Heat Controller Energy Knight B/A-HMC30BS User manual

- Category

- Split-system air conditioners

- Type

- User manual

This manual is also suitable for

Wall Mounted

Mini - Split System

HMC30AS-1/HMH30AS-1/ HMC30BS-1 Single-Zone

Air Conditioning / Heat Pump

Model : B/A-HMC30AS, B/A-HMH30AS

B/A-HMC30BS

Service Manual

CAUTION

Before servicing the unit, read the

"safety precautions" in this manual.

Only for authorized service personne.

HEAT CONTROLLER, INC.

- 2 -

Contents

Functions

.................................................................................................................................3

Product Specifications

..........................................................................................................5

Dimensions

..............................................................................................................................7

Refrigeration Cycle Diagram

..................................................................................................9

Pipe Length and the Elevation.............................................................................................10

Wiring Diagram

......................................................................................................................11

Operation Details

..................................................................................................................13

Display Function

...................................................................................................................25

Self-diagnosis Function

........................................................................................................25

Installation

.............................................................................................................................26

Operation

...............................................................................................................................42

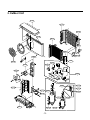

Disassembly of the parts (Indoor Unit)

...............................................................................44

3-way Valve

............................................................................................................................52

Cycle Troubleshooting Guide

...............................................................................................57

Electronic Parts Troubleshooting Guide

.............................................................................58

Electronic Control Device

.....................................................................................................64

Schematic Diagram

...............................................................................................................67

Exploded View and Replacement Parts List

.......................................................................70

- 3 -

Functions

Indoor Unit

Operation ON/OFF by Remote controller

Sensing the Room Temperature

Room temperature control

Starting Current Control

Time Delay Safety Control

Indoor Fan Speed Control

Operation indication Lamps (LED)

Healthy Dehumidification Mode

Sleep Mode Auto Control

Auto Air Control by the unit electronic control

Chaos Swing

Defrost control(Heating)

Hot-start Control (Heating)

• Room temperature sensor (THERMISTOR)

• Maintains the room temperature in accordance with the Setting Temp.

• Indoor fan is delayed for 5 seconds at the starting.

• Restarting is inhibited for approx. 3 minutes.

• High, Med, Low and Auto

• Intermittent operation of fan at low speed

• Both the indoor and outdoor fan stops

during defrosting.

• Hot start will be operated after

defrosting ends.

• The indoor fan stops until the

indoor pipe temperature will be

reached at 28°C(82°F).

• The fan is switched to low(Cooling), med(Heating) speed.

• The unit will be stopped after 1, 2, 3, 4, 5, 6, 7 hours.

• The fan is switched to intermittent or irregular operation.

• The fan speed is automatically switched from high to low speed.

• The louver can be set at the desired position or swing up

and down automatically.

--- Lights up in operation

--- Lights up in Sleep Mode

--- Lights up in Timer Mode

--- Lights up in Defrost Mode or Hot Start Mode (only Heating Model)

--- Lights up during compressor running (only Cooling Model)

OUT

DOOR

- 4 -

Healthy Dehumidification Operation Mode.

( )

Remote Controller

Operation ON/OFF

Reset

Operation Mode Selection

Temperature Setting

Timer Selection

Timer Setting

JET COOL

Timer Cancel

Sleep Operation

Airflow Direction Control

(Cooling

model only)

(Heating

model only)

TEMPERATURE

LOW HIGH

Cooling Operation Mode.( )

Heating Operation Mode.( )

Auto Operation Mode.( )

Fan Operation Mode

Horizontal Airflow Direction Control Button(Option)

Room, Temperature Display

Setting the Time or Timer

ON OFF

SET

CANCEL

Fan Speed Selection

(Low) (Med) (High) (CHAOS)

: (High:39°C, 102°F Low:11°C, 52°F)

: OFF, ON, OFF ON

: Cancel Sleep Mode, Timer ON or Timer OFF

: 1, 2, 3, 4, 5, 6, 7, Off Timer

: Fan Operates without cooling or heating.

Cooling

Down to 18°C(65°F)

Up to 30°C(86°F)

Heating

Down to 16°C(61°F)

Up to 30°C(86°F)

- 5 -

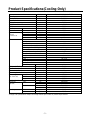

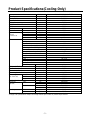

Product Specifications(Cooling Only)

* Design and Specifications subject to change without prior notice for product improvement.

