Page is loading ...

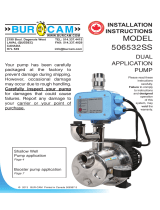

SHALLOW WELL PUMP

1 HP - Stainless Steel

47906

SET UP AND OPERATING INSTRUCTIONS

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright

©

2002 by Harbor Freight Tools

®

. All rights reserved. No portion of this manual or any artwork contained

herein may be reproduced in any shape or form without the express written consent of Harbor Freight Tools.

Diagrams within this manual may not be drawn proportionally. Due to continuing improvements, actual product may

differ slightly from the product described herein. Tools required for assembly and service may not be included.

For technical questions or replacement parts, please call 1-800-444-3353.

Revised Manual 08i, 08k; 09f, 09k

Page 2For technical questions, please call 1-800-444-3353.SKU 47906

SAVE THIS MANUAL

Keep this manual for the safety warnings

and precautions, assembly, operating, inspec-

tion, maintenance and cleaning procedures.

Write the product’s serial number in the back

of the manual near the assembly diagram (or

month and year of purchase if product has no

number). Keep this manual and the receipt in

a safe and dry place for future reference.

IMPORTANT SAFETY

INFORMATION

In this manual, on the labeling, and

all other information provided with

this product:

This is the safety alert sym-

bol. It is used to alert you

to potential personal injury

hazards. Obey all safety mes-

sages that follow this symbol

to avoid possible injury or

death.

DANGER indicates a

hazardous situation

which, if not avoided, will result

in death or serious injury.

WARNING indicates a

hazardous situation

which, if not avoided, could

result in death or serious injury.

CAUTION, used with

the safety alert

symbol, indicates a hazardous

situation which, if not avoided,

could result in minor or moderate

injury.

NOTICE is used to

address practices not

related to personal injury.

CAUTION, without the

safety alert symbol, is

used to address practices not

related to personal injury.

SAFETY WARNINGS AND

PRECAUTIONS

WARNING Read all safety warnings

and instructions. Failure to follow the

warnings and instructions may result

in electric shock, re and/or serious

injury.

Save all warnings and instructions

for future reference.

Read all instructions before use!

Keep work area clean1. . Cluttered areas

invite injuries.

Observe work area conditions2. . Do not

expose this pump to rain or submerge

in water. Keep work area well lighted.

Do not use electrically powered pumps

in the presence of ammable gases or

liquids.

Keep children away3. . Children must

never be allowed in the work area. Do

not let them handle Pump.

Use the right pump for the job4. . Do

not attempt to force a small Pump to

do the work of a larger industrial Pump.

There are certain applications for which

this Pump was designed. It will do the

job better and more safely at the rate for

which it was intended. Do not modify

this Pump and do not use this Pump for

a purpose for which it was not intended.

Dress properly5. . Do not wear loose

clothing or jewelry as they can be caught

in moving parts. Protective, electrically

non-conductive clothes and non-skid

footwear are recommended when work-

ing. Wear restrictive hair covering to

contain long hair.

Page 3For technical questions, please call 1-800-444-3353.SKU 47906

Use eye and ear protection6. . Wear

ANSI-approved impact safety goggles

and ear protection.

Do not overreach7. . Keep proper footing

and balance at all times. Do not reach

over or across running machines.

Maintain Pump with care8. . Keep Pump

clean for better and safer performance.

Inspect pump cords periodically; If dam-

aged, have them repaired by a qualied

technician.

Disconnect power9. . Unplug Pump when

not in use.

Stay alert10. . Watch what you are doing,

use common sense. Do not install Pump

when you are tired.

Check for damaged parts11. . Before us-

ing Pump, any part that appears dam-

aged should be carefully checked to

determine that it will operate properly

and perform its intended function. Check

for alignment and binding of moving

parts; any broken parts or mounting x-

tures; and any other condition that may

affect proper operation. Any part that is

damaged should be properly repaired or

replaced by a qualied technician.

Replacement parts and accessories12. .

When servicing, use only identical re-

placement parts. Use of any other parts

will void the warranty.

Do not install Pump if under the inu-13.

ence of alcohol or drugs. Read warn-

ing labels on prescriptions to determine

if your judgment or reexes are impaired

while taking drugs. If there is any doubt,

do not install the Pump.

