(Ref: 1911)

8070

CNC

Hardware configuration.

BLANK PAGE

·2·

MACHINE SAFETY

It is up to the machine manufacturer to make sure that the safety of the machine

is enabled in order to prevent personal injury and damage to the CNC or to the

products connected to it. On start-up and while validating CNC parameters, it

checks the status of the following safety elements. If any of them is disabled, the

CNC shows the following warning message.

• Feedback alarm for analog axes.

• Software limits for analog and sercos linear axes.

• Following error monitoring for analog and sercos axes (except the spindle)

both at the CNC and at the drives.

• Tendency test on analog axes.

FAGOR AUTOMATION shall not be held responsible for any personal injuries or

physical damage caused or suffered by the CNC resulting from any of the safety

elements being disabled.

DUAL-USE PRODUCTS

Products manufactured by FAGOR AUTOMATION since April 1st 2014 will

include "-MDU" in their identification if they are included on the list of dual-use

products according to regulation UE 428/2009 and require an export license

depending on destination.

TRANSLATION OF THE ORIGINAL MANUAL

This manual is a translation of the original manual. This manual, as well as the

documents derived from it, have been drafted in Spanish. In the event of any

contradictions between the document in Spanish and its translations, the wording

in the Spanish version shall prevail. The original manual will be labeled with the

text "ORIGINAL MANUAL".

HARDWARE EXPANSIONS

FAGOR AUTOMATION shall not be held responsible for any personal injuries or

physical damage caused or suffered by the CNC resulting from any hardware

manipulation by personnel unauthorized by Fagor Automation.

If the CNC hardware is modified by personnel unauthorized by Fagor

Automation, it will no longer be under warranty.

COMPUTER VIRUSES

FAGOR AUTOMATION guarantees that the software installed contains no

computer viruses. It is up to the user to keep the unit virus free in order to

guarantee its proper operation. Computer viruses at the CNC may cause it to

malfunction.

FAGOR AUTOMATION shall not be held responsible for any personal injuries or

physical damage caused or suffered by the CNC due a computer virus in the

system.

If a computer virus is found in the system, the unit will no longer be under warranty.

All rights reserved. No part of this documentation may be transmitted,

transcribed, stored in a backup device or translated into another language

without Fagor Automation’s consent. Unauthorized copying or distributing of this

software is prohibited.

The information described in this manual may be subject to changes due to

technical modifications. Fagor Automation reserves the right to change the

contents of this manual without prior notice.

All the trade marks appearing in the manual belong to the corresponding owners.

The use of these marks by third parties for their own purpose could violate the

rights of the owners.

It is possible that CNC can execute more functions than those described in its

associated documentation; however, Fagor Automation does not guarantee the

validity of those applications. Therefore, except under the express permission

from Fagor Automation, any CNC application that is not described in the

documentation must be considered as "impossible". In any case, Fagor

Automation shall not be held responsible for any personal injuries or physical

damage caused or suffered by the CNC if it is used in any way other than as

explained in the related documentation.

The content of this manual and its validity for the product described here has been

verified. Even so, involuntary errors are possible, hence no absolute match is

guaranteed. However, the contents of this document are regularly checked and

updated implementing the necessary corrections in a later edition. We appreciate

your suggestions for improvement.

The examples described in this manual are for learning purposes. Before using

them in industrial applications, they must be properly adapted making sure that

the safety regulations are fully met.

Hardware configuration.

CNC 8070

·3·

(REF: 1911)

INDEX

About the product - CNC 8070 ..................................................................................................... 9

Declaration of CE conformity and warranty conditions ............................................................... 13

Version history - CNC 8070 ........................................................................................................ 15

Safety conditions ........................................................................................................................ 19

Returning conditions ................................................................................................................... 23

CNC maintenance ...................................................................................................................... 25

CHAPTER 1 PREVIOUS INFORMATION.

CHAPTER 2 CONFIGURATION.

2.1 Central unit (Q7-A platform). ......................................................................................... 29

2.2 Central unit (ETX platform). ........................................................................................... 29

2.3 Monitor. ......................................................................................................................... 30

2.4 Central unit + Monitor. ................................................................................................... 30

2.5 Central unit + Monitor + Keyboard and Operator panel. ................................................ 31

2.6 Operator panels. ........................................................................................................... 31

2.7 USB keyboard. .............................................................................................................. 31

2.8 CAN keyboard. .............................................................................................................. 32

2.9 CAN keyboard (ETX platform only). .............................................................................. 32

2.10 CAN remote modules..................................................................................................... 33

2.11 Sercos-II remote modules.............................................................................................. 34

2.12 EtherCAT remote modules (only Q7-A platform). .......................................................... 34

2.13 General diagram (ETX platform).................................................................................... 35

2.14 General diagram for C70 (Q7-A platform)...................................................................... 36

2.15 General diagram for U70 (Q7-A platform)...................................................................... 37

CHAPTER 3 HEAT DISSIPATION. CENTRAL UNIT (CPU) ENCLOSURE (ETX PLATFORM).

3.1 Heat dissipation models................................................................................................. 41

CHAPTER 4 CENTRAL UNIT (CPU) ENCLOSURE (Q7-A PLATFORM).

4.1 Calculation of the surface needed for heat dissipation. ................................................. 45

CHAPTER 5 CENTRAL UNIT + MONITOR (ETX PLATFORM).

