Craftsman 137229151 Owner's manual

- Category

- Power tools

- Type

- Owner's manual

This manual is also suitable for

Operator's Manual

1 HP (Maximum Developed)

12 Speeds (250-3100 R.P.M.)

5/8 Inch Chuck

15-INCH DRILL PRESS

Model No,

137.229151

CAUTION:

Before using this Drill Press,

read this manual and follow

all its Safety Rules and

Operating Instructions

• Safety Instructions

• Installation

• Operation

• Maintenance

• Parts List

• EspaSol

Customer Help Line

1-800-843-1682

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

Visit our Craftsman website: www.sears.comlcraftsman

Part No. 137229151001

SECTION PAGE

Warranty ................................................................................................................ 2

Product Specificattone ............................................................................................. 2

Safety Instructions .................................................................................................. 3

Accessories and Attachments .................................................................................. 6

Carton Contents ...................................................................................................... 6

Know Your Drill Press ............................... _.............................................................. 8

Glossary of Terms ....................................................................... ;........................... 9

Assembly and Adjustment ..................................................... _...................... ,............ 10

Operation ............................................................................................................... 15

Maintenance ........................................................................................................... 20

Troubleshooting Guide ............................................................................................ 21

Parts ...................................................................................................................... 22

Espafiol ............................................................ ;..................................................... 25

FULL ONE YEAR WARRANTY

If this Driss Press fails due to a defect in material or workmanship within one year of date of purchase,

Sears will at its option repair or replace it free of charge.

Return this Drill Press to a Sears Service Center for repair, or to place of purchase for replacement.

This warranty gives you specific legal rights, and you may also have other rights which may vary from

state to state.

Sears, Roebuck and Co., Dept. 817 WA, Hoffrnan Estates, IL 60179

_q

Some dust created by power sanding, sawing, grinding, drilling and other construction activities contains

chemicals known to the state of California to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks, cement and other masonry products

• Arsenic and chromium from chemicallytreatsd lumber

Your risk from these exposures varies, depending on how often you do this type of work. To reduce )/our

exposure to these chemicals work in a well-ventnated area and work with approved safety equipmentsuch as

dust masks that are spec a y des gned to filter out microscopic particles.

Chuck Size ............................ 5/8"

Speed ................................... 12 (250 ~ 3,100 RPM)

Motor .................................... 120V, 60 Hz, 8 Amps

Horsepower ........................... 1 HP (Max. Developed)

Built-in Light ......................... 60 Watt (Maximum)

(Bulb not included)

Table Size ............................ 13-1/4" x 13-1/4"

Table Tilt ............................... 45 ° Right or Left

Spindle Travel ........................ 3-1/8"

Throat ................................. 7-1/2"

Base Size ............................. 11" x 20-3/8"

Height ...................... :........... 63-1/4"

To avoid electrical hazards, fire hazards, or damage to

the tool, use proper circuit protection.

Your drill press iswired at the factory for 120V operation.

Connect to a 120V, 15 AMP branch circuit and use a 15

AMP time delay fuse or circuit breaker. To avoid shock or

fire, replace power cord immediately if it is worn, cut or

damaged in any way.

2

GENERAL SAFETYINSTRUCTIONS 14.

BEFORE USING THE DRILL PRESS

Safety is a combination of common sense, staying alert

and knowing howto use your ddll press. 15.

REMOVE ADJUSTING KEYS AND WRENCHES.

Form the habitof checking to see that keys and

adjusting wrenches are removed from the tool before

turning =ON".

NEVER LEAVETOOL RUNNING UNATFENDED.

TURN THE POWER "OFF". Don't leave the tooluntil

itcomes to a complete stop.

To avoid mistakes that could cause sedous injury, do not 16. NEVER STAND ON TOOL Sedous injurycould occur

plug the drillpress in until you have read and understood ifthe toolisUppedor ifthe cuffingtoolis unintentionally

the following: contacted.

1. READ and become familiar with this entire instruction

manual.LEARN thetool'sapplications,limitstJons,and

possiblehazards.

2. KEEP GUARDS IN PLACE and in workingorder.

3. DON'T USE IN A DANGEROUS ENVIRONMENT.

Don't use power tools in damp or wet locations, or

expose them to rain. Keep work area well lighted.

4. DO NOT use powertoolsin the presence offlammable

liquidsor gases.

5. KEEP WORK AREA CLEAN. Cluttered areas and

benches inviteaccidents.

6. KEEP CHILDREN AWAY.AUvisitorsshouldbe keptat

a safe distance from the work area.

7. DON'T FORCE THE TOOL. It Willdo the job better

and safer at the rate for which it was designed.

8. USETHE RIGHTTOOL. Don't force tool or the

attachment to do a job for which it was not designed.

.

WEAR PROPER APPAREL DO NOT wear loose

clothing, gloves, neckties, rings, bracelets, or other

_lowelrywhich may get caught in moving parts.

onslip footwear is recommended. Wear protective

hair covering to contain long hair.

10. WEAR A FACE MASK OR DUST MASK.

Drillingoperation produces dust.

11. DISCONNECTTOOLS before servicing, and when

changing accessories, such as blades, bits, ct_ttem,

and the like.

12. REDUCETHE RISK OF UNINTENTIONAL STARTING.

Make sure the switch is in "OFF"position before

plugging in.

13. USE RECOMMENDED ACCESSORIES. Consult the

owner's manual for the recommended accessories.

The use of improper accessories may cause risk of

injury to persons.

17. DON'T OVERREACH. Keep proper footing and

balance at all times.

18. MAINTAIN TOOLS WITH CARE. Keep toolssharp

and clean for best and safest performance. Follow

instructionsfor lubricating and changing accessories,

19. CHECK FOR DAMAGED PARrs. Beforefurther useof

the tool,a guard or otherpert that is damaged should

be carefully checked to determine that it willoperate

propertyand perform its intended function.Check for

alignmentof movingparts,bindingof moving parts,

breakage of parts, mounting,and any otherconditions

that may affect itsoperation.A guard or other part that

is damaged shouldbe properly repairedor replaced.

20. MAKEWORKSHOP laD PROOF withpadlocks,master

switches,or by removing starter keys.

21.

22.

DO NOT operatethe toolif you are underthe influence

of any drugs,alcohol or medication that could affect

your abilityto use the tool properly.

Dust generated from certain materials can be

hazardous to your health. Always operate the drill

press in a well-ventilated area and provide for proper

dust removal. Use dust coflectionsystems whenever

possible.

