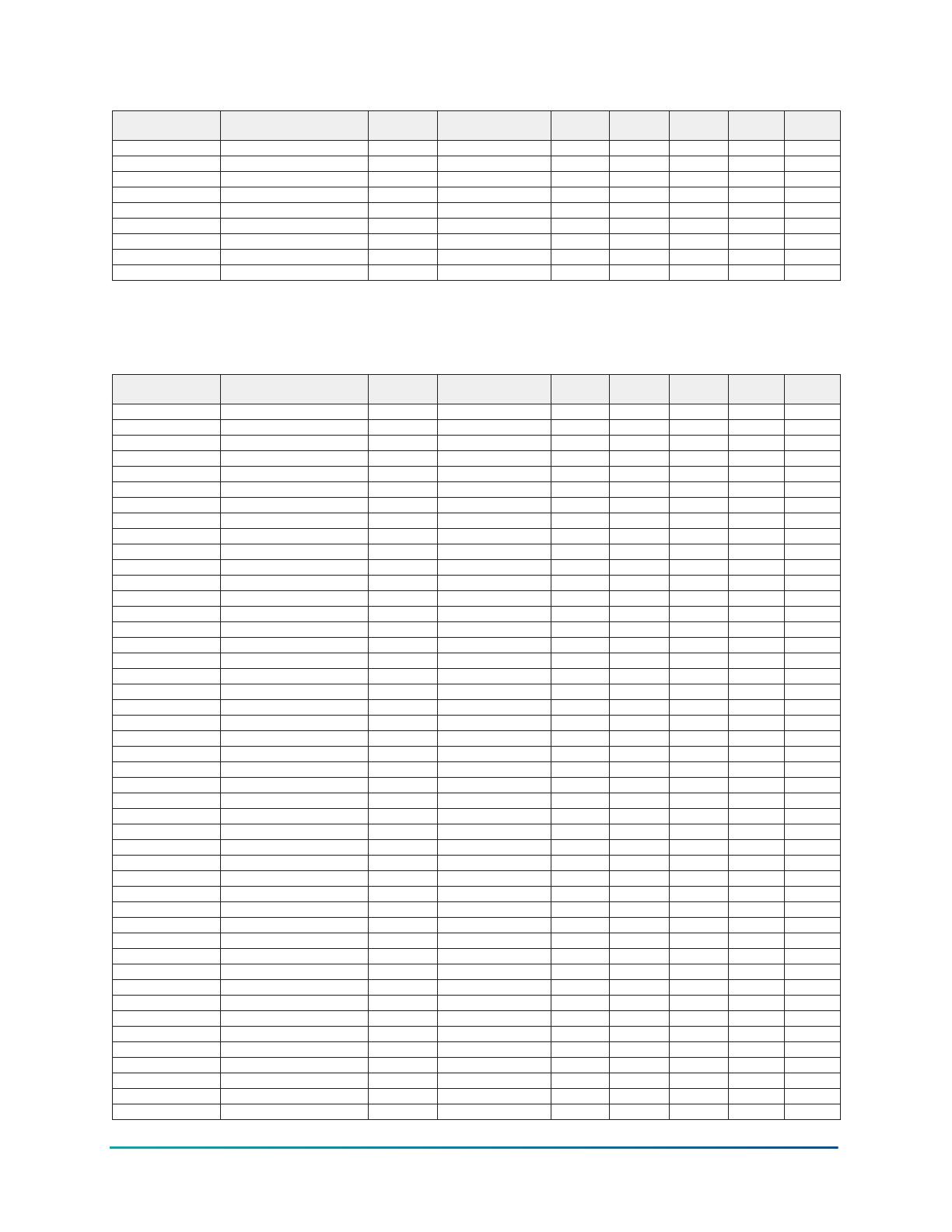

Table 12: Furnace capacity

Outdoor unit model Furnace model Furnace

width (in.)

Indoor coil model Rated CFM Net cool

(MBH)

Sens cool

(MBH)

