Page is loading ...

Installation and user’s guide

H-2000-5021-06-A

LP2 probe system

English

Français

Deutsch

Italiano

Installation and user’s guide

LP2 – LP2H – LP2DD – LP2H DD probes

Hard-wired transmission

1

English

Manuel d’installation et d’utilisation

Palpeurs LP2 – LP2H – LP2DD – LP2H DD

à transmission inductive ou câblée

2

Français

Installations- und Benutzerhandbuch

LP2 Messtaster mit induktiver oder

Kabelübertragung

3

Deutsch

Manuale d’installazione e d’uso

Sonde LP2 – LP2H – LP2DD – LP2H DD

Transmissione a induttanza o cablata

4

Italiano

This page is intentionally left blank

1-1

English

Installation and user’s guide

LP2 – LP2H – LP2DD – LP2HDD probes

1

1-2

© 2000-2015 Renishaw plc. All rights reserved.

This document may not be copied or reproduced

in whole or in part, or transferred to any other

media or language, by any means, without the

prior written permission of Renishaw.

The publication of material within this document

does not imply freedom from the patent rights of

Renishaw plc.

Disclaimer

RENISHAW HAS MADE CONSIDERABLE

EFFORTS TO ENSURE THE CONTENT OF

THIS DOCUMENT IS CORRECT AT THE

DATE OF PUBLICATION BUT MAKES NO

WARRANTIES OR REPRESENTATIONS

REGARDING THE CONTENT. RENISHAW

EXCLUDES LIABILITY, HOWSOEVER

ARISING, FOR ANY INACCURACIES IN THIS

DOCUMENT.

Trade marks

RENISHAW and the probe symbol used in the

RENISHAW logo are registered trade marks of

Renishaw plc in the United Kingdom and other

countries. apply innovation and names and

designations of other Renishaw products and

technologies are trade marks of Renishaw plc or

its subsidiaries.

All other brand names and product names used

in this document are trade names, trade marks,

or registered trade marks of their respective

owners.

Renishaw part no: H-2000-5021-06-A

Issued: 10.2015

1-3Contents

Preliminary information .................................... 1-4

Introduction

...................................................... 1-6

LP2 probe types

.............................................. 1-7

LP2 modular system

........................................ 1-8

LP2 probe moves

............................................ 1-9

Specification

.................................................. 1-11

Dimensions

.................................................... 1-13

Recommended connection diagram for LP2

with HSI interface

.......................................... 1-14

Recommended connection diagram for LP2

with MI 8-4 interface

...................................... 1-15

Typical LP2 probe systems

Machining centres

(radio transmission)

................................. 1-16

Machining centres

(optical transmission) .............................. 1-17

Machining centres

(hard-wired transmission) ........................ 1-18

Machining centres

(hard-wired transmission, tool setting) .... 1-19

Lathes (radio transmission) ..................... 1-20

Lathes (optical transmission) .................. 1-21

Lathes (hard-wired transmission)

............ 1-22

Stylus spring pressure adjustment

– gauging force

.............................................. 1-23

Stylus on-centre adjustment with probe

holders and sockets

....................................... 1-24

Stylus on-centre adjustment with shank

adaptor or shank

............................................ 1-25

Screw torque values

...................................... 1-26

Software requirements

.................................. 1-27

Service and maintenance

.............................. 1-28

Fault-finding

................................................... 1-30

Part list

........................................................... 1-32

1-4 Preliminary information

Warranty

Equipment requiring attention under warranty

must be returned to your equipment supplier.

Unless otherwise specifically agreed in writing

between you and Renishaw, if you purchased

the equipment from a Renishaw company, the

warranty provisions contained in Renishaw’s

CONDITIONS OF SALE apply. You should

consult these conditions in order to find out the

details of your warranty but, in summary, the main

exclusions from the warranty are if the equipment

has been:

• neglected, mishandled or inappropriately

used; or

• modified or altered in any way except with

the prior written agreement of Renishaw.

If you purchased the equipment from any other

supplier, you should contact them to find out what

repairs are covered by their warranty.

