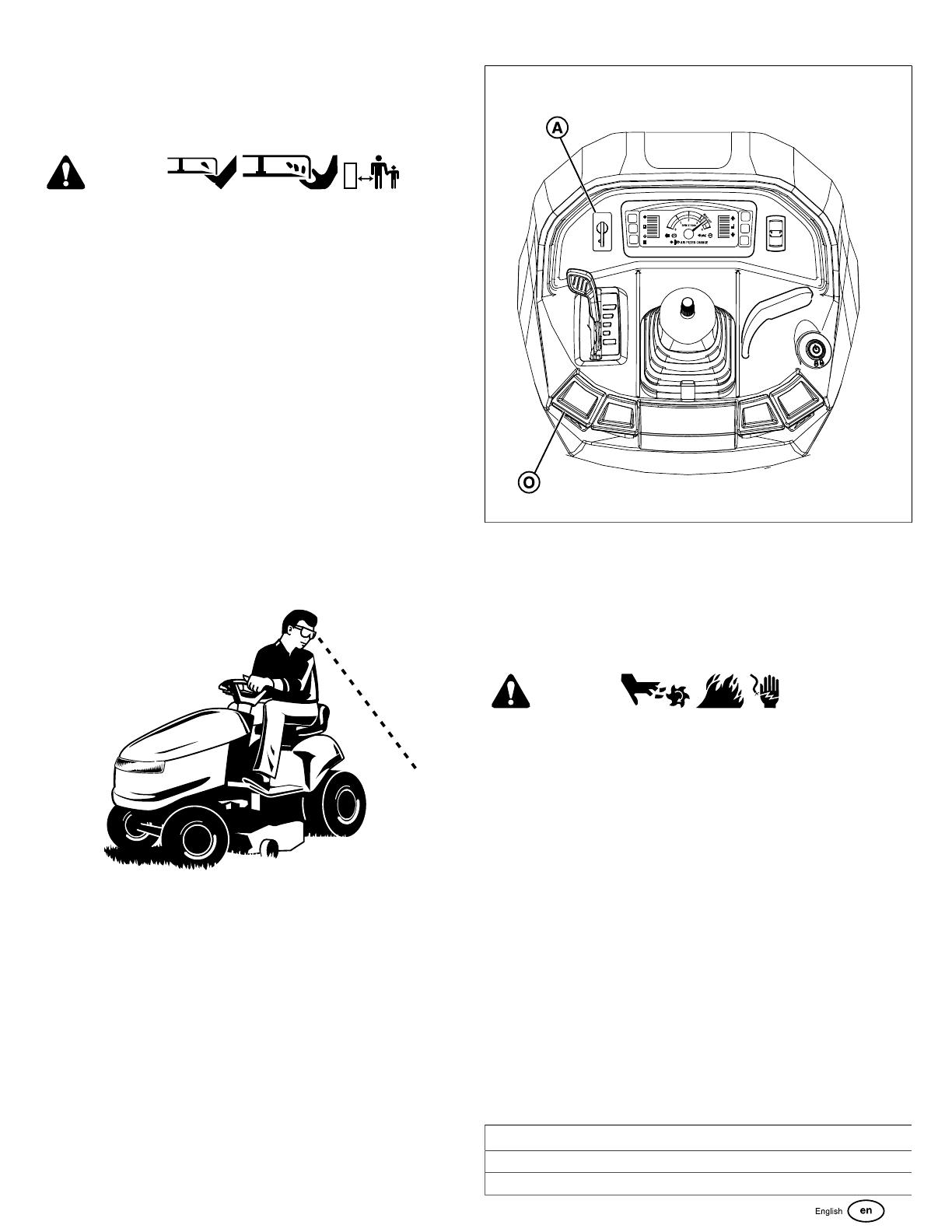

Mowing

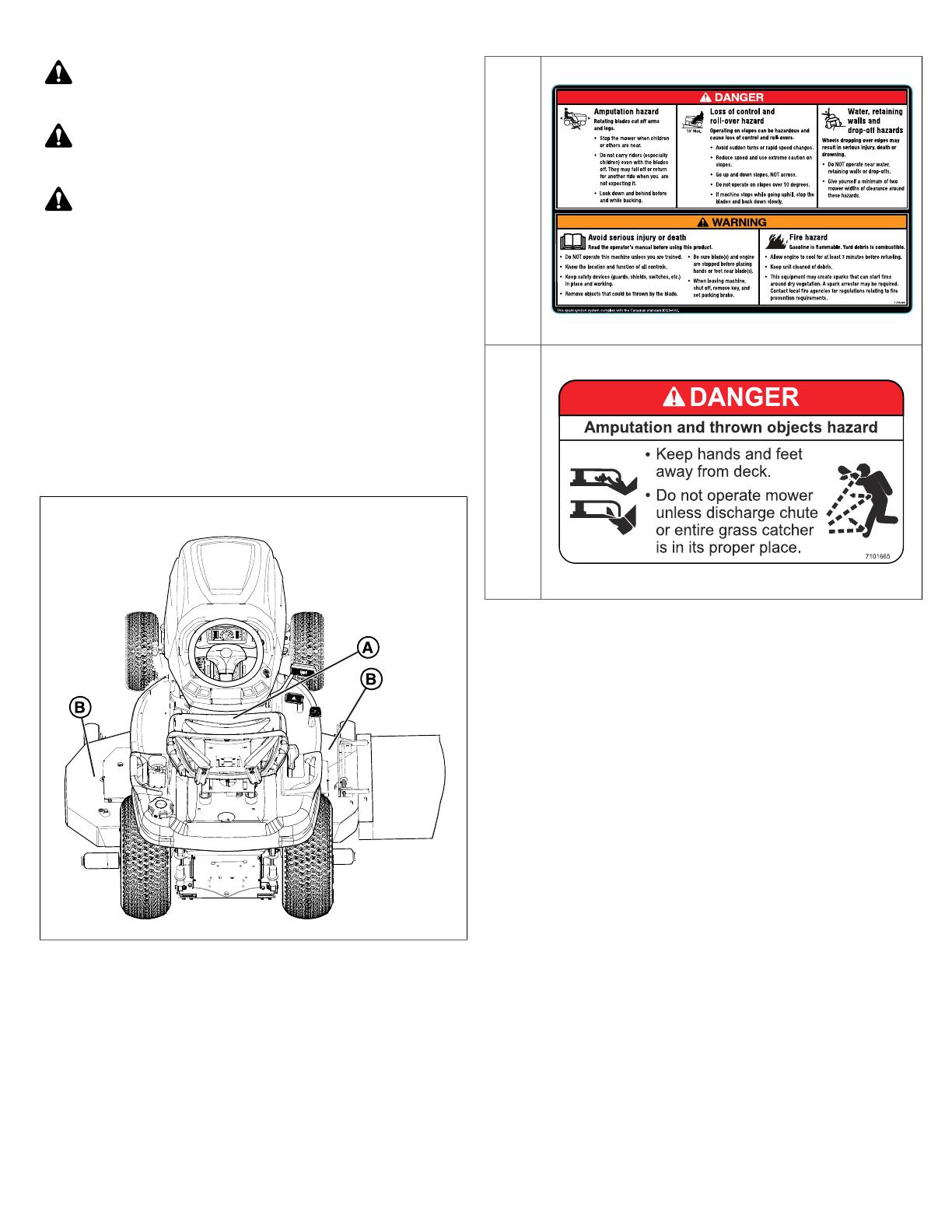

DANGER

This machine is capable of amputating hands and feet, and

throwing objects. Failure to observe the following safety

instructions could result in serious injury or death.

• Only operate the machine in daylight hours or good

artificial light.

• Avoid holes, ruts, bumps, rocks, or other hidden

hazards.

Uneven terrain can overturn the machine or cause

operator to lose their balance or footing.

• Do not direct discharge material toward anyone. Avoid

discharging material against a wall or obstruction as

material may ricochet back toward the operator.

• Stop the blade(s) when crossing gravel surface.

• Do not leave a running machine unattended. Always

park on level ground, disengage the attachment, set

parking brake, stop engine and remove starter insert or

key.