SEER2 EER2

RAC13448B21S TM9Y100C20MP11 24.5 XAFD48F 1400 46.50 32.80 13.50 11.25

RAC13448B21S TM9Y100C20MP11 21.0 XAHC48F 1375 46.00 32.20 13.50 11.25

RAC13448B21S TM9Y100C20MP11 21.0 XAHC60G 1400 47.00 33.00 13.75 11.50

RAC13448B21S TM9Y100C20MP11 24.5 XAHD48F 1375 46.00 32.20 13.50 11.25

RAC13448B21S TM9Y100C20MP11 21.0 XAHD60G 1375 47.00 32.80 13.75 11.50

RAC13448B21S TM9Y120D20MP11 24.5 XAF/XAUD60G 1450 48.00 34.00 14.00 11.75

RAC13448B21S TM9Y120D20MP11 24.5 XAFD48F 1450 47.00 33.40 13.75 11.50

RAC13448B21S TM9Y120D20MP11 24.5 XAHD48F 1450 47.00 33.40 13.75 11.50

RAC13448B21S TM9Y120D20MP11 21.0 XAHD60G 1425 47.50 33.60 14.00 11.50

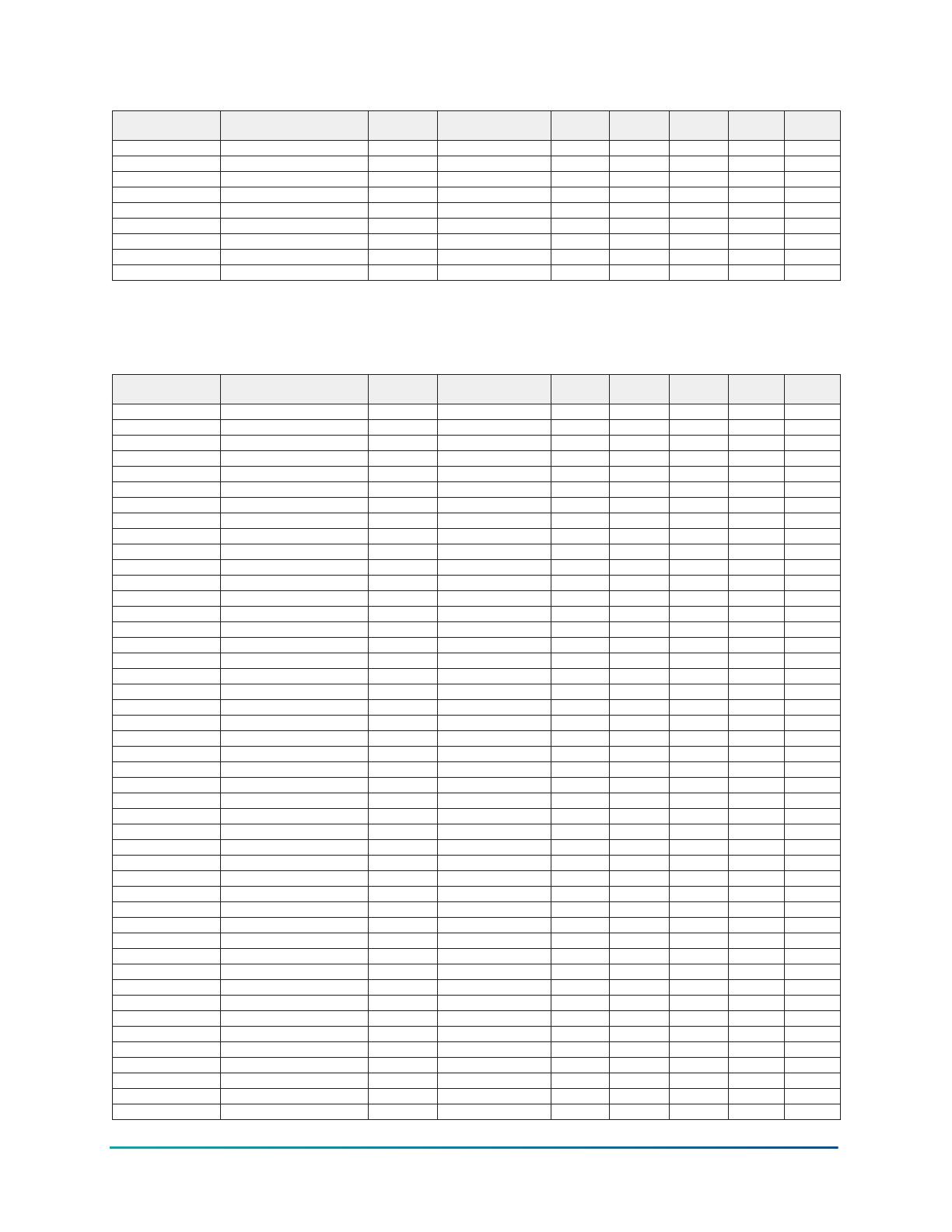

Furnace capacity - 5 ton

Table 13: Furnace capacity

Outdoor unit model Furnace model Furnace

width (in.)

Indoor coil model Rated CFM Net cool

(MBH)

Sens cool

(MBH)