Items Unit B/A-

HMC30AS, B/A-HMC30BS

Power Supply ø, V, Hz 1, 208/230, 60

Cooling Capacity BTU/h 27,000/28,000

Input W 3,450/3,600

Running Current A 16.5/16.0

COMP. Locked Rotor AMP. A A: 68. B: 29

E.E.R BTU/hW 7.79/7.81

Air Circulation m

3

/min(cfm) 21(740)

Moisture Removal l/h(pts/hr) 3.7(7.8)

Noise Level Indoor, High dB(A) 49

(Sound Med dB(A) 46

Pressure, 1m) Low dB(A) 43

Outdoor, Max dB(A) 63

Features Temperature Control Thermistor

Air Deflection 4-way

Steps, Fan/Cool 3/3

Airflow Direction Control(up&down) Auto

Airflow Direction Control(left&right) Manual

Remocon Type Wireless LCD

Setting Temperature Range, Cooling Mode 64~86°F

Temperature Increment 2°F

Auto Operation(electronic control) Yes

Self Diagnosis Yes

Timer 24hr, On/Of

Sleep Operation Yes

Healthy Dehumidification Mode Yes

Restart Delay minutes 3

Refrigerant(R-22) Charge g(oz) 2300(81)

Power cord AWG #: P*mm

2

12:3*2.5

Fuse or breaker Capacity A 30A

Connecting Cable AWG #: P*mm

2

20:4*0.75

Connecting Tube Liquid Side mm(in) 9.52(1/4)

(ø. Socket Flare) Gas Side mm(in) 15.88(1/2)

Length, std m(ft) 7.5(24.6)

Additional Drain Hose(Outer Dia.) mm(in) 15.5(5/8)

Dimensions Indoor mm 1259*349*205

(WxHxD) in 49.6*13.7*8.1

Outdoor mm 870*800*320

in 34.3*31.5*12.6

Net Weight Indoor kg(lbs) 20(44.2)

Outdoor kg(lbs) 20(44.2)

- 6 -

Product Specifications(Cooling & Heating)

Items Unit B/A-HMH30AS

Power Supply ø, V, Hz 1, 208/230, 60

Cooling Capacity BTU/h 27,000/28,000

Heating Capacity BTU/h 28,000/29,000

Input Cooling W 3,450/3,600

Heating W 3,550/3,750

Running Current Cooling A 16.5/16.0

Heating A 16.5/17.0

COMP. Locked Cooling A A: 68, B: 29

Rotor AMP. Heating A A: 68. B: 29

E.E.R BTU/hW 7.82/7.78

C.O.P 2.30/2.26

Air Circulation m

3

/min(cfm) 21(740)

Moisture Removal l/h(pts/hr) 3.7(7.8)

Noise Level Indoor, High dB(A) 49

(Sound Med dB(A) 46

Pressure, 1m) Low dB(A) 43

Outdoor, Max dB(A) 63

Features Temperature Control Thermistor

Air Deflection 4-way

Steps, Fan/Cool/Heat 3/3/3

Airflow Direction Control(up&down) Auto

Airflow Direction Control(left&right) Manual

Remocon Type Wireless LCD

Setting Temperature Range, Cooling Mode

64~86°F

Heating Mode 60~86°F

Temperature Increment 2°F

Auto Operation(electronic control) Yes

Self Diagnosis Yes

Timer 24hr, On/Off

Sleep Operation Yes

Healthy Dehumidification Mode Yes

Restart Delay minutes 3

Defrost Control Yes

Hot Start Yes

Refrigerant(R-22) Charge g(oz) 2550(89.9)

Power cord AWG #: P*mm

2

12:3*2.5

Fuse or breaker Capacity A 30A

Connecting Cable AWG #: P*mm

2

20:4*0.82

Connecting Tube Liquid Side mm(in) 9.52(3/8)

(ø. Socket Flare) Gas Side mm(in) 15.88(5/8)

Length, std m(ft) 7.5(24.6)

Additional Drain Hose(Outer Dia.) mm(in) 15.5(5/8)

Dimensions Indoor mm 1259*349*205

(WxHxD) in 49.6*13.7*8.1

Outdoor mm 870*800*320

in 34.3*31.5*12.6

Net Weight Indoor kg(lbs) 20(44.2)

Outdoor kg(lbs) 33(72.8) 20(44.2)

* Design and Specifications subject to change without prior notice for product improvement.

