I-NL3I-01.doc Issue 5 09/11/2021 1

IOM – NexLED 3 STD & EM - BULKHEAD (IND)

INSTALLATION

,

OPERATION AND MAINTENANCE INSTRUCTIONS

NEXLED 3 Standard & Emergency

Industrial

Important: Please read these instructions carefully before installing or maintaining this equipment.

Good electrical practices should always be followed, this data should be used

as a guide only.

I-NL3I-01.doc Issue 5 09/11/2021 2

IOM – NexLED 3 STD & EM - BULKHEAD (IND)

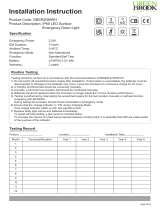

0.0 Specification

Type of Protection N/A

Standards EN 60598-1, EN 60598-2-22

Area Classification Industrial (Non- Hazardous)

Ambient Non-Emer

g

enc

y

(

-40°C to +50°C

)

,Emer

g

enc

y

(

-20°C to +50°C

)

Ingress Protection IP66/67 to EN 60529

The CE marking of this product applies to "The Electrical Equipment (Safety) Regulations

2006", "The Electromagnetic Compatibility Regulations 2004", the “Waste Electrical and

Electronic Equipment Regulations 2006”. [This legislation is the equivalent in UK law of EU

directives 2014/35/EU, 2014/30/EU, 2012/19/EU respectively].

The UKCA marking of this product applies to "The Electrical Equipment (Safety) Regulations

2016", "The Electromagnetic Compatibility Regulations 2016", the “Waste Electrical and

Electronic Equipment Regulations 2012

M Poutney Technical Manager

Luminaire is supplied with battery plug/Socket disconnected, just prior to switching

power on, connect battery plug and socket.

1.0 Introduction

The Chalmit NexLED non-emergency & emergency brings the very latest in lighting technology. It is a compact

light source that uses ultra bright light emitting diodes in 4K or 5K options to provide light from mains power and

for emergency from internal battery back up on mains failure. The electronics are housed in an impact and

corrosion resistant marine grade aluminium enclosure with a toughened glass lens. The control gear is electronic

with regulated lamp output. The LEDs work equally well at low temperatures as they do at high, giving a product

with very low overall power consumption.

The product is available with 1,2 or 3 LED modules and as an exit sign version with which a self-adhesive label

kit is used.

Wiring Diagrams

Typical NL3I/01L/LE

I-NL3I-01.doc Issue 5 09/11/2021 3

IOM – NexLED 3 STD & EM - BULKHEAD (IND)

NL3I/01L/LE/EM

2.0 Storage

Luminaires are to be stored in cool dry conditions preventing ingress of moisture and condensation.

Battery packs in storage should be cycled charged/discharged/charged every 9 months, as per instructions

below. Always fully disconnect battery plug from socket for storage.

Any specific instructions concerning emergency luminaires must be complied with.

(Warning: Battery packs not cycled and stored for a year may not be recoverable)

3.0 Installation and Safety

3.1 General

These instructions should be read fully and carefully before attempting to install the luminaire. For

details of servicing operations, opening etc. see section 6.0.

Copies of these instructions should be held in a safe place for future reference. It is the responsibility of the

installer to ensure that the apparatus selected is fit for its intended purpose and that the installation, operation

and maintenance of the apparatus complies with applicable regulations, standards or codes of practice.

Installation should be carried out in accordance with the IEE wiring regulations and any local authorised

practices.

Any specific installation instructions must be referred to. In the UK the requirements of the Health and Safety at

Work Act must be met, and electrical work associated with this product must be in accordance with the "Manual

Handling Operations Regulations" and "Electricity at Works Regulations 1989". Disposal instructions should be

complied with.

The luminaires should be considered Class 1 to EN 60598 and effectively earthed.

DO NOT MEGGER

3.2 Tools

3mm and 5mm flat blade screwdriver

Spanners for installing cable glands.

Pliers, knife, wire Strippers/cutters.

Replacement: T20 Screwdriver

3.3 Electrical Supplies

The standard unit is rated for a nominal 120-277V AC 50/60Hz and the Emergency version is rated for a nominal

220-240V AC 50/60 Hz. A maximum voltage variation of +/-6% on the nominal is acceptable; however, the driver

and Emergency Inverter are designed to accept tolerances of up to +/-10%. Luminaires should not be operated

continuously at more than +/-6% of the rated supply voltage of the control gear.

I-NL3I-01.doc Issue 5 09/11/2021 4

IOM – NexLED 3 STD & EM - BULKHEAD (IND)

3.4 LED Module

LED’s are supplied in 1187, 2245 or 3872 Lumen options with the colour temperature of 4K or 5K.