23. ALWAYS WEAR EYE

PROTECTION. Any ddll press

can throw foreignobjects into

the eyes which could cause

permanent eye damage.

ALWAYSwearSafety Goggles

(not glasses) thatcomplywith

ANSI safety standard Z87.1. Everyday eyeglasses

have only impact-resistant lenses. They ARE NOT

safety glasses.Safety Goggles are available at Seam.

NOTE: Glasses or goggles not in compliance with

ANSI Z87.1 could seriouslyhurtyou when they break.

SAVE THESE INSTRUCTIONS

3

SPECIFIC SAFETY INSTRUCTIONS

FOR THE DRILL PRESS

14.SECURE WORK. Usa clamps or viseto holdthe

work when practical.It'ssafer than using yourhand

and itfrees bothhandsto operatetool,

For yourownsafety,do nottry to use yourdrillpress or

plug itin untilit iscompletelyassembledand installed

accordingtothe instructions,and untilyou have read

and understoodthis instrucbonmanual:

15.WHEN usinga drillpressvise, always fastentothe

table.

16.MAKE SURE allclamps and locksare firmly

tightenedbeforedrilling.

1. YOUR DRILL PRESS MUST BE BOLTED securely

to a workbench. In addition,ifthere is anytendency

for yourdrillpressto move duringcertainoperations,

boltthe workbenchtothe floor.

2. THIS DRILL PRESS isintendedfor usa indry

conditions,indooruseonly.

3. WEAR EYE PROTECTION. USE face or dustmask

alongwithsafety gogglesifdrillingoperation isdusty.

USE ear protectors,especially duringextended

periodsofoperation.

4. DO NOT wear gloves, neckties,or looseclothing

5. DO NOT tryto drillmaterial too smallto be securely

held.

6. ALWAYS keephands out ofthe path of a drillbit.

Avoidawkward hand positionswhere a sudden slip

couldcause yourhandto move intothedrillbit.

7. DO NOT installor use any drill bit thatexceeds 175

mm (7") in lengthor extends 150 mm (6") below

thechuckjaws. They can suddenlybendoutwardor

break.

8. DO NOT USE wire wheels, router bits, shaper cutters,

circle(fly)cutters,or rotaryplanerson thisdrillpress.

17.SECURELY LOCK THE HEAD and table supper to

the column, and thetable to the table supportbefore

operatingthe drillpress.

18.NEVER turnyourdrillpresson beforeclearingthe

table of allobjects (tools,scrapsof wood, etc.)

19.BEFORE STARTING the operation,jog the motor

switchto make sure the drillbitdoes notwobbleor

vibrate.

20.LET THE SPINDLE REACH FULL SPEED before

startingtodrill.If yourdrillpress makes an unfamiliar

noiseor if itvibratesexcessively,stop immediately,

turnthe drillpress offand unplug.Do not restartuntil

the problemiscorrected.

21.DO NOT perform layoutassembly or set up work on

the tablewhilethe drill press isin operation.

22.USE RECOMMENDED SPEED for drill accessory

and workpiecematerial. SEE INSTRUCTIONS that

comewiththe accessory

23.WHEN DRILLING largediameter holes,clamp the

workpiece firmlytothe table. Otherwise, the bitmay

grapand spinthe workpieceat high speed. DO NOT

USE flycuttersor multiple-parf hole cutters,as they

cancome apart or become unbalancedin use.

9. WHEN cuttinga largepiece ofmaterial make sure it

isfully supportedat the table height.

24.MAKE SURE the spindle has come to a complete

stop before touching the workpiece.

10.DO NOT perform any operation freehand. ALWAYS

holdtheworkpiece firmly againstthe table so itwill

notreckor twist. Use clamps or a visefor unstable

workpiece.

11.MAKE SURE there are no nailsor foreign objectsin

the partofthe workpieceto be drilled.

12.CLAMP WORKPIECE OR BRACE against the left

side ofthe columnto prevent rotation.Ifit is too short

or thetable istilted, clamp solidlyto the table and use

the fence provided.

25.TO AVOID INJURY from accidental starting,always

turnthe switch"OFF" and unplugthe drill press

beforeinstallingor removing any accessoryor

attachmentor makingany adjustment

26.KEEP GUARDS IN PLACE and inworkingorder.

27.USE ONLY SELF-EJECTING TYPE CHUCK KEY as

providedwiththedrill press

13.IF THE WORKPIECE overhangs the table such that

it will fall or tip if not held, clamp it to the table or

provide auxiliary support.

SAVE THESEINSTRUCTIONS

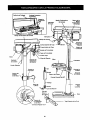

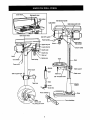

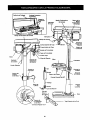

GROUNDING INSTRUCTIONS

IN THE EVENT OF A MALFUNCTION OR

BREAKDOWN, groundingprovidesa path of least

resistancefor electriccurrentand reducesthe riskof

shock.Thistoolis equipped withan electriccordthat

hasan equipmentgroundingconductorand grounding

plug.The plugMUST be pluggedintoa matching

receptacle that isproperlyinstalledand grounded in

accordancewithALL localcodesand ordinances.

DO NOT MODIFY THE PLUG PROVIDED. If it willnotfit

the receptacle,have the properreceptacleinstalledbya

qualifiedelectdcian.

Thistoolis intendedfor use on a circuitthathas a

receptaclelike theone illustratedin'FIGURE A.

FIGURE A shows a 3-prongelectricalplug and

receptaclethathas a groundingconductor.Ifa pmparly

groundedreceptacle isnotavailable,an adaPter

(FIGURE B) can be usedto temporarilyconnectthis

plugto a 2-contact ungroundedreceptacle.The adapter

(FIGURE B) hasa rigidlugextendingfrom itthatMUST

be connectedtoa permanent earth ground,such as a

properlygrounded receptacle box. THE TEMPORARY

ADAPTER SHOULD BE USED ONLY UNTIL A

PROPER GROUNDED OUTLET CAN BE INSTALLED

BY A QUALIFIED ELECTRICIAN. The Canadian

ElectricalCode prohibitsthe use of adapters.

IMPROPER CONNECTION oftheequipmentgrounding

conductorcan result inrisk ofelectricshock.The

conductorwiththe green insulation(withor without

yellowstripes)isthe equipmentgroundingconductor.If

repair or replacementofthe electriccordor plug is

necessary,DO NOT connectthe equipmentgrounding

conductorto a liveterminal.

