Page is loading ...

Repair-Parts

EP3 EP3

EP3

and and

and

EP4 EP4

EP4

Hose Hose

Hose

Pumps Pumps

Pumps

3A1939G

EN

Electric Electric

Electric

- -

-

powered powered

powered

hose hose

hose

pump pump

pump

for for

for

use use

use

in in

in

uid uid

uid

transfer transfer

transfer

and and

and

metering metering

metering

applications. applications.

applications.

For For

For

professional professional

professional

use use

use

only. only.

only.

Not Not

Not

approved approved

approved

for for

for

use use

use

in in

in

explosive explosive

explosive

atmospheres atmospheres

atmospheres

or or

or

hazardous hazardous

hazardous

locations. locations.

locations.

Important Important

Important

Safety Safety

Safety

Instructions Instructions

Instructions

Readallwarningsandinstructionsinthismanual.Savethese

instructions.

125 psi (0.9 MPa, 9 bar) Maximum Fluid

Working Pressure

See page 2 for model part numbers and

information. do

PROVENQUALITY.LEADINGTECHNOLOGY.

Contents Contents

Contents

Models...............................................................2

Warnings...........................................................3

Troubleshooting..................................................6

Repair................................................................8

BeforeYouStart..........................................8

Disassembly................................................8

Reassembly................................................12

Notes.................................................................17

Parts..................................................................18

EP3andEP4HosePumpAssembly.............18

BarePumpAssembly...................................20

PumpMatrix................................................22

PumpKitMatrix...........................................24

VariableFrequencyDrives(VFD)..................26

Notes.................................................................27

TechnicalData...................................................28

GracoStandardWarranty....................................30

Models Models

Models

Pump Pump

Pump

Model Model

Model

Hose Hose

Hose

ID ID

ID

Size Size

Size

(mm) (mm)

(mm)

Reference Reference

Reference

EP3019 EP3019

EP3019

19

SeeModelEP3019Pumps,page22foracompletelistof

pumppartnumbersanddescriptiveinformation.

EP4029 EP4029

EP4029

29

SeeModelEP4029Pumps,page23foracompletelistof

pumppartnumbersanddescriptiveinformation.

2

3A1939G

Warnings

Warnings Warnings

Warnings

Thefollowingwarningsareforthesetup,use,grounding,maintenanceandrepairofthisequipment.The

exclamationpointsymbolalertsyoutoageneralwarningandthehazardsymbolreferstoprocedure-specic

risks.Whenthesesymbolsappearinthebodyofthismanualoronwarninglabels,referbacktothese

Warnings.Product-specichazardsymbolsandwarningsnotcoveredinthissectionmayappearthroughout

thebodyofthismanualwhereapplicable.

WARNING WARNING

WARNING

FIRE FIRE

FIRE

AND AND

AND

EXPLOSION EXPLOSION

EXPLOSION

HAZARD HAZARD

HAZARD

Flammablefumes,suchassolventandpaintfumes,inwork work

work

area area

area

canigniteorexplode.Tohelp

preventreandexplosion:

•Useequipmentonlyinwellventilatedarea.

•Eliminateallignitionsources;suchaspilotlights,cigarettes,portableelectriclamps,and

plasticdropcloths(potentialstaticarc).

•Keepworkareafreeofdebris,includingsolvent,ragsandgasoline.

•Donotplugorunplugpowercords,orturnpowerorlightswitchesonoroffwhenammable

fumesarepresent.

•Groundallequipmentintheworkarea.SeeGrounding Grounding

Grounding

instructions.

•Useonlygroundedhoses.

•Holdgunrmlytosideofgroundedpailwhentriggeringintopail.

•Ifthereisstaticsparkingoryoufeelashock,stop stop

stop

operation operation

operation

immediately. immediately.

immediately.

Donotuse

equipmentuntilyouidentifyandcorrecttheproblem.

•Keepaworkingreextinguisherintheworkarea.

ELECTRIC ELECTRIC

ELECTRIC

SHOCK SHOCK

SHOCK

HAZARD HAZARD

HAZARD

Thisequipmentmustbegrounded.Impropergrounding,setup,orusageofthesystemcan

causeelectricshock.

•Turnoffanddisconnectpoweratmainswitchbeforedisconnectinganycablesandbefore

servicingorinstallingequipment.