5.1 Models with an integrated monitor. ................................................................................ 47

5.2 In-cabinet model. ........................................................................................................... 48

5.3 Specifications. ............................................................................................................... 49

5.4 Dimensions. ................................................................................................................... 51

5.4.1 U70............................................................................................................................. 51

5.4.2 U70-M. ...................................................................................................................... 52

5.4.3 C70-10K. .................................................................................................................... 53

5.4.4 C70-15. ...................................................................................................................... 54

5.4.5 C70-15T. .................................................................................................................... 55

5.4.6 C70-15AT...................................................................................................................56

5.5 Enclosure and securing of models C70-10 / C70-15. .................................................... 57

5.5.1 Ambient characteristics of the enclosure. .................................................................. 57

5.5.2 Enclosure design........................................................................................................ 57

5.5.3 Securing the module. ................................................................................................. 59

5.6 Securing the U70 module............................................................................................ 60

5.6.1 Ambient characteristics of the cabinet. ...................................................................... 60

5.6.2 Cabinet design. .......................................................................................................... 60

5.6.3 Ventilation. ................................................................................................................. 60

5.7 Power supply for the module. ........................................................................................ 61

5.7.1 Voltage supply at 24 V DC. ........................................................................................ 62

5.7.2 Power supply with a Fagor battery............................................................................. 62

5.7.3 Battery-powered RAM memory (non-volatile RAM). ................................................. 63

5.7.4 Central unit protections. ............................................................................................. 63

5.8 Hardware functionality. Connectors. .............................................................................. 64

5.8.1 Front of the monitor. USB connector. ........................................................................ 64

5.8.2 Central unit. Peripheral board. ................................................................................... 65

5.8.3 Central unit. Expansion board.................................................................................... 68

Hardware configuration.

CNC 8070

·4·

(REF: 1911)

5.8.4 Central unit. CPU board............................................................................................. 71

5.8.5 PCI expansion board (only for the MCU model). ....................................................... 73

5.8.6 Handwheel connector (only for C70-10K). ................................................................. 75

5.9 Technical/electrical characteristics of the inputs and outputs........................................ 76

5.9.1 Digital inputs. ............................................................................................................. 76

5.9.2 Digital outputs. ...........................................................................................................76

5.9.3 Analog outputs. .......................................................................................................... 76

5.9.4 Feedback inputs......................................................................................................... 77

5.10 housing for the compact flash and battery-powered RAM memory............................... 78

5.11 Insert the board into the PCI expansion (only in MCU models). .................................... 79

5.12 Connections................................................................................................................... 81

5.12.1 Probe connection. ...................................................................................................... 81

5.12.2 RS232 serial line connection. .................................................................................... 84

5.12.3 RS422 serial line connection. .................................................................................... 85

5.12.4 RS485 serial line connection. .................................................................................... 86

5.12.5 Feedback connection................................................................................................. 87

5.12.6 Connection to an Ethernet network (Fast Ethernet)................................................... 88

5.12.7 Sercos II bus. ............................................................................................................. 89

5.12.8 Mechatrolink bus........................................................................................................ 92

CHAPTER 6 CENTRAL UNIT + MONITOR (Q7-A PLATFORM).

6.1 Specifications. ............................................................................................................... 95

6.2 Dimensions. ................................................................................................................... 97

6.2.1 C70-10K. ................................................................................................................... 97

6.2.2 C70-15. ...................................................................................................................... 98

6.2.3 C70-15AT...................................................................................................................99

6.3 Enclosure and securing of the modules....................................................................... 100

6.3.1 Ambient characteristics of the enclosure. ................................................................ 100

6.3.2 Enclosure design. .................................................................................................... 100

6.3.3 Securing the module. ............................................................................................... 102

6.4 Power supply for the module. ..................................................................................... 103

6.4.1 Central unit electrical features. ................................................................................ 103

6.4.2 Protection against over-voltage and reverse voltage............................................... 103

6.4.3 Voltage supply at 24 V DC....................................................................................... 103

6.4.4 Power supply via UPS. ............................................................................................ 104

6.4.5 Ground connection................................................................................................... 104

6.4.6 Power supply requirements. .................................................................................... 104

6.4.7 NOT recommended circuits. .................................................................................... 105

6.5 Non-volatile RAM (FRAM). .......................................................................................... 106

6.6 Hardware functionality (connectors). ........................................................................... 106

6.6.1 Front of the monitor. ................................................................................................ 106

6.6.2 Rear. ....................................................................................................................... 107

6.7 Technical/electrical characteristics of the inputs and outputs...................................... 115

6.7.1 Digital inputs. ........................................................................................................... 115

6.7.2 Digital outputs. ......................................................................................................... 115

6.7.3 Analog outputs. ........................................................................................................ 115

6.7.4 Feedback inputs....................................................................................................... 116

6.8 Connections. ............................................................................................................... 118

6.8.1 Ground connection. ................................................................................................. 118

6.8.2 Connecting the relay for the emergency chain. ....................................................... 118

6.8.3 Feedback connection............................................................................................... 119

6.8.4 Handwheel connection (only C70-10K). .................................................................. 120

6.8.5 Probe connection. .................................................................................................... 121

6.8.6 Connection to an Ethernet network.......................................................................... 124

6.8.7 RS232 serial line connection. .................................................................................. 125

6.8.8 RS422 serial line connection. .................................................................................. 126

6.8.9 RS485 serial line connection. .................................................................................. 127

6.8.10 EtherCAT bus. ........................................................................................................ 128

6.8.11 CAN bus................................................................................................................... 131

6.8.12 Sercos II bus. ........................................................................................................... 134

CHAPTER 7 CENTRAL UNIT FOR CABINET (Q7-A PLATFORM).

