Wire Type and Ratings

•

All wiring must comply with local and national

regulations regarding cross-section and ambient

temperature requirements.

•

Danfoss recommends that all power connections

be made with a minimum 170°F (75°C) rated

copper wire.

•

See 10.1 Power-dependent Specifications for

recommended wire sizes.

2.4.2 Grounding Requirements

WARNING

GROUNDING HAZARD!

For operator safety, it is important to ground Adjustable

frequency drive properly in accordance with national and

local electrical codes as well as instructions contained

within these instructions. Ground currents are higher than

3.5 mA. Failure to ground Adjustable frequency drive

properly could result in death or serious injury.

NOTE!

It is the responsibility of the user or certified electrical

installer to ensure correct grounding of the equipment in

accordance with national and local electrical codes and

standards.

•

Follow all local and national electrical codes to

ground electrical equipment properly.

•

Proper protective grounding for equipment with

ground currents higher than 3.5 mA must be

established, see Leakage Current (>3.5 mA)

•

A dedicatedground wire is required for input

power, motor power and control wiring

•

Use the clamps provided on the equipment for

proper ground connections

•

Do not ground one Adjustable frequency drive to

another in a “daisy chain” fashion

•

Keep the ground wire connections as short as

possible

•

Use of high-strand wire to reduce electrical noise

is recommended

•

Follow the motor manufacturer wiring

requirements

2.4.2.1

Leakage Current (>3.5 mA)

Follow national and local codes regarding protective

grounding of equipment with a leakage current > 3.5 mA.

Adjustable frequency drive technology implies high

frequency switching at high power. This will generate a

leakage current in the ground connection. A fault current

in the Adjustable frequency drive at the output power

terminals might contain a DC component which can

charge the filter capacitors and cause a transient ground

current. The ground leakage current depends on various

system configurations including RFI filtering, shielded

motor cables, and Adjustable frequency drive power.

EN/IEC61800-5-1 (Power Drive System Product Standard)

requires special care if the leakage current exceeds 3.5m A.

Grounding must be reinforced in one of the following

ways:

•

Ground wire of at least 0.0155 in

2

[10mm

2

]

•

Two separate ground wires both complying with

the dimensioning rules

See EN 60364-5-54 § 543.7 for further information.

Using RCDs

Where residual current devices (RCDs), also known as

ground leakage circuit breakers (ELCBs), are used, comply

with the following:

Use RCDs of type B only which are capable of

detecting AC and DC currents

Use RCDs with an inrush delay to prevent faults

due to transient ground currents

Dimension RCDs according to the system configu-

ration and environmental considerations

2.4.2.2

Grounding Using Shielded Cable

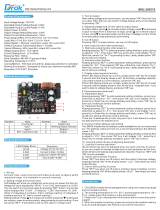

Grounding clamps are provided for motor wiring (see

Figure 2.8).

130BA266.10

+DC

BR-

B

MAINS

L1 L2 L3

91 92 93

RELAY 1 RELAY 2

99

- LC -

UVW

MOTOR

Figure 2.8 Grounding with Shielded Cable

Installation

VLT

®

HVAC Drive Instruction Manual

2-6 MG11AH22 - VLT

®

is a registered Danfoss trademark

2

2