CHECK with a qualified electrician orservice personnel

ifyou do notcompletelyunderstandthegrounding

instructions,or ifyou are notsure the toolisproperly

grounded.

USE ONLY 3-WIRE EXTENSION CORDS THAT HAVE

3oPRONG GROUNDING PLUGS AND 3-POLE

RECEPTACLE THAT ACCEPT THE TOOL'S PLUG.

REPAIR OR REPLACE DAMAGED OR WORN CORD

IMMEDIATELY.

CAUTION: In all cases, make certainthe receptaclein

questionisproperlygrounded. Ifyou are notsure have a

certifiedelectriciancheckthe receptacle.

This drill press is for indoor use only. Do not expose to

rain or use in damp locations.

Flg. A

3-Prong Plug

_" p.rGprroP_o°nl_;_o_nrin;e

GUIDELINES FOR EXTENSION CORDS

Fig. B

GroundingLug

Make sure yourextension cord is ingood condition.

When usingan extensioncord, be sure touse one heavy

enoughtocarrythe current yourproductwilldraw. An

undersizedcordwillcause a dropin line voltage

resultingin lossof powerand overheating.The table

belowshowsthecorrectsize to use accordingtocord

length and nameplate ampere rating. Ifin doubt, usethe

nextheaviergauge. The smallerthe gauge number,the

heavierthecord.

Adapter

is Connected to a

Known Ground

Be sure your extension cord is properly wired and in

goodcondition.Always replace a damaged extension

cordor have itrepaired by a qualifiedperson before

usingit. Protectyourextensioncordsfrom sharpobjects,

excessiveheatand damp or wet areas

rdI_hV_lll_[e_-*ll[el naal] :s :1,:(ii :1_K'I[el _ [l(e] _| i},.llr:t tjLt/t.

Use a separate electrical circuit for your tools. This

circuit must not be less than #12 wire and should be

protected with a 15 Amp time lag fuse. Before

connecting the motor to the power line, make sure the

switch is in the OFF position and the electric current is

rated the same as the current stamped on the motor

nameplate. Running at a lower voltage will damage the

motor.

This tool mustbe grounded while in useto protect the

operator from electrical.

(When usinc

6,mpere Rating

more than not more than

0 6

6 10

10 12

12 16

SAVE THESE INSTRUCTIONS

120 volts only)

Total length of cord in feet

25' 50' 100' 150'

18 16 16 14

18 16 14 12

16 16 14 12

14 12 Not recommended

RECOMMENDED ACCESSORIES UNPACKING AND CHECKING CONTENTS

r_r/_J=-KqKE=]

Use onlyaccessorierrecommended for this drillpress.

Followinstructionsthataccompany accessories.Use of

improperaccessoriesmay cause hazards.

VisityourSears Hardware Department or see the

CraftsmanPower and Hand Tools Catalog for the

following accessories:

• Drillbits

• Hold-Downand Guide

• DrillpressVises

• Clamping kit

Ifany part ismissingor damaged, do not plugthe drill

pressin untilthe missingor damaged part isreplaced,

and assemblyiscomplete.

Carefullyunpackthe drill press and all itsparts,and

compare againstthe list below.

To protectthe drillpress from moisture,a protective

coatinghasbeen appliedtothe machinedsurfaces.

Remove thiscoating with a softclothmoistenedwith

keroseneor WD-40.

.r_rArl,_1d_11_[e

Use onlyaccessoriesdesigned for this drill pressto avoid

injuryfrom thrownbrokenparts or workpieces.

Sears may recommend otheraccessoriesnot listedin

this manual. See your nearest Sears store or Power and

Hand Tool Catalog for other accessories.

Do not use may accessoryunless you have completely

readthe instruction or operator'smanual for that

accessory.

To avoidfire or toxic reaction, never use gasoline,

naphtha,acetone, lacquerthinneror similarhighly

volatilesolventstoclean the drillpress.

TABLE OF LOOSE PARTS

ITEM DESCRIPTION QUANTITY

A. Head assembly t

B. Table 1

C. Base 1

D. Column assembly 1

Loose partsbag:

E. Feed handle

F. Lock handle

G. Crank Handle

H. Hex botts

I. Fence assembly

J. Triangle knobs

K. T-Block

L, Washer

M. Hex wrenches

N. Wedge

O. Arbor

Boxz

P. Chuckkey

Q. Chuck

3

1

1

4

1

2

2

2

3

1

1

Page is loading ...

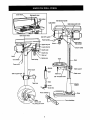

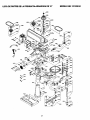

Coverknob

\

Beltguardcover

Beltpulleys

Lightswitch

Belttensionhandle

Belttensionlock knob

Belttensionknob

Motor

Cordclamp

Power cord

Table support I(

Feedspring

Bevelscale

• Upperstopnut

- Lowerstopnut

Depthscale

Depthstop

Stopnut

Springcap

-- Spindle

• Quill

Table

Tablelock

5/8"Threadeddrain

Set screws

Tablesupport

Tablearm

-.-Arbor

(_Chuck

Chuckkey

Column

support

Fenceend_\

BevelLock V _"_,,_

)'Locking setscrew

Fencebackstop

BASE - Supportsdrillpress.For additionalstability,

holesare providedin base toboltdrillpressto floor.

(See "Specific Safety Instruction for DrillPresses.")

BACKUP MATERIAL - Apiece ofscrapwood placed

betweenthe workpieceand table. The backupbeard

preventswood in the workpiecefrom splintedngwhen

the drillpassesthroughthe backsideoftheworkpiece.It

alsopreventsdrillingintothe table top.

BELT GUARD ASSEMBLY - Covers the pulleysand

beltduringoperationof the drillpress.

BELT TENSION - Refer to the"Assembly" Section,

"Installingand Tensioning Belt.".

BELT TENSION HANDLE - Turn thehandle clockwise

toapply tensionto belt, turnthe handle counterclockwise

to release belttension.

BELT TENSION LOCK KNOBS - Tighteningthe knobs

locksthemotorbracket supportand the belttension

handle,maintainingcorrectbeltdistanceand tension.

BEVEL SCALE - Shows degree of table tilt for bevel

operaions. The scale ismounted on the side ofthe arm.

CHUCK - Holdsdrill bit or otherrecommended

accessoryto performdesired operations.

