Asco Series 195 Solenoid Valve ATEX 94/9/EC Owner's manual

- Type

- Owner's manual

2 3

3835100-1

INSTALLATION AND MAINTENANCE INSTRUCTIONS

GB

Solenoid valve for use in explosive atmospheres according to ATEX 94/9/EC, intrinsically safe

II 2 G Ex ia IIC T4 - II 2 G Ex ia IIB T4 - II 2 G Ex ia IIC T6 - II 2 G Ex ia IIB T6

(Series 195)

3835100-1

• Ingress protection rating according to EN 60529 : IP65

Special conditions for safe use:

ASCO components are intended to be used only within the

technical characteristics specifi ed on the nameplate or in the

documentation. Changes to the equipment are only allowed af-

ter consulting the manufacturer or its representative.

This solenoid valve which is equipped with an Ex ia rated sole-

noid operator is designed to be installed in potentially explosive

atmospheres caused by gases, vapours or mists of group II

(category 2 G).

The surface temperature classifi cation is T6 - T4 and depends

on the power rating, ambient temperature and assembly of the

product.

ELECTRICAL CHARACTERISTICS

DC coils (=)

type (series) 195

Marquing: II 2 G Ex ia IIC T4 and II 2 G Ex ia IIC T6 :

Nominal supply voltage : Umax. = 28 V,

Max. current consumption : Imax. = 115 mA (24 V)

Max. dissipated power : Pmax. = 1,6 W

Insulation class F (155°C) 100% E.D.

classifi cation

Pn

safety parameters

U

i

= (DC)

I

I

P

I

L

I

C

I

(W)

(V) (mA) (W)

(μF)

(mH)

II 2 G Ex ia IIC T4 0,5

28 115 1,6 0 0

II 2 G Ex ia IIC T6 0,5

28 115 1,6 0 0

Marquing: II 2 G Ex ia IIB T4 and II 2 G Ex ia IIB T6 :

Nominal supply voltage : Umax. = 32 V,

Max. current consumption : Imax. = 195 mA (24 V)

Max. dissipated power : Pmax. = 1,6 W

Insulation class F (155°C) 100% E.D.

classifi cation

Pn

safety parameters

U

i

= (DC)

I

I

P

I

L

I

C

I

(W)

(V) (mA) (W)

(μF)

(mH)

II 2 G Ex ia IIB T4 0,5

32 195 1,6 0 0

II 2 G Ex ia IIB T6 0,5

32 195 1,6 0 0

The solenoid valve type 195 must be supplied with power from

a voltage barrier certifi ed for use in potentially explosive atmos-

pheres of groups IIC, IIB or IIA and having an output circuit that

is rated intrinsically safe. The valve-and-barrier combination

must be compatible in terms of intrinsic safety.

The voltage barrier for the equipment must have the following

maximum characteristics:

Uo = 28 V ; Io = 115 mA ; Po = 1,6W or

Uo = 32 V ; Io = 195 mA ; Po = 1,6W

Since the two parameters Ci and Li of the equipment are both

equal to zero, the maximum output characteristics Co and Lo

of the voltage barrier must exceed the effective values of C and

L of the connecting cable used.

Selecting the barrier and making the interconnections are at the

user’s responsibility.

Pn

(watt)

max. ambient °C

(1)

surface temperature

T6

85°C

T5

100°C

T4

135°C

IIC IIB IIC IIB IIC

IIB

insulation class F (155°C) 100% E.D.

(2)

1,6

50 50 - - 85 85

max. ambient °C

70 70 - - 80 80 max. fl uid °C

Check the power compatibility with the selected product.

Minimum ambient temperature: -40°C

This temperature may be limited by the operating temperature

rating of the pilot valve or spool valve.

Calculation of operating conditions:

I

l

(mA) =

[ V

s

- 1 ] x 1000

(R

c

+ R

l

+ R

b

)

This value (I

l

) as well as the maximum current of the barrier/

GENERAL

These Installation and Maintenance Instructions are for series

195 solenoid valves (II 2 G Ex ia IIC T4, II 2 G Ex ia IIB T4,

II 2 G Ex ia IIC T6, II 2 G Ex ia IIB T6) with mounting pad to ISO

15218 [CNOMO size 30 (06.05.80)].

In case of an assembly to or installation on another valve, the

Installation and Maintenance Instructions and Declarations of

Conformity relating to the specifi c valve must be taken into ac-

count for assembling and putting the solenoid valve into opera-

tion.