•Connectonlytogroundedpowersource.

•Allelectricalwiringmustbedonebyaqualiedelectricianandcomplywithalllocalcodes

andregulations.

MOVING MOVING

MOVING

PARTS PARTS

PARTS

HAZARD HAZARD

HAZARD

Movingpartscanpinch,cutoramputatengersandotherbodyparts.

•Keepclearofmovingparts.

•Donotoperateequipmentwithprotectiveguardsorcoversremoved.

•Pressurizedequipmentcanstartwithoutwarning.Beforechecking,moving,orservicing

equipment,followthePressure Pressure

Pressure

Relief Relief

Relief

Procedure Procedure

Procedure

anddisconnectallpowersources.

3A1939G 3

Warnings

WARNING WARNING

WARNING

ENTANGLEMENT ENTANGLEMENT

ENTANGLEMENT

HAZARD HAZARD

HAZARD

Rotatingpartscancauseseriousinjury.

•Keepclearofmovingparts.

•Donotoperateequipmentwithprotectiveguardsorcoversremoved.

•Donotwearlooseclothing,jewelryorlonghairwhileoperatingequipment.

•Equipmentcanstartwithoutwarning.Beforechecking,movingorservicingequipment,follow

thePressure Pressure

Pressure

Relief Relief

Relief

Procedure Procedure

Procedure

anddisconnectallpowersources.

TOXIC TOXIC

TOXIC

FLUID FLUID

FLUID

OR OR

OR

FUMES FUMES

FUMES

Toxicuidsorfumescancauseseriousinjuryordeathifsplashedintheeyesoronskin,

inhaled,orswallowed.

•ReadMSDSstoknowthespecichazardsoftheuidsyouareusing.

•Storehazardousuidinapprovedcontainers,anddisposeofitaccordingtoapplicable

guidelines.

PERSONAL PERSONAL

PERSONAL

PROTECTIVE PROTECTIVE

PROTECTIVE

EQUIPMENT EQUIPMENT

EQUIPMENT

Youmustwearappropriateprotectiveequipmentwhenoperating,servicing,orwheninthe

operatingareaoftheequipmenttohelpprotectyoufromseriousinjury,includingeyeinjury,

hearingloss,inhalationoftoxicfumes,andburns.Thisequipmentincludesbutisnotlimitedto:

•Protectiveeyewear,andhearingprotection.

•Respirators,protectiveclothing,andglovesasrecommendedbytheuidandsolvent

manufacturer.

PRESSURIZED PRESSURIZED

PRESSURIZED

EQUIPMENT EQUIPMENT

EQUIPMENT

HAZARD HAZARD

HAZARD

Fluidfromtheequipment,leaks,orrupturedcomponentscansplashintheeyesoronskin

andcauseseriousinjury.

•FollowthePressure Pressure

Pressure

Relief Relief

Relief

Procedure Procedure

Procedure

whenyoustopspraying/dispensingandbefore

cleaning,checking,orservicingequipment.

•Tightenalluidconnectionsbeforeoperatingtheequipment.

•Checkhoses,tubes,andcouplingsdaily.Replacewornordamagedpartsimmediately.

4

3A1939G

Warnings

WARNING WARNING

WARNING

EQUIPMENT EQUIPMENT

EQUIPMENT

MISUSE MISUSE

MISUSE

HAZARD HAZARD

HAZARD

Misusecancausedeathorseriousinjury.

•Donotoperatetheunitwhenfatiguedorundertheinuenceofdrugsoralcohol.

•Donotexceedthemaximumworkingpressureortemperatureratingofthelowestrated

systemcomponent.SeeTechnical Technical

Technical

Data Data

Data

inallequipmentmanuals.

•Useuidsandsolventsthatarecompatiblewithequipmentwettedparts.SeeTechnical Technical

Technical

Data Data

Data

inallequipmentmanuals.Readuidandsolventmanufacturer’swarnings.Forcomplete

informationaboutyourmaterial,requestMSDSfromdistributororretailer.

•Donotleavetheworkareawhileequipmentisenergizedorunderpressure.

•TurnoffallequipmentandfollowthePressure Pressure

Pressure

Relief Relief

Relief

Procedure Procedure

Procedure

whenequipmentisnotinuse.

