INSTALLATION STEP 7

Install the Door Control

Locate door control within sight of door, at a minimum

height of 5 feet (1.52 m) where small children cannot

reach, away from moving parts of door and door

hardware. If installing into drywall, drill 5/32" holes and

use the anchors provided. For pre-wired installations

(as in new home construction), it may be mounted to

a single gang box (Figure 2).

1. Strip 7/16" (11 mm) of insulation from one end of

bell wire and connect to the two screw terminals on

back of door control by color: white wire to 2 and

white/red wire to the 1.

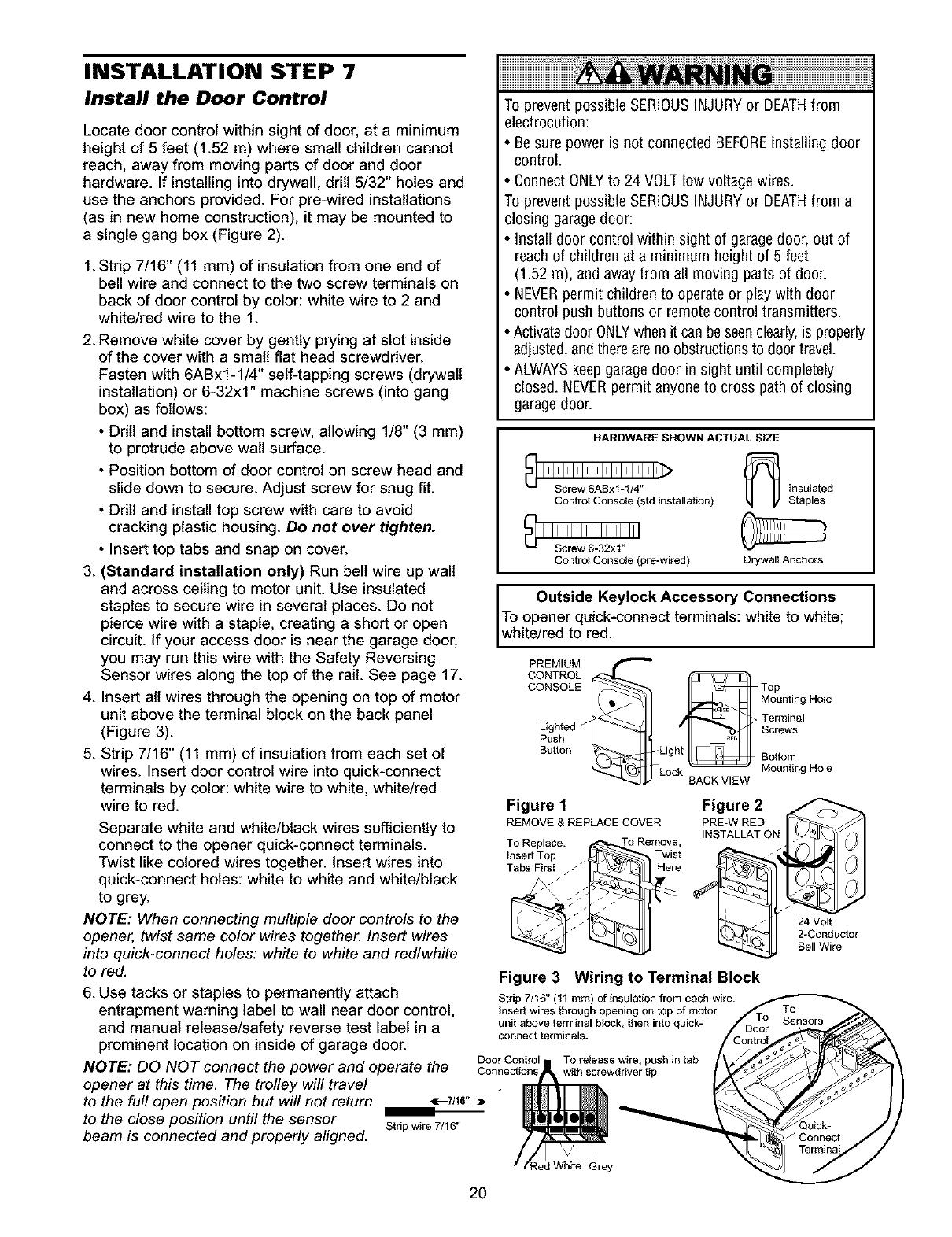

2. Remove white cover by gently prying at slot inside

of the cover with a small fiat head screwdriver.

