SEI Sacksafoam I is a helicopter dispensing system designed to enhance the efficiency of fire fighting operations. It features a sack that mounts in the Bambi bucket, eliminating spillage and corrosion. The system has an optional foam transfer pump for easy filling and a controller for precise foam injection. With its advanced features, SEI Sacksafoam I helps users protect lives and property from fires.

SEI Sacksafoam I is a helicopter dispensing system designed to enhance the efficiency of fire fighting operations. It features a sack that mounts in the Bambi bucket, eliminating spillage and corrosion. The system has an optional foam transfer pump for easy filling and a controller for precise foam injection. With its advanced features, SEI Sacksafoam I helps users protect lives and property from fires.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

SEI Sacksafoam I is a helicopter dispensing system designed to enhance the efficiency of fire fighting operations. It features a sack that mounts in the Bambi bucket, eliminating spillage and corrosion. The system has an optional foam transfer pump for easy filling and a controller for precise foam injection. With its advanced features, SEI Sacksafoam I helps users protect lives and property from fires.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

Other documents

-

Kmart 43127887 User manual

-

Crown Bolt 806536 User manual

-

Rexel 2100154 Datasheet

-

UPCART MPB-1DX Installation guide

UPCART MPB-1DX Installation guide

-

HQ W9-OHG-20BN Datasheet

-

HQ W9-IHN-20N Datasheet

-

SEI Industries BAMBI MAX User manual

SEI Industries BAMBI MAX User manual

-

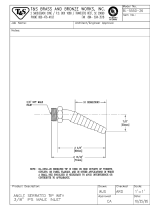

T & S Brass & Bronze Works BL-5550-26 Datasheet

T & S Brass & Bronze Works BL-5550-26 Datasheet

-

Baldor-Reliance Reducer Oil Conversion Mobil SHC634 to Kluber UH1-6-460 Owner's manual

Baldor-Reliance Reducer Oil Conversion Mobil SHC634 to Kluber UH1-6-460 Owner's manual

-

Romac Industries 243-1110 Installation guide