•Checkequipmentdaily.Repairorreplacewornordamagedpartsimmediatelywithgenuine

manufacturer’sreplacementpartsonly.

•Donotalterormodifyequipment.

•Useequipmentonlyforitsintendedpurpose.Callyourdistributorforinformation.

•Routehosesandcablesawayfromtrafcareas,sharpedges,movingparts,andhotsurfaces.

•Donotkinkoroverbendhosesorusehosestopullequipment.

•Keepchildrenandanimalsawayfromworkarea.

•Complywithallapplicablesafetyregulations.

3A1939G 5

Troubleshooting

Troubleshooting Troubleshooting

Troubleshooting

NOTE: NOTE:

NOTE:

Checkallpossibleremediesbeforedisassemblingthepump.

Problem Problem

Problem

Cause Cause

Cause

Solution Solution

Solution

Inletoroutletpipediameterstoo

small.

Increasepipesizeoraddpulsation

dampeners.

Highpumpspeed.

Reducespeedofpump.

Inletoroutletconnectionsnot

properlyanchored.

Securepiping.

Hammeringinpiping.

HighInletoroutletpressures.Addpulsationdampeners.

Lowlubricantlevel.Addhoselubetotheproperlevel.

Improperlubricant.

UseonlyGracohoselubeforlow

temperatureoperation.

Pumpeduidtemperaturetoo

high.

ConsultyourGracodistributorfor

maximumtemperaturelimitsof

yourpump.

Highpumptemperature.

Highpumpspeed/pump

undersized.

Reducethepumpspeedorswitch

toalargerpump.

Blockedoutletline.

Clearanyobstructionsintheoutlet

line.

Narrowedpipediameterdueto

settledsolids.

Determineifsolidshavesettled

inpipingandush/removeas

required.

Highoutletpressure.

Viscosityorspecicgravityof

pumpeduidtoohigh.

ConsultyourGracodistributorfor

suitableoperatingconditionsfor

yourpump.

Failedhose.

Checktoseeifthehosehasfailed.

Ifso,replacewithanewhoseand

lubricant.

Blockedinletline.

Clearanyobstructionsintheinlet

line.

Inletlinetoolongortoosmall.Trytolocatethepumpasnear

totheuidsourceaspossible.

Oversizetheinletpipingwhen

possible.

Lowinletpressure.

Viscosityorspecicgravityof

pumpeduidtoohigh.

ConsultyourGracodistributorfor

suitableoperatingconditionsfor

yourpump.

Lowow.

Failedhose.

Checktoseeifthehosehasfailed.

Ifso,replacewithanewhoseand

lubricant.

6 3A1939G

Troubleshooting

Problem Problem

Problem

Cause Cause

Cause

Solution Solution

Solution

Chemicalincompatibility.ConsultyourGracodistributorto

seeifyouhavethecorrecthose

foryourapplication.

Normalwear.

Thehosemayhavefaileddueto

normalwear.Replaceasrequired.

Failureduetopulsations.

Ifyoupumpisequippedwitha

pulsationdampener,adjustits

pressure.Ifyoudonothavea

dampener,consultyourGraco

distributor.

Toohighoutletpressure.

Checkitemslistedin“Highoutlet

pressure.”Runningthepump

againstaclosedvalve,evenfora

shortamountoftime,maydamage

hose.

Poorhoselife.

Settledsolidsinhose.

Flushthepumpandhosepriorto

turningthepumpoff.

Hoselubeleakingfromfrontcover.Coverboltsover-tightened.

Refertotorquespecicationsin

InstalltheFrontCover,page16.

Lubricantleaks

Hoselubeleakingfromhose

clamps.

Pumphousingoverlled.Check

hoselubelevelandadjustas

necessary.

Hosefailedbecauseitwrapped

aroundroller.

Pumpwasoperatedagainsta

closedoutletvalveorblockedline.

Replacehose.Checkpressure

reliefsystem.Checkthatvalves

areopen.Clearanyblockages.

3A1939G

7

Repair

Repair Repair

Repair

Before Before

Before

You You

You

Start Start

Start

1.Flushthepump.

2.Relievethepressure.

3.Disconnectpowertothepump.

