HOTPLATES

COUNTERTOPMODELS: H-33, H63, H-65, H-70, H-115

BUILT-IN MODELS: H-336, H-636, H-706, H-006

• OPERATION • INSTALLATION•

MAINTENANCE MANUAL

WELLS MANUFACTURING COMPANY

2 Erik Circle, P.O. Box 280, Verdi, NV 89439

(702) 345-0444 • FAX: 702-345-0569

TOLL-FREE FAX: (800) 356-5142, for orders only

ITEM NO. 49050

REV. A 10/96

TABLE OF CONTENTS

DESCRIPTION PAGE

Warranty Statement 3

Shipping Claim Procedure 4

Warnings! 5

Installation Instructions 6-7

Operating Instructions 7

Cleaning Instructions 7

Warranty Exclusions 8

2

WARRANTY STATEMENT

All commercial cooking equipment manufactured by WELLS is warranted against defects in materials and

workmanship for a period of one year from the date of original installation or 18 months from the date of

shipment from our factory, whichever comes first and is for the benefit of the original purchaser only, except

that;

a. with respect to the stainless steel fry pots for gas fryers, model number WFG-40-2, the

stainless steel fry pot is warranted to be free from defects that could cause shortening leaks for five

years from date of purchase, except that after one year replacement of fry pot only is covered at 75%

of list price of kettle assembly. Fry kettle includes new shrouds, insulation, flue vent, burners,

thermostats and attaching hardware; travel and labor not included. Fry pots which fail due to abuse

are not covered by standard or five year warranty - items include, but are not limited to, the firing of

burners without shortening or other cleaning solution in the fly kettle at proper level.

b. with respect to Lite Line Products, warranty is one year parts and labor on carry-in

portable models.

c. with respect to cold/refrigerated products, warranty labor is limited to 90 days after

installation. Extended warranty for labor and compressor are available at time of sale. Contact factory

sales department for details.

THIS WARRANTY IS THE COMPLETE AND ONLY WARRANTY, EXPRESSED OR IMPLIED IN

LAW OR FACT, INCLUDING BUT NOT LIMITED TO, WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR ANY PARTICULAR PURPOSE, AND/OR FOR DIRECT, INDIRECT OR

CONSEQUENTIAL DAMAGES IN CONNECTION WITH WELLS' PRODUCTS. This warranty is void if

it is determined that upon inspection by an authorized service agency that the equipment has been modified,

misused, misapplied, improperly installed, or damaged in transit or by fire, flood or act of God. It also does

not apply if the serial nameplate has been removed or service is performed by unauthorized personnel. The

prices charged by Wells for its products are based upon the limitations in this warranty. Seller's obligation

under this warranty is limited to the repair of defects without charge by a WELLS' factory authorized service

agency or one of its sub-service agencies and is limited to a 60 mile radius to the nearest authorized service

agency or one of its sub-service agencies. This service will be provided on customer's premises for non-

portable models. Portable models (a device with a cord and plug) must be taken or shipped to the closest

authorized service agency, transportation charges prepaid for service. In addition to restrictions contained in

this warranty, specific limitations are shown in the Service Policy and Procedure Guide. WELLS' authorized

service agencies are located in principal cities. This warranty is valid in the United States and Canada and

void elsewhere. Please consult your classified telephone directory, your foodservice equipment dealer or

write the Factory Service Department, Wells Manufacturing Company, P.O. Box 280, Verdi, Nevada 89439,

phone (702) 345-0444, for information and other details concerning warranty.

3

SHIPPING CLAIM PROCEDURE:

For your protection, please note that equipment in this shipment was carefully inspected and packed by

skilled personnel before leaving the factory. The transportation company assumes full responsibility for

safe delivery upon acceptance of this shipment.

IF SHIPMENT ARRIVES DAMAGED:

VISIBLE LOSS OR DAMAGE: Be certain this is noted on freight bill or express receipt and signed by

person delivering.

