Page is loading ...

Statement of Responsibilities

This document is for use by experienced and trained Qualified Cleveland Range, LLC Authorized Service

Representatives who are familiar with both the safety procedures, and equipment they service.

Cleveland Range, LLC assumes no liability for any death, injury, equipment damage, or property damage

resulting from use of, improper use of, or failure to use the information contained in this document.

Cleveland Range, LLC has made every effort to provide accurate information in this document, but

cannot guarantee that this document does not contain unintentional errors and omissions.

The information in this document may be subject to technical and technological changes, revisions, or

updates.

Cleveland Range, LLC assumes no liability or responsibility regarding errata, changes, revisions, or

updates.

Qualified Cleveland Range, LLC Authorized Service Representatives are obligated to follow industry

standard safety procedures, including, but not limited to, OSHA regulations, and disconnect / lock out /

tag out procedures for all utilities including steam, and disconnect / lock out / tag out procedures for gas,

electric, and steam powered equipment and / or appliances

All utilities (gas, electric, water and steam) should be turned OFF to the equipment and locked out of

operation according to OSHA approved practices during any servicing of Cleveland Range equipment

Qualified Cleveland Range, LLC Authorized Service Representatives are obligated to maintain up-to-date

knowledge, skills, materials and equipment.

Cleveland Range,

LLC

1333 East 179th St., Cleveland, Ohio, U.S.A. 44110

Ph: 1-216-481-4900 Fx: 1-216-481-3782

Visit our Web Site at www.clevelandrange.com

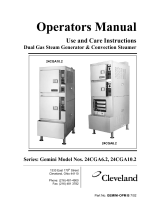

MODEL: 24CGA6.2S

ITEM NUMBER __________________________________________

JOB NAME / NUMBER __________________________________

Cleveland Standard Features

■ 54.5” (1385mm) height to top of upper compartment

(lower height makes maintenance easier by lowering the

descaling ports)

■ Each compartment has cooking capacity for 3 each

12˝ x 20˝ x 2

1

⁄2˝ Steam Table Pans

■ Doors hinged left and the controls on the right

■ High efficiency independent Power Burner Steam Generators

50,000 BTU's for each compartment

■ Each steam-cooking compartment is independently operated

and controlled by a separate stainless steel steam generator,

gas valve, Power On/Off Control Levers and a Exclusive,

Remote Probe-Type Water Level Control

■ Easy Access Cleaning Port: Each generator has a deliming

port located on the outside, top of the unit

■ Generator Cleaning Light for each compartment warns the

operator to delime generator

■ Generator Steam Standby Mode: Holds generator at a

steaming temperature, allows unit to start cooking quickly

■ Each compartment has one, 60-Minute Electro-Mechanical

Timer with "SureCook" load compensating feature.

Manual Bypass Switch for constant steaming.

■ Durable 14 Gauge, 304 Stainless Steel construction for

compartment door, cooking cavity and steam generator

■ Exclusive Gemini Drain/Power Control System:

Manual 1/2 inch "Ball Valve" type drain that controls main

power On/Off and automatically fills generator (located on the

control panel)

■ Exclusive Brass Steam Jets distribute steam even throughout

cooking compartment

■ Easy, Front -Access Generator Controls comes with a pullout

drawer for simple servicing of unit

■ 6˝ Stainless Steel Adjustable Legs with Flanged Feet

■ Approvals: CSA (AGA, CSA) and U.L/NSF#4

■ Compartment Steam Shut-Off Switch when compartment

door is opened

Options & Accessories

❐ Electronic Timer with Compensating Feature (ETC)

❐ On/Off Steam Switch Controls, no timer (MC)

❐ Propane Gas (PG)

Cleveland

SteamCraft

Gemini

TM

Model 24CGA6.2S, 54.5" high,

Two compartment steamer. Independent steam generators

,

50,000 BTU's input per compartment.

"SureCook" electro mechani-

cal timer with load compensating feature. Gas valve and water

level control system. Exclusive remote probe-type water level

controls. Exclusive Brass “Steam Jet” distribution system. Two-

piece free-floating compartment door. 14 gauge stainless steel

cavity and door. Pullout service drawer for controls and Gemini

Drain/Power Control System.

❐ Dissolve

®

Descale Solution, 6 one gallon container w/quart

markings (106174)

❐ Water Filters

Short Form Specifications

SECT. IV PAGE 11

0104

SteamCraft

®

Gemini

TM

6

SHORT SERIES PRESSURELESS STEAMER,

TWIN, INDEPENDENT GAS-FIRED GENERATORS

GAS ELECTRIC COLD WATER CLEARANCE DRAINAGE

1

1

⁄

4

˝ IPS line size,

3

⁄

4

˝ connection 120V-1Phase, 60 Hz. 35 psi minimum RIGHT = 12.00˝ 1

1

⁄

2

˝ dia.