RECOMMENDED MINIMUM WIRE

GAUGE FOR EXTENSION CORDS

(120 VOLT)

NAMEPLATE

AMPERES

(at full load)

EXTENSION CORD

LENGTH

25’ 50’ 100’ 150’

0 – 6 18 16 16 14

6.1 – 10 18 16 14 12

10.1 – 12 16 16 14 12

12.1 – 16 14 12 Do not use.

TABLE A

USE PROPER EXTENSION CORD. 14.

Make sure your extension cord is in

good condition. When using an exten-

sion cord, be sure to use one heavy

enough to carry the current your prod-

uct will draw. An undersized cord will

cause a drop in line voltage resulting in

loss of power and overheating. Table A

shows the correct size to use depending

on cord length and nameplate ampere

rating. If in doubt, use the next heavier

gauge. The smaller the gauge number,

the heavier the cord.

Maintenance15. . For your safety, mainte-

nance should be performed regularly by

a qualied technician.

Pump clean water only.16. Do not use the

pump for any other application.

People with pacemakers should consult 17.

their physician(s) before use. Electro-

magnetic elds in close proximity to

heart pacemaker could cause pacemak-

er interference or pacemaker failure.

The brass components of this product 18.

contain lead, a chemical known to the

State of California to cause birth defects

(or other reproductive harm). (California

Health & Safety code § 25249.5, et seq.)

Do not operate this pump if the power 19.

cord or electrical components are

damaged or the seals are compro-

mised. Do not plug in the power cord

Page 4For technical questions, please call 1-800-444-3353.SKU 47906

when wet or standing on damp or wet

ground. Exercise caution when work-

ing with electrical equipment in the

presence of water to maintain your

personal insulation to avoid shock.

Use GFCI (Ground Fault Circuit Inter-

rupter) outlets when using this pump.

WARNING: The brass components 20.

of this product contain lead, a chemi-

cal known to the State of California to

cause birth defects (or other reproductive

harm). (California Health & Safety code §

25249.5, et seq.)

WARNING: Handling the cord on this 21.

product will expose you to lead, a chemi-

cal known to the State of California to

cause cancer, and birth defects or other

reproductive harm. Wash hands after

handling.

(California Health & Safety Code §

25249.5, et seq.)

The warnings, cautions, and instruc-22.

tions discussed in this instruction

manual cannot cover all possible con-

ditions and situations that may occur.

It must be understood by the operator

that common sense and caution are

factors which cannot be built into this

product, but must be supplied by the

operator.

UNPACKING

When unpacking, make sure the item is

intact and undamaged. If any parts are miss-

ing or broken, please call Harbor Freight Tools

at 1-800-444-3353 as soon as possible.

SPECIFICATIONS

Power Requirements 120 V~, 60 Hz, 1 HP

Motor Speed 3400 RPM

Discharge/Intake 1” NPT

Max. Flow 900 GPH

Max. Suction Lift 26’

Max. Total Head 164’

Tank Size 5 Gallons

Pump Body Material Stainless Steel

Cut-in Pressure 20 PSI

Cut-out Pressure 50 PSI

Note: Performance of this pump (if powered

by line voltage) may vary depending on

variations in local line voltage. Extension

cord usage may also affect pump perfor-

mance.

REV 07g; 08k; 09c

Page 5For technical questions, please call 1-800-444-3353.SKU 47906

INSTALLATION

Discharge

Intake

Pressure

Meter

Priming

Inlet

Air Valve

(hidden)

Fig. 1

WARNING! TO PREVENT SERIOUS INJURY

FROM ELECTRIC SHOCK:

Install indoors or in weather-proof well

house only. This Pump is non-submers-

ible.

Do not plug in the power cord when wet

or standing on damp or wet ground. Do

not plug in the power cord until instructed

to do so.

Note: ONLY pump clean water.

Note: Additional components (such as valves

and pipes) may be required for installa-

tion, but not included.

Note: Installation requires skilled workman-

ship and compliance with local building

codes. If you are not condent in your

ability to properly and safely install

this pump, have a qualied technician

perform the installation.

The water to be pumped must be clean 1.

and must be free of sand and grit, which

would damage the pump and void the

warranty.