4.Makesurethepumpiselectricallyisolated.

Unexpectedoperationofthepumpcancause

seriousinjury.Removethefancoveronlyafter

themotorhasbeenlockedout.

Disassembly Disassembly

Disassembly

Drain Drain

Drain

the the

the

Oil Oil

Oil

1.Holdapailunderthedrainplug(17)andunscrew

theplugtodrainthelubricatingoil.Disposeof

theoilproperly.Takecare,astheoilmaybe

contaminatedbythepumpeduid.

2.Removetheventplug(15)andushthepump

housingwithacompatiblesolvent.

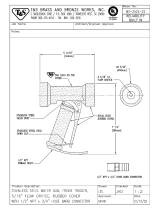

Figure1PumpDrainandVent

Remove Remove

Remove

the the

the

Front Front

Front

Cover Cover

Cover

1.Unscrewthesocketheadcapscrews(14)and

washers(13)thatholdthefrontcover(12),

removingthetopscrewandwasherlast.Take

thecoveroffthepump.SeeFig.5,page11.

2.Removethefrontcovergasket(11).

3.Inspectandcleanthesightglass(16)andcover

(12),thensetaside.

8 3A1939G

Repair

Remove Remove

Remove

the the

the

Hose Hose

Hose

1.SeeFig5,page11.Removethescrewsholding

themotorfancover(FC).Turnthefanbyhand

untiltheroller(102)stopsatthebottomofthe

pumphousing(1)inthe6o’clockposition.

NOTE: NOTE:

NOTE:

LowRPMpumpsandhighratio

gearboxesmayrequiremanyturnsofthemotor

fantomovetherollertothe6o’clockposition.

2.Removethefourscrews(21)fromeachbarb

clamp(20)ontheinletandoutletportsofthe

pumpandliftofftheclamps.

3.

On EP4 Pumps only:

Removethetophalfofthe

barbedttingpositioningwasherandkeepfor

reuse.Thebottomhalfofthewasheriswelded

inplaceandcannotberemoved.

4.Ifpossible,ensurethatthehoseclamps(104)

arepositionedwiththeclampportionatthetop.

Cutthroughtheclampwithahacksaworrotary

tool.Becarefulnottodamagethehose(103)or

thepumphousing(1).

Figure2CuttheClamp

5.Usingascrewdriver,removetheclamp,then

removetheband.

Figure3RemovetheClamp

6.Thehoseassemblyisseatedrmlyinthepump

housing(1).Placeasmooth,smalldiameter

metalrodintothebarbedttings(105)andlift

thehoseassemblytofreeit.Pullthehoseso

itextendsabout2–3in.(51–76mm)outofthe

pump.

7.Removeonebarbedtting(105)fromthehose

(103).

8.Graspthehose(103)fromtheinsideofthepump

housing(1)andpullitintothehousing.The

centerofthehosewillstillbeheldbytherollerin

the6o’clockposition.

9.Removethesecondbarbassemblyasdescribed

above.

10.Turnthemotorbyhanduntiltheroller(102)isnot

compressingthehose(103).Thiswillbenear

the9o’clockor3o’clockposition.

Figure4Rollerin3O’ClockPosition

11.Pulltheotherendofthehoseintothepump

housing(1).

12.Removeandsafelydiscardtheusedhose,per

yourfacility’swastedisposalpolicy.

3A1939G 9

Repair

Remove Remove

Remove

the the

the

Roller Roller

Roller

1.Usingexternalsnapringpliers,removetheroller

retainingring(9)fromthefrontoftheeccentric

shaft(7).Slidethebushing(10)offtheshaft.

2.Pulltheroller(102)offtheshaft.Itshouldslide

offeasily.

3.

On EP3 Pumps only:

Slidethesecondbushing

(10)offtheshaft.Removethesecondroller

retainingring(9).

4.Inspecttheinsideandoutsidediameterofthe

roller(102),andreplaceitifwornordamaged.

Figure5RemovetheHoseandRoller

10 3A1939G

Repair

Remove Remove

Remove

the the

the

Eccentric Eccentric

Eccentric

Shaft Shaft

Shaft

1.Usingexternalsnapringpliers,removethe

eccentricshaftretainingring(8)fromthemotor

outputshaft(2).SeeFig6.

