Page is loading ...

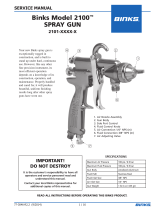

Spare parts list for

Automatic High-Pressure Spray Gun

9836 0524 01

2015–09

65135 F57

Part num bers in bold ty pe de sig na te con sump tion parts.

Service set 6103 1078 00 Con sis ting of parts with ref. Nos. 2, 5, 6, 7

(Qty 2), 8 (Qty 2), 9, 11, 13, 19 (Qty 2), 27.

Ec co 320A

Ecco 320A.........Prod. No. 8611 4114 17

Max. working fluid pressure....... 360 bar

Min./Max. control air pressure..... 4/8 bar

Ref.

No. Part num ber Qty De scrip tion

1 6103 1146 30 1 Gun bo dy

2 6103 0812 00a 1 Gas ket

3 6103 1054 01 1 Flu id nozz le

4 6003 9957 00 1 Se a ling ele ment

5 6103 1069 00a 1 – Was her

6 6103 1070 00a 1 – Gui de

7 6103 1071 00a 2 – Pack ing (PTFE)

8 0663 7110 00a 2 – O-ring (3.1 x 1.6 FPM)

9 6103 1072 00a 1 – Slee ve

10 6103 1068 00 1 – Pack ing screw

11 6103 1073 00a 1 – Gui de bus hing

12 6103 1056 00 1 Flu id need le

13 0653 9211 00a 1 Gas ket (42/50 x 1 Al)

14 6003 9958 00 1 Ser vo part

15 6103 1060 00 1 – Back he ad

16 6103 1064 00 1 – Spring

17 6103 1061 00 1 – Pis ton

18 6103 1062 00 1 – Lock screw

19 0190 1242 00a 2 – Set screw (P6SS 6 x 8 A4 S.S.)

Ref.

No. Part num ber Qty De scrip tion

20 6803 1065 00 1 – Cup se al

21 6803 1066 00 1 – Cup se al

22 6103 1063 00 1 – Gui de

23 0653 1059 00 2 Gas ket (13/17 x 1 Kpr)

24 0686 4202 03 1 Plug (G 1/4)

25 6002 0233 00 1 Nipp le (G 1/4 x 1/4” 18 NPSM)

26 6003 9827 41 1 El bow coup ling (G 1/8 – 8)

27 6101 5670 00a 1 Gasket

28 – 1 Stan dard spray tip (see spa re parts

list No. 9836 3060, ESL 12/04-16)

29 6101 6254 00 1 Re tai ning ring (M18 x 1)

De li ve red with the spray gun:

– 6103 1074 00 1 Tool set

– 0902 0111 00 1 – Hex a gon wrench (3 mm)

– 0101 1293 00 1 – Pin (ø 5 mm)

– 6000 8004 00 1 – Cle a ning brush (ø 10 mm)

Optional equipment (See also page 2)

– 6003 8001 00 1 Cleaning needle set (see above)

a Including in service set 6103 1078 00.

EC CO FI NIS HING AB , Box 93, SE-532 22 SKA RA, Swe den

Tel: +46 (0)511-134 45, Fax: +46 (0)511-180 13

E-mail: info@eccofinishing.com • www.ec co fi nis hing.com

Op tio nal equ ip ment

Cleaning needle set

Part number 6003 8001 00

Spray tip cleaning broaches to

cleaning blocked spray tips, 12 pieces

included, length 21 mm dia. 0.10 mm

with spiral handles.

ECCO

ESL 12/03-08

ECCO FINISHING

(1522)

Fluid inlet

1/4" 18NPSM

Air inlet ø 8 mm

(5 11)

II 2 G

2

Ope ra tor’s In struc tions

Use Ec co gen u ine parts and ac ces so ries on ly for best

func tion and safe ty.

Be fore start ing, read through all in struc tions care ful ly.

The high vel o ci ty flow of ma te ri al through ho ses and nozz les

may de ve lop sta tic elec tri ci ty. Be su re that the equ ip ment,

object being spray ed, spray booth, paint and was te con tai ner

are pro per ly groun ded to pre vent sta tic di schar ge orsparks.

Check the elec tri cal re sis tan ce of the high pres su re paint

ho se re gu la ry. The ope ra tor is nor mal ly con nec ted to earth

through the spray gun.

WAR NING

As the equipment works under very high pres su re the

ut most care must be observed during the work. Bearing this

in mind, never aim the spray gun at a person or towards any

part of the bo dy In the event of personal injury caused by the

spray ing pressure, immediate medical attention is essential.

Before carrying out any adjustment or repair, the equipment

must be wit ched off and the paint pres su re re li e ved.

WAR NING

If the gun does not work satisfactorily it must on no ac count be

used. Repair or replace it immediately.

