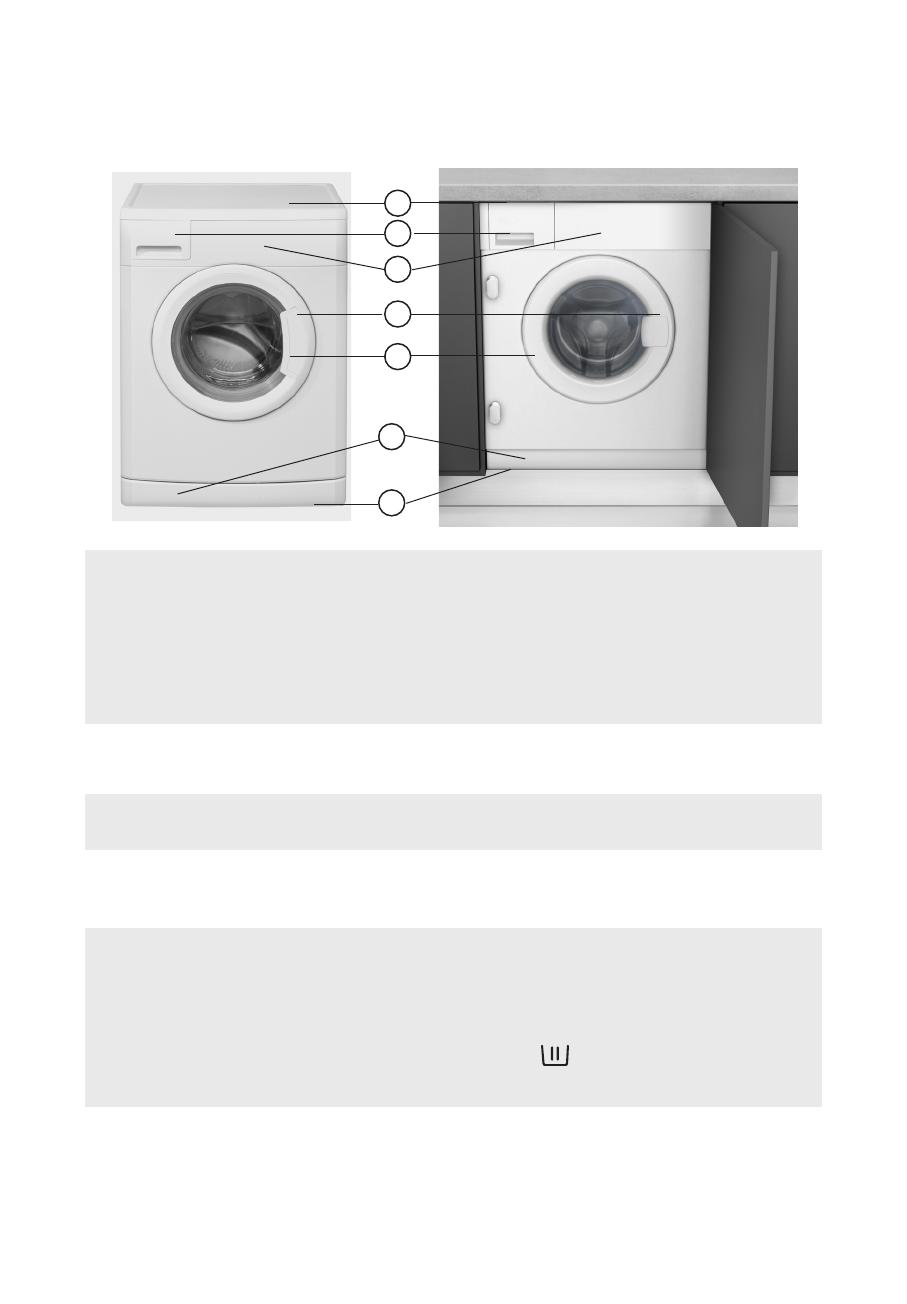

Noise, excessive vibrations and water leakages

can be caused by incorrect installation of washing

machine.