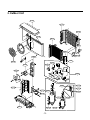

(1) Indoor Unit

- 7 -

Dimensions

W

H

Tubing hole cover

Tubing hole cover

Installation plate

D

W

mm(inch)

1,259(49.6)

H

mm(inch)

349(13.7)

D

mm(inch)

205(8.1)

Model

Dimension

30K SERIES

- 8 -

MODEL

DIM

- 8 -

W

L7 L6 L8 L9

D

L1

L2

L3

L10L11

L4L5

H

Gas side

3-way valve

Liquid side

3-way valve

W mm(in ch) 870(34.3)

H mm(in ch) 800(31.5)

D mm(in ch) 320(12.6)

L1 mm(in ch) 370(14.6)

L2 mm(in ch) 340(13.4)

L3 mm(in ch) 25(1.0)

L4 mm(in ch) 775(30.5)

L5 mm(in ch) 25(1.0)

L6 mm(in ch) 546(21.5)

L7 mm(in ch) 162(6.4)

L8 mm(in ch) 162(6.4)

L9 mm(in ch) 54(2.1)

L10 mm(in ch) 74.5(2.9)

L11 mm(in ch) 79(3.1)

30K SERIES

(2) Outdoor Unit

- 9 -

Refrigeration Cycle Diagram

INDOOR UNIT OUTDOOR UNIT

INDOOR UNIT OUTDOOR UNIT

HEAT

EXCHANGER

(EVAPORATOR)

HEAT

EXCHANGER

(EVAPORATOR)

HEAT

EXCHANGER

(CONDENSER)

HEAT

EXCHANGER

(CONDENSER)

COMPRESSOR

COMPRESSOR

ACCUMU

LATOR

Suction Line

Suction Line

3-WAY VALVE

Evaporator Line

Evaporator Line

3-WAY VALVE

CAPILLARY TUBE

CAPILLARY TUBE

CHECK VALVE

(Heating Model only)

COOLING

HEATING

REVERSING

VALVE

(Heating Model Only)

(1) Cooling Only Models

(2) Cooling & Heating Models

- 10 -

Pipe length and the elevation

* Capicity is based on standard length and maximum allowance length is the basis of

reliability.

* Oil trap should be installed per 5~7 meters(16.4~23.0ft).

CAUTION

Outdoor unit

Indoor unit

A

B

A

Oil trap

Outdoor unit

Indoor unit

B

In case more than 5m (16.4ft)

30k

5/8"(15.88mm) 3/8"(9.52mm) 7.5(25) 15(50) 30(100) 30(0.32)

(50Hz, 60Hz)

Pipe Size

Capacity

(Btu/h)

GAS LIQUID

Additional

Refrigerant

g/m(oz/ft)

Max.

Length

A m(ft)

Max.

Elevation

B m(ft)

Standard

Length

m(ft)

- 11 -

Wiring Diagram

(1) Indoor Unit (Cooling Only Models, & Heating Models)

MOTOR

SH-CAPA.

YL

PILLAR

TERMINAL

AUTO RESTART

FORCED OPERATION

CN-DISP

CN-L/R CN-U/D CN-TH

THERMISTOR

STEP

MOTOR

(UP/DOWN)

STEP

MOTOR

(L/R)

H.V.B ASM

LIMITS S/W

Negative ion

OPTION

STEP

MOTOR

(L/R)

CN-L/R

DISPLAY PCB ASM

3854A20065D

TO OUTDOOR UNIT

BL

3(L1)

4(L2)

5

BR

GN/YL

BL

RD RD

BR

GN/YL

BR

FUSE

AC250V/T2A

TRIAC

OR

BK

ZNR

CN-POWER

CN-MOTOR

WIRING DIAGRAM

- 12 -

(2) Outdoor Unit

• Cooling Only Models

• Heating Models

TO INDOOR

UNIT

POWER

INPUT

FMo

T/B

REVERSING

VALVE

Comp(B)

OLP

CAPACITOR(B)

CAPACITOR(A)

C

C

S

S

R

R

Comp(A)

5

RD

BL

BR

BK

YL

YL BR

BL BK

RD

RD

BL

BK

BK

BK

BK

OR

OR

GN/YL

BL

BR

FUSE

(250V,5A)

FUSE

(250V,5A)

FUSE(250V,3A)

CN-POWER

CN-FAN

CN-CON

CN-COMP

H

H

C

CF

CN-LEV

CN-TH2

CN-4WAY

PIPE-IN

PIPE-OUT

TEMP-IN

COIL EXPANSION

RY-HI

RY-COMP(B)