CHUCK KEY - A self-ejectingchuckkey whichwillpop

outofthe chuckwhen you let go of it.This actionis

designedto help preventthrowingofthe chuck keyfrom

thechuckwhen the peer isturned ON. Do not useany

otherkey as a substitute; ordera newone if hamaged or

lost.

COLUMN - Connects the head, table, and base on a

one piecetube for easy alignment and movement.

COLUMN COLLAR - Holds the rack to the column.

Rack remains movablein the collarto permit table

support movements.

COLUMN SUPPORT - Supports the column, guides the

rack and providesmountingholesfor columnto base.

DEPTH SCALE STOP NUTS - Lock the spindle to the

selected depth.

DEPTH SCALE - Indicates depth of hole being drilled.

DRILL BIT - The cutting tool used in the drill press to

make holes in a workpiece.

DRILL ON/OFF SWITCH - Has lockingfeature. This

feature is intended to help preventunauthorizedand

possible hazardous use by children and others. Insert

the key into the switch to turn the drill press on.

DRILLING SPEED - Changed by placingthe belt in any

of the steps(grooves) inthe pulleys.See the Spindle

Speed Chart insidebeltguard.

FEED HANDLE - Moves the chuckup or down.IF

necessary, one ortwo ofthe handles may be removed

whenevertheworkpiece isof suchunusualshape thatit

interfereswith thehandles.

FENCE - Attaches tothe table to alignthe workpieceor

for fast repetitivedrilling.Removable. Removefence

when itinterfereswith otherdrillpress accessories.

HEAD LOCKS - Locks the head tothe column.

ALWAYS lockthe head in placewhile operatingthedrill

press.

RACK - Combines withgear mechanism to provide

easy elevationofthe table by thehandoperated table

crank.

REVOLUTION PER MINUTE (R.P.M.)- The numberof

turns completedbya spinningobjectin one minute.

SPINDLE SPEED - The RPM. ofthe spindle.

SPRING CAP - Adjusts quill spring tension.

TABLE SUPPORTS LOCK - Tighteninglocksthe table

supporttocolumn.Always haveit lockedin placewhile

operatingthe dirllpress.

TABLE - Provides a working surface to supportthe

workpiece.

TABLE ARM - Extends beyond the table supportfor

mounting and aligning the table.

TABEL BEVEL LOCK - Locks the table in anyposition

from 0° - 45°

TABLE CRANK - Elevates and lowers the table. Turn

clockwise to elevate the table. Support lock must be

released before operating the crank.

TABLE LOCK - Locksthe table after it is rotated to

variouspositions.

TABLE SUPPORT - Rides on the column to supportthe

table arm and table.

THREADED DRAIN (518")- Attach a 5/8" (pipe

threaded) metal pipe to the threaded opening for

drainingexcees oilintocontainer.Fora non-draining

surfaceattacha threaded metal plug.Pipe and plugnot .

included.

WORKPIECE - Material being drilled.

ASSEMBLY INSTRUCTIONS

Foryourownsafety,neverconnectplugtopower

sourceoutletuntilall assemblyand adjustmentsteps

arecompleted, andyou havereadand understood

the safetyandoperatinginstructions.

TOOLS NEEDED

_ w_encb

III t lilt IIIt_

Frw_ing

8"S 10"AdJustab__

Comb_e_m_tre

The DdlTPressisvery heavyand MUST be liftedwiththe

helpof 2 PEOPLE OR MORE, to safetyassembly it.

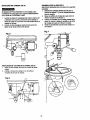

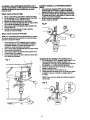

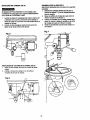

COLUMN SUPPORT TO BASE (FIG. A)

1. Position the base (1) on the floor.

2. Place the column (2) on the base, aligning the

holes in the column support with the holes in the

base.

3. Locate the four long hex bolts (3) from the loose

parts bag.

4. Place a bolt in each hole through the column

support and the base. Tighten with an adjustable

wrench.

i

INSTALLING THE TABLE (FIG. B and C)

1. Locate the table crank (1) and support lock (2) from

the loose parts bag.

2. Insert the support lock handle intothe hole (3) at

the rear of the table support assembly. Tighten by

hand.

3. InstaJIthe table crank handle (3) onto the small

shaft (4), aligning the set screw (5) with the flat

surface of the shaft (4), aligning the set screw (5)

with the fiat surface of the shaft. Tighten the set

screw with a hex wrench.

10

Rg. B

4. (FIG. C) Loosen the support lock (2). Raise the

table arm assembly by turning the crank handle (1)

clockwise. Tighten the support lock.

5. Place the table (6) in the table arm assembly.

Tighten the table lock handle (7).

Rg. C

INSTALLING EXTENSION WING

1. Place the handle (OWVG) onto the upper tube

(OWVH).

2. Place the flat washers (OT6T) onto the hex head

bolts (OJUB). Insert the bolt (OJUB) intothe upper

tube (OWVH), and tighten.

3. Insertthe hes head bolts (OJUB) onto the upper

tube (OJUB) and tighten.

4. Place the upper tube assembly under the table.

5. Place the set plate (OWVJ) ontothe clamp bolt

(OWVK). Insert the set plate assembly intothe

table and tighten.

NOTE: If length adjustment is necessary, loosen

the clamp bolt (OWVK) to the desired length and

tighten the clamp bolt.

OWVE

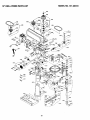

INSTALLING THE HF.AD (FIG. D)

mvl/_d_ql K_

The DrillPress h_d Is very heavy and MUST be lifted

with the help of 2 PEOPLE OR MORE,to safely

assemble the Drill Press head on the column.

1. Carefully lift the head (1) above the column (2) and

slide it ontothe column.Make sure the head slldea

down over the column as far as poealble.Algn the

head with the base.

2. Using the hexwrench, tighten the two head lock eat

screws (3) on the right side ofthe head.

Fig. D

"ry

J

_3

INSTALLING FEES HANDLES(FIG. E)

1. Locate three feed handles in the loose parts bag.

2, Screw the feed handles (1) into the threaded holes (2)

in the hub (3), Tighten

FENCE ASSEMBLY (FIG. F)

This drill press has a channeled table top.

1. Determine the desired location for the fence (1).Sllde

theT-blocks (2) Into the appropriate channels as

shown

2. Align the mounting holes ofthe fence over theT-block's

threaded hloes.

3. Place a washer (3) on the threaded end of the knob (4).

Insert the knob through the mounting hole of thefence

into theT-block,and Ugbetan.