Changes to equipment

Renishaw reserves the right to change

specifications without obligation to change

equipment previously sold.

CNC machine

CNC machine tools must always be operated by

competent persons in accordance with the

manufacturer’s instructions.

Care of the probe

Keep system components clean and treat the

probe as a precision tool.

1-5Preliminary information

WEEE directive

The use of this symbol on Renishaw products

and/or accompanying documentation indicates

that the product should not be mixed with

general household waste upon disposal. It is the

responsibility of the end user to dispose of this

product at a designated collection point for waste

electrical and electronic equipment (WEEE) to

enable reuse or recycling. Correct disposal of

this product will help to save valuable resources

and prevent potential negative effects on the

environment. For more information, please

contact your local waste disposal service or

Renishaw distributor.

Safety

Information for the user

In all applications involving the use of machine

tools or CMMs, eye protection is recommended.

Refer to the machine supplier’s operating

instructions.

The LP2 system must be installed by a

competent person, observing relevant safety

precautions. Before starting work, ensure that the

machine tool is in a safe condition with the power

switched OFF and the power supply to the HSI/

MI 8-4 is disconnected.

Information for the machine supplier

It is the machine supplier’s responsibility to

ensure that the user is made aware of any

hazards involved in operation, including those

mentioned in Renishaw product documentation,

and to ensure that adequate guards and safety

interlocks are provided.

Under certain circumstances the probe signal

may falsely indicate a probe seated condition.

Do not rely on probe signals to stop a machine’s

movement.

1-6 Introduction

Introduction

The LP2 is a compact and versatile probe for

applications on CNC lathes and machining

centres. A wide range of styli and accessories is

available to provide custom installations.

Principal applications

Horizontal lathes

Small enough to fit on a turret for part measuring,

tool setting and broken tool detection when

mounted in a suitable position.

Machining centre applications

Set-up and part measuring when spindle

mounted. Tool setting and broken tool detection

when table mounted.

Signal transmission systems

• Hard-wired – a range of hard-wired probe

sockets is available for inspection and tool

setting applications. For machining centres

with manual tool change the LP2 will fit the

MA2 probe holder.

• Optical or radio – for lathes and machining

centres. Easy installation, particularly in

retrofit applications because there is no

need for the prepared passageways required

for hard-wired transmission cables. LP2

can be used with OMP40M, OMP60M,

RMP40M, RMP60M.

Interface Unit

A hard-wired installation with LP2 may use the

HSI interface, see the HSI interface installation

guide (Renishaw part no. H-5500-8554), or the

MI 8-4 interface, see the MI 8-4 Installation and

user’s guide (Renishaw part no. H-2000-5008).

The FS1i and FS2i probe sockets with integral

interface may also be used, see the FS1i and

FS2i probe sockets data sheet (Renishaw part

no. H-2000-2073).

1-7LP2 probe types

There are four versions of the LP2 probe.

Each version is best suited to particular

applications.

LP2 – For normal setting/inspection. The

metal eyelid protects the diaphragm in a hot

chip and coolant environment.

LP2H – With higher stylus pressure for long

or heavy styli, or where there is excessive

machine vibration.

LP2DD – LP2HDD – The double diaphragm

(DD) arrangement is recommended for

grinding machines and other applications

with particle-laden coolant. The LP2HDD is a

version with a higher stylus spring pressure,

similar to the LP2H.

1. Stylus – M4 thread

2. Metal eyelid

3. Spring

4. Diaphragm

5. Rear O-ring

6. M16 thread

7. Stylus spring pressure adjustment

8. Swarf deflector – essential for LP2DD

and LP2HDD when continually exposed

to hot chips.

*

Stylus spring pressure adjustment not available

LP2DD probes are available as original equipment,

or existing LP2 probes may be converted to the DD

standard using a conversion kit.