RY-COMP(A)

3(L1)

2(L2)

4(L2)

1(L1)

MAIN

PCB ASM

3854A20153X

WIRING DIAGRAM

TO INDOOR

UNIT

POWER

INPUT

FMo

T/B

Comp(B)

OLP

CAPACITOR(B)

CAPACITOR(A)

C

C

S

S

R

R

Comp(A)

5

RD

BL

BR

BK

YL

YL BR

BL BK

RD

RD

BL

BK

BK

BK

OR

OR

GN/YL

BL

BR

FUSE

(250V,5A)

FUSE

(250V,5A)

FUSE(250V,3A)

CN-POWER

CN-FAN

CN-CON

CN-COMP

H

H

C

CF

CN-LEV

CN-TH2

PIPE-IN

TEMP-IN

COIL EXPANSION

RY-HI

RY-COMP(B)

RY-COMP(A)

3(L1)

2(L2)

4(L2)

1(L1)

MAIN

PCB ASM

3854A20153W

WIRING DIAGRAM

- 13 -

(1) The function of main control

1. Time delay Safety Control

• 3min.; The compressor operation is delayed for 3 minutes to balance the pressure of cycle.

(Protection of compressor)

• 5sec.;

The indoor fan is delayed for 5 seconds, when operating initially, to prevent noises occurred by the vertical

louver and wind.

• 2min.; The reversing valve is delayed for 2 minutes to prevent the refrigerant-gas for abnormal noise when the

heating operation is OFF or switched to the other operation mode while compressor is off.

While compressor is running, it takes 3~5 seconds to switch.

2. Chaos Swing Mode

• By the Chaos Swing key input, the upper/lower vane automatically operates with the Chaos Swing or they are

fixed to the desired direction.

• While in Chaos Swing mode, the angles of cooling and heating cycle operations are different.

Operation Details

CLOSED

OPEN

< Cooling Mode >

8°

CLOSED

OPEN

< Heating Mode >

8°

- 14 -

3. Cooling Operation Mode – 1st Stage

1) Initial start & indoor load decision stage

This stage is to decide load level of indoor and select operation compressor, which is operated according to

Table 1.

After initial start, 2nd and 3rd operating time of compressor are saved, for the purpose of selecting following

operation stage with the average value of before operated time.

- Using the average value(tm) of tm1 & tm2 and difference of outdoor temp. & desired temp., following(next)

operation stage of compressor is selected under the table 1.

- But, compressor would be restarted after 3 mins. of suspension, if it turns off.

2) If 100% compressor is selected, cooling operation-1st stage would be working.

3) If 40% compressor is selected, cooling operation-2nd stage would be working.

4) Operation Diagram

tm=(tm1+tm2)/2

Room Temp.

Desired Temp.

Desired Temp.+0.5°C

Desired Temp.-1.0°C

Desired Temp.-0.5°C

Comp

60 %

40 %

Outdoor Fan

Indoor Fan

Controlled at the Indoor Unit

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

MAX. OFF MAX. OFF

MAX.

over 3 mins. over 3 mins.

tm1 tm2

- 15 -

< Table 1 : Selecting Operation Compressor by tm >

Outdoor Temp.

- Desired Temp.

1

tm <= 250

40 %

2

tm =< 250

40 %

3

tm =< 250

40 %

4

tm =< 250

40 %

5

tm =< 250

40 %

6

tm =< 290

40 %

7

tm =< 320

40 %

8

tm =< 360

40 %

9

tm =< 400

40 %

10

tm =< 430

40 %

11

tm =< 470

40 %

12

tm =< 510

40 %

13

tm =< 540

100%

tm Scale

Selected Compressor

tm > 250

100 %

tm > 250

100 %

tm > 250

100 %

tm > 250

100 %

tm > 250

100 %

tm > 290

100 %

tm > 320

100 %

tm > 360

100 %

tm > 400

100 %

tm > 430

100 %

tm > 470

100 %

tm > 510

100 %

tm > 540

100 %

Selected Compressor

tm Scale

Unit : Sec.

- 16 -

4. Cooling Operation - 2nd Stage

1) Condition to decide operation stage

- If Room Temp. reaches at [Desired Temp. + 0.5°C] for 2 consecutive mins. after suspension of 60% compressor operation

(<°C 3, , >), [Required time to restart 60% compressor] would be examined.

