Page is loading ...

Protect yourself and others by observing all safety information, warnings, and cautions. Failure to

comply with instructions could result in personal injury and/or damage to product or property.

Please retain instructions for future reference!

2400WATT 2600PSI

PRESSURE

WASHER

ROSSPOWER RPPW2400EH

SPECIFIC SAFETY INSTRUCTIONS

IMPORTANT WARNING

NEVER operate the pressure washer using a pulsing

action. Pulsing is the repeated and rapid ON & OFF

operation of the trigger. This action could result in the

failure of components and connections that are under

pressure.

ELECTRICAL SAFETY

• If the supply cord is damaged, it must be

replaced by the manufacturer, its service agent

or similarly qualified person in order to avoid a

hazard.

• Be familiar with the controls and proper use of the

equipment.

• Before use check the supply and extension cord

for signs of damage or ageing. If the cord becomes

damaged during use, disconnect the cord from the

supply immediately. Do Not Touch The Cord Before

Disconnecting The Supply,

• Do not use the pressure washer if the mains cord is

damaged or worn..

• Keep extension cords away from pools of water.

• It is recommended that the tool be used in con-

junction with a residual current device (RCD) with a

rated residual current of 30mA or less.

WARNING

Inadequate extension cords and reels can be danger-

ous. If an extension reel is used, it must be designed

for outside use and be of suitable construction for the

product. All plug’s, sockets and connectors must be of

water/splash proof construction. Always switch off and

disconnect from the electrical power supply before

carrying out any adjustments, cleaning or user mainte-

nance.

WATER SUPPLY

• This is a clean, cold water pressure washer The

working temperature range must be between +5°C

and +40°C.

• The water supply pressure must not exceed 4 Bar

and must be clean and free of any abrasive particles

or corrosive contaminates

CAUTION

When the machine is fully pressurized and the trigger

is squeezed the release of pressure will cause the spray

gun to recoil. Adopt a stable stance and hold the spray

gun firmly in both hands before squeezing the trigger.

Failure to do so could result in an injury from a whip-

ping spray gun.

SAFE OPERATION

• High pressure jets can be dangerous if subject to

misuse.

• Do Not direct the water jet at live electrical equip-

ment or the appliance itself.

• Do Not let children or persons unfamiliar with the

machine operate the pressure washer.

• Do not direct the jet against yourself, others, ani-

mals or the unit.

• Do not use the machine to pump gasoline, kero-

sene or any other flammable or corrosive

• Do not attempt to modify the machine, connectors,

hoses or other fittings in any way.

• Do not leave the spray gun unattended while the

machine is running.

• Never let the machine run for more than 2 minutes

with the spray gun in its closed position.

• Do Not allow the machine to run dry as this will

cause serious damage to the seals and pump.

• Do not use the appliance near other persons unless

they are wearing protective clothing.

DETERGENT CLEANING

• The detergent bottle / detergent tank is designed

for use with most proprietary domestic cleaning

agents and shampoo’s.

• Do Not use domestic washing up liquid, industrial

cleaning agents or solvents. Your local motorists

accessory outlet can advise on a suitable cleaning

agent.

• The use of other cleaning agents or chemicals may

adversely affect the safety of the appliance.

• To ensure the appliance safety, use only original

pare parts from or approved by the manufacturer.

WARNING

• High pressure hose’s, fittings and couplings are

important for the safety of the machine. Use only

hoses, fittings and couplings suitable for high pres-

sure use.

• Locate the machine in areas away from combustible

materials, combustible fumes or dust.

• Keep the hose connected to the machine and he

spray gun while the system is pressurized.

• Disconnecting the hose whilst the unit is pressur-

ised is dangerous.

• Always ensure that all water pressure is released and

the machine is switched off before attempting to

disconnect any hoses or connectors.

• Cleaning areas should have adequate slopes and

drainage to reduce the possibility of a fall due to

slippery surfaces.

• This machine is rated for domestic use only and

should not be used for professional or commercial

purposes.

CAUTION

The machine consists of a motor and pump protected

by an outer casing of shock resistant material. The

outer casing has been manufactured to offer an easy

clean surface with a handle and wheels, where fitted,

for easy mobility.

The machine can be used for washing roller shutters,

main doors, tiles, fencing, patio paving, drive ways,

cars and campers etc., where water pressure is neces-

sary to remove dirt. The foam bottle / detergent tank

can be used to carry out foaming and washing with a

suitable cleaning agent.

EXTENSION LEADS

This tool may require the use of an extension lead .

Only use extension leads suitable for outside use. The

cross section of the wire must be at least 1.5 mm2.