NATURAL PROPANE BTU 2 Blowers & Controls 60 psi maximum LEFT = 3.00˝ Do not connect other

Piping

3

⁄

4

˝ N.P.T. Piping

3

⁄

4

˝ N.P.T. 50,000 each 150 watts each C2

3

⁄

8

˝ dia. NPT for Generator REAR = 3.00˝ units to this drain

Supply pressure Supply pressure Generator, C1

3

⁄

8

˝ dia. NPT for Condenser Allow 6˝ space min.

4.50˝ W.C. Min. 11.00˝ W.C. Min. 100,000 total from rear and sides Drain must be vented

14.00˝ W.C. Max. 14.00˝ W.C. Max. When located near

combustible walls Do not use PVC pipe

Manufacturer must be notified if unit will

be used above 2,000 feet

20.63"

(524mm)

33.13"

(842mm)

4.87"

(124mm)

3.00" TYP

(76mm)

7.75"

(197mm)

10.44"

(265mm)

5.00"

(127mm)

4.00"

(102mm)

12.00"

(305mm)

24.00"

(508mm)

12.76"

(324mm)

15.06"

(383mm)

17.43"

(443mm)

37.13"

(943mm)

13.25"

(337mm)

10.00"

(254mm)

20.88"

(530mm)

4.75"

(121mm)

13.88"

(353mm)

20.36"

(517mm)

17.25" TYP

(438mm)

21.50"

(546mm)

59.21"

(1504mm)

30.25"

(768)

5.00"

(127mm)

7.34"

(186mm)

20.50"

(521mm)

2.06"

(52mm)

6.60"

(168mm)

33.13"

(842)

6.13"

(156mm)

24.00"

(610mm)

OPERATING

CLEARANCE

SECONDARY

CLEARANCE

C2

D

C1

(NOT TO SCALE)

SECT. IV PA GE 12

0104

Litho in U.S.A.

Each Compartment has

Capacity for:

• Three 2

1

⁄

2˝ x 12˝ x 20˝

Steam Table Pans

• Six 1˝ x 12˝ x 20˝

Steam Table Pans

•Two 4˝ x 12˝ x 20˝

Steam Table Pans

C

NOTES:

Cleveland Range reserves right of design improvement or modification, as warranted.

Many regional, state and local codes exist and it is the responsibility of the owner and installer to comply with the codes.

Cleveland Range equipment is built to comply with applicable standards for manufacturers. Included among those approval agencies are UL/NSF#4 and CSA (AGA, CGA).

D

WATER QUALITY

REQUIREMENTS

The quality of water varies

greatly from region to

region. Steam equipment

generators must be

drained daily and chemi-

cally descaled periodically

to ensure proper operation.

To minimize service prob-

lems caused by the accu-

mulation of minerals and

chemicals in water review

the following quality guide-

lines with a local water

treatment specialist. Inlet

water that is beyond these

specified guidelines should

be treated to achieve these

acceptable limits. Total

Dissolved Solids less than

60 ppm, Alkalinity less than

20 ppm, Silica less than 13

ppm, pH factor greater

than 7.5, Chlorine less

than 30 ppm.

Right - 3”, Left - 3”,

Rear - 3”

(12” on control side if

adjoining wall or

equipment is over 30”

high for service access)

Contact factory

for variances to

clearances.

Cleveland Range Inc.

1333 East 179th St., Cleveland, Ohio, U.S.A. 44110

Ph: 1-216-481-4900 Fx: 1-216-481-3782

Visit our Web Site at www.clevelandrange.com

MODEL: 24-CGA-10.2

ITEM NUMBER __________________________________________

JOB NAME / NUMBER __________________________________

Cleveland Standard Features

■ Cooking Capacity for up to ten 12˝ x 20˝ x 2 1/2˝ deep

Cafeteria Pans, five each compartment.

■ Totally independent cooking compartments, each has its'

own generator, gas valve and water level controls - no

shared components

■ Exclusive High Efficiency Gas Power Burner (forced air)

Generator: Produces more steam for faster cooking while

lowering operating costs (72M BTU's per compartment)

■ Easy Access Cleaning Port: Each generator has a deliming

port located on the outside, top of the unit

■ Generator Cleaning Light for each compartment warns the

operator to delime generator

■ Instant Steam Standby Mode: Holds generator at a

steaming temperature, allows unit to start cooking instantly

■ Each compartment has one, 60-Minute Electro-Mechanical

Timer with load compensating feature.Manual Bypass

Switch for constant steaming.