SEER2 EER2

RAC13460B21S RGF19080CE20MP13 21.0 XAF/XAUC60G 1750 56.00 41.00 13.50 11.00

RAC13460B21S RGF19080CE20MP13 24.5 XAF/XAUD60G 1775 56.00 41.00 13.40 11.25

RAC13460B21S RGF19080CE20MP13 24.5 XAF/XAUD60H 1750 56.00 41.00 13.50 11.25

RAC13460B21S RGF19080CE20MP13 21.0 XAFC60H 1750 56.00 41.00 13.50 11.25

RAC13460B21S RGF19080CE20MP13 21.0 XAHC60G 1750 56.00 41.00 13.50 11.00

RAC13460B21S RGF19080CE20MP13 21.0 XAHC60H 1750 56.00 41.00 13.50 11.25

RAC13460B21S RGF19080CE20MP13 21.0 XAHD60G 1725 56.00 40.50 13.50 11.25

RAC13460B21S RGF19080CE20MP13 24.5 XAHD60H 1750 56.00 41.00 13.50 11.25

RAC13460B21S RGF19100CE20MP13 21.0 XAF/XAUC60G 1725 56.00 40.50 13.40 11.00

RAC13460B21S RGF19100CE20MP13 24.5 XAF/XAUD60G 1600 55.00 39.00 13.40 11.25

RAC13460B21S RGF19100CE20MP13 24.5 XAF/XAUD60H 1575 55.00 39.00 13.50 11.25

RAC13460B21S RGF19100CE20MP13 21.0 XAFC60H 1600 55.00 39.50 13.50 11.25

RAC13460B21S RGF19100CE20MP13 21.0 XAHC60G 1725 56.00 40.50 13.40 11.00

RAC13460B21S RGF19100CE20MP13 21.0 XAHC60H 1600 55.00 39.50 13.50 11.25

RAC13460B21S RGF19100CE20MP13 21.0 XAHD60G 1700 55.50 40.00 13.50 11.25

RAC13460B21S RGF19100CE20MP13 24.5 XAHD60H 1725 55.50 40.50 13.50 11.25

RAC13460B21S RGF19120DE20MP13 24.5 XAF/XAUD60G 1625 55.00 39.50 13.40 11.00

RAC13460B21S RGF19120DE20MP13 24.5 XAF/XAUD60H 1625 55.00 39.50 13.40 11.25

RAC13460B21S RGF19120DE20MP13 21.0 XAHD60G 1600 55.00 39.50 13.40 11.00

RAC13460B21S RGF19120DE20MP13 24.5 XAHD60H 1600 55.00 39.50 13.40 11.00

RAC13460B21S RGF1L080CE20MP12 21.0 XAF/XAUC60G 1625 55.00 39.50 13.40 11.00

RAC13460B21S RGF1L080CE20MP12 24.5 XAF/XAUD60G 1625 55.50 39.50 13.40 11.25

RAC13460B21S RGF1L080CE20MP12 24.5 XAF/XAUD60H 1625 55.00 39.50 13.50 11.25

RAC13460B21S RGF1L080CE20MP12 21.0 XAFC60H 1625 55.00 39.50 13.50 11.25

RAC13460B21S RGF1L080CE20MP12 21.0 XAHC60G 1625 55.00 39.50 13.40 11.00

RAC13460B21S RGF1L080CE20MP12 21.0 XAHC60H 1625 55.00 39.50 13.50 11.25

RAC13460B21S RGF1L080CE20MP12 21.0 XAHD60G 1600 55.00 39.00 13.40 11.00

RAC13460B21S RGF1L080CE20MP12 24.5 XAHD60H 1625 55.00 39.50 13.50 11.25

RAC13460B21S RGF1L100CE20MP12 21.0 XAF/XAUC60G 1725 55.50 40.50 13.40 11.00

RAC13460B21S RGF1L100CE20MP12 24.5 XAF/XAUD60G 1625 55.00 39.50 13.40 11.25

RAC13460B21S RGF1L100CE20MP12 24.5 XAF/XAUD60H 1625 55.00 39.50 13.50 11.25

RAC13460B21S RGF1L100CE20MP12 21.0 XAFC60H 1625 55.00 39.50 13.50 11.25

RAC13460B21S RGF1L100CE20MP12 21.0 XAHC60G 1625 55.00 39.50 13.40 11.00

RAC13460B21S RGF1L100CE20MP12 21.0 XAHC60H 1625 55.00 39.50 13.50 11.25

RAC13460B21S RGF1L100CE20MP12 21.0 XAHD60G 1675 55.50 40.00 13.40 11.00

RAC13460B21S RGF1L100CE20MP12 24.5 XAHD60H 1625 55.00 39.50 13.50 11.25

RAC13460B21S RGF1L120CE20MP12 21.0 XAF/XAUC60G 1625 55.50 39.50 13.40 11.00

RAC13460B21S RGF1L120CE20MP12 24.5 XAF/XAUD60G 1650 55.50 40.00 13.40 11.25

RAC13460B21S RGF1L120CE20MP12 24.5 XAF/XAUD60H 1650 55.50 40.00 13.50 11.25

RAC13460B21S RGF1L120CE20MP12 21.0 XAFC60H 1650 55.50 40.00 13.50 11.25

RAC13460B21S RGF1L120CE20MP12 21.0 XAHC60G 1650 55.50 40.00 13.40 11.00

RAC13460B21S RGF1L120CE20MP12 21.0 XAHC60H 1650 55.50 40.00 13.50 11.25

RAC13460B21S RGF1L120CE20MP12 21.0 XAHD60G 1625 55.00 39.50 13.40 11.00

RAC13460B21S RGF1L120CE20MP12 24.5 XAHD60H 1625 55.00 39.50 13.50 11.25

RAC13460B21S RGF1L130DE20MP12 24.5 XAF/XAUD60G 1800 56.00 41.00 13.40 11.00

RAC13460B21S RGF1L130DE20MP12 24.5 XAF/XAUD60H 1800 56.00 41.50 13.50 11.25

31Technical Guide: RAC Series RAC134 Models - 13.4 SEER2 Split-System Air Conditioner - Single-Phase

Johnson Controls Ducted Systems