60% compressor would be restarted when [Required time to restart 60% compressor] is passed (<°C 3, >)..

The current condition would be maintained when it reaches at [Required time to restart 60% compressor], if [Required

time to restart 60% compressor] is not passed (<°C 3, >).

2) Condition to shift operation stage

1] It shifts to the Cooling Operation- 1st Stage when the operation such as of 1) is repeated in a series of 2 times.

2] 40% compressor operation would be suspended when the Room Temp. goes down to [Desired temp. – 1.0°C] after stop-

ping 60% compressor operation (<°C 3, >).

It shifts to the Cooling Operation-3rd Stage when the 40% compressor operation is suspended in a series of 2 times by

falling of room temperature after stopping 60% compressor operation.

3] It starts 60% compressor operation immediately and returns to the initial stage of Cooling Operation-2nd

Stage when the single operation time of 40% compressor pass more than 1 hour.

3) Operation Diagram

Room Temp.

Desired Temp.

Desired Temp.+0.5°C

Desired Temp.-1.0°C

Desired Temp.-0.5°C

Comp

60 %

40 %

Outdoor Fan

Indoor Fan

OFF

OFF

OFF

ON

ON

ON

OFF

ON

ON

ON

OFF

ON

ON

ON

OFF

ON

Off

Off

MAX.

MIN. MAX. MIN. MAX. MIN. MAX. MIN.

Off

b

c

a

ON

ON

MAX.

ON

ON

MAX.

6 mins.

6

mins. 6 mins.

100 %

40 %

0 %

Comp

3

mins

Controlled at the Indoor Unit

- 17 -

5. Cooling Operation - 3rd Stage

1) This operation works when the indoor load is small. The single operation of 40% compressor is performed as follows.

- The single operation of 40% compressor works when the Room Temp. reaches at [Desired Temp. + 0.5 °C].

- 40% compressor operation stops when the Room Temp. reaches at [Desired Temp. - 0.5 °C].

(But, the compressor can restart after 3 mins of compressor's off.)

2) Condition to shift operation stage

- It operates the Cooling Operation -2nd Stage when the desired temp. goes to "Desired Temp +1.0°C" more than 3 mins.

during its operation.

- It shifts to 100-40% operation after standby until 40% operation goes OFF, if the single operation of 40% compressor works

more than 1 hour.

3) Operation Diagram

Room Temp.

Desired Temp.

Desired Temp.+0.5

Desired Temp.-0.5

Comp

60 %

40 %

Outdoor Fan

Indoor Fan

Controlled at the Indoor Unit

Room Temp.

OFF

OFF

OFF

OFF

ON

MIN.

OFF

OFF

OFF

3 mins. 3 mins.

OFF

OFF

OFF

OFF

ON

MIN.

- 18 -

6. Heating Operation - 1st Stage

1) Operation Condition : This stage means the 1st elapsed time which the room temperature reaches around at the desired

temperature after starting the heating operation.

- 60% & 40% compressor operations would be operated until the room temperature reaches at [Desired Temp. +0.5°C].

In other words, 100% operation would be performed.

- 60% & 40% compressor operations would be all suspended when the room temperature goes to [Desired Temp. +0.5°C].

2) Condition to decide load

: This stage performs the 100% compressor On/Off 2 times.

- 100% compressor operation would be performed when 3-minutes pass after suspension of the previous stage and

the room temperature reaches at [ Desired Temp. -0.5°C].

- 60% & 40% compressor operations would be suspended when the room temperature goes to [Desired Temp. +0.5°C].

- Criteria to decide following operation stage

a. when the average time during 2 times compressor operations is more than 360 seconds,

b. when the temperature falls more than – 3°C within 3 minutes after OFF of compressor,

c. when the outdoor temperature is under 7°C.

- It operates the heating operation -2nd stage if any condition among the above criteria would be satisfied.

MAX.OFF

OFF

OFF

OFF MAX

.

OFF

OFF

Controlled at the Indoor Unit

MAX.

ON

ON

60%

40%

Outdoor Fan

Indoor Fan

Desired Temp. +1.0°C

Desired Temp. -0.5

Desired Temp. +0.5

Desired Temp.

Comp

more than 3 mins. more than

3 mins.

Room Temp.

tm1 tm2

ON

ON

ON

ON

- 19 -

7. Heating Operation - 2nd Stage

1) Operation

- 100% compressor operation would be performed when 3-minutes pass after suspension of the previous stage and the room

temperature reaches at [ Desired Temp. -0.5°C].

