A.O. Smith DSE-5 THRU DSE-120 User manual

- Category

- Water heaters & boilers

- Type

- User manual

This manual is also suitable for

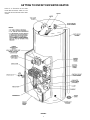

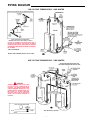

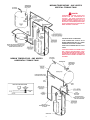

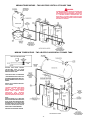

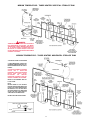

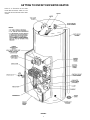

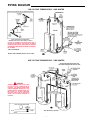

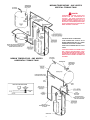

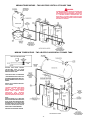

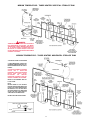

A.O. Smith DSE-5 THRU DSE-120 is a commercial water heater with a maximum KW input of 90 and a recovery rate of up to 1229 gallons per hour. It is designed for commercial use and can be used in a variety of applications, including hotels, restaurants, and hospitals. The heater is available in a variety of sizes, from 5 to 120 gallons, and can be installed on a floor or wall. It is also equipped with a variety of features, including a temperature limiting control, a hydrogen gas detector, and a relief valve.

A.O. Smith DSE-5 THRU DSE-120 is a commercial water heater with a maximum KW input of 90 and a recovery rate of up to 1229 gallons per hour. It is designed for commercial use and can be used in a variety of applications, including hotels, restaurants, and hospitals. The heater is available in a variety of sizes, from 5 to 120 gallons, and can be installed on a floor or wall. It is also equipped with a variety of features, including a temperature limiting control, a hydrogen gas detector, and a relief valve.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

A.O. Smith DSE-5 THRU DSE-120 User manual

- Category

- Water heaters & boilers

- Type

- User manual

- This manual is also suitable for

A.O. Smith DSE-5 THRU DSE-120 is a commercial water heater with a maximum KW input of 90 and a recovery rate of up to 1229 gallons per hour. It is designed for commercial use and can be used in a variety of applications, including hotels, restaurants, and hospitals. The heater is available in a variety of sizes, from 5 to 120 gallons, and can be installed on a floor or wall. It is also equipped with a variety of features, including a temperature limiting control, a hydrogen gas detector, and a relief valve.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

A.O. Smith DVE-150, DHE-200 User manual

-

A.O. Smith ELECTRIC WATER HEATER Owner's manual

-

A.O. Smith Hot Water Generator Technical Documents

-

A.O. Smith 100121410 User manual

-

A.O. Smith Gold Series Technical Documents

-

A.O. Smith dre-80 User manual

-

A.O. Smith BTI-366A User manual

-

A.O. Smith CYCLONE XHE BTH-150 User manual

-

A.O. Smith BTP(V)-540A User manual

-

A.O. Smith BTR 305 Installation Operation & Maintenance

Other documents

-

Lochinvar HS 80 Series 100 User manual

-

State 100120971 Installation guide

-

Lochinvar CSB-52-15-SFE User manual

-

Bradford White VR-600-(kW) User manual

-

Rheem EVRO[150-1000] User guide

-

Lochinvar Commercial gas water heaters User manual

-

Bradford White 9kw User manual

-

Lochinvar HS 80 Series 100 User manual

-

Lochinvar HS 80 Series 100 User manual

-

PVI Industries Durawatt CL Installation guide