(max. length of extension cord: 30M) Keep extension

cords away from pools of water.

NOTE: Extension leads longer than 30M will re-

duce the performance of the tool.

GENERAL SAFETY RULES

WARNING! Read all instructions Failure to follow

all instructions listed below may result in electric

shock, fire and/or serious injury. The term “power

tool” in all of the warnings listed below refers to your

mains operated (corded) power tool or battery oper-

ated (cordless) power tool.

SAVE These Instructions

1) WORK AREA

A) Keep work area clean and well lit.

CLUTTERED and dark areas invite accidents.

B) Do not operate power tools in explosive at-

mospheres, such as in the presence of ammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

C) Keep children and bystanders away while op-

erating a power tool. Distractions can cause you to

lose control.

2) ELECTRICAL SAFETY

A) Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools. Unmodi-

ed plugs and matching outlets will reduce risk of

electric shock.

B) Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and re-

frigerators. There is an increased risk of electric shock

if your body is earthed or grounded.

C) Do not expose power tools to rain or wet con-

ditions. Water entering a power tool will increase the

risk of electric shock.

D) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of elec-

tric shock.

E) When operating a power tool outdoors, use

an extension cord suitable for outdoor use. Use

of a cord suitable for outdoor use reduces the risk of

electric shock.

3) PERSONAL SAFETY

A) Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under the

inuence of drugs, alcohol or medication. A moment

of inattention while operating power tools may result

in serious personal injury.

B) Use safety equipment. Always wear eye protec-

tion. Safety equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

C) Avoid accidental starting. Ensure the switch is

in the off position before plugging in. Carrying power

tools with your nger on the switch or plugging in

power tools that have the switch on invites accidents.

D) Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left at-

tached to a rotating part of the power tool may result

in personal injury.

E) Do not overreach. Keep proper footing and bal-

ance at all times. This enables better control of the

power tool in unexpected situations.

F) Dress properly. Do not wear loose clothing or jew-

ellery. Keep your hair, clothing and gloves away from

moving parts. Loose clothes, jewellery or long hair can

be caught in moving parts.

G) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

these devices can reduce dust related hazards.

4) POWER TOOL USE AND CARE

A) Do not force the power tool. Use the correct

power tool for your application. he correct power tool

will do the job better and safer at the rate for which it

was designed.

B) Do not use the power tool if the switch does

not turn it on and off. Any power tool that cannot

be controlled with the switch is dangerous and must

be repaired.

C) Disconnect the plug from the power source

before making any adjustments, changing ac-

cessories, or storing power tools. Such preventive

safety measures reduce the risk of starting the power

tool accidentally.

D) Store idle power tools out of the reach of chil-

dren and do not allow persons unfamiliar with

the power tool or these instructions to operate

the power tool. Power tools are dangerous in the

hands of untrained users.

E) Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts and any

other condition

that may affect the power tools operation. If damaged,

have the power tool repaired before use. Many acci-

dents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly main-

tained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

G) Use the power tool, accessories and tool

bits etc., in accordance with these instructions and in

the manner intended for the particular type of power

tool, taking into account the working conditions and

the work to be performed. Use of the power tool for

operations different from intended could result in a

hazardous situation.

5) SERVICE

A) Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

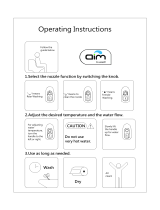

COMPONENT IDENTIFICATION

COMPONENT LIST

1. Detergent container

2. Water supply inlet

3. ON/OFF switch

4. Gun assembly

5. High pressure hose

6. Adjustable lance

7. Cleaning needle

8. Quick connector (Male)

9. Inlet filter

10. Cable holder

11. Turbo lance

12. Fixed brush

13. NA

14. NA

15. Extension adaptor

16. Hose reel handle

TECHNICAL SPECIFICATION

Rated voltage: 230-240~50Hz

Rated power: 2400W

Protection class: 1

Degree of protection: IPX5

Permissible pressure: 180 Bar / 2600psi

Rated pressure: 120 Bar / 1750psi

Supply water temperature: 5-60ºC

Nozzle spray angle: 0-90º

Max output flow rate: 6L/min

Net weight (machine only): 20Kg

Cable length: 5m

Hose length: 6m

Sound Pressure Level: Lpa 85dB

Sound Power Level: Lwa 95dB

Vibration Level: 1.0m/s2

UNPACKING AND ASSEMBLY

CAUTION! This packaging contains sharp ob-

jects. Take care when unpacking. This machine could

require two persons to lift, assemble and move this

machine. Remove the machine, together with the ac-

cessories supplied, from the packaging. Check carefully

to ensure that the machine is in good condition and

account for all the accessories listed in this manual.