The LEDs are maintenance free and at 25°C can last up to a calculated 133,000 hrs at L70. Therefore, in many

applications replacement of the LED module will be unnecessary. If replacement is required ensure mains

supplies are isolated before commencing work. Remove the front cover and then remove the LED array and

mounting plate assembly by disconnecting the cables. Assembly is the reverse of disassembly making sure that

the earth is connected and ensuring the gasket/glass mating surfaces are clean and cables are not trapped.

3.5 Control Gear

System life >100,000hrs

Therefore, replacement of this component should be unnecessary. If replacement is required ensure mains

supplies are isolated before commencing work. Remove the front cover then drop down the LED array.

The LED array should be dis-connected first by removing wires from the terminal block, then using an 8mm nut

driver the hanging straps should be removed.

The geartray can now be taken out with the removal of the 2 Torx head screws.

Assembly is the reverse of disassembly, making sure that the earth is connected and ensuring the gasket/glass

mating surfaces are clean and cables are not trapped.

3.5 Mounting

Luminaires should be installed where access for maintenance is practical and in accordance with any lighting

design information provided for the installation. Mounting is by 4 holes in the base of the body casting external to

the gasket. These should be secured with lock washers or self-locking nuts and bolts and are accessed by

removing the front cover. Any mounting attitude may be used.

3.6 Cabling and Cable Glands

3.6.1 Cables

The maximum conductor size is 4mm². Internal earth point is provided next to the main terminal block. 300/500V

cable ratings are adequate and no special internal construction is necessary. The standard looping cable size is

up to 4mm². The selection of cable size must be suitable for the fuse rating. Terminals are supplied with

suitability for looping. Where looping is used the maximum current is 16A. Terminals are accessed by removing

the front cover and LED array assembly. Maximum cable temperature rise is 20oC above ambient.

3.6.2 Cable glands

The installer and user must take responsibility for the selection of cables, cable glands and seals. Three tapped

cable entries are provided. Sealing plugs are provided and a tool must be used for their removal. Cable entries

are M20x1.5.

The cable and gland assembly when installed must maintain a minimum of IP66/67 rating.

The cable glands must be suitable for the application. Where brass cable glands are used in a corrosive

environment, cadmium or nickel plating should be used.

3.7 Exit Sign Version

To apply the exit label assembly, loosen the M6 wire rope fastener from the front cover, position the assembly

and fix in place using the M6 fasteners provided. The illuminated height of the label is 140mm with a maximum

visible distance of 28m as defined by EN1838.

3.8 Emergency Operation

When there is a disruption to the mains supply the Nexled will switch over to battery backup instantly.

3.9 Battery Maintenance

The battery pack is a 3.5Ah NiMH cell pack. Periodic testing (minimum period of one year) allowing full

discharge will enable the cells to remain in a healthy condition. Should the battery pack need to be replaced

spares may be ordered from Chalmit Lighting.

The luminaire must not be operated without the battery connected. If the battery is removed and not replaced

the control gear supply must be disconnected at the mains terminal block and secured.

4.0 Inspection and Maintenance

Visual inspection should be carried out at a minimum of 12 monthly intervals and more frequently if conditions

are severe.

I-NL3I-01.doc Issue 5 09/11/2021 5

IOM – NexLED 3 STD & EM - BULKHEAD (IND)

4.1 Routine Maintenance

Visual tests and checks should be carried out at intervals described by the appropriate regulations and should

include the following:

Check that the LEDs are working.

Check for mechanical damage/corrosion.

Check for loose connections including earthing.

Check for undue accumulations of dust or dirt.

Verification of tightness of fixing, glands, blanking plugs etc.

Check for unauthorised modifications.

Check condition of enclosure gasket and fastenings.

Check for any accumulation of moisture.

Periodic inspection of the enclosure seal should be carried out to ensure that the seal is sound.

If the luminaire has been subjected to abnormal conditions, for example, severe mechanical impact or chemical

spillage, it must be de-energised until it has been inspected by an authorised and competent person. If in doubt,

the unit should be returned to Chalmit for examination and if deemed necessary replacement.

Before re-assembling, all connections should be checked, and any damaged cable replaced.

4.2 Routine Testing of Emergency Lighting Functions

Users should ensure that the performance of emergency lighting remains adequate for their purposes by

conducting periodic tests and recording the results. Requirements will differ between countries, applications and

organisations.

4.2.1 Emergency Lighting Functions

Battery Management Test (BMT) comes as standard on the NexLED III Emergency luminaire range

4.2.2 Commissioning

After installation of the Luminaire and initial connection of the mains supply and battery supply the luminaire will

commence charging the batteries for 20 hours (initial charge). Afterwards, the luminaire initiates a

commissioning test for the full duration.

Note: If Interrupted this will only delay the process until the battery is fully charged.