7.1 Specifications. ............................................................................................................. 138

7.2 Dimensions. ................................................................................................................ 140

7.3 Enclosure and securing of the modules....................................................................... 141

7.3.1 Ambient characteristics of the cabinet. .................................................................... 141

7.3.2 Cabinet design. ........................................................................................................ 141

7.3.3 Ventilation. ............................................................................................................... 141

7.4 Power supply for the module. ..................................................................................... 142

7.4.1 Central unit electrical features. ................................................................................ 142

7.4.2 Protection against over-voltage and reverse voltage............................................... 142

7.4.3 Voltage supply at 24 V DC....................................................................................... 142

7.4.4 Power supply via UPS. ............................................................................................ 143

Hardware configuration.

CNC 8070

·5·

(REF: 1911)

7.4.5 Ground connection................................................................................................... 143

7.4.6 Specs of the power supply. ...................................................................................... 143

7.4.7 NOT recommended circuits. .................................................................................... 144

7.5 Non-volatile RAM (FRAM). .......................................................................................... 145

7.6 Hardware functionality (connectors). ........................................................................... 146

7.6.1 Front. ....................................................................................................................... 146

7.6.2 Top. ......................................................................................................................... 147

7.6.3 Bottom. .................................................................................................................... 147

7.6.4 Connector identification. .......................................................................................... 148

7.7 Technical/electrical characteristics of the inputs and outputs. ..................................... 156

7.7.1 Digital inputs............................................................................................................. 156

7.7.2 Digital outputs. ......................................................................................................... 156

7.7.3 Analog outputs. ........................................................................................................ 156

7.7.4 Feedback inputs....................................................................................................... 157

7.8 Connections. ................................................................................................................ 159

7.8.1 Ground connection. ................................................................................................. 159

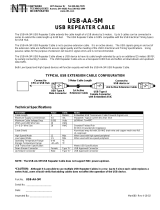

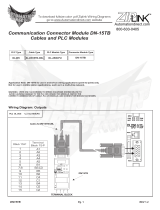

7.8.2 Connecting the USB2.0 port. .................................................................................. 159

7.8.3 Connecting the DVI-D video output.......................................................................... 160

7.8.4 Connecting the relay for the emergency chain......................................................... 160

7.8.5 Feedback connection. .............................................................................................. 161

7.8.6 Probe connection. .................................................................................................... 162

7.8.7 Connection to an Ethernet network.......................................................................... 165

7.8.8 EtherCAT bus. ......................................................................................................... 166

7.8.9 Bus Sercos-II............................................................................................................ 169

7.8.10 CAN bus................................................................................................................... 172

CHAPTER 8 LCD-15SVGA. PASSIVE MONITOR " LCD15-SVGA".

8.1 Possible configurations. ............................................................................................... 176

8.2 Technical characteristics.............................................................................................. 177

8.3 Hardware dimensions. ................................................................................................ 178

8.4 Dimensions and characteristics of the enclosure......................................................... 179

8.4.1 Enclosure design...................................................................................................... 179

8.4.2 Securing the module. ............................................................................................... 180

8.5 Elements (connectors). ................................................................................................ 181

8.6 Overall connection. ...................................................................................................... 183

CHAPTER 9 MONITOR-21 MULTITOUCH.

9.1 Specifications............................................................................................................... 186

9.2 General diagram. ........................................................................................................ 187

9.3 Dimensions. ................................................................................................................ 188

9.4 Enclosure and mounting of the module. ...................................................................... 189

9.4.1 Enclosure design...................................................................................................... 189

9.4.2 Securing the module. ............................................................................................... 190

9.5 Voltage supply for the module. .................................................................................... 192

9.6 Configuring the video signal from the monitor. ............................................................ 193

9.7 Connectors. ................................................................................................................. 194

9.8 Cable characteristics.................................................................................................... 197

9.8.1 VGA video signal...................................................................................................... 197

9.9 OSD (On Screen Display) menu.................................................................................. 198

9.9.1 Using the rear keyboard with the OSD menu........................................................... 198

9.9.2 OSD menu. .............................................................................................................. 199

9.9.3 Locks and unlocks the OSD menu........................................................................... 204

CHAPTER 10 HORIZONTAL KEYB / HORIZONTAL KEYB+MOUSE.

10.1 Specifications. ............................................................................................................. 205

10.2 General diagram. ........................................................................................................ 206

10.3 Dimensions. ................................................................................................................ 207

10.4 Enclosure and mounting of the module. ...................................................................... 208

10.4.1 Enclosure design...................................................................................................... 208

10.4.2 Securing the module. ............................................................................................... 209

10.5 Power supply for the module. ..................................................................................... 210

10.6 Hardware functionalities............................................................................................... 211

10.6.1 Ground connection. ................................................................................................. 211

10.6.2 Rear connectors. ..................................................................................................... 211

10.7 Bus CAN (CANfagor/CANopen protocols)................................................................... 214

10.7.1 Identification of the modules at the bus.................................................................... 215

10.7.2 Identification of the first and last elements of the bus. Line terminating resistor...... 216

10.7.3 CAN bus type selection (CANfagor/CANopen). ....................................................... 216

10.7.4 Selecting the speed for the CANfagor bus............................................................... 216

10.7.5 Selecting the speed for the CANopen bus. .............................................................. 216

Hardware configuration.

CNC 8070

·6·

(REF: 1911)

CHAPTER 11 VERTICAL KEYB / VERTICAL KEYB+MOUSE.