4. Repeatfor the other knobandT-block.

Fig. F

11

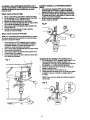

INSTALUNG THE CHUCK (FIG. G, H, and I

1. Clean out the tapered hole In the chuck (1) wltha

CkHlndoth.

2. Clean taperedsurfacasonthe arbor(2) and spindle(3).

CAUTION: Make sure there am no foreignparticles

stk:kingto the surfaces.The slightestpiece ofdirt on

any of these surfaces willprevent the chuck from

seating properly.This willcause the ddll chuck and

bit to wobble. Iftapered hole is extremely dirty, use a

cleaning solvent.

Fig. G

7. Using a robber mallet, plastic-tippedhammer, or a

mOCKOTwood and a hammer, firmlytap the chuck

upward intoposi_n on the spindle shaft.

Fig. I

3. 4(FIG. H) Push the chuck(1) ontothe spindle

arbor (2). Tap gentlyto ensure seat.

4. 5Lower the spindle byturning thefeed handles (8)

countemlockwise, untilthe slot (4) appears on the

quill (5).

5. Push the chuck and spindlearborup intothe spindle,

making sure the tang (6) (upper narrow end of the

spindle arbor shank) is engaged and lockedin the

inner slot (7) of the spindle.This can be seen

throughthe outer slot (4) of the quillby rotatingthe

chuck and arbor untilthe two slotsare aligned.

6. Open the jaws of the chuck (1) by rotatingthe chuck

sleeve clockwise.To preventdamage, make sure the

jaws are completely receded intothe chuck.

Fig. H 4 _. "----,_ I

INSTALLING UGHT BULB (RG. J) (not Included)

1. Installa light bulb(no larger than 60 watt)intothe

socket inside the head.

Fig. J

12

DRILL PRESS ADJUSTMENTS

CAUTION: All the adjustments for the opera,on of the

ddl press have been completed at the lectory.Due to

normalwear and use, some occasionalmadjustmente

may be necessary.

!_W_,I -'l_l_[el

Topreventpersonalinjury,a dysciscor. thepaugfnxn

the powersourcewhen ma;dnganyadjustments

SQUARING TABLE TO HEAD (RG. K and L)

NOTE: The table arm and supporthas a preddlledhole

witha lockingset screw insertedfor lockingthe table to

a predetermined0° horizontal_. Itmustbe loosened

to change the angle of the table.

1. Insert a 1/4", or larger diameter,precisionground

stsetrod(1), approximately3" long,intothechuck(2).

Tighten the chuckjaws.

2. Raise table to workingheightand lock.

3. Usingthe combinationsquare (3), placeena edge

fiat on the tebie, and alignthe other edge verlfoally

beside the rod (1).

Fig. K

Fig. L

5

6

4

7

BEVEL SCALE (FIG. L and M)

NOTE: The bevel scale has been included to measure

approximate bevel angles. If precision is necessary,

a square or othermeasuring toolshould he used to

positionthe table.To use the bevel scale (7):

1. Loosenthe Ioddngset screw (4) to RELEASE itfrom

the table support.

2. Loosen the large hex head bevel lockingbolt(6).

2

1

3

I I I I I I I I I I I I

[

4. If an adjustment is necessary,loosen thelockingset

screw (4) with the 3 mm hex key to RELEASE the

table from the horizontal position.

5. Loosen the large hex head bevel lockingbolt(6).

Tolprevent injury,be sure to hold the table &table arm

assembly,so it willnot swivelor tilt.

6. Alignthe square to the red byrotating the table until

the square and rodare in line.

7. Retightenthe large bex belt. (6).

To prevent injury,be sure to holdthe table & table arm

assembly,so it willnot swivel or tilt.

3. Tilt the table,aligningthedesired angle measurement

to the zero line oppositethe scale (7).

4. Tighten the bevel lockingbolt. (6).

5. To returnthe table to itsoriginalposition,loosen the

bevel lockingbolt (6). Realignthe bevel scale (7) to

the 0° position.

6. Tighten the lockingset screw(4) untilit is seated in

the horizontal 0_hole of the table support.

Fig. M

5

6

7

13

_[wr_,1=t_'llKl[e_

To prevent personalinjury,always disconnect plug

from the power sourcewhen making any adjustment.

SPINDLE I QUILL (FIG. N)

Rotate the feed handles counterclockwiseto lower

spindleto its lowestposition.Hand supportthe

spindlesecurely and move itback and fortharound

the axis. If there is too much play,do the following:

1. Loosenthe lock nut(1).

2. Turn the screw (2) clockwiseto eliminate the play,

butwithoutobstructingthe upward movement of

the spindle. (A littleplay in the spindleisnormal.)

3. Tighten the lock nut(1).

Fig. O

Fig. N

QUILL RETURN SPRING (FIG. O)

The quillreturnspring may need adjustment ifthe

tensioncause the quillto returntoo rapidly or too

slowly.

1. Lowerthe table for additionalclearance.

2. Placea screwdriverin the lower front notch(1) of

the springcap (2). Hold it in place while loosening

and removingonlythe outerjam nut (3).

3. With the screwdriverstillengaged inthe notch,

loosenthe inner nut(4) just untilthe notch(5)

disengagesfrom the boss (6) on thedrillpress

head.

CAUTION: DO NOT REMOVE THIS INNER NUT,

because the springwill forcibly unwind.

4. Carefully turn the spring cap (2) counterclockwise

with the screwdriver, engaging the next notch.

5. Lower the quill to the lowest position by rotating the

feed handle in a counterclockwise direction while

holding the spring cap (2) in position.

6. If the quill moves up and down as easily as you

desire, tighten the standard nut (4) with the

adjustable wrench. If too loose, repeat steps 2

through 5 to tighten. If too tight, reverse steps 4 and

5.

DO NOT OVERTIGHTEN and restrict quill

movement.

7. Replace the jam nut (3) and tighten against the

standard nut (4) to prevent the standard nut from

reversing.

2

To avoidinjury from an accidental start, ALWAYS

make sure the switch is in the "OFF" position, the

switch key is removed, and the plug is not connected

to the power source outlet before making belt

adjustments.

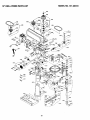

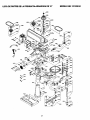

BELT TENSION (FIG. P)

Make sure pulleysare alignedproperly as shown in

FigureR on page 15.

