Emerson Process Management 51000 User manual

- Type

- User manual

Emerson Process Management 51000 is a low flow control valve designed for demanding applications where space is limited. It provides a compact and lightweight alternative to flanged body globe valves, making installation easier. The 51000 is suitable for a wide range of pressures, temperatures, and other application specifications, ensuring reliable performance in various industrial settings.

Emerson Process Management 51000 is a low flow control valve designed for demanding applications where space is limited. It provides a compact and lightweight alternative to flanged body globe valves, making installation easier. The 51000 is suitable for a wide range of pressures, temperatures, and other application specifications, ensuring reliable performance in various industrial settings.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

Emerson Process Management 51000 User manual

- Type

- User manual

Emerson Process Management 51000 is a low flow control valve designed for demanding applications where space is limited. It provides a compact and lightweight alternative to flanged body globe valves, making installation easier. The 51000 is suitable for a wide range of pressures, temperatures, and other application specifications, ensuring reliable performance in various industrial settings.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Other documents

-

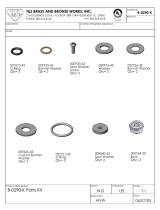

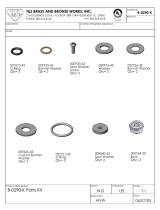

T & S Brass & Bronze Works B-0290-K Datasheet

T & S Brass & Bronze Works B-0290-K Datasheet

-

Emerson FIELDVUEDVC2000 Quick start guide

-

Emerson FIELDVUEDVC2000 User manual

-

Fisher & Paykel 81823 User guide

-

Fisher & Paykel 81823 User guide

-

Fisher & Paykel 81812 User guide

-

Jordan Valve Mark 675 Series Maintenance Manual

-

Emerson FIELDVUEDVC2000 User manual

-

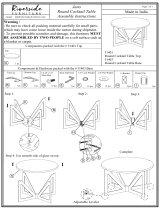

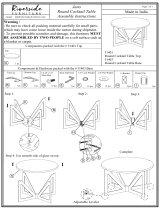

Riverside Furniture 51401 Assembly Instructions

Riverside Furniture 51401 Assembly Instructions

-

Emerson 67D Quick start guide