FILE CLAIM FOR DAMAGES IMMEDIATELY: Regardless of extent of damage.

CONCEALED LOSS OR DAMAGE: If damage is unnoticed until merchandise is unpacked, notify

transportation company or carrier immediately, and file "concealed damage" claim with them. This

should be done within (15) days of date of delivery is made to you. Be sure to retain container for

inspection.

Wells cannot assume responsibility for damage or loss incurred in transit; however, we will furnish the

necessary documents to support your claim.

4

WARNINGS!

For Countertop Hotplates:

FOR YOUR SAFETY

Wells Countertop Hotplate is equipped with a three-prong electrical plug. This three-prong plug is

part of a system that will protect you if something goes wrong with the electrical wiring in the hotplate.

Be sure the three-prong plug is plugged into. a matching three-prong socket. DO NOT cut or break

off the large third prong in this plug, or the protective system will not work.

For All Hotplate Models:

IMPORTANT!

Make sure that incoming voltage is the same as unit is rated for. An electrical specification

plate specifying rated voltage, wattage, HZ and phase of unit is attached to the hotplate.

Plugging or wiring hotplate into greater voltage than unit is rated for may cause severe damage

to the infinite control, elements and other components. Plugging or wiring hotplate into

less voltage than unit is rated for may cause significant decrease in performance.

CAUTION

DO NOT SUBMERGE COUNTERTOP HOTPLATES IN WATER. DO NOT

SPLASH OR POUR WATER ONTO CONTROL PANELS OR WIRING.

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE

5

INSTALLATION INSTRUCTIONS:

1. Remove Hotplate carefully from carton. Remove all loose packaging and accessories.

2. IMPORTANT: Read all installation instructions carefully BEFORE starting installation.

3. It is the responsibility of the installer to comply with local codes.

4. Any installation not matching the specifications discussed in this manual will void the warmers

warranty.

Installing Countertop Hotplates:

1. Carefully place hotplate on a suitable countertop or table.

2. Hotplates are equipped with 4-inch adjustable legs (1-inch legs for Model H-115). Screw legs (4 each

packed with unit) into holes on bottom corners of hotplate. Set unit upright on countertop or table.

CAUTION: HOTPLATES SHOULD NOT BE OPERATED WITHOUT HAVING

LEGS INSTALLED.

3. H-63 Hotplates are provided with power cord. All Hotplates are equipped with a spacer to keep unit

spaced properly from the wall. SPACER SHOULD NOT BE REMOVED FOR ANY REASON!

WARNING: HOTPLATES SHOULD MAINTAIN A MINIMUM CLEARANCE OF

1-INCH FROM COMBUSTIBLE WALLS FROM THE SIDES AND

REAR OF THE UNIT.

4. Plug unit into a grounded 120V or 208/240V (depending on the model purchased), single phase

receptacle. Check metal rating plate on the unit to verify correct voltage. Hotplate models without

cordsets should be hardwired by a licensed electrician to the correct voltage. MAKE SURE THAT

INCOMING VOLTAGE IS THE SAME AS UNIT IS RATED FOR..

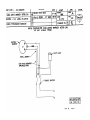

Electrical Grounding Instructions: Hotplates with power cords are equipped a three-prong (grounding)

plug for your protection against shock hazard and should be plugged directly into a properly grounded three-

prong receptacle. DO NOT CUT or remove the grounding prong from this plug.

Installation Requirements/or Built-in Hotplates:

1. Built-in hotplates must be installed into an all metal countertop.

2. The specification sheet covers Underwriters Laboratories conditions of acceptability, installation,

fabrication, and cut-out dimensions.

3. The installation of Built-in Hotplates varies depending on the model chosen. Each hotplate has

features and capabilities that affect the installation.