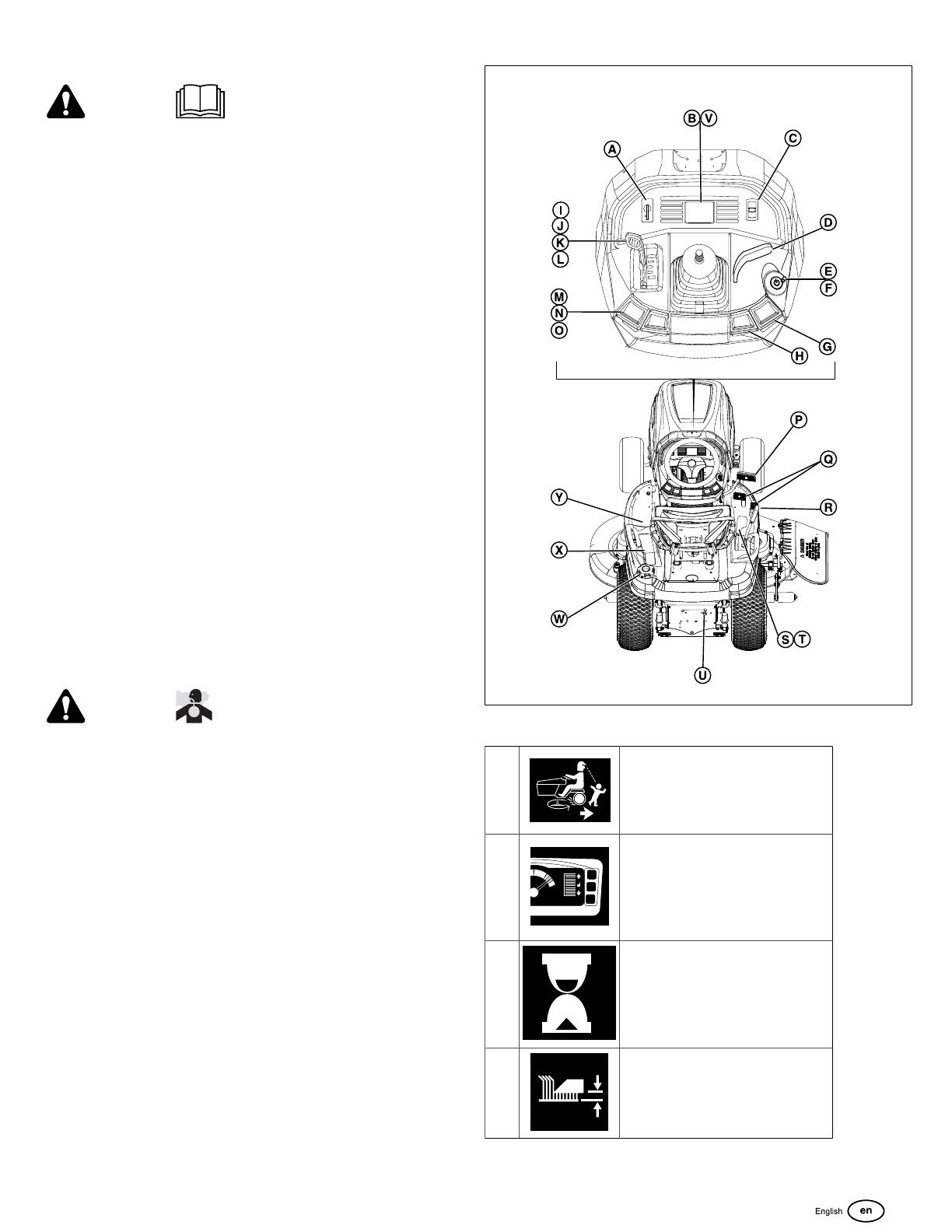

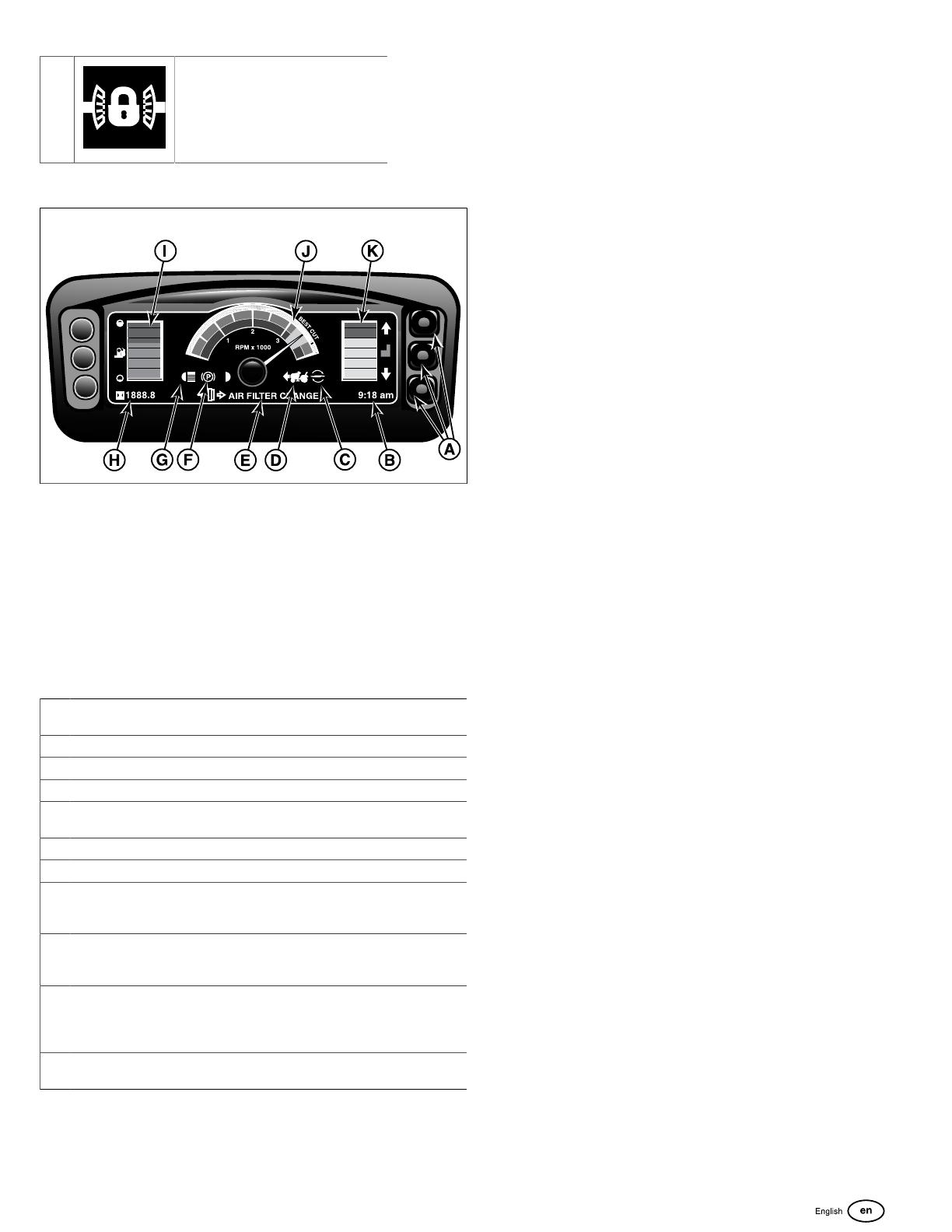

1. Engage the parking brake control (H, Figure3).

2. Make sure the PTO switch (M)is disengaged.

3. Start the engine. SeeStart Engine.

4. Set the throttle control (J)to the FAST position.

5. Engage the PTO (N) to activate the mower blades.

6. Use the Height-of-Cut Electric Switch (C)to set the

cutting height to the desired level. SeeAdjusting the

Mower Cutting Height.

7. Disengage the parking brake (H), then begin to mow.

8. Turn off the PTO.

9. STOP the engine. SeeStop Tractor and Engine.

WARNING

The engine will shut off if the reverse ground speed pedal

is depressed while the PTO is on and the RMO has not

been activated. The operator must always turn the PTO off

prior to driving across on roads, paths, or areas that can be

used by other vehicles. Sudden loss of drive could create a

hazard.

Adjust Mower Cutting Height

The mower lift lever (D and R, Figure3) lowers the deck

to the cutting position or raises the deck to the transport

position.

Lower the Deck

Mechanical Lift - (if equipped)

1. On the right side, pull back the mower lift lever (R,

Figure3) a small distance.

2. Push it to the right.

3. Move it down.

Power Lift - (if equipped)

1. Start the unit. Make sure that the brake pedal (P,

Figure3) is not pushed down.

2. Push the power lift lever (D, Figure3) forward to lower the

deck to cutting position.

Raise the Mower Deck

Mechanical Lift - (if equipped)

1. On the right side, pull up on the mower lift lever (R,

Figure3).

2. Lock in notch to the left.

Power Lift - (if equipped)

1. Start the unit. Make sure that the brake pedal

(P,Figure3) is not pushed down.

2. Pull the power lift lever (D, Figure3) back until the deck is

at its highest position. This is transport mode.

Note:Do not cut when raised in transport position.