Malfunction, damage or injury may occur if these instructions

are not followed.

This component is not a safety accessory, it is intended only for

the compliant use either as an individual component or incor-

porated in apparatus, machinery and installations.

All assembly, operation, use, and maintenance must be per-

formed by qualifi ed, authorised personnel.

Personnel working with the components must be familiar with

the safety regulations and requirements relating to the com-

ponents, apparatus, machinery and electrical installations (for

valves, solenoid valves, electronic control equipment, air serv-

ice equipment). In case of problems, please contact ASCO or

one of its authorised representatives.

DESCRIPTION

The solenoid valve type195 is intended for fl uid control.

Essential Health and Safety Requirements:

This solenoid valve (type 195) is designed in accordance

with Annex II of European Directive 94/9/EC and standards

EN 60079-0 and EN 60079-11.

Classifi cation II 2 G Ex ia IIC T4

II 2 G Ex ia IIB T4

II 2 G Ex ia IIC T6

II 2 G Ex ia IIB T6

The certifi cates of conformity in compliance with these

standards are available at www.asconumatics.eu

EC type examination certifi cate no.: LCIE 08 ATEX 6083

MARKING

The marking includes the following information:

ASCO

BP17

28111 LUCE

FRANCE

Marking : LCIE 08 ATEX 6083

Type designation : 195

Year of manufacture : 20..

Serial number : xxxxxxxx

Specifi c marking : q II 2 G

Additional marking : Ex ia IIC T4, IIB T4 or IIC T6, IIB T6

Ambient/operating : Tamb. = -40°C , + 50°C

INSTALLATION

Preparation:

• Check the preliminary storage conditions required for the com-

ponent. They must be in accordance with the product’s speci-

fi cations.

• Carefully remove the components from their packaging.

• Power off and depressurise the apparatus, machinery, or

installation designed to receive the component. Stipulate

power off and depressurisation requirements to guard against

any unauthorised intervention.

• Make sure that the unit, its components, and their environ-

ment are clean, and protect them against deterioration.

• In order to protect the equipment, install an adequate strainer

or fi lter upstream from and as close as possible to the compo-

nent.

• Do not modify the device.

• Make sure the solenoid valve’s mating surface is clean to pre-

vent damage to the seals.

• Make sure that the fl uid is compatible with the materials it con-

tacts.

Fluids used: air or neutral gas, fi ltered (50µm.)

Allowable fl uid temperature: -40°C to +70°C

This temperature may be limited by the operating tempera-

ture rating of the pilot valve or spool valve. Dew point -20°C.

• The solenoid valve must be installed in a non-corrosive, air or

liquid environment.

3835100-A

Availability, design and specifi cations are subject to change without notice. All rights reserved.

INSTALLATION AND MAINTENANCE INSTRUCTIONS

GB

Solenoid valve for use in explosive atmospheres according to ATEX 94/9/EC, intrinsically safe

II 2 G Ex ia IIC T4 - II 2 G Ex ia IIB T4 - II 2 G Ex ia IIC T6 - II 2 G Ex ia IIB T6

(Series 195)

interface (if it is non-linear) must exceed 37 mA.

I

l

(mA) Minimum supply current for the product

R

b

(Ω) Max. barrier resistance

T

a

(°C) Max. ambient temperature

R

l

(Ω) Max. resistance of connecting cables

V

s

(V) Min. no-load voltage of barrier/interface

R

c

(Ω) Max. coil resistance:

R

c

=

297 (T

a

+ 234 + 10)

254

Depending on the ambient temperature/power rating, a heat

resistant cable suitable for the temperature indicated on the

coil must be used.

The installer is required to proceed in accordance with European

Directive 1999/92/EC and associated standards.

COMPATIBLE BARRIERS AND INTERFACES

These 24 V DC solenoid valves are compatible with the barriers

given in the table on page 26.

These barriers and interfaces allow to feed the intrinsically safe

solenoid valves located in explosive areas.

This equipment must be ordered from its respective manu-

facturers specifying that they are intended to feed intrinsically

safe solenoid valves 195, ll 2 G Ex ia llC T4 / ll 2 G Ex ia llB T4

/ ll 2 G Ex ia llC T6

/ ll 2 G Ex ia llB T6.

According to the zones and following the country legislation,

apply the certifi cation procedure relative to the association of

IS products.