Im por tant

Do not use halogenated hydrocarbons in coating ap pli ca tion

equipment where aluminium or gal va ni zed parts come

in contact with the solvent or coating ma te ri al.

Ha log en at ed hydrocarbons e.g. 1,1,1-thri chlo ro et ha ne and

methylene chloride react, violently with such parts, causing

corrosion and dan ger for ex plo sion.

WAR NING

65135 F56

Ecco 320A

Dimension in mm.

Optional equipment

65130 F308

Ref.

No. Part num ber Qty De scrip tion

30 6003 6565 00 1 Nipple

31 6803 3077 00 1 Edge filter, slot width 0.127 mm (0.005”)

Suitable for tips with equivaent oriffice

diameteter = 0.279 – 0.457 mm

(0.011” – 0.018”)

31 6803 3078 00 1 Edge filter, slot width 0.229 mm (0.009”)

Suitable for tips with equivaent oriffice

diameteter = 0.483 mm

(0.019”) and larger

3

Clean ing the spray tip

1. If the spray tip clogs while spray ing shut off pump and re lief paint

pres sure.

2. Loos en the re tain ing nut, for the spray tip, and re lease pres sure slow ly

be fore re mov ing com plete ly.

3. Then re move spray tip and put it in sol vent.

4. Blow ob struc tion out with air from front of spray tip, or let it soak

long enough to dis solve the par ti cle.

5. If it won’t dis solve, clean it with a Ec co clean ing broach from front

of spray tip.

Al ways re move spray tip from gun to clean it.

Be very care ful when re mov ing spray tip or hose from gun.

The pump must be switched off and paint pres sure re lieved.

A plugged high pres sure hose con tains fluid un der high

pres sure. Loos en tip re tain ing nut or hose coupling slight ly and

release slowly before removing completely.

WAR NING

Trouble shooting

Introduction

Always commence troubleshooting by checking the general condition

of the spray gun. This can most easily be determined by test spraying,

which provides an opportunity for checking the spray pattern and capacity

and gasket leakage.

The following external factors can cause malfunctioning and should be

thoroughly checked:

1. The quality of the paint, i.e. its viscosity, purity. etc.

2. The paint pressure in relation to viscosity of the paint and

spray tip used.

3. The size of paint hoses.

Trouble shoouting chart (see the last page)

Types of problems

Collection of information which makes it possible to identify the error

symptoms applicable to the spray gun in the event of malfunctioning

is a matter of vital importance. Identification of symptoms makes it

possible to decide whether the spray gun itself is the direct cause of the

malfunctioning or if this may have been caused by an external factor.

Replacement of fluid needle and fluid needle

gaskets

Removal

1. Shut off pump and re lief paint pres sure.

2. Undo the two screws (19).

3. Remove the servo part (14) by screwing out the back head (15).

4. Unscrew the sealing element (4).

5. Withdraw fluid needle (12) and take away the washer (5).

6. Unscrew the guide bushing (11).

7. Press the packing set out with the aid of the 5-mm pinprovided in the

tool set. Note! Take care to avoid damaging the outside diameter of

the packing screw (10) which is a sealing surface. Use the flats of the

packing screw when clamping between the jaws of a vice.

8. Clean and inspect all parts.

Assembly

All moving parts must be lubricated

1. Mount the packing set on the fluid needle (12) in the following order:

The washer (5), the guide (6), the packings (7) with the o-rings (8)

and finally the sleeve (9). Note! The packings (7) are to be fitted with

the tip of the Vee facing away from the valve cone in the fluid needle.

2. Screw the assembled sealing element (4) into the gun body.

3. Drip a little oil onto the sealing surface of the packing screw and mount

the servo part (14).

4. Secured the fluid needle with the two lock screws (19).

Replacement of fluid needle only

1. Unscrew the retaining ring (29) and remove the spray tip (28) together

with its gasket (27)

2. Uns crew the fluid nozzle (3) with its gasket (2).

3. Undo the lock screws (19) and pull the fluid needle (12) out from the

front.

4. Insert a new fluid needle and tighten the lock screws (19).

5. Fit the fluid nozzle (3) and spray tip (28). Don’t forget to refit the gaskets

(2 and 27).

• Max. fluid pres su re 360 bar.

• Fluid ho se con nec tion 1/4-18 NPSM.

• Min./Max. control air pressure 4/8 bar.

• Control air tube con nec tion is elbow coupling for 6/8 mm nylon tubing.

• Blow the fluid and air tube clean before connecting them.

• When as ses sing the re ac tion ti me of the con nec ted spray gun

(the ti me from the start im pul se until spray ing com men ces) the

re ac tion time of the control valve must be taken into con si de ra tion.