2.Removetheeccentricshaft(7)fromthemotor

outputshaft.Be Be

Be

sure sure

sure

to to

to

retain retain

retain

the the

the

eccentric eccentric

eccentric

shaft shaft

shaft

key key

key

(6). (6).

(6).

NOTE: NOTE:

NOTE:

Youmayneedtouseapullerto

disengagetheeccentricshaftfromthemotor

outputshaft.

Remove Remove

Remove

the the

the

Motor Motor

Motor

Output Output

Output

Shaft Shaft

Shaft

NOTE: NOTE:

NOTE:

Themotoroutputshaftisheldinplacewith

aretainingring(3)locatedbehindtheouteru-cup

seal(4).Theoutersealmustberemovedbefore

removingtheretainingring.Thissealwilllikelybe

damagedwhenremovedsinceitisheldinplaceby

atightpresst.

1.Usingaatheadscrewdriver,removetheouter

u-cupseal(4).

2.Usinginternalsnapringpliers,removethe

retainingring(3)fromthepumphousing(1).

3.Removethefourscrews(109)andwashers(108)

holdingthegearboxandmotorassembly(107)

tothepumphousing(1).Removethegearbox

andmotorassemblytoallowaccesstotheinner

u-cupseal(5).Be Be

Be

sure sure

sure

to to

to

retain retain

retain

the the

the

motor motor

motor

output output

output

shaft shaft

shaft

key key

key

(106). (106).

(106).

NOTE: NOTE:

NOTE:

Formotorandgearboxrepairinformation,

contactSEW-Eurodrive.

4.Removetheinneru-cupseal(5).Thissealwill

likelybedamagedwhenremovedsinceitisheld

inplacebyatightpresst.

5.Tapthegearboxendoftheshaft(2)witharubber

mallettodrivetheshaftoutthroughthefrontof

thepumphousing(1).

Figure6RemovetheEccentricShaftandMotorOutputShaft

3A1939G

11

Repair

Reassembly Reassembly

Reassembly

Clean Clean

Clean

and and

and

Inspect Inspect

Inspect

All All

All

Parts Parts

Parts

NOTICE NOTICE

NOTICE

UseonlygenuineGracoreplacementparts.

Non-standardpartswillvoidyourwarrantyand

maydamageyourequipment.

•Discardallusedseals,gasketsandwornparts.

•Ensurethatallnewandexistingpartsareclean

andundamaged.

•Thoroughlycleanallpartswithacompatible

solventandinspectfordamageorwear.Replace

allgaskets,washers,wornpartsandhardwareas

necessary.

•Inspecttheinnerdiameterofthepumproller.Ifthe

surfacehasbeenworn,replacetheroller.

•Inspectthebearingsonthemotoroutputshaft(2).

Ifthebearingsareworn,replacetheshaft.

•Inspecttheshaftandbearingboreinthepump

housing(1).Ensureitisround,withoutgroovesor

othersignsofwear,andfreeofdirt,lings,orother

debris.Adirtyordamagedbearingborewillgreatly

reducethelifeofthebearings.

•Inspectallmetalpartsforsignsofwearorcracks.

Replaceallwornparts.

NOTICE NOTICE

NOTICE

Thepumphousingisaluminum.Tohelpprevent

galling,blowoutthethreadswithcompressedair

beforeinstallinganyttingsorfasteners.

Install Install

Install

the the

the

Motor Motor

Motor

Output Output

Output

Shaft Shaft

Shaft

1.Inspectthebearingsandmakesurethatallrotate

freelyandareseatedagainsttheshoulderofthe

shaft(2).SeeFig7.

2.Coattheouterracesoftheshaftbearingsand

theinnerdiameterofthebearingborewithlight

lubricatingoil.Makesurethereisnodirtordebris

oneitherthebearingsorthebearingbore.

3.Inserttheshaft(2)intothepumphousing(1)from

thefront,makingsurethatthebearingsengage

thebearingboreushandstraight.Taptheroller

endoftheshaftwitharubbermalletuntilthe

shaftisrmlyseatedinthepumphousing.

NOTICE NOTICE

NOTICE

Donotforcetheshaftandbearingsintothe

pumphousing.Thismaycausedamagetothe

bearingsorthehousing.