ASCO declines any responsibility for the use of products from

other suppliers and the possible modifi cations of their charac-

teristics.

ELECTRICAL INSTALLATION

The solenoid valve must be installed under the responsibility

of the company operating the industrial site. The system as a

whole must conform to standard EN60079-14.

Before starting any work, turn off the electrical current to

power off the components.

All screw terminals must be tightened to the appropriate torque

prior to operation.

!

Install the cable so that there is no tension on the valve body.

When connecting the cables to the series 195 solenoid valves,

fi rst place all the cables in the cable trays or wireways before

attaching them to the connectors.

The electrical connection is made by

• Detachable connector with an IP65 protection (when properly

mounted). Tighten each wire on the connector’s terminal to

the specifi ed torque. The tightening torque for the cable gland

is 2,5 ±0,1 N.m to ensure tightness to IP65.

Spade plug connector, ISO 4400/EN 175301-803, form A

(cable entry dia. 6 to 8 mm).

The connector delivered with each product MUST be

mounted. Any other assembly/installation will invalidate

the approval. Do not mount or remove the connector while

the power is ON.

Operation: Before pressurising the system, fi rst carry out an

electrical test. Apply power to the coil several times and listen

for the metallic «click» indicating the solenoid operator is work-

ing.

Personnel working with the components must be familiar with

electric controls, such as redundancies and feedback (electron-

ic controls), where applicable.

Use: The coils are designed for continuous operation and may

therefore become hot.

If the solenoid valve is easily accessible, provide for means of

protection to prevent accidental contact that may cause burns.

To avoid overheating, do not operate the solenoid valve in a

confi ned space without suffi cient ventilation.

CONNECTION

• Connect all ports that may come in contact with fl uids. Mount

in accordance with the ISO 15218 (CNOMO size 30) mount-

ing pad pattern. Make sure to check that all seals are placed

on the mounting pad.

Pre-install the 2 CM4 x 35 screws alternately and evenly up to

a tightening torque of 0,3/0,5 Nm, and then tighten them to a

tightening torque of 1 Nm

±0,2

(E).

• Clean the conduits that will connect to the component.

• Be sure to observe the direction of fl ow of the fl uid.

• Use only the provided connection possibilities.

• Ensure that no foreign matter enters the circuit, in particular

when making the connection leakproof.

• The manual override, which is indicated by the symbol (

),

allows you to operate the valve without electrical power.

• Be sure to observe the allowed bend radius for tubing; do not

restrict the ports for fl uid circulation.

• Tubes and connection elements must not exert any force,

torque, or strain on the product.

• Use appropriate tools and place assembly tools as close as

possible to the connection point.

• Be sure to observe the recommended torque when tightening

piping connections.

• Connections must be made to last.

CAUTION

Failure to stay within the electrical range of the coil rating will

result in damage to or premature failure of the coil. This will also

invalidate its approval for use in explosive atmospheres caused

by gases.

WARNING: Unauthorised personnel is not permitted to disas-

semble or remove the coil or connector assembly.

Take care not to damage the mating surfaces when disassembling

or re-assembling the connector/coil assembly/clip.

Wrong assembly will invalidate the approval.

OPERATION

To prevent the risk of personal injury or property damage, do

not touch the coil. The coil can become hot under normal op-

eration conditions. If the solenoid valve is easily accessible, the

installer must provide protection against accidental contact.

To prevent electrostatic hazard, clean coil surface with a damp

cloth only. Do not use solvents.

MAINTENANCE

CAUTION: Turn off electrical power before servicing.

Strictly follow all procedures recommended by European Direc-

tive 1999/92/EC and associated standards during maintenance.

There are no ATEX spare parts kits available.

The solenoid valve cannot be disassembled or adjusted.

Do not remove the coil from the pneumatic part of the solenoid

valve.

DISASSEMBLY/REASSEMBLY:

This operation must be carried out by suitably qualifi ed person-

nel.

Unscrew and remove the connector. Remove the plug (6) and

the coil.

Reassemble in the reverse order of disassembly (make sure to

observe the tightening torques (A..D)).

The solenoid valve and the assembly consisting of the seal and

the connector must be completely re-assembled for IP65 pro-

tection to be certifi ed.

Wrong assembly will invalidate the approval.

In case of replacement of parts by the user, the traceability

of the fi nal product cannot be guaranteed by ASCO and

must be ensured by the user.