4. There must be a minimum 1-inch clearance between the unit and rear wall of the counter;

minimum '/4-inch clearance between the unit and adjacent cooking appliances; minimum 2-inch

clearance between the unit and side wall of counter; minimum 9-inch clearance between the

countertop and bottom metal shield.

5. The metal shield must be a minimum No. 22 MSG, and installed at least 9-inches below the

countertop (may have openings which will not permit entrance of a %-inch diameter rod). Please

review specification sheet carefully before beginning installation of Built-in Hotplates. Final

installation must meet all local codes.

6

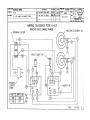

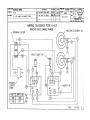

Installing Built-in Hotplates:

1. Please refer to the backside of the specification sheet (General Layout Data) provided with this

manual for specific "cutout" dimensions and installation of the hotplate you have purchased.

2. Install electrical conduit (if required by local code) between hotplate and electrical box.

3. Cut and/or drill holes as required in countertop apron.

4. Mount unit and control panel.

OPERATING INSTRUCTIONS:

1. Heat controls are equipped with an infinite switch for each cooking/heating element, allowing

adjustable temperature setting (OFF, LOW and HI) per element.

2. Control light glows when the heat is turned ON, warning the operator to turn off the unit when not in

use.

3. "High Speed" elements are super-sized, providing instant heat for extra-fast warming — cold to full

heat in 26 seconds.

Cooking Hints:

1. Save energy costs by turning the unit off when not in use. Due to instant warm-up, it's not

necessary to leave the unit on low heat during intermittent usage.

2. Hotplates will hold up to 16 quart pots or pans.

3. Hotplates with solid element, maximize heat efficiency by using flat bottom pots or pans.

CLEANING INSTRUCTIONS:

Before using your new hotplate, wipe entire unit clean using a clean, damp cloth/sponge with mild detergent

and towel dry.

1. Turn temperature control knob to the OFF position.

2. Allow unit to completely cool.

3. Unplug hotplate (if countertop model).

4. Wipe entire unit down using a clean cloth/sponge and a mild detergent.

WARNING: DO NOT SUBMERGE HOTPLATE IN WATER (COUNTERTOP

UNITS). DO NOT SPLASH/POUR WATER ONTO THE CONTROL PANEL

OR WIRING. POSSIBLE SHOCK HAZARD MAY RESULT AND UNIT

MAY BE DAMAGED (COUNTERTOP AND BUILT-IN UNITS).

5. Wipe the stainless steel cabinet down with a damp cloth, this allows "lifetime" stainless steel to keep

its luster permanently.

IMPORTANT: DO NOT USE STEEL WOOL FOR CLEANING.

6. To clean hotplates with swing-up elements, remove the heat reflector pans and clean with a damp

cloth and mild detergent, or place pans in a dishwasher.

7

WELLS MANUFACTURING COMPANY SERVICE

POLICY AND PROCEDURE GUIDE ADDITIONAL

WARRANTY EXCLUSIONS

1. Resetting the safety thermostats, circuit breakers, overload protectors, or fuse replacements unless

warranted conditions are the cause.

2. All problems due to operation at voltages other than specified on equipment nameplates -conversion to

correct voltage must be the customer's responsibility.

3. All problems due to electrical connections not made in accordance with electrical code requirements and

wiring diagrams supplied with the equipment.

4. Calibration of heat controls after the first sixty (60) days on original components. Replacement of item&

subject to normal wear to include such items as knobs, light bulbs, baskets, grids, mechanical timers and

thermocouples. Normal maintenance functions including lubrication, adjustments of airflow, thermostats,

door mechanisms, microswitches, burners and pilot burners and replacement of fuses and indicating lights

are not covered by warranty.

5. All fry pots welded in the field.

6. Deterioration of aluminum vessels due to insertion of food product or use of abrasive cleaners is not

covered by warranty.

7. Full use, care, and maintenance instructions are supplied with each machine. Those miscellaneous

adjustments noted are customer responsibility. Proper attention will prolong the life of the machine.