- 60% & 40% compressor operations would be all suspended when the room temperature goes to [Desired Temp. +0.5°C].

- Criteria to shift to the following operation stage

: It shifts to the Heating Operation-3rd Stage from the Heating Operation-2nd Stage, if the operation time of compressor is

within 6 minutes and at the same time the outdoor temperature is over [Outdoor Temperature possible for 60% Operation]

whenever it checks every operation time.

2) Operation Diagram

Room Temp.

Desired Temp.

Desired Temp.+0.5°C

Desired Temp.-5.0°C

Comp.

40 %

60 %

Outdoor Fan

Indoor Fan

Controlled at the Indoor Unit

Room Temp.

OFF

OFF

OFF

ON

ON

MAX.

OFF

OFF

OFF

3 mins. 3 mins.

OFF

OFF

OFF

ON

ON

MAX.

Outdoor Temp. >

7°C

6 mins. 6

mins.

- 20 -

8. Heating Operation - 3rd Stage

1) Condition to decide operation stage

a. [Restart Time of 40% compressor] should be examined, when the Room Temp. falls and stays under [ Desired Temp. -

0.5°C] over 1 minutes after suspension of 40% compressor operation.

If [Restart Time of 40% compressor] pass, 40% compressor would be restarted.

If [Restart Time of 40% compressor] doesn't pass, the current condition should be maintained until it reaches and 40%

compressor would be restarted after passing some times.

b. 60% compressor operation would be suspended when the room temperature goes to [Desired Temp. +1.0°C] after sus-

pension of 40% compressor operation.

60% & 40% compressors operations would be all suspended when the room temperature goes to [Desired Temp. +0.5°C].

c. 40% compressor would be started when the Room Temperature is maintained between [Desired Temp. +1.0°C] and

[Desired Temp. -0.5°C] more than 1 hour after suspension of 40% compressor operation.

2) Condition to shift following operation stage

: It shifts from the operation stage during load and shows condition to perform following operation stage.

a. It operates Heating Operation-1st Stage when operation such as the above ®Ë of a. in the 1) item is performed in a series

of 2 times.

b. It operates Heating Operation-4th Stage, when operation such as the above b. of 1) in a series of 2 times and the average

time in 2 times of [60% single operation] is within 3-minutes.

3) Operation Diagram

MAX.

on

off

.

MAX. MAX.

.

ON

OFF

MAX.

.

MAX.

M

A

X

MAX. MAX.

ON

OFF

ON

OFF

Controlled at the Indoor Unit

MAX.

OFF

OFF

Indoor Fan

60%

40%

Outdoor

Fan

Desired Temp. +1.0°C

Desired Temp. -0.5°C

Desired Temp. +0.5°C

Desired Temp.

ON

ON

ON

ON

ON

ON

ON

Comp.

8 mins.

8 mins.

Room Temp.

ON

8 mins.

1min

.

1min

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

Heat Controller Energy Knight B/A-HMC30BS User manual

- Category

- Split-system air conditioners

- Type

- User manual

- This manual is also suitable for

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Heat Controller HMC30AS-1 User manual

Heat Controller HMC30AS-1 User manual

-

Heat Controller VMC30SB-1 Service User manual

Heat Controller VMC30SB-1 Service User manual

-

Heat Controller DMH18DB-1 User manual

Heat Controller DMH18DB-1 User manual

-

Heat Controller DMH24DB-1 User manual

Heat Controller DMH24DB-1 User manual

-

Heat Controller A-MMH24FA-1 User manual

-

Heat Controller DMC18SB-1 User manual

Heat Controller DMC18SB-1 User manual

-

Heat Controller Energy Knight B/A-HMC12AS User manual

-

Heat Controller Energy Knight B/A-HMC12AS User manual

-

LG A-MMH24FA-1 Owner's manual

-

LG A-MMH24FA-1 Owner's manual

Other documents

-

LG HSNC096QMA4 Owner's manual

-

LG HMC009KD Owner's manual

-

Amvent A55GW2C-ELT Operating instructions

Amvent A55GW2C-ELT Operating instructions

-

LG HMC030KD1 Owner's manual

-

LG HMC030KD1 Owner's manual

-

LG PZCWRCG3 Owner's manual

-

Whirlpool AMD 306 User guide

-

LG PTEGM0 Installation guide

-

LG JRNU09GSEA2.ANONE Installation guide

-

LG ASUH091FUG0 Owner's manual