Chore-Time MV1832P 48- and 52-Inch HYFLO® Fans User manual

- Type

- User manual

This manual is also suitable for

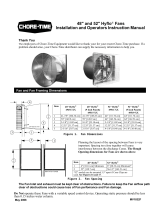

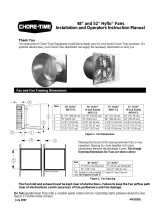

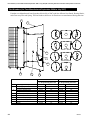

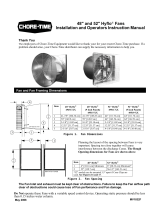

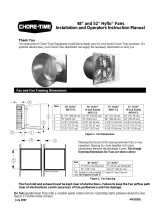

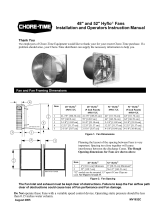

Chore-Time MV1832P 48- and 52-Inch HYFLO® Fans are designed for efficient air circulation in various agricultural and industrial applications. These fans feature a durable construction with corrosion-resistant materials, ensuring longevity in demanding environments. The aerodynamically designed blades deliver powerful airflow, optimizing ventilation and cooling. The adjustable fan speed allows for precise control over airflow volume, catering to specific ventilation requirements.

Chore-Time MV1832P 48- and 52-Inch HYFLO® Fans are designed for efficient air circulation in various agricultural and industrial applications. These fans feature a durable construction with corrosion-resistant materials, ensuring longevity in demanding environments. The aerodynamically designed blades deliver powerful airflow, optimizing ventilation and cooling. The adjustable fan speed allows for precise control over airflow volume, catering to specific ventilation requirements.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

Chore-Time MV1832P 48- and 52-Inch HYFLO® Fans User manual

- Type

- User manual

- This manual is also suitable for

Chore-Time MV1832P 48- and 52-Inch HYFLO® Fans are designed for efficient air circulation in various agricultural and industrial applications. These fans feature a durable construction with corrosion-resistant materials, ensuring longevity in demanding environments. The aerodynamically designed blades deliver powerful airflow, optimizing ventilation and cooling. The adjustable fan speed allows for precise control over airflow volume, catering to specific ventilation requirements.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Chore-Time MV1832F 48- and 52-Inch HYFLO® Fans Installation and Operators Instruction Manual

Chore-Time MV1832F 48- and 52-Inch HYFLO® Fans Installation and Operators Instruction Manual

-

Chore-Time MV1832E 48- and 52-Inch HYFLO® Fans Installation and Operators Instruction Manual

Chore-Time MV1832E 48- and 52-Inch HYFLO® Fans Installation and Operators Instruction Manual

-

Chore-Time MV1832C 48- and 52-Inch HYFLO® Fans Installation and Operators Instruction Manual

Chore-Time MV1832C 48- and 52-Inch HYFLO® Fans Installation and Operators Instruction Manual

-

Chore-Time MV1832B 48- and 52-Inch HYFLO® Fans Installation and Operators Instruction Manual

Chore-Time MV1832B 48- and 52-Inch HYFLO® Fans Installation and Operators Instruction Manual

-

Chore-Time MV1832D 48- and 52-Inch HYFLO® Fans Installation and Operators Instruction Manual

Chore-Time MV1832D 48- and 52-Inch HYFLO® Fans Installation and Operators Instruction Manual

-

Chore-Time MV1896A 36-Inch Galvanized Direct Drive HYFLO® Fan Installation and Operators Instruction Manual

Chore-Time MV1896A 36-Inch Galvanized Direct Drive HYFLO® Fan Installation and Operators Instruction Manual

-

Chore-Time MV1902B 36-Inch HYFLO® Retrofit Kit Installation and Operators Instruction Manual

Chore-Time MV1902B 36-Inch HYFLO® Retrofit Kit Installation and Operators Instruction Manual

-

Chore-Time MV1896C 36-Inch Galvanized Direct Drive HYFLO® Fan Installation and Operators Instruction Manual

Chore-Time MV1896C 36-Inch Galvanized Direct Drive HYFLO® Fan Installation and Operators Instruction Manual

-

Chore-Time MV2386E 36-Inch Galvanized Belt Drive HYFLO® Fans Installation And Operator's Manual

Chore-Time MV2386E 36-Inch Galvanized Belt Drive HYFLO® Fans Installation And Operator's Manual

-

Chore-Time MV1902A 36-Inch HYFLO® Retrofit Kit Installation and Operators Instruction Manual

Chore-Time MV1902A 36-Inch HYFLO® Retrofit Kit Installation and Operators Instruction Manual