*

8

4

4

7

*

LP2

LP2H

LP2HDD

1

2

3

4

5

6

7

LP2DD

1-8 LP2 modular system

M4 styli

Stylus weak link

Swarf deflector

Radio or

optical

receiver

FS3

FS2

FS1

Probe sockets

Transmission module

LP2 LP2H LP2DD LP2HDD

Hard-wired transmission

Shank

MA2 probe

holder

Shank adaptor

Square holder

LPE extension bar

MA 4 adapter

1-9LP2 probe moves

With a double touch sequence, the first move

finds the surface quickly, then the probe is

reversed to a position clear of the surface before

making the second touch at a slower feedrate,

thereby recording the surface position at a higher

resolution.

Probe trigger

A probe trigger signal is generated when the

probe’s stylus is driven against a surface. The

machine control records the contact position and

instructs the machine motion to stop.

Although high probing speeds are desirable, it is

essential to choose a probing velocity which allows

the machine to stop within the limits of stylus

overtravel and machine measuring capability.

Follow feedrate guidelines given by the supplier.

To ensure a trigger signal is generated, drive the

probe against the workpiece to a target beyond

the expected surface, but within the limits of stylus

overtravel.

After the probe stylus touches the surface, reverse

clear of the surface.

Single and double touch

If the probe operating sequence is based on a

single touch, then, following a gauging move, the

probe may be returned to its start point.

With some types of controllers, it is an advantage

to use a double touch method as poor repeatability

can result from using higher feedrates.

Z

1

Start position

Overtravel limits (see page 1-12)

2

X/Y

1-10 LP2 probe moves (continued)

System delays

System delays are repeatable to less than 2 µs,

and are constant in each direction in which

measurement is taken.

Delays are automatically compensated for,

provided a calibration move is made in the

same direction and at the same velocity as each

measurement move.

Calibrating a system

Calibrate the probe system at a constant

measurement speed in the measurement

direction, to automatically compensate for errors,

in the following circumstances:

1. Before the system is used.

2. When a new stylus is used.

3. If the stylus is bent.

4. To allow for machine thermal growth.

5. Where there is poor shank relocation

repeatability in the machine spindle.

1-11Specification

Variants LP2 / LP2DD LP2H / LP2HDD

Principal application

Workpiece inspection and job set-up on all sizes of lathes,

machining centres and CNC grinders.

Transmission type

Hard-wired, or in conjunction with optical or radio transceiver

modules

Compatible

interfaces

Hard-wired

Optical

Radio

HSI, MI 8-4, FS1i or FS2i

OMI-2 / OMI-2T / OMI-2H / OMI-2C or OSI / OMM-2

RMI-Q

Recommended styli

50 mm (1.97 in) to 100 mm

(3.94 in)

Stylus material depends on

application.

50 mm (1.97 in) to 150 mm

(5.91 in)

Stylus material depends on

application.

Weight

65 g (2.29 oz)

Sense directions

±X, ±Y, +Z

Unidirectional repeatability

1.00 µm (40 µin) 2s (see note 1) 2.00 µm (80 µin) 2s (see note 1)

Stylus trigger force

(see notes 2 and 3)

XY low force

XY high force

+Z direction

0.50 N, 51 gf (1.80 ozf)

0.90 N, 92 gf (3.24 ozf)

5.85 N, 597 gf (21.04 ozf)

2.00 N, 204 gf (7.19 ozf)

4.00 N, 408 gf (14.39 ozf)

30.00 N, 3059 gf (107.91 ozf)

1-12

NOTE: For stylus recommendations, please refer to the Styli and accessories technical specification

(H-1000-3200).

Note 1 Performance specification is tested at a standard test velocity of 480 mm/min (18.9 in/min) with a 35 mm stylus. Significantly

higher velocity is possible depending on application requirements.

Note 2 Trigger force, which is critical in some applications, is the force exerted on the component by the stylus when the probe

triggers. The maximum force applied will occur after the trigger point (overtravel). The force value depends on related

variables including measuring speed and machine deceleration.

Note 3 These are the factory settings, manual adjustment of the LP2/LP2DD is possible, but the LP2H/LP2HDD is NOT adjustable.

