Page is loading ...

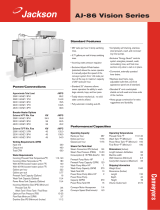

Standard Specifications

• Patented wash flow design allows for washed produce to be

automatically collected into the stainless steel unloading baskets.

• 3 bay wash tank. 2 and 4 bay systems available on separate

specification sheets.

• Custom models available. Full range of Power Soak customization

available including custom tabling, shelving, and accessories.

• Low profile wash jets average every three inches along the back

wall of wash tank above the wash tank intake. Average flow rate

per wash jet (regardless of tank length) is approximately 10 gpm,

providing free flowing uniform wash action.

• Stainless steel self draining pump housing and impeller, all wetted

parts of the pump assembly are stainless steel.

• Wash Tanks supported by 1-5/8” stainless diameter legs with 1 ¼”

stainless cross members and adjustable stainless steel bullet feet.

• Type 304 stainless steel construction throughout tanks, drain

boards, splashes and channel rims 14ga

• High quality ½” faucet assembly with pre-rinse spray

• Rear-exit stainless ball valve drain for 100% drainage

• Control – Pistol Grip ON/OFF mechanical Start/Stop switch

• ¾ HP heavy duty (TEFC) wash pump motors (high service factor)

are provided with all stainless steel pump assemblies

• Modular design allows quick and easy access to: motor, pump and

all major components

• Three years parts and three year labor warranty (USA only).

Application

The Produce Soak provides patented Free Flowing wash action,

reaching hard to reach areas on produce, washing both Raw

Agricultural Commodities (RAC) and/or Processed Produce being

consumed by the customer when used in conjunction with the proper

FDA & EPA approved free rinsing chemical.

Ideal for:

• Institutional Market

• Multi-Unit Food Service Operations

• QSR'S

• Retail Market

Electrical Service

Electrical Connection: PS-50 On/Off Control for 3/4HP Wash Pump

208/230V 1ph , 5.2/4.8 Amp

Optional Equipment Available

Stainless steel backsplash extensions

Additional unload baskets

Additional strainer for unload basket

Stainless steel chemical brackets and shelves

Notes:

* Machine construction compliant with NSF standard 2, insert and accessories approval

pending.

Patents Pending

33837 - 10/6/2010

50PSP75L3B1

SPECIFICATIONS

ITEM#

P

r

o

d

u

c

e

S

o

a

k

5

0

P

S

P

7

5

L

3

B

1

P

r

o

d

u

c

e

S

o

a

k

by Power Soak Systems, Inc.

903 E. 104th Street, Suite 130

Kansas City, MO 64131

www.producesoak.com

- Page 1 -

*

Elevation View:

Section View:

Plan Vew:

- PAGE 2 -

33837 - 10/6/2010

Patents Pending

5

838

38

PRODUCE DRYER

BY OTHERS

SEPARATE POWER SUPPLY REQUIRED

3/4" DIA. HOLES AND

3/4" STAINLESS TUBE

FOR CHEMICAL

ELECTRICAL CONNECTION

#PS-50 CONTROL, 1/2 INCH CONDUIT

208/230 60Hz/1ph, 5.2/4.8 AMPS (15 AMP SERV. REQD)

11/16" Dia.

HOLE

27

43.5

35.5

34

20

4

8.625

1

0.75

24.75

SINKS

12

19

7

REMOVABLE DIVIDERS FOR

PRODUCE WASHING BASKETS

1.5

2

99

31.5

DRAIN

75

18

27 WASH

30

30

/