Foot

Valve

Check

Valve

Well

Seal

Shallow

Well Pump

To

Household

Water

System

Standing Water Level

(With Well Pump Off)

Pumping Water Level (with Well Pump Operating)

Outlet Water

Level

Vertical Well Lift

Head

SLOPE SLIGHTLY DOWNWARD TO WELL

Length of off-set line

(Add when calculating total suction

lift due to friction.)

Fig. 2

2. The illustration above shows an

example of a proper shallow well pump

installation. The total suction lift (vertical

well lift + length of off-set line) must not

exceed the Maximum Suction Lift listed

on the Specications chart.

Note: This pump is intended for shallow well

application only and is not intended to be

used as a booster pump.

Note: For optimal performance, install the

pump as close to the well head as pos-

sible.

Install a Foot Valve at the bottom of the 3.

suction pipe. The Foot Valve must be

under the Pumping Water Level, the

level that the water falls to when the

pump operates.

Install a sterile Well Seal at the top of 4.

the suction pipe to keep the well clean.

Protect from rust inside a frost-proof

enclosure.

REV 05l, 07g, 09d, 09e

Page 6For technical questions, please call 1-800-444-3353.SKU 47906

Intake and discharge pipes must be at 5.

least 1” in diameter.

Lay an off-set line from the well to the 6.

structure the pump will be installed in.

The off-set line should slope slightly

towards the well (see Fig. 2). Systems

with longer off-set lines should use larger

diameter pipe to improve efciency.

Install the pump on a rigid, level, dry 7.

platform. This platform must provide a

solid, level surface that is capable of

supporting the weight of the pump and

attached piping lled with water. Do

not allow water to contact the pump’s

housing.

Caution: DO NOT INSERT ttings into the

Intake Hole farther than 1/2”; this can

DAMAGE the Pump, diminish Pump

functions, and/or STOP water ow.

Keep the Head, the height that the 8.

pump discharge must push water before

discharge, to a minimum. The Vertical

Well Lift, Off-set Line Length, and Head

added together must be less than Max.

Total Head to have ow at output.

Effective ow decreases to 0 GPH as

Total Head reaches its maximum.

For your protection, the power outlet 9.

used should have a Ground Fault Circuit

Interrupter (GFCI). Have it installed by

a qualied electrician. Keep power line

away from water.

The inlet and discharge lines should not 10.

be wedged or stressed in a way that puts

strain on the pump. Do not support the

pump with the inlet and discharge lines.

REV 09d

Page 7For technical questions, please call 1-800-444-3353.SKU 47906

OPERATION

Compression Tank has a rubber bladder 1.

inside. This bladder must be pumped

up to 26-29 PSI of air at all times. Use a

bicycle pump (not included) to inate the

bladder. On the end of the Compression

Tank opposite the side with the Pressure

Meter, is an air valve located under a

cover. Remove the cover over the air

valve and periodically monitor this air

valve with an air pressure gauge to

insure that the rubber bladder maintains

the required air pressure.

Make sure the intake pipe is fully 2.

submerged before continuing.

Before starting the pump for the rst 3.

time, prime it by pouring clean water

into the Priming Inlet.

This is a self-starting pump that uses a 4.

pressure switch. Once the power cord

is connected and the unit is switched on,

the pump can start at any time. Do not

handle or perform maintenance on the

pump if the power cord is plugged in.

To begin pumping, plug in the power 5.

cord and turn the switch on. When the

line is pressurized, the pump will go to

standby mode until the pressure falls

below its starting pressure.

Page 8For technical questions, please call 1-800-444-3353.SKU 47906

REV 06c; 07g; 07l; 08l; 09d

MAINTENANCE

WARNING! Disconnect pump from power

source before maintenance.

Clean the inlet screen on the intake port 1.

regularly to remove accumulated debris.

Wipe the pump clean with a soft, damp 2.

cloth with soapy water. Do not use sol-

vents. Do not get the electrical compo-

nents wet.

Drain water from pump before storage 3.

by disconnecting the water lines and

turning the Pump upside down. If storing

the pump for a long time, store it in a dry

location, and apply a light layer of oil to

the metal parts prior to storage, to inhibit

rust. Do not expose to freezing tem-

peratures.

After storage, check the Impeller to make 4.

sure it turns easily and is not oxidized.

Note: Turn off the Switch and unplug the

pump when performing maintenance.

Troubleshooting

Problem Cause Solution

The pump won’t start No power.1.