Also make sure that all the accessories are complete. If

any parts are found to be missing, the machine and

its accessories should be returned together in their

original packaging to the retailer.

Do not throw the packaging away, keep it safe

throughout the warranty period, then recycle if pos-

sible, otherwise dispose of it by the proper means. Do

not let children play with empty plastic bags due to the

risk of suffocation.

ASSEMBLY

Note: Before carrying out any assembly or disas-

sembly of the unit please ensure that the unit is not

connected to the electrical supply.

FITTING THE LANCE

Before using the washer fit the lance to the gun.

Grip the end of the gun and screw the lance

on to the gun ensuring it is tight, Fig 1. Do not over

tighten as this could damage both the connectors.

HOSE CONNECTIONS

Connect the high pressure hose connector to the con-

nector on the underside of the gun assembly ensuring

that it is tight, Fig 2. Do not over tighten as this could

damage both the connectors.

Note: During normal operation the pressure washer

pump motor will only start when the trigger is

squeezed and will stop when the trigger is released.

HIGH PRESSURE LANCE SAFETY LOCK

In order to prevent accidental operation of the high

pressure lance, the gun is fitted with a safety lock. To

disable the safety lock, push the safety lock button to

the right, Fig 7. To enable the safety lock, release the

trigger and push the button to the left.

Check that the On/Off switch is in the OFF (0) position,

Fig 3.

The water inlet is fitted with a particle filter and if

not fitted must be fitted prior to use. Fig 4. This

filter must not be removed except for examination

and cleaning. The inlet water filter should ideally be

checked and if required cleaned before each use.

Screw the high pressure hose to the high pressure

water outlet, Fig 6. Do not use water which exceeds

60°C.

PRIME THE PRESSURE WASHER

Turn on the water supply and squeeze the gun trigger

until the water flows in a steady stream through the

lance.

Screw the male, quick connector onto the pressure

washer water supply inlet, Fig 5. Attach a hose pipe

with a female quick release connector (not supplied) to

the male quick connector on the power washer.

OPERATION

CAUTION!

Before connecting to the mains power supply please

ensure that the ON / OFF switch is in the OFF posi-

tion and the water supply is connected and is turned

on. Running the pressure washer without any water

supplied to it will damage the pump and VOID your

warranty.

SWITCHING ON

Connect the pressure washer mains lead to the mains

electricity supply via a residual current device (RCD)

(not supplied). Start the power washer by turning the

On/Off switch to the ON (I) position, Fig 7.

FIg 6

Note: before using the pressure washer to clean patio

paving slabs it is advisable to test a small area first,

some paving slabs are manufactured from inferior ma-

terials and the use of a pressure washer could damage

the surface.

HELPFUL HINTS

Before starting cleaning remove any objects which

could cause a hazard. Ensure that all doors and win-

dows are closed (where appropriate).

The adjustable lance allows you to use a variety of

spray patterns from a fan to a pencil jet. When using

the pressure washer to clean decking, patios, vehicles,

etc., always start by using the fan spray and begin

spraying from a minimum 30cm away to avoid dam-

aging the surface of the material to be cleaned. The

pressure of the spray on the surface you are cleaning

increases as you move the nozzle closer to the surface.

We recommend that for most cleaning applications a

45° spray angle should be used to avoid damaging the

surface being cleaned. Spraying directly “head-on”

tends to cause dirt particles to embed in the surface.

WARNING! Do not adjust the nozzle while the

trigger is squeezed.

NOZZLE CLEANING INSTRUCTIONS

A clogged or partially clogged nozzle can cause a

significant reduction of water coming out of the noz-

zle and cause the unit to pulsate or totally stop while

spraying, To clean out the nozzle:

•Turnoffandunplugtheunit.

•Turnoffthewatersupplyandrelieveanypressure

within the unit by squeezing the trigger 2-3 times.

•Separatethelancefromthegun.

•Rotatethenozzletothenarrowstreamsetting.This

opens up the fan blades.

•Usingthecleaningneedleoranunfoldedpaperclip,

insert the needle into the nozzle hole and move it back

and forth until the debris is dislodged, Fig 9.

• Remove additional debris by back-flushing water

through the nozzle. To do this, place the end of a gar-

den hose (with water running) to the end of the nozzle

for 30-60 seconds.