■ Durable 14 Gauge, 304 Stainless Steel construction for

compartment door, cooking cavity and steam generator

■ Exclusive Two-Piece Compartment door: Slammable,

self-adjusting door provides and airtight seal, reversable

door gasket for extended life

■ Exclusive Gemini Drain/Power Control System:Simple,

reliable 1/2" ball valve style drain automatically turns power

ON/OFF

■ Exclusive Brass Steam Jets distribute even-high velocity

steam throughout cooking compartment for faster cooking

times

■ Easy, Front -Access Generator Controls comes with a

pullout drawer for simple servicing of unit

■ 6˝ Stainless Steel Adjustable Legs with Flanged Feet

■ Approvals: CSA (AGA, CSA) and U.L/NSF#4

■ Compartment Steam Shut-Off Switch (SCS)

Options & Accessories

❐ Electronic Timer with Compensating Feature (ETC)

❐ On/Off Steam Switch Controls, no timer (MC)

Shall be Two Compartments, Cleveland Convection Steamer series

SteamCraft

Gemini

TM

10

, Model 24-CGA-10.2, Twin Gas Atmospheric

Steam Generator, 72M BTU"s input per compartment.

Independent

steam generator, gas valve and water level control system.

Automatic Generator Blowdown. Steam Generator with Automatic Water

Fill on start up.

Exclusive remote probe-type water level controls.

Exclusive Brass “Steam Jet” distribution system. Two-piece free-

floating compartment door.

Type 430 Stainless Steel exterior and cook-

ing compartments.

Pullout service drawer for controls and Gemini

Drain/Power Control System.

Exclusive Cold Water Condenser design.

Choice of Compartment Controls. Manual

❐ Propane Gas (PG)

❐ Dissolve

®

Descale Solution, 6 one gallon container w/quart

markings (106174)

❐ Water Filters

Short Form Specifications

SECT. IV PAGE 13

0402

SteamCraft

®

Gemini

TM

10

TWO COMPARTMENT FLOOR MODEL DESIGN

PRESSURELESS CONVECTION STEAMER

TWIN, INDEPENDENT GAS-FIRED GENERATORS

(NOT TO SCALE)

SECT. IV PAGE 14

0402

Litho in U.S.A.

GAS ELECTRIC COLD WATER CLEARANCE DRAINAGE

1

1

⁄

4

˝ IPS line size,

3

⁄

4

˝ (13mm) connection 120V-1Phase, 60 Hz. 35 psi minimum RIGHT = 3˝ operating, 1

1

⁄

2

˝ dia.

NATURAL PROPANE BTU 2 Blowers & Controls 60 psi maximum 12˝ if adjoining wall or Do not connect other

Piping

3

⁄

4

˝ N.P.T. Piping

3

⁄

4

˝ N.P.T. 72,000 each 150 watts each LEFT = 3˝ units to this drain

Supply pressure Supply pressure Generator, One (E) 1/4" dia. REAR = 3˝

4.50˝ W.C.Min. 11.00˝ W.C.Min. 144,000 total NPT for Generator Allow 6˝ space min. Drain must be vented

14.00˝ W.C.Max. 14.00˝ W.C. Max. from rear and sides

One (D) 1/4" dia when located near Do not use PVC pipe

Manufacturer must be notified if unit will NPT for Condenser combustible walls

be used above 2,000 feet

C

D

NOTES:

Cleveland Range reserves right of design improvement or modification, as warranted.

Many regional, state and local codes exist and it is the responsibility of the owner and installer to comply with the codes.

Cleveland Range equipment is built to comply with applicable standards for manufacturers. Included among those approval agencies are UL/NSF#4 and CSA (AGA, CGA).

Each Compartment has

capacity for:

• Five, 12˝ x 20˝ x 2

1

⁄2˝ deep

Cafeteria Pans.

WATER QUALITY

REQUIREMENTS

The quality of water varies

greatly from region to region.

Steam equipment generators

must be drained daily and

chemically descaled periodically

to ensure proper operation. To

minimize service problems

caused by the accumulation of

minerals and chemicals in water

review the following quality

guidelines with a local water

treatment specialist. Inlet water

that is beyond these specified

guidelines should be treated to

achieve these acceptable limits.

Total Dissolved Solids less than

60 ppm, Alkalinity less than 20

ppm, Silica less than 13 ppm,

pH factor greater than 7.5,

Chlorine less than 30 ppm.

Right - 3”, Left - 3”,

Rear -3”

(12” on control side if adjoining

wall or equipment is over 30”

high for service access)

Contact factory

for variances to

clearances.