4.Installthebearingretainingring(3)infrontofthe

outerbearing.

Install Install

Install

the the

the

Seals Seals

Seals

1.Pressanewinneru-cupseal(5)ontothegearbox

endoftheshaft(2)andintotheboreattherear

ofthepumphousing(1).Thelipsoftheu-cup

mustfaceintothepumphousing.SeeFig7.

2.GreasethepumpwithNLGI#2typegrease.

Removetheplug(18)fromthepumphousing

andreplacewithazerktting.Addgreaseuntil

itpassesthroughtheouterbearingoftheshaft.

Thisprovidesavisualreferenceoftheproper

amountofgrease.Donotover-grease.Remove

thezerkttingandreinstalltheplug(18).

3.Pressanewouteru-cupseal(4)ontothepump

endoftheshaft(2)andintotheboreatthefront

ofthepumphousing(1).Thelipsoftheu-cup

mustfacetowardtheshaftbearings.

4.Makesurethattheshaftrotatessmoothly.

12

3A1939G

Repair

Figure7InstalltheMotorOutputShaftandEccentricShaft

Key Key

Key

for for

for

Figure Figure

Figure

7 7

7

Note Note

Note

Description Description

Description

1

Lipsoftheu-cup(4)mustfacetowardtheshaftbearings.

2

Lipsoftheu-cup(5)mustfaceintothepumphousing.

3

Lubricatewithhoselube.

Install Install

Install

the the

the

Motor Motor

Motor

and and

and

Gearbox Gearbox

Gearbox

1.Lubricatethemotoroutputshaft(2)andthe

keywaywithananti-seizecompound.

2.Thegearboxismanufacturedwithahollow

bore.Removetheplasticcaponthebackofthe

gearboxtohelpwithalignmentoftheshaft.

3.Slidethemotorandgearboxassembly(107)

ontotheshaft(2).Installthekey(106).Secureto

thepumphousing(1)withthefourscrews(109)

andwashers(108).

Install Install

Install

the the

the

Eccentric Eccentric

Eccentric

Shaft Shaft

Shaft

1.Ensurethatthekeywayonthemotoroutputshaft

(2)isfacingup.Itmaybenecessarytoturnthe

motorfanbyhandtopositiontheshaft.

2.Slidetheeccentricshaft(7)overtheendof

themotoroutputshaft(2).Installthekey(6).

Theeccentricandthekeyshouldslideeasily

together.

3.Securetheeccentricshaft(7)withtheeccentric

shaftretainingring(8).

3A1939G 13

Repair

Install Install

Install

the the

the

Roller Roller

Roller

NOTE: NOTE:

NOTE:

Therollersizeistypicallymarkedonthe

roller.Verifythatyouhavethecorrectlysizedroller.

1.

On EP3 Pumps only:

Installarollerretainingring

(9)usingexternalsnapringpliers.Makesure

thattheringisfullyseatedinthegrooveonthe

eccentricshaft(7).Installabushing(10).See

Fig8.

2.Lubricatetheeccentricshaft(7)withhoselube.

Slidetheroller(102)ontotheshaft.Theroller

shouldtontotheshaftsnuglywithminimal

radialmovement.

3.Installabushing(10)andarollerretainingring

(9).Verifythattheroller(102)turnsfreelyon

theshaft(7).

Figure8InstalltheRoller,Hose,andFrontCover

Key Key

Key

for for

for

Figure Figure

Figure

8 8

8

Note Note

Note

Description Description

Description

4

EP3019:Torqueto115in-lb(13.0N•m).

EP4029:Torqueto140in-lb(16.0N•m).

5

EP3019:Torqueto25in-lb(2.8N•m).

EP4029:Torqueto35in-lb(4.0N•m).

14

3A1939G

Repair

Install Install

Install

the the

the

Hose Hose

Hose

1.Movetheroller(102)byturningthemotorfan

untiltherollerreachesthe6o’clockposition.

Figure9Rollerin6O’ClockPosition

2.Installoneendofthehose(103)throughthe

rearportofthepumphousingonthelefthand

sidewhenlookingatitfromthefront.Extend

thehose2-3in.(51–76mm)beyondthepump

housing(1).

3.Slidethehoseclamp(104)overthehoseand

installthebarbedtting(105).