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

26

CONNECTION

GB

RACCORDEMENT

FR

ANSCHLUSS

DE

RACORDAJE

ES

COLLEGAMENTO

IT

AANSLUITING

NL

ANSLUTNING

SE

TILKOBLING

NO

LIITÄNTÄ

FI

FORBINDELSE

DK

LIGAÇÃO

PT

ÓÕÍÄÅÓÇ

GR

PIPOJENÍ

CZ

PODCZENIE

PL

CSATLAKOZTATÁS

HU

RU

----

27

CONNECTION

GB

RACCORDEMENT

FR

ANSCHLUSS

DE

RACORDAJE

ES

COLLEGAMENTO

IT

AANSLUITING

NL

ANSLUTNING

SE

TILKOBLING

NO

LIITÄNTÄ

FI

FORBINDELSE

DK

LIGAÇÃO

PT

ÓÕÍÄÅÓÇ

GR

PIPOJENÍ

CZ

PODCZENIE

PL

CSATLAKOZTATÁS

HU

RU

----

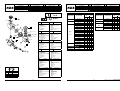

F

Rep. N.m Inch.Pounds

A 0,6 ±0,1 5,3 ±0,9

B 2,5 ±0,2 22 ±1,8

C 0,25 ±0,1 2,2 ±0,9

D 2 ±0,2 17,6 ±1,8

195

Ex ia

ATEX

4

C

4 x 90˚

B

E

2

3

6

5

1

Ø 8..10 mm

Ø 6..8 mm

A

(Pg 11p)

1

2

7

8

D

4 x 90˚

GB

Designation

FR

Désignation

1. Screw

2. Housing

3. Terminal block

4. Connector seal

5. Coil

6. Screw plug

7. Core tube

8. Screw

1. Vis

2. Boîtier

3. Support de bornier

4. Joint

5. Bobine

6.

Bouchon de serrage

7. Tube-culasse

8. Vis

DE

Bezeichnung

ES

Designación

1. Schraube

2. Gehäuse

3. Klemmenblock

4. Dichtung/Leitungsdose

5. Magnetspule

6. Schraubstopfen

7. Führungsrohr

8. Schraube

1. Tornillo

2. Caja

3. Soporte de bornero

4. Junta

5. Bobina

6. Tapón de apriete

7. Tubo culata

8. Tornillo

IT

Descrizione

NL

Aanduiding

1. Vite

2. Contenitore

3.

Supporto del blocco terminale

4. Guarnizione

5. Bobina

6. Dado di chiusura

7. Cannotto

8. Vite

1. Schroef

2. Huls

3. Steun voor klemmenbord

4. Pakking

5. Spoel

6. Plug met schroefdraadl

7. Plunjergang

8. Schroef

NO

BESKRIVELSE

SE

BESKRIVNING

1. Skrue

2. Koplingsboks

3. Terminalblokk

4. Koplingsboksens tetning

5. Spole

6. Skrueplugg

7. Kjernerør

8. Skrue

1. Skruv

2. Hölje

3. Anslutningsplint

4. Anslutningsförsegling

5. Spole

6.

Skruvpropp

7. Kärna rör

8. Skruv

FI

KUVAUS

DK

BESKRIVELSE

1. Ruuvi

2. Liitinkotelo

3. Kytkintaulun pidin

4. Tiiviste

5. Kela

6. Kierretulppa

7. Sisäletku

8. Ruuvi

1. Skrue

2. Hus

3. Holder til klemrække

4. O-ring

5. Spole

6. Skrueprop

7. Nippel

8. Skrue

PT

DESCRIÇÃO

GR

ÐÅÑÉÃÑÁÖÇ

1. Parafuso

2. Manga

3.