A B C

DE

CLEVELAND RANGE GEMINI 24CGA 6.2

AND 24CGA10.2

SEQUENCE OF OPERATIONS

Mechanical Timer

Starting with the timed manual switch in the timed position, and no time on the timer.

1. To turn the unit on, turn the ON/OFF lever clockwise to the ON position

• This mechanically closes the drain.

• The red “Power On” indicator is energized.

• 115 VAC is sent through the timer to the three-second timer, which activates the

buzzer for three seconds.

• 115 VAC is sent through the normally closed R1 contacts to the fan motor, turning it

ON

• 115 VAC is sent to H and N of the water level board

2. With the water level board energized and no water in the generator

• 115 VAC is sent from the FILL terminal to the fill solenoid.

• The fill solenoid opens and the generator fills.

3. The water fills to the low probe shorting it to ground

• 115 VAC is sent from the HEAT terminal to the timed manual switch.

• 115 VAC is sent through the high limit to the primary of the 24VAC transformer.

• The water continues to fill until the water level reaches the high probe then 115 VAC is

removed from the FILL terminal and the fill solenoid is turned off

4. 24VAC is sent to the ignition module.

• Spark is sent to the igniter.

• 24VAC is sent to the pilot coil of the gas valve and the coil of the R1 relay.

• The normally closed R1 contacts open, turning off the fan

• The pilot lights, which acts as a standby heater. When the pilot is ignited and the

module detects 1.0 micro amps DC, the MV terminal on the module is energized it

remains in this standby heat mode until a cooking compartment is turned “ON” (see

step 5).

5. When the timed/manual switch is in the timed position and time is on the timer or the timed

manual switch is set to the manual position:

• 115 VAC is sent to the clean light timer.

• When the clean light timer times down 115 VAC is sent to the clean light switch.

• When the clean light switch is depressed the timer is reset.

• 115 VAC is sent from the compartment timer through the door switch to the normally

closed contacts of the compartment thermostat and R2 relay coil.

• The “Sure Cook” light is energized.

• 115 VAC is also sent from the door switch through the now closed contacts of the R1

relay to the fan motor.

• The fan motor turns ON, and comes up to speed.

• The fan prover switch makes allowing 24 VAC to the normally open R2 contacts.

• The normally open R2 contacts close and 24 VAC is sent to the main coil of the gas

valve.

• The main burner is ignited and the water heated to steam.

• Steam enters the cabinet and the compartment thermostat closes at 193 degrees.

• The “Sure Cook” light is de-energized.

• If in the timed mode, 115 VAC is sent to the timer motor and the timer begins

counting down.

• The condensate solenoid is energized sending cold water down condensate spray

nozzle pulling the steam around the product and down the drain.

6. When the timer times out or the unit is switched to the timed mode (with no time on the

timer) from the manual mode, 115 VAC is sent to the 3 second timer and then to the buzzer

for 3 seconds.

7. Whenever the water level drops below the high probe for 5 seconds 115 VAC is sent to the

FILL terminal again.

8. When the on/off lever is turned off :

• The drain is mechanically opened, and the generator begins to drain.

• The red “Power On” indicator light is de-energized.

• 115 VAC is sent to the 3-minute timer and the fill solenoid is energized for 3 minutes

flushing the drain.

BUZZER

VALVE

BLOWER MOTOR

MV

GAS VALVE

DESCALE REQUIRED INDICATOR

GEMINI GAS - MECHANICAL TIMER

24V

IGNITOR

PROVER

MV/PV

SPARK CONTROL MOD

SINGLE COMPARTMENT SHOWN

DUPLICATE FOR SECOND COMPARTMENT

GND

GND

SPARK

24V24V

GND

R1

PV

MV

C NO

PV

TIMER

DOOR

MAGNETIC

120V

TRANSFORMER

ELECTRO-MECHANICAL

OVER TEMP

HI LIMIT

GENERATOR

MANUAL

TIMED

BLOWER

NC

R1

R2

C

NO

M

SWITCH

1

2

NO NO

R

ON

POWER ON

TIMER

3 MINUTE

SW1

OFF

1

2

3

78 5

3 SEC TIMER

3

ON

SW2

OFF

FILL

VALVE

120VAC

COMMON TO UPPER AND LOWER COMPARTMENTS

CUSTOMER

CONNECTION

DESCALE

TIMER

BLK

3

4

2

1

6

GND

TB

& RESET SWITCH

N

L1

A

L L

L300095 C

WHT

MANUAL

NC

C NO

C

NO

NC

C

NC

NO

TIMED

R2

CONDENSER

A

COMPARTMENT

PAUSE

XL

N

HI C

HEAT

H

FILL

BOARD

WATER

PROBES

THERMOSTAT

(SCS)