ADJUSTING THE SPRAY PATTERN

Pencil or fan water spray patterns can be clockwise or

anti-clockwise, Fig 8. The fan spray pattern is the most

commonly used for general cleaning operations. The

pencil spray pattern is used to remove localized stub-

born contamination such as oil stains.

Note: The motor only runs when the trigger is operat-

ed. When the pressure washer is not in use, we recom-

mend that you lock the gun using the trigger lock for

safety reasons. Switch the unit OFF when not in use for

extended periods of time and expel pressurised water

in the unit by operating the trigger gun while the unit

is in the OFF position.

MOTOR PROTECTION

To prevent damage to the motor due to overheating,

the pump motor is equipped with a thermal switch. If

during use the pressure washer stops operating allow

5-10 minutes for the motor to cool down before re-

starting. If the motor continues to cut out due to over-

heating please contact our customer help line.

EXTENSION ADAPTOR

Accessories require the use of the extension adaptor.

Remove the lance from the gun and attach the adap-

tor as necessary. Grip the end of the gun and screw

the adaptor onto the gun ensuring it is tight, Fig 10.

Do not over tighten as this could damage both the

connectors.

Fit the accessories into the gun assembly by pushing

them into the gun assembly and locating the lugs, at

the same time turn clockwise to lock

into position, Fig 11.

TURBO LANCE

A turbo lance, sometimes referred to as a rotary lance,

is a very effective tool that can significantly reduce

cleaning time.

The turbo nozzle combines the power of a narrow

high impact stream and the efficiency of a 25 degree

fan pattern. This swirls the narrow high impact stream

into a cone shape that cleans a larger area.

Caution Since a turbo lance uses a narrow high

impact stream, only use it in applications where the

leaning surface cannot be damaged by a narrow high

impact spray. Always test on an inconspicuous area

first to ensure you do not damage the surface.

Note: The turbo lance is NOT adjustable and cannot be

used to apply detergent.

FIXED BRUSH

Your pressure washer is supplied with a fixed brush. It

has soft bristles and can be used in conjunction with

the detergent dispenser to apply detergent to the

surface you are cleaning.

It is ideal for cleaning car bodywork, windows etc. This

is a low pressure setting.

The fixed brush connects to the gun assembly.

WARNING! Do not t brushes when the power is

on.

Caution Ensure the brush is clean and free from de-

bris.

Ensure the surface to be cleaned is sound and will not

be damaged by the brushing action. Test on an incon-

spicuous area first. Any grit or debris on the surface to

be cleaned or in the brush can cause damage to that

surface. Please ensure both are checked prior to

cleaning.

HOW TO AVOID DAMAGING SURFACES

Damage to cleaning surfaces occurs because the im-

pact force of the water exceeds the durability of the

surface. Never use a narrow high impact stream or a

turbo/rotary lance on a surface that is susceptible to

damage. Avoid spraying windows with a narrow high

impact stream or turbo lance as this may cause

breakage.

Follow these simple steps to avoid damaging your

surfaces:

1. Before triggering the gun, adjust the nozzle to a

wide fan pattern.

2. Place the nozzle approximately 1.5 to 2 metres from

cleaning surface and begin spraying.

3. Vary the fan pattern spray angle and the distance to

the cleaning surface until optimum cleaning efficiency

is achieved without damaging the surface.

USING DETERGENT

Add detergent to the container and replace the cap.

Do not overll.

Set the adjustable lance at low pressure.

• Pull forward on the adjusting sleeve of the standard

lance Fig 11A.

• Depress the trigger to spray detergent.

Note: The detergent function does not work on high

pressure.

Fig 11A

DETERGENTS

The use of detergents can dramatically reduce cleaning

time and assist in the removal of difficult stains. Some

detergents have been customized for pressure washer

for specific cleaning tasks. These detergents are

approximately as thick as water.

The cleaning power of detergents comes from apply-

ing them to a surface and giving the chemicals time to

break down the dirt and grime. Detergents work best

when applied at low pressure. Follow this with a high

pressure rinse for best cleaning results.

On vertical surfaces, apply the detergent starting at the

bottom and work your way upward. This will prevent

the detergent form sliding down and causing streaks.

High pressure rinsing should also progress from the

bottom upwards. On particularly tough stains it may be

necessary to use a brush in combination with deter-

gents and high pressure rinsing.

USAGE

The following cleaning procedure will help you organ-

ize your cleaning task and ensure that you achieve the

most beneficial results in the shortest amount of time.

Remember to use the spraying/ cleaning techniques

previously listed.

1. Surface Preparation

It is important to prepare the surface that is to be

cleaned. This is done by clearing the area of furniture

and making sure that all windows and doors are closed

tight. In addition, you should make sure that all plants

and trees adjacent to the cleaning area are protected

by a drop cloth. This will ensure that your plants won’t

be sprayed by the detergents.

