First Co 36HBQB Installation guide

- Category

- Split-system air conditioners

- Type

- Installation guide

This manual is also suitable for

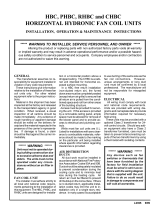

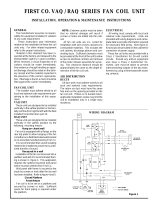

First Co 36HBQB is a fan coil unit designed for both residential and commercial applications. It can be installed in either an upflow or horizontal position. The unit is U.L. listed for installation with zero inches clearance to combustible materials. The 36HBQB has a direct expansion refrigerant coil and a hot water coil. The refrigerant coil is used for cooling and the hot water coil is used for heating. The unit also has a built-in condensate drain pan and a filter to prevent dirt buildup on the coil surface. The 36HBQB is a versatile unit that can be used in a variety of applications, including:

First Co 36HBQB is a fan coil unit designed for both residential and commercial applications. It can be installed in either an upflow or horizontal position. The unit is U.L. listed for installation with zero inches clearance to combustible materials. The 36HBQB has a direct expansion refrigerant coil and a hot water coil. The refrigerant coil is used for cooling and the hot water coil is used for heating. The unit also has a built-in condensate drain pan and a filter to prevent dirt buildup on the coil surface. The 36HBQB is a versatile unit that can be used in a variety of applications, including:

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

First Co 36HBQB Installation guide

- Category

- Split-system air conditioners

- Type

- Installation guide

- This manual is also suitable for

First Co 36HBQB is a fan coil unit designed for both residential and commercial applications. It can be installed in either an upflow or horizontal position. The unit is U.L. listed for installation with zero inches clearance to combustible materials. The 36HBQB has a direct expansion refrigerant coil and a hot water coil. The refrigerant coil is used for cooling and the hot water coil is used for heating. The unit also has a built-in condensate drain pan and a filter to prevent dirt buildup on the coil surface. The 36HBQB is a versatile unit that can be used in a variety of applications, including:

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

First Co MB-HW Series User manual

-

First Co HBQB User manual

-

First Co CW-HW(X) Fan Coil Units Installation guide

-

First Co 24HX5R410ATXV Installation guide

First Co 24HX5R410ATXV Installation guide

-

First Co 60VHBXBHWTXV410 Installation guide

First Co 60VHBXBHWTXV410 Installation guide

-

First Co 13HBC3 LH Installation guide

First Co 13HBC3 LH Installation guide

-

First Co 36HBXBHWTXV410 Installation guide

-

First Co 24VAQ3 Installation guide

First Co 24VAQ3 Installation guide

-

First Co CW(X) Fan Coil Units Operating instructions

-

First Co CDX-HW User manual

Other documents

-

Crown Boiler Santa Fe 3 Installation guide

-

EMI SEHX-SDXW Installation & Operation Manual

-

COMFORT-AIRE HWCG48X0A-CY Operating instructions

-

COMFORT-AIRE HWCG23T0A-CY Operating instructions

-

Envision Peripherals Series User manual

-

Weil-McLain Air H User manual

-

Weil-McLain Air H User manual

-

Envision Peripherals R-410A Residential User manual

-

Trane T2GN026NNR10NNA Installation guide

-

Vortex combo-pac Installation Instructions Manual