11.1 Specifications. ............................................................................................................. 217

11.2 General diagram. ........................................................................................................ 218

11.3 Dimensions. ................................................................................................................ 219

11.4 Enclosure and mounting of the module. ...................................................................... 220

11.4.1 Enclosure design. .................................................................................................... 220

11.4.2 Securing the module. ............................................................................................... 221

11.5 Power supply for the module. ..................................................................................... 222

11.6 Hardware functionalities. ............................................................................................. 223

11.6.1 Ground connection. ................................................................................................. 223

11.6.2 Rear connectors. ..................................................................................................... 223

11.7 Bus CAN (CANfagor/CANopen protocols)................................................................... 226

11.7.1 Identification of the modules at the bus. .................................................................. 227

11.7.2 Identification of the first and last elements of the bus. Line terminating resistor...... 228

11.7.3 CAN bus type selection (CANfagor/CANopen). ....................................................... 228

11.7.4 Selecting the speed for the CANfagor bus............................................................... 228

11.7.5 Selecting the speed for the CANopen bus............................................................... 228

CHAPTER 12 HORIZONTAL KEYB 2.0 + TOUCHPAD.

12.1 Specifications. ............................................................................................................. 229

12.2 General diagram. ........................................................................................................ 230

12.3 Dimensions. ................................................................................................................ 231

12.4 Enclosure and mounting of the module. ...................................................................... 232

12.4.1 Enclosure design. .................................................................................................... 232

12.4.2 Securing the module. ............................................................................................... 233

12.5 Voltage supply for the module. .................................................................................... 234

12.6 Connectors. ................................................................................................................. 235

12.7 Selecting the language and the keyboard distribution. ................................................ 235

12.8 Using the Fagor logo key. ........................................................................................... 237

12.9 Numeric keypad........................................................................................................... 237

12.10 Touchpad (touch screen). ........................................................................................... 238

CHAPTER 13 OP-PANEL / OP-PANEL+SPDL RATE.

13.1 Specifications. ............................................................................................................. 239

13.2 General diagram. ........................................................................................................ 240

13.3 Dimensions. ................................................................................................................ 241

13.4 Enclosure and mounting of the module. ...................................................................... 242

13.4.1 Enclosure design. .................................................................................................... 242

13.4.2 Securing the module. ............................................................................................... 243

13.5 Power supply for the module. ..................................................................................... 244

13.6 Hardware functionalities. ............................................................................................. 245

13.6.1 Ground connection. ................................................................................................. 245

13.6.2 Rear connectors. ..................................................................................................... 245

13.7 Handwheel connection. ............................................................................................... 249

13.8 Bus CAN (CANfagor/CANopen protocols)................................................................... 250

13.8.1 Identification of the modules at the bus. .................................................................. 251

13.8.2 Identification of the first and last elements of the bus. Line terminating resistor...... 252

13.8.3 CAN bus type selection (CANfagor/CANopen). ....................................................... 252

13.8.4 Selecting the speed for the CANfagor bus............................................................... 252

13.8.5 Selecting the speed for the CANopen bus............................................................... 252

CHAPTER 14 MOUSE MODULE.

14.1 Especificaciones. ........................................................................................................ 253

14.2 Dimensions. ................................................................................................................ 254

CHAPTER 15 EMERGENCY BATTERY (ONLY ETX PLATFORM).

15.1 Battery dimensions. .................................................................................................... 256

15.2 Connectors and connection. ........................................................................................ 257

15.3 Operation of the emergency battery. ........................................................................... 258

CHAPTER 16 CNC-FPS. FAGOR-UPS (Q7-A PLATFORM ONLY).

16.1 Specifications. ............................................................................................................. 260

16.2 Dimensions. ................................................................................................................ 260

16.3 Securing the module.................................................................................................... 261

16.4 Protection fuse. ........................................................................................................... 261

16.5 UPS Connection Diagram............................................................................................ 262

Hardware configuration.

CNC 8070

·7·

(REF: 1911)

CHAPTER 17 INSTALLING AND CONFIGURING A THIN CLIENT (EPATEC MODEL).

17.1 Install and configure the communication software at the CNC. ................................... 265

17.2 Configuring the Thin Client. ......................................................................................... 267

17.2.1 Configure the network protocol (for network or point-to point connection)............... 267

17.2.2 Configure the communication between the CNC and the Thin Client...................... 268

17.2.3 Configuring the startup of the Thin Client................................................................. 269

17.2.4 Disable the mouse at the Thin Client. ...................................................................... 270

CHAPTER 18 INSTALLING A SENSOR FOR GAP CONTROL (LASER MODEL).

BLANK PAGE

·8·

Hardware configuration.

CNC 8070

·9·

(REF: 1911)

ABOUT THE PRODUCT - CNC 8070

BASIC CHARACTERISTICS.

(*) Differential TTL / Sinusoidal 1 Vpp (**) TTL / Differential TTL / Sinusoidal 1 Vpp / SSI protocol / FeeDat / EnDat

Basic characteristics. ·BL· ·OL· ·L·

Number of axes. 3 to 7 3 to 31 3 to 31

Number of spindles. 1 1 to 6 1 to 6

Number of tool magazines. 1 1 to 4 1 to 4

Number of execution channels. 1 1 to 4 1 to 4

Number of interpolated axes (maximum). 4 3 to 31 3 to 31

Number of handwheels. 1 to 12

Type of servo system. Analog / Digital Sercos

Digital Mechatrolink

Analog

Sercos Digital

Communications. RS485 / RS422 / RS232

Ethernet

PCI expansion. No Option No

Integrated PLC.

PLC execution time.

Digital inputs / Digital outputs.

Marks / Registers.

Timers / Counters.

Symbols.