Pressure switch disconnected.2.

Thermal Protection cut out.3.

Blocked impeller.4.

Check connections, and breaker/fuse.1.

Check gauge.2.

Allow pump to cool.3.

Free the impeller.4.

The pump operates

but it won’t discharge

water

Pump not primed.1.

Lift height exceeded.2.

Inlet tube not submerged.3.

Air in suction pipe.4.

Inlet screen clogged.5.

Prime pump.1.

Reduce lift height.2.

Submerge the inlet.3.

Check pipe and seals.4.

Clean screen.5.

Only a low volume of

water ows

Inlet pipe is too small.1.

Liquid is too dirty.2.

Lifting height exceeded.3.

Tank’s rubber bladder under-inated.4.

Piping corroded, causing friction.5.

Increase pipe diameter.1.

Clean screen frequently.2.

Reduce lifting height.3.

Inate to 26-29 PSI.4.

Replace piping, with plastic where 5.

possible.

Motor overheats often Extension cord too long or wire size too 1.

small.

Pump cycling too often.2.

Eliminate use of extension cord or use 1.

shorter/heavier gauge cord.

Cut-in and cut-out pressure may be set 2.

too closely; Have the pressure switch

adjusted by a qualied technician.

Pump/motor cycles

rapidly

Cut-in and cut-out pressure may be set too

closely.

Have the pressure switch adjusted by a

qualied technician.

Tank bladder will not

hold pressure

Air inlet valve is leaking. 1.

Bladder is broken.2.

Check air tank for leaks using soapy 1.

water and replace bladder if needed.

Replace bladder.2.

Water pumps

intermittently

Water level is being drawn below foot valve. Lower foot valve.

Follow all safety precautions whenever diagnosing or servicing the pump.

Disconnect power supply before service.

Do not disassemble the pump or motor as this will damage the water seals.

All repairs should be performed by a qualied technician.

Page 9For technical questions, please call 1-800-444-3353.SKU 47906

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY

DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR

DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE

OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED

TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR

EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY

CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK

AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT

PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

Problem Cause Solution

Pump will not hold

prime

Foot/check valve not installed in suction 1.

line.

Foot/check valve leaks water back to well.2.

Install foot and check valve in suction 1.

line.

Replace foot/check valve.2.

Water is full of

bubbles at outlet

Pumping bubbles temporarily as air is 1.

purged after initial setup.

Leak in suction side of pump system.2.

Well is gaseous.3.

Water level below suction inlet of foot 4.

valve.

Temporary self-remedying issue. 1.

Check for and x leaks.2.

Install a sleeve in the well.3.

Lower suction line into water and re-4.

prime. If water is deeper than 26 ft,

then a deep well pump may be needed.

Motor runs, but water

is not pumping

Improper priming. 1.

Air leakage. 2.

Vertical lift too high. 3.

Water level below suction inlet of foot 4.

valve.

Frozen pipes. 5.

Foot valve in dirt or sand.6.

Foot/check valve clogged.7.

Pressure switch is set too low.8.

Prime the pump by pouring clean water 1.

into the Priming Inlet.

Check all pipes and joints in the suction 2.

line for air leakage using soapy water.

Reduce vertical lift to within 3.

specications. See Installation

instructions.

Lower suction line into water and re-4.

prime. If water is deeper than 26 ft,

then a deep well pump may be needed.

Thaw the pipes. Bury pipes below 5.

freeze line/insulate pipes.

Raise foot valve to clean water level.6.

Clean or replace foot/check valve.7.

Have the pressure switch adjusted by 8.

qualied technician (20-50 psi).

Pump does not shut-

off

Pressure switch contacts welded together. 1.

Faucet is open or leaking.2.

Toilet leaking.3.

Impeller is clogged.4.

Tank bladder pressure is too low.5.

Pipeline leakage.6.

Foot/check valve leaks water back to well.7.

Have the pressure switch replaced by a 1.

qualied technician.

Close or repair faucet.2.

Repair leaky toilet.3.

Clean impeller.4.

Inate to 26-29 psi.5.

Repair pipeline.6.

Replace foot/check valve.7.

Follow all safety precautions whenever diagnosing or servicing the pump.

Disconnect power supply before service.

Do not disassemble the pump or motor as this will damage the water seals.

