NOTICE

3-41 Ramp 1 Ramp Up Time and 3-42 Ramp 1 Ramp Down

Time must be the same for the master drive and for all

follower drives in the system.

4. Set the ramps fast enough to enable the PID

controller to maintain control of the system.

4.1.3 Closed Loop Control

The master drive is the primary controller for the system. It

monitors the output pressure, adjusts the speed of the

frequency converters and decides when to add or remove

stages.

To perform this function:

1. setup the master drive closed loop mode with a

feedback sensor connected to an analog input of

the frequency converter.

2. setup the PID controller of the master drive to

match the needs of the installation.

For further information on setting up the PID parameters,

see the VLT

®

AQUA Drive Programming Guide. See also

6.1 Master/Follower.

4.1.4

Staging/De-staging of Variable Speed

Pumps

Staging occurs when the speed of the frequency converter

has reached the value in 27-31 Stage On Speed [RPM]

(27-32 Stage On Speed [Hz]). At this speed the system

pressure is still maintained but the pumps start to operate

outside of their peak efficiency points. Staging on an

additional pump will lower the speed of all running pumps

and provide a more energy efficient operation.

In master-follower configurations and mixed pump config-

urations the variable speed pumps are staged and de-

staged based on the speed of the frequency converters.

De-staging occurs when the speed of the frequency

converters drops below the value in 27-33 Stage Off Speed

[RPM] (27-34 Stage Off Speed [Hz]). At this speed the system

pressure is still maintained but the pumps are beginning

to operate below their peak efficiency points. De-staging a

pump will cause the speed of the frequency converters to

increase into a more energy efficient range.

27-31 Stage On Speed [RPM] (27-32 Stage On Speed [Hz]) and

27-33 Stage Off Speed [RPM] (27-34 Stage Off Speed [Hz]) are

installation dependent. These parameters are indexed

parameters with one set of entries for each pump stage.

The stage on and de-stage off speed can be auto tuned

during automation or set manually. If Auto-tune is enabled

the system will start operation using default settings or the

pre settings done by the user in 27-31 Stage On Speed

[RPM] (27-32 Stage On Speed [Hz]) and 27-33 Stage Off

Speed [RPM] (27-34 Stage Off Speed [Hz]) before enabling

the auto-tune.

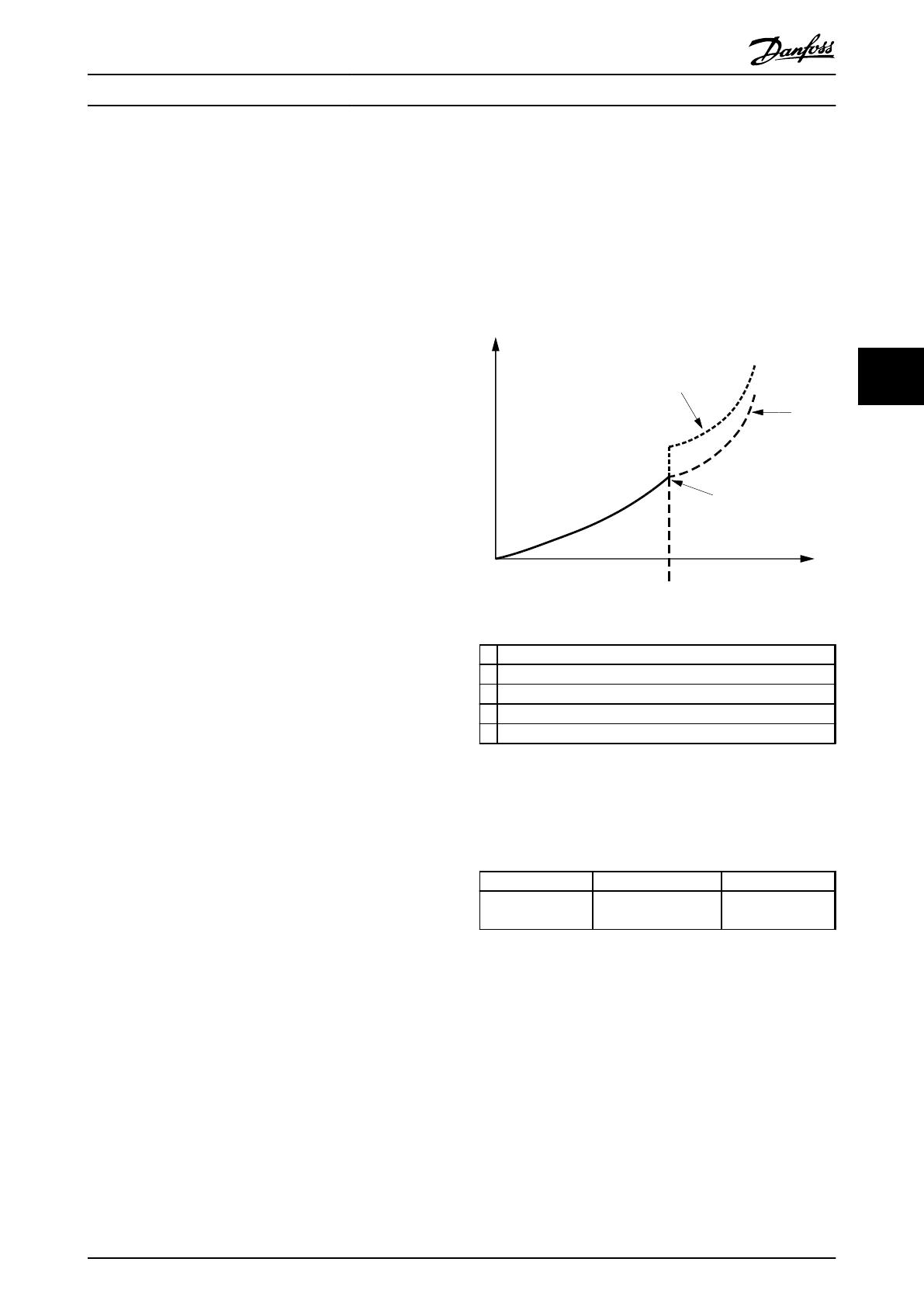

The tuning ensures optimum energy efficiency of the

system. See Illustration 4.2.

Illustration 4.2

1 1 pump running

2 2 pumps running

A Incorrect stage on speed adjustment

B Correct stage on speed adjustment

C Stage on speed pump 2

Table 4.2

During operation the system monitors the actual energy

consumption and optimises every time a stage or de-stage

takes place.

Parameter Range Default

27-30 Auto Tune

Staging Speeds

{[0] Disabled, [1]

Enabled}

[1] Enabled

Table 4.3

4.1.5

Staging/De-staging of Fixed Speed

Pumps

Fixed speed pumps are staged based or de-staged based

on system pressure.

To avoid rapid turning on and off of pumps, define an

acceptable range of system pressure along with a period

of time the pressure is allowed to be outside of this band

before staging or de-staging occurs. Set the values

through:

Configuring the System

VLT

®

AQUA Drive MCO 101/MCO 102

MI38C402 - VLT

®

is a registered Danfoss trademark 17

4 4