1. To unlockthe belt tension,turnthe belt tensionlock

knobs (1) on each side of the drillpresshead

counterclockwise.

2. Tightenthe belts by turningthe belt tension handle

(2) clockwise.

3. Loosenthe beltsby turning the belt tensinhandle

(2) counterclockwise.Set belts on pulleystepsfor

desired speed.

4. Lockthe belt tensionlockknobs(1) byturning

clockwise.

NOTE: Belt tension is correct ifthe belt deflects

approximately 1/2 inch when pressed at itscenter.

Fig. P

14

_vlvh_=1_[I

To avoid injury from an accidental start, ALWAYS

make sure the switch is in the "OFF" position, the

switch key is removed, and the plug is not connected

to the power source outlet before making belt

adjustments.

ALIGNING THE BELT PULLEYS (FIG. N)

Open the head cover of the Drill Press. Check

alignment of the pulleys with a straight edge (5) such

as a framimg square, a level, or a piece of a wood.

Lay the straight edge across the top of the pulleys. If

all three pulleys are NOT aligned:

1. Release belt pressure by loosening the belt tension

lock knobs (4) on either side of the head, unlocking

the belt tension handle (1).

2. Loosen the motor mount nuts (2). Lift or lower the

motor (3) until the pulleys are in line.

3. Tighten the motor mount nuts (2) using an

adjustable wrench.

NOTE: To avoid rattles or other noise, the motor

housing should not touch the lower belt guard

housing.

4. Retighten the belts by turning the belt tension

handle (1) clockwise, until the belt deflects

approximately 1/2 inch when pressed in the center.

NOTE: Refer to the chart inside the belt guard

cover for recommended drilling speeds and

belt/pulley positions.

5. Lock the belt tension lock knobs (4) by turning

clockwise.

NOTE: When the belts are new, it may be difficult to

move the belts. As the machine is used, the belts will

gain more elasticity and will be easier to adjust.

Fig. Q

BASIC DRILL PRESS OPEATIONS

SPEEDS AND BELT PLACEMENT (FIG. R)

This drill press has 12 speeds, as listed below:

250 RPM 600 RPM 1620RPM

340 RPM 650 RPM 1900RPM

390 RPM 990 RPM 2620 RPM

510 RPM 1550 RPM 3100RPM

See inside of the pulley guard for specific placement

of the belts on the pulleys to change speeds.

To avoid possible injury, keep guard closed, in place,

and in proper working order while tool is in operation.

Fig. R

9

250 trim_

o

510 tdmin

i

9

9

9

9

9

9

Q

9

9

3100 tr_lin

1 4 3

15

ON I OFF SWITCH PANEL (FIG. S)

The "ON I OFF" switchhas a removable, yellow

plastickey.With the key removed from the switch,

unauthorizedand hazardous use bychildrenand

otheris minimized.

1. To turnthe drillpress "ON', insertkey (1) intothe

slotof theswitch(2), aqd movethe switchupward

to the"ON" position

2. To turnthedrillpress"OFF', movethe switch

downward.

3. To lockthe switchinthe =OFF"position, graspthe

end,or yellowpart,of the switchtoggle, and pullit

out.

4. Withthe switchkey removed, theswitchwillnot

operate.

5. If theswitchkey is removedwhilethe drillpress is

running,itcan beturned "OFF"butcannotbe

restartedwithoutinsertingthe switchkey.

6. To turnthe worklight"ON", pressthe rockerswitch

(3).

7. Never leavethe drillpressunattended. Turn the

lightswitchand powerswitch"OFF" and waituntilit

comesto a completestop.

Rg. S

f

m

_3

--2

BI

ALWAYS lock theswitch"OFF" when the drill press is

not in use. Remove the key and keep it in a safe place.

In the event of a power failure, blown fuse, or tripped

circuit breaker, turn the switch "OFF" and remove the

key, preventing an accidental startup when power comes

on.

INSTALLING DRILL BIT IN CHUCK (FIG. T)

1.With theswitch"OFF"and the yellow switchkey

removed, openthe chuckjaws (1) usingthe chuckkey

(2). Turn thechuck key counterclockwiseto openthe

chuckjaws (1).

2. Insertthe drillbit (3) into the chuck far enoughto

obtainmaximum grippingbythejaws, butnot far

enoughtotouchthe spiralgrooves(flutes) ofthedrill

bitwhenthe jaws are tightened.

3. Make surethat the drillis centered inthe chuck.

4. Turn the chuckkey clockwiseto tightenthejaws.

To avoidinjury or accident by the chuckkey ejecting

forcibly from the chuck when the power is turned "ON",

use only the self-ejecting chuck key supplied with this

drill press.ALWAYS recheck and remove the chuck key

before turning the power"ON".

Fig.T

To preventthe workpieceor backup materialfrom being

tom from your hands while drilling, you MUST position

the workpiece against the LEFT side of the column. If the

workpiece or the backup material is not long enough to

reach the column, clamp them to the table, or use the

fence provided with the drill press to brace the workpiece.

Failure to secure the workpiece could result in personal

injury.

USING THE FENCE (FIG. U)

The fence provides a way of accuratelyand quickly

settingup the workpiecefor more precisionorfor repitive

drillingoperations.

1. Usingthecenterpunchor sharpnail, make an

indentationin the workpiecewhere _ou wantto drill.

2. Lowerthe drillbit toalignwith the indentationon the

workpiece.See "HOLDING A DRILLING LOCATION"

page 19.

3. Loosenthe knobs(1) and slidethe fence backstop (2)

firmly againstthe longside ofthe workpiece.Tighten

the knobswhen inposition.

4_ Loosenthe wingnut (3) and slidethe end stop(4)

alongthe fence untilitisfirmly againstthe leftsideof

the workpiece.Tightenthe wing nut.

5. Check the accuracybydrillinga scrapworkpiece.

Adjust ifneeded.

6. Holdwithyourhandor clamp thetop surface ofthe

workpiecefirmly toprevent it from liftingoff thetable

when the bit is raised.

Fig. U

234

16

DRILLING TO A SPECIFIC DEPTH (FIG. V)

Drillinga blindhole (not all the way throughworkpiece)

toa givendepthcan be done twoways:

Workpleca method

1. Mark the depth(1) ofthe holeon the side ofthe

workpiece.

2. W'_ththe switch"OFF", bringthe drillbitdownuntil

thetip iseven with themark.

