Page is loading ...

Removing and Replacing the Quik-Lok® Cord

For instant field replacement, Catalog No. 6755-1 features the

exclusive MILWAUKEE Quik-Lok® Cord.

1. To remove the Quik-Lok® Cord, turn the cord nut 1/4 turn

to the left and pull it out.

2. To replace the Quik-Lok® Cord, align the connector key-

ways and push the connector in as far as it will go. Turn the

cord nut 1/4 turn to the right to lock.

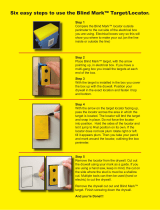

Inserting Bits (Fig 1.)

1. To insert Bit Holders and Bits, unplug tool. Remove Locator

Assembly by pulling it away from the tool.

2. Push Insert Bit into Bit Holder until it snaps into place. Then

push Bit Holder into nose of the tool until it snaps into place.

3. Push Locator Assembly until it snaps into place.

Adjusting Locator Assembly (Fig 2.)

The Locator Assembly controls the driving depth of your tool.

Your MILWAUKEE Drywall Driver features a pop-off Locator

Assembly with a one-handed depth adjustment. Depth adjust-

ments can be made easily and quickly by using one hand to

turn the Locator. Detents inside the Sleeve “lock” the depth

you have selected with the Locator.

Start with about 1/16” clearance between the head of the screw

and Nose with the clutch disengaged as shown. The detents on

the inside of the Sleeve represent different depths. Every two

clicks of the Locator equal 1/64”. Continue adjusting the

Locator until you reach the depth needed for your job.

1. To adjust depth setting, simply rotate the Locator in the

direction labeled. “DEEPER “increases driving depth.

2. Turning Locator in the opposite direction decreases driv-

ing depth. The detents will “lock” the Locator in place, ensur-

ing an accurate depth setting.

The pop-off Locator Assembly allows you to remove the

assembly by simply pulling it away from the tool.

Reattachment does not alter your depth setting.

Milwaukee Tool

Heavy-Duty Drywall Screw Driver

Model Numbers: 6755-1, 6757-1, 6758-1

Operating Instructions

Page 1

RenTrain INC

RenTrain INC

To reduce the risk of injury, always unplug tool

before attaching or removing accessories. Use

only specifically recommended accessories.

Others may be hazardous.

WARNING!

ASSEMBLY

Fig. 1

1.

3.

1. Bit Holder

2. Insert Bit

3. Locater assembly

2.

Fig. 2

1.

1. Locater

1/16”

Starting, Stopping and Controlling Speed

Your Drywall Driver may be used at any speed from 0-4000

RPM.

1. To start tool, pull Trigger.

2. To vary the driving speed, simply increase or decrease

pressure on Trigger. The further the Trigger is pulled, the

greater the speed.

3. To stop the tool, release Trigger.

Using Forward/Reverse Switch (Fig 3.)

1. For forward (clockwise) rotation, push the forward/reverse

switch to FWD as shown.

2. For reverse (counterclockwise) rotation, push the

forward/reverse switch to REV as shown. Although an inter-

lock prevents reversing the tool while the motor is running,

allow the motor to come to a full stop before reversing.

Locking Trigger Switch (Fig. 4.)

The Lock Button, located next to the Trigger Switch, holds

Trigger in the ON position for continuous full speed use.

1. To lock Trigger Switch, push Lock Button in while pulling

Trigger. Then release Trigger.

2. To unlock Trigger Switch, pull Trigger and release.

Driving Drywall Screws (See Figs. 5 & 6 - next page)

Standard Drywall Screws are generally designed for attaching

drywall to wood studs and 25 through 20-gauge steel studs.

Your 0-4000 RPM ScrewDriver is ideal for driving these types

of drywall screws. The depth setting is very important. Refer

to the guide at the right for the correct depth setting.

1. To insert screws, select the proper Drywall Screw for each

job. Pilot holes are not needed. Place screw onto the insert bit,

then align the screw against the work surface, making sure you

are holding the tool and screw square to the work surface as

shown at right. If you misalign the tool or the screw, the screw

will not drive into the work surface, or it will not drive straight.

2. Pull the Trigger and push tool forward with a “punching”

motion to sink the screw into the drywall. A punching motion

will engage the clutch, cause the screw to start rotating, sink

the screw and disengage the clutch within a fraction of a sec-

ond. If you do not maintain pressure on the tool after engaging

the clutch, the screw will not properly seat.

The clutch will automatically disengage and the insert bit will

stop rotating once the screw has been driven to the selected

(Continued on next page)

Operating Instructions (continued)

Page 2

RenTrain INC

RenTrain INC

To reduce the risk of injury, always wear

eye protection.

WARNING!

To reduce the risk of electric shock, check

work area for hidden pipes and wires before

driving screws.

WARNING!

Fig. 3

Fig. 4

1.

1.

2.

2.

OPERATION

APPLICATIONS

1. Trigger

2. Lock button

1. Reverse

2. Forward

depth. Remember that the insert bit and screw will not rotate

until you “punch” the tool against the work surface.

NOTE: Practice driving screws into pieces of scrap material to

familiarize yourself with the tool and the clutch action before

attempting to drive screws into your workpiece.

3. To remove screws, pop off the locator assembly and switch

the reverse lever to REV. Reattaching the Locator Assembly

will not change your depth setting.

Metal Studs

Your Drywall Driver can be used to attach drywall to 25

through 20-gauge metal studs. This tool is not recommended

for use with metals heavier than 20-gauge because it operates

at 4000 RPM and will dull the sharp tip on metal screws. When

working witty heavier sheet metal, MILWAUKEE recommends

using a drywall driver with a rated speed of 2540 RPM.

When working with light gauge sheet metal, follow the same

steps as you do when working with wood studs. Refer to the

depth guide on page 15 to help you set the proper depth.

You may notice that the screw hesitates slightly when it fin-

ishes breaking through the drywall and starts to penetrate the

sheet metal. This is normal. Just remember to use a “punching”

motion to drive the screw and keep firm pressure on the tool

until the screw is seated.

Operating Instructions (continued)

Page 3

RenTrain INC

RenTrain INC

Fig. 5

1. Correct Head of screw is

below surface, but does not

puncture facing.

2. Too Deep Head of screw

punches hole in drywall

face, making finishing diffi

cult and allowing moisture

beneath facing. Decrease

depth

3. Too Shallow Head of

screw extends above dry

wall face and can not be fin

ished off. Increase depth.

90

0

Work Surface

Fig. 6

/