Stylus overtravel limits

LP2 LP2DD LP2H LP2HDD

±X / ±Y 14.87 mm

(0.55 in)

±12.5°

19.06 mm

(0.73 in)

±15°

14.87 mm

(0.55 in)

±12.5°

19.06 mm

(0.73 in)

±15°

Z 6.5 mm (0.26 in)

4.5 mm (0.18 in) when fitted with

a swarf deflector

5.0 mm (0.20 in)

4.5 mm (0.18 in) when fitted with

a swarf deflector

Mounting

M16 thread, for LPE extension bars and adaptors.

Sealing

IPX7 (EN/IEC 60529)

Storage temperature

-10 °C to +70 °C (+14 °F to +158 °F)

Operating temperature

0 °C to +60 °C (+32 °F to +140 °F)

Specification (continued)

1-13

Dimensions given in mm (in)

Dimensions

LP2 – LP2H

LP2DD – LP2HDD

7.5 (0.30)

6.5 (0.26)

40.8 (1.61)

Ø25 (0.98)

20 (0.79)

Ø7 (0.27)

M16x1

12.5°

12.5°

M4 stylus

4.5 (0.18)

6.5 (0.26)

40.8 (1.61)

Ø25 (0.98)

20 (0.79)

Ø7 (0.27)

M16x1

15°

15°

M4 stylus

1-14

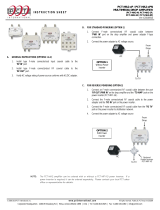

NOTES:

When connecting the

LP2 probe to the HSI

interface, please use

the connection labelled

STANDARD PROBE.

When the SSR output

is connected as

normally open (N/O),

the LP2 probe will

remain in the non-

triggered (seated) state

if the power supply is

interrupted or if the

probe is damaged.

Recommended connection diagram for LP2 with HSI interface

HSI interface

1 0 V

2 Inhibit return

3 Inhibit

4 External LED 0 V

5 External LED 10 V

6 N/O*

7 Common

8 N/C**

10 Screen

CNC controller

Standard connector (3 way)

Controller connector (12 way)

11 Supply 0 V

12 Supply 12 V – 30 V

9 12 V – 30 V out (fused 100 mA)

Status

Output

SSR

Power

input

1 Probe input +

2 Probe input -

3 Screen

0 Vdc

12 – 30 Vdc

Screen

Controller protective earth

(also referred to as PE

starpoint or earthplate)

Probe

input

I/O supply

skip input

Connect either pin 6 or pin 8,

but do not connect both wires

Probe inhibit

function, see HSI

installation guide

(Renishaw part no

H-5500-8554)

Inner spring pin

Outer spring pin

Probe holder fixed socket for

LP2 probe

Controller reference ground

Status *Normally

open

(N/O)

**Normally

closed

(N/C)

Probe

triggered

Closed Open

Probe

seated

Open Closed

1-15

Power to

interface

CNC controller

+Vdc

0 Vdc

Controller

protective

earth **

Controller

protective

ground

Green/Yellow

Optional

+Vdc from I/O supply

Skip input (G31)

-Vdc from I/O supply

MI 8-4 interface

A10 output + supply

A11 probe status output (totem pole)

A12 output - supply

B4 SELX-

B5 X-

B6 SELX+

B7 X-

B8 SELZ-

B9 Z-

B10 SELZ+

B11 Z+

A7 inspection select

A8 inhibit

A9 input resistors common

Power input

B1 +Vdc

B2 0 Vdc

B3 screen

Green/Yellow

Green/Yellow

Green/Yellow

Inspection system input + A4

Inspection system input - A5

Screen A6

Probe

input

Screen A1

Probe + A2

Probe - A3

Optional

Inspection

probe

Inspection

probe

interface

Blue

Green

LP2 Probe

LP2

Machine tool

**Can also be referred to as ‘PE’, ‘starpoint’ or ‘earthplate’

For more information regarding these connections, see the MI 8-4

installation and user’s guide (Renishaw part no. H-2000-5008).

Recommended connection diagram for LP2 with MI 8-4 interface

1-16 Typical LP2 probe systems

Machining centres (radio transmission)

CNC

machine

control

RMI-Q receiver

Workpiece

LP2 probe

Stylus

Typical radio

module

CNC machine

spindle

Cable

Mounting

bracket

/