1

3

2

R

TIMER

60 MINUTE

ON

MANUAL

MOTOR

WHT

WHT/RED

YEL

YEL

SW1

BLU

WHT/RED

GRA

RED

BLK

C

BLK

NCNO

NC

SW2

NO

C

BLU

GRN

GRN

BLK

RED

RED

WHT/RED

BLK

TAN

TAN

PNK

87

PRP

PRP

3 2

4

5

1

6

BLU

HEAT

LT BLU

ORN

WHT

9

FILL H N

XL

HI

C

RED

WHT

5

MV/PV

GND (BNR)

24V (GND)

4

MV

1

PV

32

24V

765

11

10

GRA

WHT

YEL

213

BLUWHT/ORNYEL

WHT/ORN

BLU

WHT/ORN

PRP

PNK

PRP

BLK

BLK

WHT/RED

BLK

BLK

WHT/BLU

21 3

WHT/ORN

BLU

GRN

GRN

ORN

GEMINI GAS / MECHANICAL TIMER

4

BLU

SPARK

3

8 9

15

2

PV

PV/MV

MV

RED

1

BLK

ORN

WHT

ORN

7

8

YEL

ORN

RED

BLK

RED

BLK

W/R

WHT/RED

WHT/RED

GRA

WHT

LT BLU

6

16 17

CUSTOMER

DRAWER

P300095 C

STEAM CUTOFF SWITCH - SCS

TERMINAL BLOCK SECTION (QTY. 2)

TIMED / MANUAL SWITCH W / INDICATOR

IGNITOR CABLE ASSEMBLY

TERMINAL BLOCK ASSEMBLY

INDICATOR (RED)

30027824

26

25

41350

20477 3 SECOND TIMER

BUZZER

2030420

21A

22

23

21

108979

110198

20302

20301

17

19

18

15

16

222231

108981

12159

108880

22218

GROUND LUG

ELECTRO-MECHANICAL TIMER

TERMINAL BLOCK END

FILL VALVE

CONDENSER VALVE

GAS VALVE, PROPANE

GAS VALVE, NATURAL

COMPONENT PARTS LIST

IGNITOR, NATURAL GAS

IGNITOR, PROPANE GAS

SPARK IGNITION TRANSFORMER

BLOWER W/ SENSOR (GEMINI 10)

WATER LEVEL CONTROL BOARD

DESCALE INDICATOR / RESET SWITCH

MANUAL DRAIN VALVE WITH SWITCHES

LEVEL CONTROL PROBE

3 MINUTE INTERVAL TIMER

HI LIMIT CAPILLARY SWITCH

IGNITION CONTROL MODULE

CONNECTIONS

205284

9

12

14

13

10

11

106911

110613

19994

20478

107239

7

8

6

5

108285

107241

105966

300094

108995

DESCALE TIMER

24VAC RELAY

120VAC RELAY

3

1

2

1098771

105693

109877

1057842

1057841

ITEM P/N DESCRIPTION

120VAC

19

COMPONENT

WHT

CHASSIS

GROUND

WHT

W/R

WHT

RED

GND

20

21

21A

COMPARTMENTS

COMMON TO UPPER AND LOWER

L1N

WHT

BLK

BLK

LT BLU

WHT

YEL

YEL

GRA

RED

BLK

GRA

BLU

LT BLU

ORN

NC

PNK

C NO

28

BLK

BLK

GRA

PRP

BLK

BLK

27

GRA

23

28 109602

INDICATOR (AMBER)

27 19972 COMP. THERMOSTAT

R1 R2

26

25

24

22

18

14

13

12

RED

LT BLU

YEL

ORN

2-6

3-3

1-1

1-2

1-3

GRN

3-2

3-1

3-5

3-4

3-6

3-7

3-8

3-10

3-9

3-13

3-14

3-12

3-11

2-1

2-2

2-3

2-4

2-5

2-7

2-8

2-9

9-3

2-11

9-2

9-8

2-12

2-13

9-7

9-7

2-14

7-5

7-4

7-6

11-3

11-1

11-6

11-5

11-2

7-3

7-2

7-1

2-10

OFF

ON

NOTES:

1. UPPER COMPARTMENT CIRCUIT SHOWN

DUPLICATE FOR LOWER COMMPARTMENT.

2. UNIT SHOWN IN THE OFF MODE WITH DRAIN

VALVE OPEN AND SWITCH 2 ACTUATED.

