1. Print Cylinder (Drum) Preparation

Important: When installing a black ink cartridge, this procedure is not necessary.

Please skip to the procedure 2.

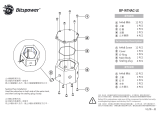

1) Remove the Print cylinder (drum) cover, the Bottle SW cover, and the Bottle guide.

Note: Disconnect the connecter of the Bottle Set SW wireharness from the Bottle guide.

2) Depending on the ink color, cut off the corresponding Jumper wireharness referring to

the table below.

Important: Be sure to cut off the Jumper wireharness from the joint and remove

completely.

3) Fix the Bottle guide, the Bottle SW cover, and the Print cylinder (drum) cover.

Important: Be sure to connect the connecter of the Bottle Set SW wireharness

to the Bottle guide.

2. Insert an Ink cartridge

1) Set an ink cartridge to the Print cylinder (drum).

Be sure to lead ink to the nozzle of the cartridge in advance.

Important: Be sure that the Print Cylinder (drum) temperature is above 59 °F (10 °C).

2) Install the Print cylinder (drum) in the printer.

3) Start the test mode.

Note: If the error code No. d04-534 appears on the control panel, remove the Print

cylinder (drum) and then check the ink cartridge and the Jumper wireharness.

4) Input the test item code No.887 and press the start key .

3. Operation Check

1) Make a master with Riso test chart No.15 and print 200 copies at speed 2.

2) Check density balance.

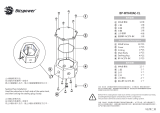

4. Labeling

Affix an ink color indication label on the Print cylinder (drum) cover as illustrated.

RISO KAGAKU CORPORATION Models

RISO CZ series

1.

Print cylinder (drum) ...................................

1 unit

2. Ink color indication label ...................... 1 sheet

3.

Installation guide (This manual)

................ 1 copy

Nobody but Riso-authorized service

representatives is allowed to install this unit.

Types of Applicable Printers

The following printer models are the intended basic

units for installing the

CZ series inkless Print cylinder

(drum).

Packing List

This package contains the following items.

Installation Procedure for The CZ Series

Inkless Print Cylinder (Drum)

Bottle guid