2. Initial High Pressure Rinse

The next step is to spray the cleaning surface with

water to clear off any dirt or grime that may have col-

lected on the surface. This will allow your detergent to

attack the deep down dirt that has worked its way into

the cleaning surface.

Before triggering the gun, adjust the nozzle to a wide

fan pattern and slowly adjust to the desired spray

pattern. This will help you avoid applying too much

concentrated spray to the surface which could cause

damage.

TIPS FOR EXTENDING THE LIFE OF

YOUR PRESSURE

1. Never operate the unit without water.

2. This pressure washer is not designed to pump hot

water. Never connect it to the hot water supply as this

will significantly reduce the life of the pump.

3. Only use detergents specifically designed for pres-

sure washers. Other types of detergent may cause

internal damage to the unit, as might chemicals such

as bleach, washing-up liquid, etc.

4. Never operate the unit for more than one (1)

minute without spraying water. Otherwise, the result-

ing heat build up will damage the pump.

5. Winter Storage:

For storage during the winter months we recom-

mend the use of a solution of 50/50 mix of antifreeze

and water. This will keep the pump from freezing and

getting damaged and will protect the internal compo-

nents.

Method:

You will need a length of garden hose and a funnel.

Attach the garden hose to the inlet and pour the

antifreeze into the unit via the funnel. Switch the unit

on for a few seconds to allow the solution to flow

through the system.

Disconnect your pressure washer from the mains

power, and then pack away in your storage area.

WARNING! Before reusing completely ush the

unit out with clean water. Anti-freeze can damage

paintwork so you must ensure there is no antifreeze

left in the system before using it again.

ADJUSTABLE CARRY HANDLE

To extend the carry handle to its full height press the

carry handle release button and pull upwards, Fig 11.

After use, press the carry handle release button and

push down until it clicks into place.

ADJUSTABLE HANDLE

To extend the carry handle to its full height press

the carry handle release button and pull

upwards, Fig 12. After use, press the carry

handle release button and push down until it

clicks into place.

USING THE HOSE REEL

To use the hose reel locate the hose reel handle on the

side of the pressure washer and pull outwards, Fig 13.

To extend the length of hose you require turn the

handle anti-clockwise. To shorten the length of the

hose turn the handle clockwise.

Conforms to relevant standards.

Read the instruction manual.

Do not direct the water jet at yourself, other,

animals or the pressure washer.

General warning

Disconnect from the power supply when

not in use or for maintenance and repair.

Protect the unit from freezing conditions

MEANING OF SYMBOLS

The rating plate and the product may show symbols. These represent important information about the

product, instructions on its use or safety

For information on all ROSS products

please visit: www.rosstools.com.au

The ROSS logo and Bull device are trademarks of J.W. Ross Pty Ltd.

WARRANTY

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled

to a replacement or refund for a major failure and for compensation for any other reasonably foreseeable loss or

damage. You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality

and the failure does not amount to a major failure.

This product is covered by a 12 month warranty.

This warranty will not apply:

(i) where this product has been subjected to misuse, abuse, accident or want of care;

(ii) where this product has been used for a purpose for which it was not designed or is not suited;

(iii) where the service of this product has been undertaken by a non-authorised person or company or if non-

approved parts have been used;

(iv) where this product has been used for industrial purposes.

Should service become necessary during the warranty period, the purchaser should contact an Authorised Ser-

vice Centre or J W Ross. In order to obtain warranty service, the purchaser must present the store receipt show-

ing the name of the retailer and the date of purchase.

The period of the warranty begins from the original date of purchase, notwithstanding any

subsequent repair or parts replacement.

Purchaser shall be responsible for all transport charges to and from the Authorised Service

Centre.

Damage in transit is not covered by this warranty. The purchaser should remove from the product any liquids (if

applicable) before sending the tool for service or repair. The tool should be packed securely to prevent damage.

WARRANTY EXCLUSIONS

Wear parts or service related parts required when performing normal and regular maintenance of this product

are not covered by warranty unless it is found to be defective by an Authorised Service Centre. These include,

but are not limited to: seals, filters, hoses.

Distributed in Australia by J W Ross and Sons ( Australia ) Pty Ltd.

PO Box 352 North Ryde BC, NSW, 1670

For you local service centre: www.jwross.com.au

Ph:1800 251 338

The J.W. Ross policy is one of continuous improvement and the company reserves the right to alter designs,

colours and specifications without notice.

/