For freestanding models: NEVER move the

washing machine by carrying it at the worktop.

REMOVE TRANSPORT BOLTS! (pict.1)

Important:

- Not removed transport bolts cause damages

to the appliance!

- Keep the transport bolts for further

transporting of the appliance; in this case

refit the transport bolts in reverse order.

1.Loosenthescrewsofall4transportboltsby

about35mm;use12mmwrench(pict.2a).

2.Pushscrewinsideofmachinetostopposition

(min.20mm)(pict.2b).

3.Pullouttherubberringsfromtheholes(donot

pullthescrews!).Thewholetransportboltcan

beremovednow(pict.2c).

4.Pushtheplasticcapsdeliveredwithyour

washingmachineontheholestoclosethem

(pict.2d).

ADJUSTMENT OF THE FEET

Theappliancemustbeinstalledonasolidandlevel

floorsurface(ifnecessaryuseaspiritlevel).

Iftheapplianceistobeinstalledonawoodenor

floatingfloor,distributetheweightbyplacingitona

sheetofplywoodmeasuringatleast60x60cmand

thicknessofatleast3cmwhichissecuredtothe

floor.Ifthefloorisuneven,adjustthe4levellingfeet

asrequired;donotinsertpiecesofwoodetc.under

thefeet.

Screwoutthewashingmachine´sfeetbyhandwith

2-3anticlockwiseturnsandthenslackenthelocknut

by13mmwrench(seepict.3,4).

Slightlyliftthemachineandadjusttheheightofthe

footrevolvingit(pict.4).

Important:tightenthelocknutbyturningitanti-

clockwisetowardstheappliancecasing(pict.5, 6).

CONNECT THE WATER INLET HOSE

Ifthewaterinlethoseisnotalreadyinstalled,screw

byhandthebentendoftheinlethosetothevalveon

thewashingmachine‘sback(pict.7, 8).

Screwbyhandthestraightendoftheinlethoseto

thetap,tighteningthenut.

Attention:

• Nokinksinthehose!

• Theappliancemust not beconnectedtothe

mixingtapofanun-pressurizedwaterheater.

• Checkwater-tightnessofconnectionsbyturning

thetapcompletelyon.

• Ifthehoseistooshort,replaceitwithasuitable

lengthofpressureresistanthose(1000kPamin,

EN50084approvedtype).

INSTALLATION GUIDE

Pictures are on the cover of this Instruction for Use.

For built-in washing machines: observe the separate Built-in Instructions

GB15

Ifyouneedalongerwaterstophose,contact

ourAfterSalesServiceoryourdealer.

• Checktheinlethoseregularlyforbrittleness

andcracksandreplaceifnecessary.

• Thewashingmachinecanbeconnectedwithout

abackflowvalve.

CONNECT THE DRAIN HOSE

1.Incasethedrainhoseisinstalledasshownon

pict.9:Unclipitfromtheholdersmarkedwith

arrows.

2. Incasethedrainhoseisinstalledintheupper

partofthewashingmachine(pict.10):Unclipit

frombothholdersmarkedwitharrows

(dependingonthemodel).

3.Firmlyconnectthedrainhosetothesiphonor

anotheroutletfordrainwater.

• Makesuretherearenokinksinthedrainhose.

• Securethehosesothatitcannotfalldown.

• Smallhandbasinsarenotappropriate.

• Tomakeanextension,useahoseofthesame

typeandsecuretheconnectionswithclips.

• Heightforsiphon-drainhoseconnectionmust

beminimum60cmandmaximum125cm

• Max.Overalldrainhoselength:2,50m(inthis

case,themaximumheightforfixationis90cm).

ELECTRICAL CONNECTION

• Useasocketwithanearthconnection.

• Donotuseextensionleadsormultisockets.

• Theelectricalpowercablemustbereplaced

exclusivelybyalicensedelectrician.

• Electricalconnectionsmustbemadeinaccordance

withlocalregulations.

I-2012