110786 BLOWER W/ SENSOR (GEMINI 6)

30015029 60 MINUTE TIMER

WHT/BLU

PRP

11-4

BLU

PS-3

PS-6

BRN

WHT/BRN

PS-7

PRP

PS-7

PS-5

WHT/RED

PS-2

PS-1

PS-2

PS-1

PS-4

PRP

29

21 3

FK300279 SWITCH ASSEMBLY (REPLACEMENT KIT)

GND SPARK CONTROL MOD GAS VALVE

DUPLICATE FOR SECOND COMPARTMENT

SINGLE COMPARTMENT SHOWN

L300096 C

TRANSFORMER

ELECTRONIC

BLOWER

PROVER

IGNITOR

24V

SPARK

GND

MV/PV

MV

PV

GND

24V

120V

24V

TRANSFORMER

FU

TIMER

24 VAC

R1

PV

R2

C

NO

MV

R1

CNC

M

BLOWER MOTOR

NO

NO

NC

COMMON TO UPPER AND LOWER COMPARTMENTS

GEMINI GAS - ELECTRONIC TIMER

DESCALE REQUIRED INDICATOR

POWER ON

R

OFF

ON

NC

NO

C

SW1

ON

SW2

OFF

2

1

3 MINUTE

TIMER

3

6

587

DESCALE

TIMER

1

2

4

3

BLK

CONNECTION 120VAC

L1 N

CUSTOMER

TB

CXL HI

WATER

BOARD

FILL

N

H

HEAT

FILL

VALVE

C

NO NO

LL

A

& RESET SWITCH

WHT

GND

THERMOSTAT

R2

CONDENSER

VALVE

PROBES

COMPARTMENT

OVER TEMP

HI LIMIT

GENERATOR

(SCS)

SWITCH

MAGNETIC

DOOR

2

60 MINUTE

MANUAL

TIMER

1

TIMED

3

R

MANUAL

ON

TIMED

MANUAL

WHT/ORN

GEMINI GAS / ELECTRONIC TIMER

WHT/RED

BLK

BLK

23

25

WHT YEL

YELBLK

RED

PRP

27

GRA

26

ORN

BLK

BLK

24

18

BLU

BLK

4

LT BLU

5

PV

PV/MV

MV

2

15

WHT/ORN

GRN

GRN

ORN

BLU

1

4132765 89

WHT

YEL

YEL

SPARK

3

GND (BNR)

24V (GND)

24V

MV/PV

MV

PV

22

GRN

WHT/ORN

YEL

YEL

YEL

BLU

PRP

12

GRA

RED

BLK

WHT/RED

13

BLK

RED

WHT

7

4

PRP

3

6

2

1

5

8

FILL

ORN

LT BLU

9

HEAT

WHT

BLU

RED

C

H

HI

XL

N

GRN

RED

BLK

WHT/RED

CUSTOMER

CONNECTIONS

RED RED

WHT

ORN

ORN

BLK

6

16

17

7

RED

WHT/ORN

PRP

PNK

BLU

YEL

ORN

WHT/RED

GRA

WHT/RED

8

LT BLU

WHT

PRP

19

COMPONENT

COMPARTMENTS

COMMON TO UPPER AND LOWER

CHASSIS

WHT

WHT/RED

BLK

WHT

WHT

BLK

W/R

WHT

RED

W/R

DRAWER

GROUND

20

21

21A

WHT

BLK

L1N

GND

120VAC

P300096 C

10

GRA

WHT

YEL

11

1 23

GRA

BLK

BLU

14

GRA

BLU

BLK

YEL

ORN

LT BLU

RED

R2

R1

1-1

1-2

3-3

3-2

3-1

3-4

3-5

3-7

3-8

3-10

3-9

3-6

3-14

3-13

3-12

3-11

2-1

2-2

2-3

2-4

2-5

2-11

PNK

2-12

TAN

9-8

9-3

9-2

TAN

2-13

2-10

9-7

9-7

2-6

2-7

2-8

2-14

7-6

7-4

7-5

7-1

7-2

7-3

11-3

11-2

11-6

NC

NO

SW1

C

SW2

OFF

CNCNO

ON

VALVE OPEN AND SWITCH 2 ACTUATED.

2. UNIT SHOWN IN THE OFF MODE WITH DRAIN

DUPLICATE FOR LOWER COMMPARTMENT.

