7

TABLE OF CONTENTS

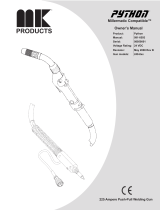

MAGNUM

®

PRO AL Gun

Page

Installation ...........................................................................................................................Section A

.......................................................................................................... A-1

Support Equipment Required............................................................................................ A-1

Installation Instructions ............................................................................................................ A-1

Gun Lead Connections...................................................................................................... A-2

Coolant Connections ......................................................................................................... A-2

Gun Tube Removal/Installation ......................................................................................... A-2

Lead Assy Spiral Wrap Installation .................................................................................... A-3

Calibration ............................................................................................................................... A-4

Operation ............................................................................................................................ Section B

General Description................................................................................................................. B-1

Controls and Settings .............................................................................................................. B-1

Poentiometer ..................................................................................................................... B-1

Micro Switch ...................................................................................................................... B-1

Trigger Sensitivity .............................................................................................................. B-1

Sensitivity Adjustment ....................................................................................................... B-1

Drive Roll and Idler Rolls ......................................................................................................... B-1

Drive Roll Installation and Removal .................................................................................. B-1

Idler Roll Installation and Removal .................................................................................... B-1

General Options/Accessories .......................................................................................... Section C

Cable Covers........................................................................................................................... C-1

Maintenance ....................................................................................................................... Section D

Recommended Spare Parts List ............................................................................................. D-1

Troubleshooting .................................................................................................................Section E

How to Use Troubleshooting Guide......................................................................................... E-1

Troubleshooting Guide ............................................................................................................ E-2

Diagrams .............................................................................................................................Section F

Diagrams / Parts List ................................................................................................................F-1

Electrical ...................................................................................................................................F-8