4.Positionthehoseclampabout1/4in.(6mm)

fromtheendofthehose.Ensurethatthe

bandwilltintotherecessesofthebarbclamp

(20)andpumphousing(1).Usingthe24L497

ClampingTool,tightentheclamptosecurethe

hoseontothebarbedtting.

Figure10TightentheClamp

5.Cuttheexcessband,thenattentheendwitha

rubbermallet.

Figure11SeattheBarbedFitting

6.Pushtheassembledhoseendintothebarb

clamprecess,usingasmoothmetalrodtohold

thebarbinplace.Thetmaybetight;usea

rubbermallettoseatthebarbedttingassembly.

NOTE: NOTE:

NOTE:

Verifythatthebarbedtting(105)is

correctlypositioned.Thehexonthebarbedtting

(105)mustbealignedwiththecorrespondinghex

onthepumphousing.Thiswillholdthebarbed

ttingrmlyinplace.

7.

On EP4 Pumps only:

Installthetophalfofthe

barbedttingpositioningwasher.Thebottom

halfofthewasherisweldedinplace.

8.Installtheclamp(20)andscrews(21).Torque

thescrewsto115in-lb(13N•m)fortheEP3

Pumpsandto140in-lb(16.0N•m)fortheEP4

Pumps.

9.Loopthehose(103)360degreesandpassthe

otherendthroughthefrontportontherighthand

sideofthepumphousing(1).Assemblethe

barbedtting(105)andclamp(104)asexplained

insteps3–8.

10.Turntheroller(102)tothe12o’clockpositionto

compressthehose,thenpushthehoseintothe

pumphousing.Usearubbermalletifthehose

isdifculttoseat.

11.Returntheroller(102)tothe6o’clockposition.

Itiscriticalthattherollerisatthebottomofthe

pumptoensurethecorrectcapacityofhoselube.

Reinstallthemotorfancover.

NOTICE NOTICE

NOTICE

Therollermustbereturnedtothe6o’clock

positionbeforeinstallingthefrontcover.

Failuretodosowillresultinoverllingofthe

pumpwithhoselube.

3A1939G 15

Repair

Install Install

Install

the the

the

Front Front

Front

Cover Cover

Cover

1.Scrapealldebrisfromthegasketmatingsurfaces

onthefrontcover(12)andthepumphousing

(1),thencleanwithacetoneorbrakecleanerto

removeanyresidue.Thisiscriticaltoensurea

leak-freeassembly.

NOTE: NOTE:

NOTE:

Thepumphousingandfrontcovermust

befreeofdirt,debrisandresiduetoensurea

leak-freeseal.

NOTE: NOTE:

NOTE:

Theholepatternofthefrontcover(12),

gasket(11),andhousingareasymmetric.This

ensuresthatthegasketandcovergooninonly

onedirection.

2.Lineuptheholesinthegasket(11)withtheholes

inthecover(12).Placethegasketonthecover.

3.Lineupthefrontcover(12)andgasket(11)with

thepumphousing(1)byplacingasockethead

capscrew(14)andwasher(13)inthetophole

andscrewingitintothepumphousing.

4.Installtheremainingfrontcoverscrews(14)and

washers(13).Torquethescrewsoppositelyto

25in-lb(2.8N•m)fortheE3Pumpsandto35

in-lb(4.0N•m)fortheE4Pumps.

NOTE: NOTE:

NOTE:

Donotover-tightenthefrontcover

screws.Thiswillcausethegaskettodeformand

thepumptoleak.

Lubricate Lubricate

Lubricate

the the

the

Pump Pump

Pump

NOTICE NOTICE

NOTICE

Thepumphousingisaluminum.Tohelpprevent

galling,blowoutthethreadswithcompressedair

beforeinstallinganyttingsorfasteners.

1.Wrapthedrainplug(17)threadswithPTFEtape

andinstalltheplug.

2.Wrapthesightglass(16)threadswithPTFEtape

andinstall.

3.Usingafunnel,addhoselubethroughthevent

portuntiltheoilbecomesvisiblethroughthe

sightglass.Theoillevelmustnotriseabovethe

halfwaypointontheroller.

NOTE: NOTE:

NOTE:

Do Do

Do

not not

not

overll. overll.

overll.