All repairs should be performed by a qualied technician.

Page 10For technical questions, please call 1-800-444-3353.SKU 47906

Part Description Qty.

1 Screw M8x12 4

2 Motor Housing 1

3 Fan Blade 1

4 Rear Cover 1

5 Spring Washer 1

6 Motor Bolt M5x125 4

7 Stator 1

8 Bearing 1

9 Rotor 1

10 Bearing 1

11 Rubber Sheath 1

12 Screw 4.2x15 2

13 Cable Block 1

14 Cable Sleeve 1

17 Waterproof Cover 1

19 Sealing 1

20 Capacitor Cover 1

21 Capacitor 1

22 Side Cover 1

24 Waterproof Switch 1

25 Screw 3.5 x 20 3

26 Hex Nut M8x20 4

27 Front Cover 1

Part Description Qty.

28 Rubber Ring 1

29 O-ring 1

30 Flange 1

31 Immobile Ring 1

33 Impeller 1

34 Flow Guide Plate 1

35 O-ring 1

36 Flow Guide Assy. 1

37 O-ring 1

38 Pump Shell 1

42 Screw M8x20 4

43 O-ring 1

45 Small Valve Cover 1

52 Retaining Ring 1

53^ PTFE Thread Seal Tape Roll 1

54^ Foot Valve 1

55^ Check Valve 1

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM IN THIS

MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DISTRIBUTOR MAKES ANY

REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO MAKE

ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE

PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS

AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS

AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER

REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR

HER INSTALLATION OF REPLACEMENT PARTS THERETO.

Record Product’s Serial Number Here:

Note: If product has no serial number, record month and year of purchase instead.

Note: Some parts are listed and shown for illustration purposes only, and are not available

individually as replacement parts.

PARTS LIST

^ Parts marked with a caret (^) are not shown on the diagram.

Page 11For technical questions, please call 1-800-444-3353.SKU 47906

ASSEMBLY DRAWING

REV 08f, 09c

Page 12For technical questions, please call 1-800-444-3353.SKU 47906

PARTS LIST AND ASSEMBLY DRAWING A

Note: When ordering a part from this drawing, you must include the sufx “A” with the number.

Part Description Qty

1A Compression Tank 1

2A Pump Assembly 1

3A Hex Bolt 2

4A Hex Nut 2

5A Pressure Meter 1

6A Cable 1

7A Switch 1

8A Cord 1

9A Tube 1

10A Latex Seal 1

51A Rubber Bladder (not shown) 1

5B Bushing 1

10B Latex Seal 1

REV 05h, 08f, 09c

Page 13For technical questions, please call 1-800-444-3353.SKU 47906

REV 07g

LIMITED 1 YEAR / 90 DAY WARRANTY

Harbor Freight Tools Co. makes every effort to assure that its products meet high qual-

ity and durability standards, and warrants to the original purchaser that for a period of ninety

days from date of purchase that the engine/motor, the belts (if so equipped), and the blades

(if so equipped) are free of defects in materials and workmanship. Harbor Freight Tools also

warrants to the original purchaser, for a period of one year from date of purchase, that all other

parts and components of the product are free from defects in materials and workmanship (90

days if used by a professional contractor or if used as rental equipment). This warranty does

not apply to damage due directly or indirectly, to misuse, abuse, negligence or accidents, re-

pairs or alterations outside our facilities, normal wear and tear, or to lack of maintenance. We

shall in no event be liable for death, injuries to persons or property, or for incidental, contingent,

special or consequential damages arising from the use of our product. Some states do not

allow the exclusion or limitation of incidental or consequential damages, so the above limita-

tion of exclusion may not apply to you. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF MER-

CHANTABILITY AND FITNESS.

To take advantage of this warranty, the product or part must be returned to us with trans-

portation charges prepaid. Proof of purchase date and an explanation of the complaint must

accompany the merchandise. If our inspection veries the defect, we will either repair or re-

place the product at our election or we may elect to refund the purchase price if we cannot

readily and quickly provide you with a replacement. We will return repaired products at our ex-

pense, but if we determine there is no defect, or that the defect resulted from causes not within

the scope of our warranty, then you must bear the cost of returning the product.

This warranty gives you specic legal rights and you may also have other rights which

vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • (800) 444-3353

/