< 1ms/K

1024 / 1024

8192 / 1024

512 / 256

Unlimited

Block processing time. < 1 ms < 1 ms

Remote modules. RIOW RIO5 RIO70 RIOR RCS-S

Valid for CNC. 8070

8065

8060

8070

8065

8060

8070

8065

- - -

D

I

S

C

O

N

T

I

N

U

E

D

8070

8065

8060

8070

8065

8060

Communication with the remote modules. CANopen CANopen CANfagor CANopen Sercos

Digital inputs per module. 8 24 / 48 16 48 - - -

Digital outputs per module. 8 16 / 32 16 32 - - -

Analog inputs per module. 4 4 8 - - - - - -

Analog outputs per module. 4 4 4 - - - 4

Inputs for PT100 temperature sensors. 2 2 - - - - - - - - -

Feedback inputs. - - - - - - 4 (*) - - - 4 (**)

Customizing.

PC-based open system, fully customizable.

INI configuration files.

Tool for display configuration FGUIM.

Visual Basic®, Visual C++®, etc.

Internal databases in Microsoft® Access.

OPC compatible interface

Hardware configuration.

CNC 8070

·10·

(REF: 1911)

SOFTWARE OPTIONS.

Some of the features described in this manual are dependent on the acquired software options. The active

software options for the CNC can be consulted in the diagnostics mode (accessible from the task window

by pressing [CTRL] [A]), under software options.

Consult the ordering handbook for information on the software options available for your model.

SOFT ADDIT AXES

Additional shaft.

Add axes to the default configuration.

SOFT ADDIT SPINDLES

Additional spindle.

Add spindles to the default configuration.

SOFT ADDIT TOOL MAGAZ

Additional tool magazine.

Add tool magazines to the default configuration.

SOFT ADDIT CHANNELS

Additional channel.

Add channels to the default configuration.

SOFT 4 AXES INTERPOLATION LIMIT

Limited to 4 interpolated axes.

It limits the number of axes to 4, where the CNC can also

interpolate these at the same time.

SOFT i4.0 CONNECTIVITY PACK

Industry 4.0.

This option allows for the use and capture of data using the

FSYS.

SOFT OPEN SYSTEM

Open system.

The CNC is a closed system that offers all the features

needed to machine parts. Nevertheless, at times there are

some customers who use third-party applications to take

measurements, perform statistics or other tasks apart

from machining a part.

This feature must be active when installing this type of

application, even if they are Office files. Once the

application has been installed, it is recommended to close

the CNC in order to prevent the operators from installing

other kinds of applications that could slow the system

down and affect the machining operations.

SOFT DIGITAL SERCOS

Sercos digital bus.

Sercos digital bus.

SOFT DIGIT NO FAGOR

Non-Fagor digital servo system.

Mechatrolink digital bus.

SOFT EDIT/SIMUL

EDISIMU mode (editing and simulation).

It allows for the editing, modification and simulation of a

part-program.

SOFT IEC 61131 LANGUAGE

IEC 61131 language

IEC 61131 is a PLC programming language that is very

popular in alternative markets, which is slowly entering

into the machine-tool market. With this feature, the PLC

may be programmed either in the usual Fagor language

or in IEC 61131 format.

SOFT TOOL RADIUS COMP

Compensación de radio.

Tool compensation allows programming the contour to be

machined based on part dimensions of the and without

taking into account the dimensions of the tool that will be

used later on. This avoids having to calculate and define

the tool path based on the tool radius.

SOFT PROFILE EDITOR

Profile editor.

Allows for the part profiles to be edited graphically and to

import dxf files.

SOFT RTCP

Dynamic RTCP (Rotating Tool Center Point).

The dynamic RTCP option is required for interpolation

machining with 4, 5 or 6 axis.

Hardware configuration.

CNC 8070

·11·

(REF: 1911)

SOFT C AXIS

C axis.

It activates the kinematics for working with the C axis and

the associated canned cycles. The CNC can control

several C axes. The parameters of each axis indicate if it

will function as a C axis or not, where it will not be

necessary to activate another axis for the machine

parameters.

SOFT TANDEM AXES

Tandem axes.

A tandem axis consists in two motors mechanically

coupled (slaved) and making up a single transmission

system (axis or spindle). A tandem axis helps provide the

necessary torque to move an axis when a single motor is

not capable of supplying enough torque to do it.

When activating this feature, it should be kept in mind that

for each tandem axis of the machine, another axis must be

added to the entire configuration. For example, on a large

3-axis lathe (X Z and tailstock), if the tailstock is a tandem

axis, the final purchase order for the machine must

indicate 4 axes.

SOFT SYNCHRONISM

Synchronization of axes and spindles.

The axes and ballscrews may be synchronized in two

ways: in terms of speed or position. The CNC

configuration takes into consideration the synchronization

of 2 axes or 2 spindles. Once synchronized, only the

master displays and programs the element.

SOFT HSSA II MACHINING SYSTEM

HSSA-II machining system.

This is the new version of algorithms for high speed

machining (HSC). This new HSSA algorithm allows for

high speed machining optimization, where higher cutting

speeds, smoother contours, a better surface finishing and

greater precision are achieved.

SOFT TANGENTIAL CONTROL

Tangential control.

"Tangential Control" maintains a rotary axis always in the

same orientation with respect to the programmed tool

path. The machining path is defined on the axes of the

active plane and the CNC maintains the orientation of the

rotary axis along the entire tool path.

SOFT DRILL CYCL OL

Drilling ISO cycles for the OL model.

Drilling ISO cycles for the OL model (G80, G81, G82,

G83).

SOFT PROBE

Probing canned cycles.

