Table of Contents

1 General Site Preparation Guidelines...........................................................................7

Electrical Factors.....................................................................................................................................7

Synopsis.............................................................................................................................................7

AC Electrical Distribution System...............................................................................................7

AC Power Quality Devices..........................................................................................................8

UPS Recommendations................................................................................................................8

Power Consumption....................................................................................................................8

Grounding Systems......................................................................................................................9

Comprehensive Discussion...............................................................................................................9

Computer Room Safety...................................................................................................................10

Fire Protection............................................................................................................................10

Fire Suppression.........................................................................................................................10

Lighting Requirements for Equipment Servicing......................................................................10

Cabinet Recommendations........................................................................................................10

Working Space for Product Access............................................................................................11

Power Consumption........................................................................................................................11

Electrical Load Requirements (Circuit Breaker Sizing)...................................................................11

Power Quality..................................................................................................................................11

Sources of Voltage Fluctuations.................................................................................................11

Power System Protection............................................................................................................12

Distribution Hardware....................................................................................................................12

Wire Selection.............................................................................................................................12

Raceway Systems (Electrical Conduits) (LAHJ).........................................................................12

Building Distribution.................................................................................................................13

Grounding Systems.........................................................................................................................13

Power Distribution Safety Grounding (LAHJ)..........................................................................13

Main Building Electrical Ground..........................................................................................13

Electrical Conduit Ground....................................................................................................13

Power Panel Ground.............................................................................................................13

Computer Safety Ground.....................................................................................................13

Dual Power Source Grounding.............................................................................................14

Cabinet Performance Grounding (High-Frequency Intercabinet Ground)...............................14

Raised Floor “High-Frequency Noise” Grounding...................................................................14

Equipment Grounding Implementation Details........................................................................15

System Installation Guidelines........................................................................................................15

Acclimatization..........................................................................................................................16

Wiring Connections....................................................................................................................16

Data Communications Cables....................................................................................................16

Environmental Elements.......................................................................................................................16

Synopsis...........................................................................................................................................16

Air Quality.................................................................................................................................16

Airflow.......................................................................................................................................17

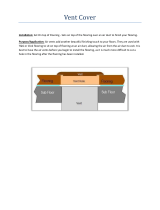

Equipment Orientation..............................................................................................................18

Electrostatic Discharge (ESD): Source of Greatest Failure Rate Without Detection..................18

Cellular Telephone and Wireless Usage.....................................................................................18

Comprehensive Discussion.............................................................................................................18

Computer Room Preparation..........................................................................................................19

Airflow.............................................................................................................................................19

Row Orientation.........................................................................................................................19

Dust and Pollution Control........................................................................................................20

Metallic Particulate Contamination...........................................................................................21

Table of Contents 3