3. Hold thefeed handle (2) at thisposition.

4. Spinthe lowernut (3) downtocontactthe depth

stop(4) on the head.

5. Spinthe upper nut(5) down and tightenagainstthe

lower nut (3)..

6. The drillbitwill nowstopafter travelingthe distance

marked on theworkpiece.

Depth scale method

Note: With the chuckup the tipof'the drillbit mustbe

just slightlyabove thetop of theworkpiece.

1.With theswitch"OFF", turn the feed handle (2) until

depth stop (4) points to the desired depth on the

depth scale (6) and hold the feed handle in that

position.

2. Spin the lower nut (3) down to contact the depth

stop (4).

3. Spin the upper nut (5) against the lower stop nut (3)

and tighten.

4. The drill bit will stop after traveling the distance

selected on the depth scale.

Fig. V

LOCKING THE CHUCK AT THE DESIRED DEPTH

(FIG. W)

1. Withthe switch"OFF",turnthe feed handlesuntilthe

chuck (1) isat the desireddepth_Hold the feed

handlesat this position.

2. Turn the stopnut (2), located underthe depthstop

(3), counterclockwiseand upwards,untilitisagainst

the depthstop.

3. The chuckwillnow be heldat this positionwhen the

feed handlesare released.

Flg.W

REMOVING CHUCK AND ARBOR (FIG. X)

1. With the switch"OFF", adjust thedepth stopnut(1) to

holdthedrillat a depthofthree inches. (See

instructionsfor "LOCKING CHUCK AT DESIRED

DEPTH").

2. Align the key holesinthe spindle(2) and quill(3) by

rotatingthe chuckbyhand.

3. Insertthe key wedge (4) into the key holes(2 & 3).

4. Tap the key wedge (4) lightlywith a plastictipped

hammer, until the chuckand arborfall out ofthe

spindle.

NOTE: Place one hand below the chuck to catch it

when it falls out.

Fig. X

S

4

17

BASIC OPERATION INSTRUCTIONS

To getthe bestresultsand minimizethe likelihoodof

personalinjury,follow these instructionsfor operating

yourdrillpress.

Foryourownsafety, always observethe SAFETY

INSTRUCTIONS listedhere and on pages 3, 4 and 5

ofthe instructionmanual.

YOUR PROTECTION

To avoidbeing pulledintothe powertool,do notwear

looseclothing,gloves,neckties,orjewelry. Always tie

backlonghair.

1. If any part ofyour drill press is missing, malfunctioning,

damaged or broken, stopoperation immediatelyuntil

that partis properlyrepairedor replaced.

2. Never placeyourfingers in a positionwhere they

couldcontactthe drillbitor othercuttingtool. The

workpiecemay unexpectedlyshift,or your handcould

slip.

3. To avoidinjuryfrom partsthrownbythe spring,follow

instructionsexactlywhen adjustingthe springtension

of thequill.

4. To preventheworkpiecefrom being tornfrom your

hands,thrown,spunby the tool,or shattered, always

properlysupportyourworkpiece as follow:

a. Always positionBACKUP MATERIAL (used

beneathworkpiece) sothat itcontactsthe left

sideofthe column,or use the fence providedand

a clamp to brace a small workpiece.

b. Whenever possible,positiontheWORKPIECE to

contactthe leftside ofthe column. Ifit istoo short

or thetable istilted, usethe fence providedor

clampsolidlyto the table, usingthe table slots.

c. When usinga drillpressvise, always fasten itto

thetable.

d. Never do anywork freehand (hand-holdingthe

workpieceratherthan supportingiton the table),

exceptwhen polishing.

e. Securelylockthe head and supporttothe column,

thetable arm tothe support,and the table tothe

tablearm, beforeoperatingthe drillpress.

f. Never movethe head or the table while thetool is

running.

g. Beforestartingan operation,jog the motorswitch

tomake sure the drillor othercuttingtooldoes not

wobble orcause vibration.

h. Ifa workpieceoverhangsthe table so itwillfall or

tip ifnot held,clamp ittothe table or provide

auxiliarysupport.

i. Use fixturesfor unusualoperationsto adequately

hold,guide,and positionworkpiece.

j. Use the SPINDLE SPEED recommended for the

specificoperation and workpiecematerial. Check

the panel on the insidepulleycover or the chart

belowfor drillingspeed information.For

accessories,refer tothe instructionsprovidedwith

eachaccessory.

5. Never climbon the drillpresstable, it couldbreak

or pullthe entiredrillpressdownon you.

6. Turn the motorswitch"OFF", and putaway the

switchkey when leaving the drillpress.

7. To avoidinjuryfrom thrownwork or toolcontact,do

notperfornlayout, assembly,or set up work on the

table whilethe cuttingtool isrotating.

DRILLING SPEED TABLE (rpm)

Drill Bit Material

Diam. Wood 6.1umi- Plastic Mild Stain-

(Inches) mum Steel less

1/32 3100 3100 3100 3100 3100

1620

1/16 2620

1620 990

1/8 2620 1550

990 600

3/16 1550 650

1620 1620

1/4 2620 2620

600 340

5/16 650 510

990 990

3/8 1550 1550

1630 340 250

7/16 2620 510

600 600

1/2 650 650

9/16

5/8

18

POSITIONING THE TABLE AND WORKPIECE

(FIG. Y and Z)

1. Lockthetable (1) to thecolumn(2) at a positionso

thetipofthe drillbit (3) is just abovethe topofthe

workpiece(4).

2. ALWAYS place a BACK-UP MATERIAL (scrap

wood)on the table beneaththe workpiece.Thiswill

preventsplinteringor heavyburringon the

undersideof theworkpiece. To keep the back-up

material from spinning out of control, it MUST

contact the LEFT side of the column.

To prevent the workpiece or backup material from being

torn from your hands while drilling, you MUST position it

against the LEFT side of the column. If the workpiece or

the backup matedal is not long enough to reach the

column, use the fence provided with the drill press to

brace the workpiece. Failure to do this could result in

personal injury.

HOLDING A DRILLING LOCATION

1. Usinga centerpunchor sharpnail,make an

indentationintheworkpiecewhereyouwantthe

hole.

2. Usingthefeed handles,bdng thedrilldowntoalign

withthe indentationbeforeturningthedrillON.

TILTING THE TABLE (FIG. AA)

NOTE: The table arm and support (1) has a preddlled

hole with a locking set screw inserted for locking the

table into a predetermined 0 ° horizontal position.