The CNC may have two probes; usually a tabletop probe

to calibrate tools and a measuring probe to measure the

part.

This option activates the functions G100, G103 and G104

(for probe movements); probe canned cycles are not

included.

SOFT THIRD PARTY I/Os

Third-party CANopen.

Enables the use of non-Fagor CANopen modules.

SOFT FVC STANDARD

SOFT FVC UP TO 10m3

SOFT FVC MORE TO 10m3

Volumetric compensation.

5-axis machines are generally used during the

manufacturing of large parts. The accuracy of the parts is

limited by the machine manufacturing tolerances and is

effected by temperature variations during machining.

In sectors such as the aerospace industry, machining

demands mean that classic compensation tools are

becoming suboptimal. Volumetric compensation FVC

comes in to complement the machine adjusting tools.

When mapping the total work volume of the machine, the

CNC knows the exact position of the tool at all times. After

applying the required compensation, the resulting part is

made with the desired precision and tolerance.

There are 3 options, which depend on the size of the

machine.

• FVC STANDARD: 25-point compensation on each

axis. Quick calibration (time), but less precise than the

other two, but sufficient for the desired tolerances.

• FVC UP TO 10m3: Volume compensation up to 10 m³.

More accurate than FVC STANDARD, but requires a

more accurate calibration using a Tracer or Tracker

laser).

• FVC MORE TO 10m3: Volume compensation greater

than 10 m³. More accurate than FVC STANDARD, but

requires a more accurate calibration using a Tracer or

Tracker laser.

SOFT 60 PWM CONTROL

Pulse-Width Modulation.

This function is only available for Sercos bus controlled

systems. It is mostly oriented toward laser machines for

the cutting of very thick sheets, where the CNC generates

a series of PWM pulses to control the power of the laser

when drilling the starting point.

This feature is essential for cutting very thick sheets and

it requires two quick digital outputs located on the central

unit. With this new feature, the OEM does not need to

install or program any external device, which reduces

machine costs and installation times. The end user also

benefits, since the “Cutting with PWM ” feature is much

easier to use and program.

SOFT 60 GAP CONTROL

Gap control.

This is mostly oriented toward laser machines. Gap

control makes it possible to maintain a set distance

between the laser nozzle and the surface of the sheet. This

distance is calculated by a sensor connected to the CNC,

so that the CNC offsets the sensor variations on the

distance programmed with additional movements in the

axis programmed for the gap.

SOFT DMC

Dynamic Machining Control.

DMC adapts the feedrate during machining to maintain the

cutting power as close as possible to ideal machining

conditions.

SOFT FMC

Fagor Machining Calculator.

The FMC application consists of a database of materials

to be machined and machining operations (milling and

turning) with an interface to choose suitable cutting

conditions for these operations.

SOFT FFC

Fagor Feed Control.

During the execution of a canned cycle of the editor, the

FFC function makes it possible to replace the feedrate and

speed programmed in the cycle with the active values of

the execution, which are acted upon by the feed override

and speed override.

SOFT 60/65/70 OPERATING TERMS

Temporary user license.

The "Operating Terms" option activates a temporary user

license for the CNC, which is valid until the date

determined by the OEM.

Hardware configuration.

CNC 8070

·12·

(REF: 1911)

SOFT MANUAL NESTING

Manual nesting

Nesting consists of creating a pattern on the sheet material

using previously defined figures (in dxf, dwg or parametric

files), so as to use most of the sheet as possible. Once the

pattern has been defined, the CNC creates a program.

During manual nesting, the operator distributes the parts

on top of the sheet material.

SOFT AUTO NESTING

Automatic nesting

Nesting consists of creating a pattern on the sheet material

using previously defined figures (in dxf, dwg or parametric

files), so as to use most of the sheet as possible. Once the

pattern has been defined, the CNC creates a program.

During automatic nesting, the application distributes the

figures on the sheet material and optimizes the spaces.

Hardware configuration.

CNC 8070

·13·

(REF: 1911)

DECLARATION OF CE CONFORMITY AND

WARRANTY CONDITIONS

DECLARATION OF CONFORMITY

The declaration of conformity for the CNC is available in the downloads section of FAGOR’S corporate

website. http://www.fagorautomation.com. (Type of file: Declaration of conformity).

WARRANTY TERMS

The warranty conditions for the CNC are available in the downloads section of FAGOR’s corporate website.

http://www.fagorautomation.com. (Type of file: General sales-warranty conditions.

BLANK PAGE

·14·

Hardware configuration.

CNC 8070

·15·

(REF: 1911)

VERSION HISTORY - CNC 8070

Here is a list of the features added to each manual reference.

Ref. 0601

Ref. 0609

Ref. 0705

Ref. 0706

Ref. 0710 / Ref. 0801

Ref. 0804

Ref. 0809

Ref. 0907

The PCI central unit is removed from the manual.

New monitor LCD-15".

The floppy disk unit with USB connectors is removed from the manual.

Remote modules (bus CAN with CANopen protocol).

ICU central unit.

MCU central unit.

15" passive screen.

Corrected the numbering of the pinout of "Phoenix Contact" connectors

The handwheel module with the E-stop button has been removed from the manual.

Corrected mouse dimensions.

The PC104 central unit is removed from the manual.

The VGA cable for passive screens is valid for cable carrying chains.

The remote modules with CANopen are now called RIO5 remote modules.

The remote modules with CANfagor are now called RIO70 remote modules.

New RIOW remote modules.

Corrected errors. Remote modules RIOW and RIO5 cannot handle a probe.

RS485 pinout correction.