8. Travel mileage is limited to sixty (60) miles from an Authorized Service Agency or one of its sub-service

agencies.

9. All labor shall be performed during regular working hours. Overtime premium will be charged to the

buyer.

10. All genuine Wells replacement parts are warranted for ninety (90) days from date of purchase on non-

warranty equipment. This parts warranty is limited only to replacements of the defective part. Any use of

non-genuine Wells parts completely voids any warranty.

11. Installation, labor, and job check-outs are not considered warranty.

12. Charges incurred by delay's, waiting time or operating restriction's that hinder the service technicians

ability to perform service are not covered by warranty. This includes institutional and correctional

facilities.

8

WARRANTY POLICY & INSTRUCTIONS GENERAL

This policy and procedures is the controlling document for submitting warranty claims. The information

provided must be reviewed and understood by all service, parts, and warranty administration personnel,

including branch and sub-agents involved in the servicing of Wells Manufacturing Equipment.

1. The warranty statement and service agency listing provides our

customers with our warranty statement, authorized service agencies and additional warranty

exclusions, and is provided to customers with all Wells Manufacturing equipment.

2. Warranty claims that have charges which are excluded or limited in the

warranty statement and service agency listing without prior factory

approval will be rejected. Included, but not limited to, are items such

as:

A. Travel charges for portable equipment, items with power cords such as F-49 fryers,

hotplates, waffle bakers, pop-up toasters, etc. These items must be taken to the closest

authorized service agency or their sub-agent by the end-user.

B. Any mileage/travel labor charges in excess of 60 miles one way on any equipment.

C. Calibration of heat controls after the first sixty (60) days on original components.

Replacement of items subject to normal wear to include such items as knobs, light bulbs,

baskets, grids and thermocouples. Normal maintenance functions including lubrication,

adjustments of airflow, thermostats, door mechanisms, microswitches, burners and pilot

burners and replacement of fuses and indicating lights are not covered by warranty.

3. Care must be taken not to exceed the value of the equipment. Wells Manufacturing Co. will not

be responsible for costs which exceed replacement cost of the equipment. If repair costs are

estimated to be near or above the replacement cost of the unit, contact the factory for repair or

replacement directions.

4. We are using the CFESA/NAFEM Warranty Service Report. It is

available through Wells Manufacturing Co., p/n 58831, in packages of 100, or through CFESA

headquarters. All other warranty forms will be rejected.

5. All warranty claims must be submitted in a timely manner. All

warranty claims must be submitted within six months of the completion date.

PROCEDURES GENERAL

1. All information must be typed or printed clearly.

2. All required information must be provided in accordance with the warranty form instructions

(see pages 3 and 4).

3. Distribution:

A. Mail the original copy of the warranty form to Wells

Manufacturing, attention Service/Warranty.

B. Attach one copy of the warranty form to the parts that are being returned to the

Factory.

4. We use your agency invoice number as our control number and your invoice number can

only be used once during a two year period. The invoice number can be 10 digits in any

alphanumeric combination.

5. Only one serial number may be used per warranty report. If more than one unit is serviced

at a location, submit a warranty report for each unit. You may use a "-1" on your agency

invoice, i.e., Invoice #10701, 10701-1, 10701-2, etc. Travel and mileage may be charged to

only one serial number.

NOTE

Failure to comply with these requirements and the warranty form

instructions will result in rejection of your claim or delay in

processing of the warranty claim.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Wells OC-4T Operating instructions

-

Wells HC-225 User manual

-

Wells Manufacturing HC100 Operating instructions

-

Wells Manufacturing H-706 Operating instructions

-

Wells HC100 Specification

-

Wells Manufacturing H70 Operating instructions

-

Wells Manufacturing H-706 Operating instructions

-

Wells Manufacturing H-2412G Operating instructions

-

Bloomfield H-636 Specification

-

Wells HC1006 Specification