Overllingthepump

housingwithhoselubewillincreasepressure

inthepumphousing,causinghoselubetoleak

fromthecoverortheclamparea.Seethetable

belowforthecorrectamountofhoselubefor

yourpump.Pre-measuringthecorrectamount

willhelppreventoverlling.

Pump Pump

Pump

Model Model

Model

Amount Amount

Amount

of of

of

Hose Hose

Hose

Lube Lube

Lube

(approximate) (approximate)

(approximate)

EP3019

0.25gal.(1liter)

EP4029

0.5gal.(2liters)

Figure12HoseLubeLevelinSightglass

NOTE: NOTE:

NOTE:

Higheroperatingspeedsprovidemore

vigorouslubrication,whichmaycausesplashing

ofoil.Whenoperatingataspeedof85RPM

orgreater,reducetheamountofhoselubeas

showninthetablebelow.

Oper- Oper-

Oper-

ating ating

ating

Speed Speed

Speed

(RPM) (RPM)

(RPM)

Amount Amount

Amount

of of

of

Hose Hose

Hose

Lube Lube

Lube

0–84Asrecommendedinthetable

above.

85–104

70%ofrecommendedquantity

105–114

60%ofrecommendedquantity

115and

above

50%ofrecommendedquantity

4.Wraptheventplug(15)threadswithPTFEtape

andscrewitintotheventportcarefully.

16 3A1939G

Parts

Ref. Ref.

Ref.

No. No.

No.

Part Part

Part

No. No.

No.

Description Description

Description

Qty Qty

Qty

24L888

ASSEMBLY,pump;

EP3019;seeBarePump

Assembly,page20

1 101

24L889

ASSEMBLY,pump;

EP4029;seeBarePump

Assembly,page20

1

24K589

ROLLERKIT;forEP3019;

includesitems9and10

(page20)

1

102

24K614

ROLLERKIT;forEP4029;

includesitems9and10

(page20)

1

103

SeeHOSEKIT;includestwo

hoseclamps(104)

1

10424M117KIT,hoseclamp;package

of10

1

BARBEDFITTINGKIT;

forEP3019;kitincludes

onebarbedttingandone

clamp(104)

2

105

See

Pump

Matrix,

page22

BARBEDFITTINGKIT;for

EP4029;kitincludesone

barbedtting,oneclamp

(104),andonehalf-washer

2

---

KEY,motorshaft;EP3019

1

106

---

KEY,motorshaft;EP4029

1

Ref. Ref.

Ref.

No. No.

No.

Part Part

Part

No. No.

No.

Description Description

Description

Qty Qty

Qty

MOTORandGEARBOX(s-

eePumpMatrix,page22f-

orthemotorandgearbox

usedonyourpump)

24L9871.5HP;35.91gearratio;

EP3019

24L9881.0HP;100.36gearratio;

EP3019

24L9892.0HP;19.70gearratio;

EP4029

24L9902.0HP;34.29gearratio;

EP4029

107

24L9912.0HP;79.72gearratio;

EP4029

1

---

WASHER,splitlock;M8;

EP3019

4

108

---

WASHER,splitlock;M10;

EP4029

4

---

SCREW,cap,hexhd;M8

x25mm;EP3019

4

109

---

SCREW,cap,hexhd;M10

x30mm;EP4029

4

119

u

24K694

HOSELUBE,glycerin;1

gallon(3.8liter);notshown

1

u

Hose lube is also available in a 1 quart (0.95 liter)

bottle. Order Part No. 24K692.

Parts labeled --- are not available separately.

3A1939G 19

Parts

Bare Bare

Bare

Pump Pump

Pump

Assembly Assembly

Assembly

Model Model

Model

24L888 24L888

24L888

Pump Pump

Pump

Assembly, Assembly,

Assembly,

Series Series

Series

A, A,

A,

for for

for

EP3019 EP3019

EP3019

Pumps Pumps

Pumps

Includesitems1–23

Model Model

Model

24L889 24L889

24L889

Pump Pump

Pump

Assembly, Assembly,

Assembly,

Series Series

Series

A, A,

A,

for for

for

EP4029 EP4029

EP4029

Pumps Pumps

Pumps

Includesitems1–23

20 3A1939G

/