Mechatrolink bus.

PCI expansion module for MCU central unit.

Hardware configuration.

CNC 8070

·16·

(REF: 1911)

Ref. 1007

Ref. 1304

Ref. 1309

Ref. 1404

Ref. 1405

Ref. 1408

Ref. 1512

Ref. 1703

Corrected errors. Position of the dip-switches for selecting the speed in the CAN bus with CANopen protocol, in the

OP-PANEL-HE and Jog-Panel.

RIOW remote modules. The name of the RIOW-CANOPEN has been changed to RIOW-CANOPEN-ECO.

RIOW remote modules. New module RIOW-CANOPEN-STAND.

ICU - MCU central unit. Configure the serial line as RS232, RS422 or RS485.

RS485. At the line terminating resistor, pin 2 must NOT be jumpered with pins 7/9 nor pin 3 with pins 6/8.

Thin Client.

Corrected the characteristics of the feedback inputs of the central unit.

The RIO70 remote modules are now Class III. New protection considerations about electrical choques.

Change the CN371 battery.

Corrected the protection degree of the front panel of the central unit; IP 65.

New model LCD-10K.

New keyboard VERTICAL-KEYB.

New keyboard HORIZONTAL-KEYB.

New operator panel OP-PANEL.

Hardware.

• The LCD-10 model has been eliminated.

• The LCD-10K model (front mounting) has been eliminated.

• The LCD-15 model (front mounting) has been eliminated.

• The OP-PANEL-H/E module has been eliminated.

• The JOG-PANEL module has been eliminated.

• The KB-PANEL-H module has been eliminated.

The remote modules have been eliminated. New manual.

15" passive screen.

New dimensions of the central unit with LCD-15 monitor.

New dimensions of the central unit with LCD-10K monitor.

Work temperature: 0-45 ºC.

Corrected the handwheel connector (X11) of the central unit with LCD-10K monitor.

Central unit with LCD-15 monitor. Corrected dimensions of the enclosure.

Central unit with LCD-10K monitor. Corrected dimensions of the enclosure.

New peripheral board, with 4 USB.

Corrected the protection degree of the front panel of the central unit; IP 65.

Módulo OP-PANEL. Feedback cable connection to the ground plate of the electrical cabinet.

Laser model.

• Installing a sensor for gap control (laser model).

LCD 15" SVGA passive monitor. - DISCONTINUED -.

Hardware configuration.

CNC 8070

·17·

(REF: 1911)

Ref. 1709

Ref. 1805

Ref. 1901

Ref. 1911

New. HORIZONTAL KEYB 2.0 + TOUCHPAD.

New. C70-15AT model.

New. C70-15A model.

Model C70-15. - DISCONTINUED -.

Model C70-15T. - DISCONTINUED -.

Model C70-15A. - DISCONTINUED -.

Model C70-15 available again.

Corrected the resolution of the model C70-15AT.

New. Q7-A central unit.

New. FAGOR-UPS.

New. Q7-A central unit for cabinet.

BLANK PAGE

·18·

Hardware configuration.

CNC 8070

·19·

(REF: 1911)

SAFETY CONDITIONS

Read the following safety measures in order to prevent harming people or damage to this product and those

products connected to it. Fagor Automation shall not be held responsible of any physical or material damage

originated from not complying with these basic safety rules.

PRECAUTIONS BEFORE CLEANING THE UNIT

PRECAUTIONS DURING REPAIRS

In case of a malfunction or failure, disconnect it and call the technical service.

PRECAUTIONS AGAINST PERSONAL HARM

Before start-up, verify that the machine that integrates this CNC meets the 2006/42/EC Directive.

Do not get into the inside of the unit. Only personnel authorized by Fagor Automation may access the

interior of this unit.

Do not handle the connectors with the unit

connected to AC power.

Before handling these connectors (I/O, feedback, etc.), make sure

that the unit is not powered.

Do not get into the inside of the unit. Only personnel authorized by Fagor Automation may access the

interior of this unit.

Do not handle the connectors with the unit

connected to AC power.

Before handling these connectors (I/O, feedback, etc.), make sure

that the unit is not powered.

Interconnection of modules. Use the connection cables provided with the unit.

Use proper cables. To prevent risks, only use cables and Sercos fiber recommended for

this unit.

To prevent a risk of electrical shock at the central unit, use the proper

connector (supplied by Fagor); use a three-prong power cable (one

of them being ground).

Avoid electric shocks. To prevent electrical shock and fire risk, do not apply electrical voltage

out of the indicated range.

Ground connection. In order to avoid electrical discharges, connect the ground terminals

of all the modules to the main ground terminal. Also, before

connecting the inputs and outputs of this product, make sure that the

ground connection has been done.

In order to avoid electrical shock, before turning the unit on verify that

the ground connection is properly made.

Do not work in humid environments. In order to avoid electrical discharges, always work with a relative

humidity (non-condensing).

Do not work in explosive environments. In order to avoid risks, harm or damages, do not work in explosive

environments.

Hardware configuration.

CNC 8070

·20·

(REF: 1911)

PRECAUTIONS AGAINST DAMAGE TO THE PRODUCT

SAFETY SYMBOLS

Symbols that may appear in the manual.

Work environment. This unit is ready to be used in industrial environments complying with

the directives and regulations effective in the European Community.

Fagor Automation shall not be held responsible for any damage

suffered or caused by the CNC when installed in other environments

(residential, homes, etc.).

Install this unit in the proper place. It is recommended, whenever possible, to install the CNC away from

coolants, chemical product, blows, etc. that could damage it.