1. UPPER COMPARTMENT CIRCUIT SHOWN

NOTES:

CONDENSER VALVE2221816

110613

110786

P/N

1057841

1057842

109877

105693

1098771

108995

300094

105966

107241

108285

107239

20478

19994

106911

20528

COMPONENT PARTS LIST

108880

6

2

ITEM

1

3

5

4

8

7

10

9

13

11

12

14

15

BLOWER W/ SENSOR (GEMINI 10)

IGNITION CONTROL MODULE

HI LIMIT CAPILLARY SWITCH

SPARK IGNITION TRANSFORMER

GAS VALVE, NATURAL

DESCRIPTION

IGNITOR, PROPANE GAS

IGNITOR, NATURAL GAS

GAS VALVE, PROPANE

BLOWER W/ SENSOR (GEMINI 6)

MANUAL DRAIN VALVE WITH SWITCHES

DESCALE INDICATOR / RESET SWITCH

WATER LEVEL CONTROL BOARD

STEAM CUTOFF SWITCH - SCS

120VAC RELAY

24VAC RELAY

LEVEL CONTROL PROBE

DESCALE TIMER

3 MINUTE INTERVAL TIMER

300278

106909

300150

12159

108981

222231

20301

20302

104389

108979

20304

104390

19972

25

21

18

17

19

20

22

21A

23

24

28

27

26

TRANSFORMER

ELECTRONIC TIMER

TERMINAL BLOCK ASSEMBLY

TIMED / MANUAL SWITCH W / INDICATOR

TERMINAL BLOCK SECTION (QTY. 2)

FILL VALVE

GROUND LUG

INDICATOR (RED)

TERMINAL BLOCK END

IGNITOR CABLE ASSEMBLY

2AMP, 250V FUSE

60 MINUTE TIMER

COMP. THERMOSTAT

PRP

PRP

11-5

GRA

GRA

PRP

BLU

WHT/RED

11-6

BRN

WHT/BRN

ORN

11-1

BLU

PS-2

PS-2

WHT/RED

PS-7 11-4

PS-4

PS-7

ORN

PS-3

PS-5

PRP

PRP

28

21 3

PAUSE

FK300279 SWITCH ASSEMBLY (REPLACEMENT KIT)

GRN

1-3

Adjust or

replace the

on/off micro

switch

Yes

Connect power

to steamer.

No

Is the red light on?

Is there power to

the steamer?

Is there water in

the sight glass?

Yes

See

Steamer won't

fill.

No

Has the pilot

ignited?

Yes

No

Does the steamer

steam in manual

mode?

Yes

Replace

the timer

Yes

Is there power to

the Timed/Manual

switch?

No

Replace the

wiring to the

switch

Is there power

from the Timed/

Manual switch?

Yes

Replace the

switch

No

Does the steamer

steam with the

door switch

bypassed?

Yes

Replace the

door switch

Yes

Is there 120 VAC

to the R2 relay?

No

PROBLEM:

24CGA6

24CGA10.2

Steamer won't

steam with handle

in on position

Replace

the wiring

to relay

No

Is the fan

turning?

Yes

Is there 120 VAC

to the fan?

Replace

the fan

Check the

R1 relay

Yes

No

Is there 24 VAC to

the main coil of the

gas valve?

Yes

Replace the

gas valve?

Yes

Does the coil to

the main gas valve

get 24 VAC when

the fan prover

switch is

bypassed?

No

Replace the

the fan prover

switch.

Replace the R2

relay.

Yes

No

No

See

Steamer won't

ignite

No

No

Steamer won't

steam

PROBLEM:

24CGA6

24CGA10.2

Steamer won't fill

with the handle in

the on position

Is there power

to the steamer?

Connect

power to the

steamer

No

Is there water to

the steamer?

Yes

Supply

water to the

steamer.

No

Is there 120 VAC

between the

terminals H and N

on the watr level

board?

Yes

Adjust or

replace on/off

micro switch

No

Is there 120 VAC

between terminals

Fill and N on the

water board?

Yes

With the wire

removed from the HI

terminal on the water

level board, is there

120 VAC between

terminals Fill and N?

No

Replace the

water level

board.

No

Is there debris on

the HI probe in the

probe assy?

Yes

Replace the

wire to the HI

probe.

No

Clean or

replace the

probe assy.

Yes

Is there 120 VAC

across the coil of

the fill solenoid?

Yes

Adjust or

replace the on/

off micro switch

No

Is water leaving

the fill solenoid?

Yes

Replace the fill

solenoid.

No

Does the manual

drain valve close

completely?

Yes

Clean or

replace the

drain valve.

No

Yes

Steamer won't

fill

Is there 120 VAC

between the

terminals Heat and

N on the water

level board with

the the low probe

submerged?

Is there 120 VAC

between Heat and N

terminals on the water

level board with a

jumper between

terminal XL and C?

No

Clean or

replace the

probe assy.

Replace water

level board.

No

Yes

Is there 120 VAC

across the primary

of the 24 VAC

ignition

transformer?

yes

Is there 24 VAC to

the secondary of

the ignition

transformer?