• Re com men ded sizes for control val ve and air hoses:

– Con trol valve, 3-way, G1/4. Min. flow area 28 mm2.

Mechan i cally, pneu mat i cal ly or electrically actuated.

– Air hose, nylon, dia. 6/8 mm, max. Iength 7.5 m for control air.

• To prevent the fluid hose from getting stuck on account of dried

paint, it is recommended that the connection threads be greased

with vasseline or a similar lubricant.

• Ta ke gre at ca re to keep the spray gun clean and to lubricate all

mo ving parts at regular intervals.

• Lu bri cants for paint spraying equipment must not contain silicones.

• Check that all connections are tight.

• If the gun does not work satisfactorily it must on no account be used.

Repair or replace it immediately.

Paint spray ing

Ad vice on high-pres sure spray ing

1. Con sult your paint sup pli er for in for ma tion to choose the cor rect

spray tip for the ac tu al paint.

2. As rule the best spray ing dis tance is 30-40 cm.

3. The spray pass es do not need to over lap as much as in spray paint ing

with air atom i za tion.

4. The ca pac i ty of high pres sure spray ing is very large. To avoid runs, the

spray gun should usu al ly be moved fast er than in spray paint ing

with air atom i za tion.

Maintenance

The entire spray gun gun should be cleaned at the end of each working

day. The spray tip should be cleaned more frequently.

Wipe the spray gun thoroughly clean on outside and clean it internally by

flushing a suitable solvent through it.

More extensive cleaning and overhauling should be carried out at least

once a month, depending on the material being sprayed.

Trouble shoouting chart

Correct Spray Pattern

The paint is uniformly dipersed over the entire spray angle.

a) Increase the paint pressure. Not that too

high a paint pressure causes excessive

spray mist.

b) Thin the paint cautiously or change to a

different spray tip size or spray angle.

c) Choose the correct size of spray tip.

d) Clean the spray tip with solvent. Use a

brush and, if necessary, a sliver of wood.

e) Change the spray tip.

Symmetrical edge stripes

a) Paint pressure too low.

b) Paint viscosity too high.

c) Wrong choice of spray tip.

c) Spray tip orifies partly clogged.

d) Spray tip damaged.

Asymmetrical edge stripes

a) Spray tip damaged. a) Change the spray tip.

Spray Pattern Cause Remedy

Paint leaking

Paint leaking Worn needle packings and/or needle. Replace damaged parts with new ones.

Paint leaking through the spray tip when

the gun is closed. Pollution between the needle and the fluid nozzle

(3) or fluid needle (12) and nozzle worn or dam-

aged.

Clean carefully and check for any sign of damages

or wear.

Cause Remedy

Paint leaking

4

5

S

Återvinning

ECCO Finishing AB jobbar för en hållbarare global miljö, därför vill vi att förbrukad produkt återvinns på bästa sätt.

Detta görs lämpligast genom att skicka tillbaka den förbrukade produkten till ECCO Finishing AB (paketet märkt med

”Återvinning”), eller om möjlighet finnas att demontera produkten och källsortera delarna enligt gällande föreskrifter.

Retur adress:

ECCO Finishing AB

Att. Återvinning

Afsengatan 6

532 37 Skara

Sweden

GB

Recycling

ECCO Finishing AB is working for a more sustainable global environment, that’s why we would like to make sure

that the consumed product is recycled in the best possible way. This is best done by returning the consumed

product to ECCO Finishing AB (package marked with "recycling"), or isible dismantled and recycled according to

the applicable local regulations.

Return address:

ECCO Finishing AB

Att. Recycling

Afsengatan 6

532 37 Skara

Sweden

D

Recycling

ECCO Finishing AB bemüht sich um nachhaltigen Umgang mit Ressourcen und Umweltschutz. Deshalb möchten

wir sicherstellen, dass Produkte und Materialien in der bestmöglichen Weise recycelt werden. Deshalb bieten wir die

Möglichkeit der Rücksendung von ‘verbrauchten’ Produkten zum Recyceln an. Bitte demontieren Sie die Produkte

soweit es möglich ist, und sende diese in einem Paket mit der Kennzeichnung ‘Recycling’ an uns zurück.

Rücksendeanschrift:

ECCO Finishing AB

Att. Recycling

Afsengatan 6

532 37 Skara

Sweden

FR

Recyclage

Ecco Finishing AB réalise des efforts permanents pour la protection de l’environnement, c’est pourquoi nous

voulons nous assurer du meilleur recyclage possible de nos produits. Il est préférable pour cela de retourner les produits

marqués « recyclable » directement à Ecco Finishing, ou si possible de les recycler sur place dans le respect de

la régulation locale.

Adresse de retour:

ECCO Finishing AB

Att. Recycling

Afsengatan 6

32 37 Skara

Sweden

/