5© Munters Corporation, October 2020

QM1078r2

[B]

[C]

[D]

[E]

[F]

[G]

[H]

[J]

[K]

[L]

[M]

[N]

[R]

[T]

[X]

Unpacking the EquipmentChapter 1

[AA]

[BB]

[CC]

[DD]

[EE]

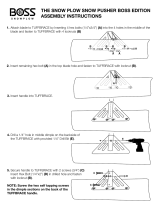

HP1389 – Hardware Package for 1 – WM54K

ID Qty. Cat. No. Description

[B] 1 KS1901 6.3mm x 19mm Tapping Screw, ZP

[C] 4 KS1928 M8-1.25 x 25mm Hex Bolt, ZP (HP1382 only)

[D] 4 KW4906 M8 Star Lock Washer, BLK

[E] 4 KN1849 M8-1.25 x 8mm Hex Nut, ZP

[F] 4 KS1926 M6-1.0 x 30mm Hex Bolt, ZP

[G] 4 KW4901 M6 x 12mm Flat Washer, ZP

[H] 4 KN1855 M6-1.0 x 6mm Hex Nut, ZP

[J] 1 KS1931 M10-1.5 x 25mm Hex Bolt, ZP

[K] 1 KW3509 10mm Splitlock Washer, ZP

[L] 1 KN1860 M25-2.0 x 10mm Hex Nut, ZP

[M] 1 KX1130 Shaft Shield for Prop Sheave, AL

[N] 1 KX1208 40mm Cover Cap, Black PL

[R] 8 FH1968 1-Hole Pivoting Shutter Clip, PL

[T] 1 AC0211 & AC0212 Azuma Bolt & Nut, Blue PL

[X] 1 KS1046 M10-1.5 x 50mm Hex bolt, ZP

1 HK1001 Hardware Kit WM54K Fan Assembly, #1 of 2

1 HK1002 Hardware Kit WM54K Fan Assembly, #2 of 2

1 LB2647 Specifi cation Label for WM54K

HK1001 – Hardware Kit for 1 – WM54K Fan

ID Qty. Cat. No. Description

[AA] 18 KS1007

5

⁄16”-18 x 1.25” Hex Head Bolt, SS

[BB] 4 KS1029

5

⁄16”-18 x 1.75” Hex Head Bolt, SS

[CC] 7 KS1075

5

⁄16”-18 x 2.75” Hex Head Bolt, SS

[DD] 37 KN0704

5

⁄16”-18 SRTD Flange Nut, SS

[EE] 10 KW3011

5

⁄16” x 1¼ ”O.D. Flat Washer, SS

HK1002 – Hardware Kit for 1 – WM54K Fan

ID Qty. Cat. No. Description

[FF] 4 KS2258 #10-16 x ⁵⁄₈” TEK Screw, SS

[GG] 7 KS1400 #10-12 x

3

⁄4”, SLTDHX, Seal-Washer Screw, ZP

[HH] 1 KW3012 ¹⁄₄” x 1”O.D. Flat Washer, SS

[JJ] 2 AC1381

1

⁄8” Dia. Cable Clamp, ZP

[KK]

2 KX1158 Hole Plug, 0.73”-0.76” Dia., BLK PL

[LL]

1 KS2463

1

⁄4” x 1.5” HEX Lag Screw,ZP

[FF]

[GG]

[HH]

[JJ]

[KK]

[LL]