Yes

Is there 24 VAC to

the ignition

module?

Yes

Replace the

transformer

No

Replace the wires

to the ignition

module.

No

Is there spark from

the module until

the 90-second lock

out?

Yes

Replace the

ignition module

No

Is there 24 VAC to

the pilot coil on the

gas valve until the

90-second lock

out?

Yes

No

Does the steamer

have gas supplied?

Yes

Supply gas to

the steamer

No

Does the pilot gas

valve open when

the 24 VAC is

applied?

Replace the

gas valve.

No

Is spark generated

at the igniter?

Yes

Replace the

igniter and

wire

No

Is there at least

1.0 micro amps

DC at the burner

ground terminal on

the ignition

module?

Yes

Replace the

ignition module

Yes

Is the pilot flame

blue and

enveloping the

igniter?

Replace the

ground wire

Yes

Replace the

pilot assy

No

Replace

the high

limit

No

Yes

Is the red light on?

Is there power to

the steamer?

Connect power

to the steamer

No No

Adjust or

replace the

on/off micro

switch

Is there water in

the sight glass?

Yes

Yes

Yes

See

Steamer won't

fill

No

PROBLEM:

24CGA6

24CGA10.2

Steamer won't

ignite

No

Steam generator

won't ignite

PROBLEM:

24CGA6, 24CGA10.2

Electronic timer displays "PAUS" and won't count down

START

Is steam heating

the cooking

cabinetabove 192

degrees (the set

temp of the

thermo-switch)?

Does the timer

count down when

the thermo-switch

is bypassed?

Yes

See

Steamer

won't steam

No

Replace the

electronic timer

No

Replace the

thermo-switch

Yes

PROBLEM:

24CGA6, 24CGA10.2

Steam leaks around the door.

START

Is COLD water

supplied to the

steamer?

Supply cold

water (35-60

PSI) to the

steamer.

No

Is the door gasket

physically

damaged?

Yes

Turn over the

gasket or

replace it.

Yes

Is the door out of

alignment?

No

Replace the

door bearings

and pins.

Yes

Is the drain

obstructed?

No

Remove the

obstruction

Yes

Is there 120 VAC

across the coil of

the condensate

solenoid?

No

Replace the

wiring to the

condensate

solenoid.

No

Is the solenoid

opening?

Yes

Replace the

condensate

solenoid.

No

Replace the

condensate spray

nozzle

Yes

Descaling Procedure-SteamCraft Ultra and Gemini Series

1. Turn the unit OFF and open the

doors:

This will drain and rinse the generator for about

3 minutes.

2. Turn the unit power back On:

The generator will begin to refill with water.

3. Select Timed with the Timed/Manual

switch:

DO NOT start the timer, since you do not want

to heat the water during descaling. Leave the

doors open.

4.

Remove descaling port cap and add

with the specified amount of

DISSLOVE:

(See chart above)

Do this while the unit is refilling. The generators

can take-up to 8 minutes to refill.

5.

After refill has stopped, add extra tap

water into the descaling port until

liquid is seen entering the cooking

cabinet.

Note: Ultra 10 gas will have liquid

coming out of the drain,

Adding extra water when descaling will raise the

descaling solution higher than the normal fill level,

allowing the DISSOLVE to work on sensors and

surfaces above the water line

6. Let the descaler soak in generator for

approximately one hour:

7. After one hour, turn the unit power

Off:

This will drain and rinse the generator

for about 3 minutes.

8. After the 3-minute drain cycle

completes, turn the unit back ON. After

the filling has stopped, add water until

liquid enters the cooking compartment (or

drain for the ultra 10 gas), and then turn

the unit OFF. This will drain and flush any

residue from the water level control

assembly. Replace descaling cap.

9.

After the 3 minute drain cycle

completes, Turn the unit ON and set

the Timer for 20 minutes:

Make sure the

Time/Manual switch is in the timed setting

and the doors are closed.

10. When the timer times out (after 20

minutes) turn the power Off:

This will drain and rinse the generator for

about 3 minutes.

This ends the descaling procedure. You can

now turn the unit back on and resume normal

startup and cooking operations.

How Much DISSOLVE to Use

Model Dissolve

Ultra 3 1/2 Gallon

Ultra 5 1 Gallon

Ultra 10 (Elec.) 1 Gallon (ea.)

Ultra 10 (Gas) 1½ Gallon

Gemini 6 & 10 1 Gallon (ea.)

Note: Some SteamCraft Ultra models (the

electric powered Ultra 10 and Gemini 6 and 10,

for example) have two generators and two

descaling ports. Both units should be descaled

at the same time, using this procedure

/