Fasten with 6ABx1-1/4" self-tapping screws (drywall

installation) or 6-32x1" machine screws (into gang

box) as follows:

• Drill and install bottom screw, allowing 1/8" (3 mm)

to protrude above walt surface.

• Position bottom of door control on screw head and

slide down to secure. Adjust screw for snug fit.

• Drill and install top screw with care to avoid

cracking plastic housing. Do not over tighten.

• Insert top tabs and snap on cover.

3. (Standard installation only) Run bell wire up wall

and across ceiling to motor unit. Use insulated

staples to secure wire in several places. Do not

pierce wire with a staple, creating a short or open

circuit. If your access door is near the garage door,

you may run this wire with the Safety Reversing

Sensor wires along the top of the rail. See page 17.

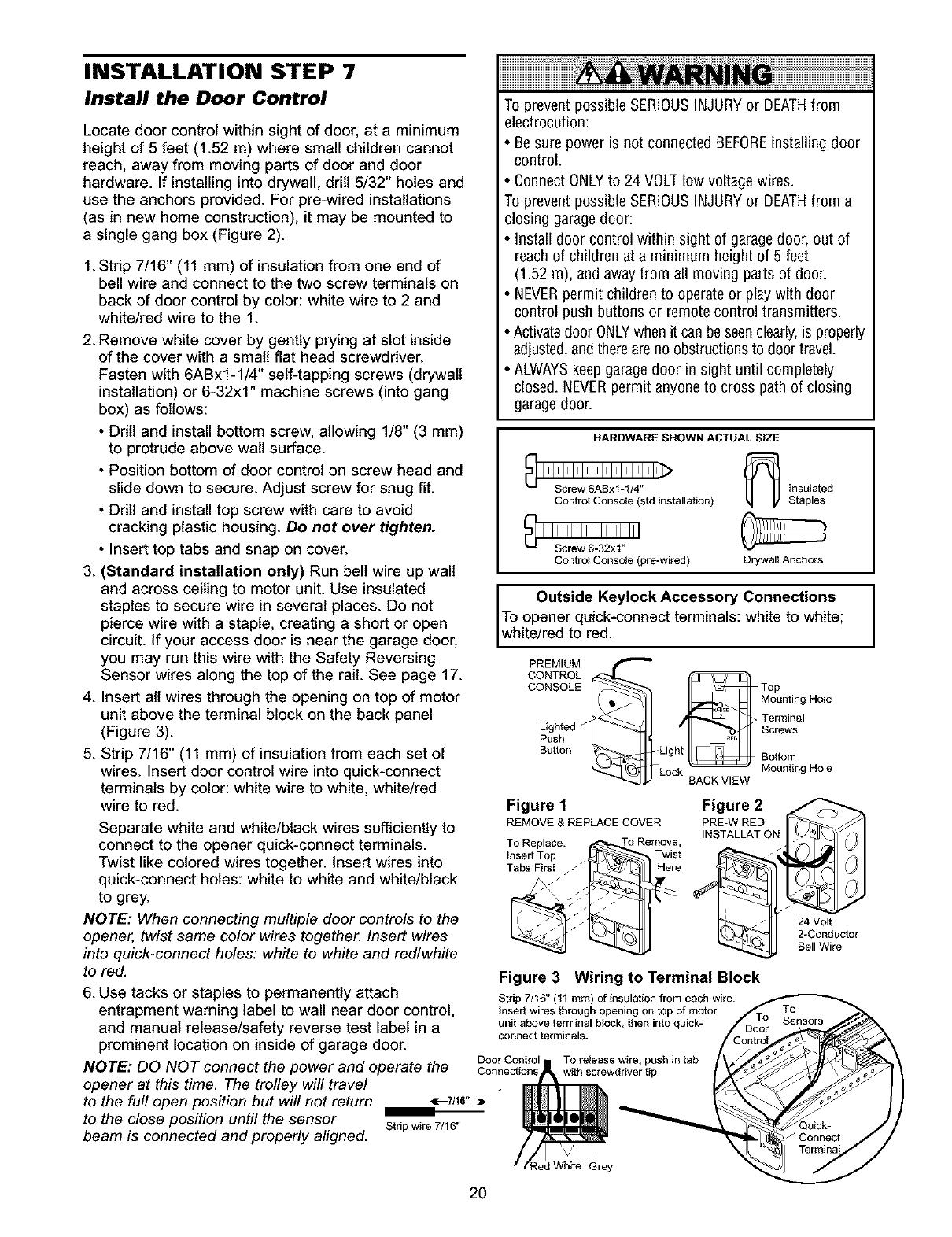

4. Insert all wires through the opening on top of motor

unit above the terminal block on the back panel

(Figure 3).

5. Strip 7/16" (11 mm) of insulation from each set of

wires. Insert door control wire into quick-connect

terminals by color: white wire to white, white/red

wire to red.

Separate white and white/black wires sufficiently to

connect to the opener quick-connect terminals.

Twist like colored wires together. Insert wires into

quick-connect holes: white to white and white/black

to grey.

NOTE: When connecting multiple door controls to the

opener, twist same color wires together. Insert wires

into quick-connect holes: white to white and red/white

to red.

6. Use tacks or staples to permanently attach

entrapment warning label to wall near door control,

and manual release/safety reverse test label in a

To prevent possible SERIOUSINJURYor DEATHfrom

electrocution:

• Besure power is not connected BEFOREinstalling door

control.

• ConnectONLYto 24 VOLTlow voltagewires.

To prevent possible SERIOUSINJURYor DEATHfrom a

closing garage door:

• Install door control within sight of garagedoor, out of

reachof children ata minimum height of 5 feet

(1.52 m), and away from all moving parts of door.

• NEVERpermit children to operateor playwith door

control push buttons or remote control transmitters.

• Activatedoor ONLYwhenit canbe seenclearly,is properly

adjusted,and thereareno obstructionsto door travel.

• ALWAYSkeepgarage door in sight until completely

closed. NEVERpermit anyoneto cross path of closing

garage door.

HARDWARE SHOWN ACTUAL SIZE

insulated

Control Console (std installation) Staples

Control Console (pre-wired) Drywall Anchors

Outside Keylock Accessory Connections

To opener quick-connect terminals: white to white;

white/red to red.

CONTROL

CONSOLE Top

Mounting Hole

Terminal

Lighted Screws

Push

Button Lig Bottom

Lock BACK VIEW Mounting Hole

Figure 1

REMOVE & REPLACE COVER

TO Replace, To Remove,

insert Top _ Twist

Tabs_ _First ///_ -__/ Here

Figure 2

PRE-WIRED

INSTALLATION

Figure 3 Wiring to Terminal Block

Strip 7/16" (11 ram) of insulation from each wire.

insert wires through opening on top of motor

unit above terminal block, then into quick-

24 Volt

2-Condu_or

Bell Wi_

prominent location on inside of garage door. connect terminals. /

the Door Control To release wire, push in tab

/\

NOTE: DO NOT connect the power and operate _ Connection, withscrewdriverlnverbp I_tip

opener at this time. The trolley will travel _

to the full open position but will not return €--7116--_

to the close position until the sensor

Strip wire 7/16"

beam is connected and properly aligned.

2O