The 20 hours recharge occurs also if a new battery is connected or the module exits the rest mode condition.

The following automatic commissioning duration test is only performed when a battery is replaced and fully

charged (after 20 hrs) and the interval time is not set to zero, otherwise the system is expected to perform the

testing.

Note: If the mains supply is to be interrupted for more than 7 days, then the battery MUST be disconnected.

4.2.3 Functional test

The default setting is a 5 seconds test on a weekly basis.

4.2.4 Duration test

The default setting is a duration test conducted every 52 weeks.

For luminaires with Emergency Indicator the following procedure and displays apply.

LED Indication Status Comment

Permanent

g

reen S

y

stem OK AC mode

Fast flashing green (0.1 sec on –

0.1 sec off

)

Function test underway

Slow flashing green (1 sec on – 1

sec off

)

Duration test underway

Red LED on Load failure Open circuit/Short circuit/LED

failu

r

e

Slow flashing red (1 sec on – 1 sec

off)

Battery failure Battery failed the duration test or

function test/Battery is defective or

deep discharged/incorrect battery

volta

g

e

Fast flashing red (0.1sec on – 0.1

sec off

)

Charging failure Incorrect charging current

I-NL3I-01.doc Issue 5 09/11/2021 6

IOM – NexLED 3 STD & EM - BULKHEAD (IND)

Double pulsing green Inhibit mode Switching into inhibit mode via

controller

Binary transmission of address via

g

reen/red LED

Address identification During address identification mode

Green and red off DC mode Battery operation (emergency

mode

)

4.3 Electrical Fault Finding and Replacement (Refer EN / IEC 60079-19)

The supply must be isolated before opening the luminaire.

Any live fault finding must be done by a competent electrician and, if carried out with luminaire in place, under a

permit to work. When electronic high frequency gear is fitted do not megger.

If LED’s go out repeatedly, and replacement LED’s do not work or expected life is reduced, the control gear

should be returned for replacement / testing. The electronic drivers are approved components.

On re-assembly, all faulty/damaged wiring should be replaced, and connections checked.

4.3.1 Battery Check and Replacement (Refer EN / IEC 60079-19)

Do not open luminaire when a hazardous atmosphere is present. Isolate before opening. The battery is detached

at the plug and socket. Remove the two screws to release the battery. Re-assembly is in reverse order.

Important: Although the battery pack is fitted with a polarised plug and socket to prevent accidental

shorting, Care must be taken not to short the leads together as this can cause sparking which, in turn, could lead

to a fire.

The emergency duration is 3 hours for the 01L, 02L and the 04L. This is in accordance with IEC 60598 2-22. The

battery must be replaced when the duration is not acceptable.

Protect the batteries from water ingress and mechanical damage then transport from the hazardous area as

soon as practical. Take care to fully discharge batteries before transporting or otherwise ensure that there can

be no release of stored energy in transit.

4.3.2 Checking of Battery separately

If the battery is to be checked separately, it should be charged using a constant current charger at 175/350mA

for 30/15 hours for the 3.5Ah. Discharge measurement is not easy as the current is proportional to the voltage

for resistance loads, so it must be averaged. Discharge the battery at 1 to 2A and multiply current by time. Do

not discharge below 1 volt per cell, which is 4V. The capacity should be 75% or more of normal.

5.0 Disposal of Material

Any disposal must satisfy the requirements of the WEEE directive [2012/19/EU and Regulations 2012] and

therefore must not be treated as commercial waste. The unit is mainly made from incombustible materials. The

control gear contains plastic resin and electronic components. All electrical components may give off noxious

fumes if incinerated.

5.1 Battery Disposal

Nickel Hydride batteries are defined as 'controlled waste' under the hazardous waste regulations and the person

disposing needs to observe a 'duty of care'.

Batteries can be returned to the manufacturers for recycling. They must be stored and transported safely, and

any necessary pollution control forms completed prior to transportation. Take care to fully discharge batteries

before transporting, or otherwise ensure that there can be no release of stored energy in transit. For further

details refer to our Technical Department.

6.0 Fuse ratings

With the availability of MCB's with a wide range of characteristics, the individual engineer can make a better

judgement of what is required. Use MCB's suitable for inrush currents to reduce ratings. Where MCB's are used,

the type with the higher short time tripping current ratio used for motor starting and lighting should be specified.

The inrush current can be calculated where circuit conditions are known. The inrush currents can be obtained

from the manufacturer.

The fuse ratings for LED strips in circuits need to take account of the Driver within the construction of the

Luminaire. All calculations must satisfy wiring regulations.

I-NL3I-01.doc Issue 5 09/11/2021 7

IOM – NexLED 3 STD & EM - BULKHEAD (IND)

Note: Line currents for 230V, 50Hz are as indicated below in Table A and Table B

Power Factor 0.9 Minimum

Table A - Series Standard Circuit.