1. To use the table in a bevel (tilted) position, turn the

locking set screw (2) with the hex key

counterclockwise to release it from the table

support.

2. Loosen the large hex head bevel locking bolt (3).

_t

To prevent injury,be sure to hold the table& table

arm assembly, so it will not swivel or tilt.

Fig. Y

2

Fig. AA

\

3. For small pieces that cannot be clamped to the

table, use a drill press vise (optinal accessory).

The drill press vise MUST be clamped or bolted to the

table to avoid injury from a spinning workpiece, or

damaged vise or bit parts.

Remove the drill press fence when it interferes with other

drill press accessories.

Fig. Z

3. Tilt the table, aligning the desired angle

measurement to the zero line opposite the scale (4).

Tighten the bevel locking bolt.

4 To return the table to its original position, loosen

the bevel locking bolt (3). Realign the bevel scale (4)

to the 0° position

5 Using the hex key, turn the locking set screw (2)

clockwise to seat into the hole.

To avoid injury from spinning work or tool breakage,

always clamp workpiece and backup material

securely to the table before operating the drill press

with the table tilted

FEEDING

1. Pull down the feed handles with only enough effort

to allow the drill bit to cut.

2 Feeding too slowly might cause the drill bit to burn.

Feeding too rapidly might stop the motor, cause the

belt or drill to slip, or tear the workpiece loose and

break the drill bit

3. When drilling metal, it may be necessary to

lubricate the drill bit tip with motor oil, to prevent

burning the tip.

19

MAINTAINING YOUR DRILL PRESS

Foryourownsafety, turnthe switch=OFF"and remove

theplugfrom the powersourceoutletbeforemaintaining

or lubricatingyourdrillpress.

Frequentlyblow out, usingan air compressoror dust

vacuum,anydustthat accumulatesinsidethe motor.

A coatofautomotivepastewax appliedto thetable and

columnwillhelpto keep the surfaceclean.

To avoidshock or fire hazard, ifthe powercordiswornor

cutin anyway, have itreplaced immediately.

LUBRICATION

Allofthe drillpressball bearingsare packedwith grease

at the factory. They requireno further lubrication.

Periodicallylubricatethe gear and rack, table elevation

mechanismofthe spindlethe rack(teeth) ofthequill.

20

TROUBLESHOOTING GUIDE

To avoidinjuryfrom an accidentalstart,turnthe switch"OFF" and always removethe plugfrom thepowersourcebefore

makinganyadjustment.

• ConsultyourlocalSears Service Center iffor any reasonthemotorwillnotrun.

PROBLEM

Noisyoperation

Drill bit burn.

Runoutof drill bit point -

drilled holenot round.

Wood splinters on

underside.

Workpiece torn loose from

hand.

Drill bit binds inworkpiece.

Excessive drill bit runout

orwobble.

Quill returns too slow or

too fast.

Chuck will not stay

attached to spindle. It falls

off when trying to install.

POSSIBLE CAUSES

1. Incorrectbelttension.

2. Dry spindle.

3. Loose spindlepulley.

4. Loosemotor pulley.

1. Incorrect speed.

2. Chips notcomingout of

hole.

3. Dull drill bit.

4. Feeding too slowly.

5. Not lubricated.

1. Hand grain in wood or

lengths of cutting flutes

and/or angles not equal.

2. Bent drill bit.

1. No backup material under

workpiece.

1.Not supported or clamped

properly.

1. Workpiece pinching drill bit,

or excessive feed presure.

2. Improper belt tension.

1. Bent drill bit.

2. Worn bearings.

3. Drill bit not propedy installed

in chuck.

4. Chuck not properly installed.

1. Spring has improper tension.

1. Dirt, grease, or oil on the

tapered inside surface of

chuck or on the spindle's

tapered surface.

REMEDY

1. Adjust tension. See Section

"ASSEMBLY - TENSIONING BELT"

2. Lubricate spindle.See Section

"LUBRICATION".

3. Check tightness of retaining nut on pulley, and

tighten if necessary.

4. Tighten set screw in motor pulley.

1. Change speed. See Section" BASIC DRILL

PRESS OPERATION - SPINDLE SPEEDS"

2. Restract drill frequently to clear chips.

3. Resharpen drill bit.

4. Feed fast enough - allow drill to cut.

5. Lubricate drill. See Section "BASIC DRILL

PRESS OPERATION-FEEDING"

1. Resharpen drill bit correctly.

2. Replace drill bit.

1. Use backup material. See Section "BASIC

DRILL PRESS OPERATION".

1. Support workpiece or clamp it. See Section

"BASIC DRILL PRESS OPERATION".

1. Support workpiece or clamp it. See Section

"BASIC DRILL PRESS OPERATION".

2. Adjust tension. See Section" ASSEMBLY -

TENSIONING BELT".

1. Use a straight drill bit.

2. Replace bearings.

3. Install drill properly. See Section "BASIC

DRILL PRESS OPERATION" and

"ASSEMBLY".

4. Install chuck properly. See Section

"ASSEMBLY - iNSTALLING THE CHUCK".

1. Adjust spring tension. See Section

"ASSEMBLY - ADJUSTMENTS -QUILL

RETURN SPRING".

1. Using a household detergent, clean the

tapered surface of the chuck and spindle to

remove all dirt, grease and oil. See Section

"ASSEMBLY - INSTALLING THE CHUCK".

21

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

Craftsman 137229151 Owner's manual

- Category

- Power tools

- Type

- Owner's manual

- This manual is also suitable for

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

in other languages

Related papers

-

Craftsman 137.2191 Owner's manual

-

Craftsman ZJQ4116D Owner's manual

-

Craftsman 137.229201 Owner's manual

-

Craftsman 113.213100 Owner's manual

-

Craftsman 113213150 Owner's manual

-

Craftsman 137.229130 Owner's manual

-

Craftsman 137219100 User manual

-

Craftsman 113213850 Owner's manual

-

Craftsman 113.213130 Owner's manual

-

Craftsman 113.213213 Owner's manual

Other documents

-

Genesis GDP805P User guide

-

KNOVA KN DP-2000 Owner's manual

-

Genesis GFDP160 User manual

-

Genesis GDP1012A User guide

-

Hitachi B 16RM Instruction Manual And Safety Instructions

-

Hitachi B16RM User manual

-

Stark 53501-H1 User manual

-

Wachsmuth & Krogmann ZJ4116QA User manual

-

Sears 113.21308 User manual

-

Genesis GDP500 User guide