Suporte do conjunto de terminais

4. Anel

5. Bobina

6. Bujão de parafuso

7. Tubo central

8. Parafuso

1. Âßäá

2. ÈÞêç

3. ÓôÞñéîç èÞêçò

4. ÐáñÝìâõóìá

5. Ðçíßï

6. ÂéäùôÞ ôÜðá

7. ÐõñÞíáò

8. Âßäá

2

3

1

INTERFACES ZENER BARRIERS

manufacturer module type

II 2 G Ex ia

manufacturer module type

II 2 G Ex ia

T6 T4 T6 T4

IIB IIC IIB IIC IIB IIC IIB IIC

G.M. International

D1040Q-2

x

CEAG

SB-3729

xx

D1042Q-2

xx

SB-3728

x

MTL

MTL 3022

xx

MTL

MTL 728P

xx

MTL 5021

x

Pepperl

+

Fuchs

Z728

xxxx

Pepperl

+

Fuchs

KFD2-SD-Ex1.36

xx

Z728.H

xx

KFD2-SL2-Ex1

xx

Z728.CL

xxxx

KFD2-SL2-Ex1.B

xx

Stahl

9001/01-280-100-101

xx

KFD2-SL2-Ex1.LK

xx

9001/01-280-110-101

xxxx

KFD2-SL2-Ex2

xx

KFD2-SL2-Ex2.B

xx

KFD2-VD-Ex1.1560

xxxx

KCD0-SD-Ex1.1245

xx

KSD2-BO-Ex

xx

HIC2871

xx

LB-2102

xx

LB-2104

x

FB-2202

xx

FB-2204

x

Turck

MC72-41Ex-T/24VDC

xxxx

MC72-44Ex-T

xxxx

Siemens ET200IS double

xx

WAGO 750-535

xx

PR-electronics 5203B-F

xxxx

ASCO JOUCOMATIC SA

32 Av. Albert 1

er

- BP 312 - 92506 RUEIL Cedex - France

Tel. (33) 147.14.32.00 - Fax (33) 147.08.53.85 - http://www.asconumatics.eu

Page is loading ...

Page is loading ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

Asco Series 195 Solenoid Valve ATEX 94/9/EC Owner's manual

- Type

- Owner's manual

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

in other languages

- italiano: Asco Series 195 Solenoid Valve ATEX 94/9/EC Manuale del proprietario

- français: Asco Series 195 Solenoid Valve ATEX 94/9/EC Le manuel du propriétaire

- español: Asco Series 195 Solenoid Valve ATEX 94/9/EC El manual del propietario

- Deutsch: Asco Series 195 Solenoid Valve ATEX 94/9/EC Bedienungsanleitung

- Nederlands: Asco Series 195 Solenoid Valve ATEX 94/9/EC de handleiding

- português: Asco Series 195 Solenoid Valve ATEX 94/9/EC Manual do proprietário

- dansk: Asco Series 195 Solenoid Valve ATEX 94/9/EC Brugervejledning

- svenska: Asco Series 195 Solenoid Valve ATEX 94/9/EC Bruksanvisning

- suomi: Asco Series 195 Solenoid Valve ATEX 94/9/EC Omistajan opas

Related papers

-

Asco Series 302 Mini Solenoid Valve Owner's manual

-

Asco Series 195 Solenoid Valve Aluminum Owner's manual

-

Asco Series 195 Solenoid Explosive Atmosphere Owner's manual

-

Asco Series LI Solenoid Owner's manual

-

Asco Series 121 Solenoid Valve Flameproof User manual

-

Asco Series 131 CPV1 Flameproof Owner's manual

-

Asco Series 131 CPV1 MPV1 Owner's manual

Other documents

-

LEDPRO 101510-2 Plaza Up and Down Outdoor Wall Lamp Installation guide

LEDPRO 101510-2 Plaza Up and Down Outdoor Wall Lamp Installation guide

-

LEDPRO COLD 5 DOWNLIGHT, DRIVER INKLUDERT, HVIT Installation guide

LEDPRO COLD 5 DOWNLIGHT, DRIVER INKLUDERT, HVIT Installation guide

-

LEDPRO BY NORLUX TANIA MINI S4 LAMPE, SVART Installation guide

LEDPRO BY NORLUX TANIA MINI S4 LAMPE, SVART Installation guide

-

LEDPRO BY NORLUX TANIA MINI S1 LAMPE, HVIT Installation guide

LEDPRO BY NORLUX TANIA MINI S1 LAMPE, HVIT Installation guide

-

LEDPRO BY NORLUX TANIA MINI S2 LAMPE, SVART Installation guide

LEDPRO BY NORLUX TANIA MINI S2 LAMPE, SVART Installation guide

-

LEDPRO BY NORLUX TANIA MINI S3 LAMPE, HVIT Installation guide

LEDPRO BY NORLUX TANIA MINI S3 LAMPE, HVIT Installation guide

-

AVENTICS Series G3 NAMUR Input Module Owner's manual

-

AVENTICS Series G3 NAMUR Input Module Owner's manual

-

AVENTICS Series G3 NAMUR Input Module Owner's manual

-

AVENTICS Series G3 NAMUR Input Module Owner's manual