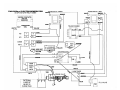

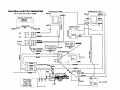

Cleveland Range 24-CEM-36 is an electric boiler base with a 10.6 kW heating element and a capacity of 36 gallons. It provides a continuous supply of hot water or steam for various commercial applications. The unit features automatic water level control to maintain the desired water level, ensuring consistent operation. It is equipped with safety features such as a high-limit pressure switch to prevent over-pressurization and a low water cut-off switch to protect the heating element from damage. The unit also includes built-in diagnostics to simplify troubleshooting.

Cleveland Range 24-CEM-36 is an electric boiler base with a 10.6 kW heating element and a capacity of 36 gallons. It provides a continuous supply of hot water or steam for various commercial applications. The unit features automatic water level control to maintain the desired water level, ensuring consistent operation. It is equipped with safety features such as a high-limit pressure switch to prevent over-pressurization and a low water cut-off switch to protect the heating element from damage. The unit also includes built-in diagnostics to simplify troubleshooting.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

Cleveland Range 24-CEM-36 User manual

- Category

- Clothes steam cleaners

- Type

- User manual

Cleveland Range 24-CEM-36 is an electric boiler base with a 10.6 kW heating element and a capacity of 36 gallons. It provides a continuous supply of hot water or steam for various commercial applications. The unit features automatic water level control to maintain the desired water level, ensuring consistent operation. It is equipped with safety features such as a high-limit pressure switch to prevent over-pressurization and a low water cut-off switch to protect the heating element from damage. The unit also includes built-in diagnostics to simplify troubleshooting.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Cleveland 24-CSM User manual

-

Convotherm CCE106 Obsolete 2005 Specification

Convotherm CCE106 Obsolete 2005 Specification

-

Cleveland CombiCraft CCE-210X Specification

Cleveland CombiCraft CCE-210X Specification

-

Cleveland 24-CSM User manual

-

Cleveland Classic Gas User manual

Cleveland Classic Gas User manual

-

Cleveland 24-CGM-200 User manual

Cleveland 24-CGM-200 User manual

-

Cleveland 6-CGM-200 User manual

-

Cleveland Range 10-CKEM-36 User manual

-

Cleveland Range 24-CSM User manual

-

Cleveland 36CSM16 User manual

Other documents

-

Cleveland 24-CGM-200 Supplementary Manual

Cleveland 24-CGM-200 Supplementary Manual

-

Cleveland 24CGA10 User manual

Cleveland 24CGA10 User manual

-

Cleveland SteamCraft Power 10 User manual

-

Cleveland 24CEA10 User manual

Cleveland 24CEA10 User manual

-

Vulcan Hart VSX24G-ML-52163 User manual

-

Vulcan-Hart VL3DSS-ML-52756 User manual

-

Cleveland 24CGA6.2 User manual

Cleveland 24CGA6.2 User manual

-

Cleveland 24CGA10.2 User manual

Cleveland 24CGA10.2 User manual

-

Cleveland 21CET8 User manual

Cleveland 21CET8 User manual

-

Groen (2)CC20-EF User manual