Model No. Of

LED Strips Nominal Volts Lumen Nominal Circuit

Power (W)

Line

Current (Amp)

01L

1 x 140mm 120-277Vac 50/60 Hz

127-300Vdc 1187 10 0.05

02L

2 x 140mm 120-277Vac 50/60 Hz

127-300Vdc 2245 19 0.09

04L

3 x 140mm 120-277Vac 50/60 Hz

127-300Vdc 3872 31 0.15

Table B - Series Emergency Circuit.

Model No. Of

LED Strips Nominal Volts Lumens

Mains/EM

Nominal Circuit

Power (W)

Line

Current (Amp)

01L NM

1 x 140mm 220-240Vac 50/60 Hz 537 4 0.02

01L

1 x 140mm 220-240Vac 50/60 Hz

1187/537 11 0.05

02L

2 x 140mm 220-240Vac 50/60 Hz

2245/502 20 0.09

04L

3 x 140mm 220-240Vac 50/60 Hz

3872/519 32 0.15

To comply with the Waste Electrical and Electronic Equipment directive 2012/19/EU and

Regulations 2012 the apparatus cannot be classified as commercial waste and as such

must be disposed of or recycled in such a manner as to reduce the environmental impact.

I-NL3I-01.doc Issue 5 09/11/2021 8

IOM – NexLED 3 STD & EM - BULKHEAD (IND)

I-NL3I-01.doc Issue 5 09/11/2021 9

IOM – NexLED 3 STD & EM - BULKHEAD (IND)

EU/UK-Declaration of conformity

UE-Déclaration de conformité

EU-Konformitätserklärung

Manufacture

r

Chalmit Address 388 Hillin

g

ton Road, Glas

g

ow. G52 4BL Scotland UK

P

r

oduct NexLED 3 Bulkhead Industrial

(

Standard and Emer

g

enc

y)

Catalogue NL3I/***/LE/EM Example: NL3I/01L/LE/EM

Area Classification Industrial

(

Non- Hazardous

)

In

g

ress Protection IP66/67

Ambient Non-Emergency -40°C to +50°C Emergency -20°C to +50°C

Terms of the directive: Standard & Date Certified to Standards Date Declared to

Prescription de la directive: Standard & date certifiée à Normes date Déclaré

Bestimmungen der Richtlinie: Standard & Datum zertifiziert

nach

Standards Datum erklärt

2014/30/EU

Regulations 2016 Electromagnetic compatibility EN 55015 : 2019

2014/30/UE Compatibilité électroma

g

nétique EN 61547 : 2009

2014/30/EU Elektroma

g

netische Verträ

g

lichkeit EN 61000-3-2 : 2019

2014/35/EU

Re

g

ulations 2016 Low voltage equipment EN 60598-1 : 2015

2014/35/UE Équipements électriques à bas voltage EN 60598-2-5 : 2015

2014/35/EU Niederspannun

g

s

g

eräte / -s

y

steme EN 60598-2-22 : 2014

EN 60529 : 1992+A2:2013

2012/19/EU

Re

g

ulations 2012 Waste of electrical and electronic equipment

2012/19/UE Déchets d'équipements électriques et élect

r

oniques

2012/19/EU Entsorgung der elektrischen und elektronischen

Geräte / S

y

steme

2011/65/EU

Re

g

ulations 2012 RoHS II Directive

On behalf of the Chalmit, I declare that, on the date the equipment accompanied by this declaration is placed on the market, the equipment conforms to all

technical and regulatory requirements of the above listed directives.

En tant que représentant du fabricant Chalmit, je déclare qu'à la date où les équipements accompagnant cette déclaration sont mis sur le marché, ceux-ci

sont conformes à toutes les dispositions réglementaires et techniques des directives énumérées ci-dessus.

Hiermit bestätige ich, im Namen von Chalmit, dass am Tag der Lieferung des Produkts/der Produkte zusammen mit dieser Erklärung das Gerät/die Geräte

alle technischen und regulativen Anforderungen der oben aufgeführten Direktiven erfüllt.

Name and Date Mark Poutney 09/11/2021

Technical Manager

Nom et Date Directeur technique

Name und Datum Technischer Leiter

Qualit

y

Mana

g

ement S

y

stem Ac

r

editation: ISO 9001

Système de Management Qualité Accréditation :

Qualitätsmana

g

ements

y

stem Akkreditierun

g

:

Environmental Mana

g

ement S

y

stem. ISO 14001

Système de gestion de l'environnement.

b

y/par/durch

Umwelt kont

r

oll s

y

stem. Loyd's Register

Certificate No./Certificat N°/Zertifikat Nr. LRQ 4005876

/