This unit meets the European directives on electromagnetic

compatibility. Nevertheless, it is recommended to keep it away from

sources of electromagnetic disturbance such as:

Powerful loads connected to the same mains as the unit.

Nearby portable transmitters (radio-telephones, Ham radio

transmitters).

Nearby radio / TC transmitters.

Nearby arc welding machines.

Nearby high voltage lines.

Enclosures. It is up to the manufacturer to guarantee that the enclosure where the

unit has been installed meets all the relevant directives of the

European Union.

Avoid disturbances coming from the

machine.

The machine must have all the interference generating elements

(relay coils, contactors, motors, etc.) uncoupled.

Use the proper power supply. Use an external regulated 24 Vdc power supply for the keyboard,

operator panel and the remote modules.

Connecting the power supply to ground. The zero Volt point of the external power supply must be connected

to the main ground point of the machine.

Analog inputs and outputs connection. Use shielded cables connecting all their meshes to the corresponding

pin.

Ambient conditions. Maintain the CNC within the recommended temperature range, both

when running and not running. See the corresponding chapter in the

hardware manual.

Central unit enclosure. To maintain the right ambient conditions in the enclosure of the central

unit, it must meet the requirements indicated by Fagor. See the

corresponding chapter in the hardware manual.

Power switch. This switch must be easy to access and at a distance between 0.7 and

1.7 m (2.3 and 5.6 ft) off the floor.

Danger or prohibition symbol.

This symbol indicates actions or operations that may hurt people or damage products.

Warning or caution symbol.

This symbol indicates situations that certain operations could cause and the suggested actions to prevent

them.

Obligation symbol.

This symbol indicates actions and operations that must be carried out.

Information symbol.

This symbol indicates notes, warnings and advises.

Symbol for additional documentation.

This symbol indicates that there is another document with more detailed and specific information.

i

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

-

113

113

-

114

114

-

115

115

-

116

116

-

117

117

-

118

118

-

119

119

-

120

120

-

121

121

-

122

122

-

123

123

-

124

124

-

125

125

-

126

126

-

127

127

-

128

128

-

129

129

-

130

130

-

131

131

-

132

132

-

133

133

-

134

134

-

135

135

-

136

136

-

137

137

-

138

138

-

139

139

-

140

140

-

141

141

-

142

142

-

143

143

-

144

144

-

145

145

-

146

146

-

147

147

-

148

148

-

149

149

-

150

150

-

151

151

-

152

152

-

153

153

-

154

154

-

155

155

-

156

156

-

157

157

-

158

158

-

159

159

-

160

160

-

161

161

-

162

162

-

163

163

-

164

164

-

165

165

-

166

166

-

167

167

-

168

168

-

169

169

-

170

170

-

171

171

-

172

172

-

173

173

-

174

174

-

175

175

-

176

176

-

177

177

-

178

178

-

179

179

-

180

180

-

181

181

-

182

182

-

183

183

-

184

184

-

185

185

-

186

186

-

187

187

-

188

188

-

189

189

-

190

190

-

191

191

-

192

192

-

193

193

-

194

194

-

195

195

-

196

196

-

197

197

-

198

198

-

199

199

-

200

200

-

201

201

-

202

202

-

203

203

-

204

204

-

205

205

-

206

206

-

207

207

-

208

208

-

209

209

-

210

210

-

211

211

-

212

212

-

213

213

-

214

214

-

215

215

-

216

216

-

217

217

-

218

218

-

219

219

-

220

220

-

221

221

-

222

222

-

223

223

-

224

224

-

225

225

-

226

226

-

227

227

-

228

228

-

229

229

-

230

230

-

231

231

-

232

232

-

233

233

-

234

234

-

235

235

-

236

236

-

237

237

-

238

238

-

239

239

-

240

240

-

241

241

-

242

242

-

243

243

-

244

244

-

245

245

-

246

246

-

247

247

-

248

248

-

249

249

-

250

250

-

251

251

-

252

252

-

253

253

-

254

254

-

255

255

-

256

256

-

257

257

-

258

258

-

259

259

-

260

260

-

261

261

-

262

262

-

263

263

-

264

264

-

265

265

-

266

266

-

267

267

-

268

268

-

269

269

-

270

270

-

271

271

-

272

272

-

273

273

-

274

274

-

275

275

-

276

276

Fagor CNC 8070 Owner's manual

- Type

- Owner's manual

- This manual is also suitable for

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Fagor CNC 8065 Owner's manual

-

Fagor CNC 8070 for other applications Owner's manual

-

Fagor Laser 8060 CNC Owner's manual

-

Fagor CNC 8070 for other applications Owner's manual

-

Fagor CNC 8065 User manual

-

Fagor CNC 8065 Owner's manual

-

Fagor CNC 8058elite M Owner's manual

-

Fagor CNC 8058elite M Owner's manual

-

Fagor CNC 8065 Owner's manual

-

Fagor Laser 8060 CNC User manual

Other documents

-

poscope POMPG2 Pulse Generator User manual

poscope POMPG2 Pulse Generator User manual

-

SBS CO9P30550 Datasheet

-

iKey DT-2000-TB Technical Drawing

-

FlowerHouse SHMD766 Operating instructions

-

FlowerHouse FHFH700 Dimensions Guide

-

SBS CO9P30515 Datasheet

-

SBS CO9P30215 Datasheet

-

NTI Computer Hardware USB-AA-5M User manual

NTI Computer Hardware USB-AA-5M User manual

-

HP t505 Flexible Thin Client Reference guide

-

Automation Direct DL205 Operating instructions

Automation Direct DL205 Operating instructions