Page is loading ...

Manual for use and maintenance

CCU5000

Farm Climate Controller

Ag/MIS/UmGB-2077-02/13 rev. 1.4

P/N: 110143

CCU5000

© Munters AB, 2013

2

CCU5000

Manual for use and maintenance

Revision

: N.1.4 of 10.2013

Product Software

: Version 1.01

This manual for use and maintenance is an integral part of the apparatus together with the attached

technical documentation.

This document is destined for the user of the apparatus: it may not be reproduced in whole or in part,

committed to computer memory as a file or delivered to third parties without the prior authorization of the

assembler of the system.

Munters reserves the right to effect modifications to the apparatus in accordance with technical and legal

developments.

© Munters AB, 2013

3

Index

Chapter page

1

INTRODUCTION

----------------------------------------------------------------------------------------

5

1.1 Disclaimer ----------------------------------------------------------------------------------------------------------- 5

1.2 Introduction --------------------------------------------------------------------------------------------------------- 5

1.3 Notes ----------------------------------------------------------------------------------------------------------------- 5

1

SAFETY ASPECTS

---------------------------------------------------------------------------------------

6

1.1 Grounding ---------------------------------------------------------------------------------------------------------- 6

1.2 Filtering -------------------------------------------------------------------------------------------------------------- 6

1.3 Checking the battery level -------------------------------------------------------------------------------------- 6

2

BEFORE USING

-----------------------------------------------------------------------------------------

7

2.1 User interface ------------------------------------------------------------------------------------------------------ 9

2.2 Hot keys ------------------------------------------------------------------------------------------------------------- 9

2.3 Menu structure --------------------------------------------------------------------------------------------------- 10

2.4 Main screen features ------------------------------------------------------------------------------------------ 10

2.5 Alarms ------------------------------------------------------------------------------------------------------------- 11

3

INSTALLATION

----------------------------------------------------------------------------------------

12

3.1 Connection the mains voltage ------------------------------------------------------------------------------- 18

3.2 Electrical grounding for controllers ------------------------------------------------------------------------ 18

3.2.1 Ground rods ................................................................................................................. 18

3.2.2 Ground wire ................................................................................................................. 19

3.2.3 Ground clamps ............................................................................................................. 19

3.2.4 What should be grounded? ........................................................................................ 19

4

TECHNICAL DATA

------------------------------------------------------------------------------------

20

5

USING CCU5000

------------------------------------------------------------------------------------

21

5.1 Initial setup-------------------------------------------------------------------------------------------------------- 21

5.1.1 Setting the basic parameters ....................................................................................... 21

5.1.2 Setting the growth day ................................................................................................. 21

5.2 Calibrating the sensors ---------------------------------------------------------------------------------------- 22

5.3 Heating function------------------------------------------------------------------------------------------------- 22

5.3.1 Setting the relays .......................................................................................................... 23

5.3.2 Target temperature defintion ....................................................................................... 23

© Munters AB, 2013

4

5.4 Humidity compensation --------------------------------------------------------------------------------------- 25

5.4.1 What is humidity compensation?................................................................................. 25

5.4.2 How is humidity compensation performed? ................................................................ 26

5.5 Setting the misting function ----------------------------------------------------------------------------------- 26

5.6 Setting the alarms ----------------------------------------------------------------------------------------------- 27

5.7 Testing sensors and relays ----------------------------------------------------------------------------------- 27

5.8 Configuring the history function ----------------------------------------------------------------------------- 28

6

COOLING FUNCTIONS

----------------------------------------------------------------------------

29

6.1 5026 cooling ---------------------------------------------------------------------------------------------------- 29

6.1.1 Setting the 5026 minimum ventilation (Stage 1) ........................................................ 30

6.1.2 Setting 5026 Stage 2 and higher ............................................................................... 30

6.1.3 How does 5026 cooling work? .................................................................................. 30

6.2 5124/5222 cooling ------------------------------------------------------------------------------------------ 32

6.2.1 Setting the 5124/5222 variable fan speed (Stage 1) .............................................. 33

6.2.2 How does 5124 cooling work? .................................................................................. 34

6.2.3 How does 5222 cooling work? .................................................................................. 35

7

TROUBLESHOOTING

--------------------------------------------------------------------------------

38

8

WARRANTY

--------------------------------------------------------------------------------------------

40

© Munters AB, 2013

5

1 Introduction

1.1 Disclaimer

Munters reserves the right to make alterations to specifications, quantities, dimensions etc. for production

or other reasons, subsequent to publication. The information contained herein has been prepared by

qualified experts within Munters. While we believe the information is accurate and complete, we make no

warranty or representation for any particular purposes. The information is offered in good faith and with

the understanding that any use of the units or accessories in breach of the directions and warnings in this

document is at the sole discretion and risk of the user.

1.2 Introduction

Congratulations on your excellent choice of purchasing a CCU5000!

In order to realize the full benefit from this product it is important that it is installed, commissioned and

operated correctly. Before installation or using the fan, this manual should be studied carefully. It is also

recommended that it is kept safely for future reference. The manual is intended as a reference for

installation, commissioning and day-to-day operation of the Munters Controllers.

1.3 Notes

Date of release: December 2012

Munters cannot guarantee to inform users about the changes or to distribute new manuals to them.

All rights reserved. No part of this manual may be reproduced in any manner whatsoever without the

expressed written permission of Munters. The contents of this manual are subject to change without notice.

© Munters AB, 2013

6

1 Safety aspects

1.1 Grounding

• Always connect temperature and sensor shields to earth ground. Avoid mixing high voltage

wiring with sensor and low voltage wiring.

• Keep the controller as far as possible from heavy contactor boxes and other sources of

electrical interference.

• Do not connect communication wire shields, which go from one house to another at both ends.

Connect them at one end only. Connection at both ends can cause ground loop currents to

flow, which reduce reliability.

• The COM connection for communications is not the shield wire. The COM, RX and TX wires

must connect to each other at all controllers.

1.2 13BFiltering

• If this installation includes a power inverter to drive variable speed fans, install an EMI filter in

front of the inverter, according to the specifications provided by the inverter manufacturer. Refer

to the inverter documentation.

1.3 14BChecking the battery level

• Check the battery once a year. The output must be 2.7 volts (minimum). Authorized personnel

only must replace the battery if the output is below the minimum required level or every five

years.

© Munters AB, 2013

7

2 Before using

The following section provides an introduction to the CCU5000 Farm Climate Controller units.

The CCU5000 controller provides a comprehensive solution for growers seeking a low cost solution

without sacrificing quality. CCU5000 enables control over the temperature and humidity in buildings

using intelligent, user-friendly climate control software. The CCU5000 comes in three models:

Figure 1: 5026 Unit Figure 2: 5124 Unit

Figure 3: 5222 Unit

The following tables detail the model options.

© Munters AB, 2013

8

Table 1: CCU Models and Options

5026

5124

5222

Number of Variable Fan Stages 0 1 2

Number of Heat Stages 2 2 2

Number of Cool Stages 6 4 2

Number of Misting Stages 1 1 1

Table 2: 5026 Relay Options

Relay

Options

Relay

Options

1

• Stage 2 Cool

5

• Stage 6 Cool

2

• Stage 3 Cool

6

• Stage 7 Cool/Heat

3

• Stage 4 Cool

7

• Stage 8 Cool/Heat

4

• Stage 5 Cool

8

• Alarm

Output

Options

Solid State Relay

• Cool Stage 1 Ramping Timer

Table 3: 5124 Relay Options

Relay

Options

Relay

Options

1

• Stage 2 Cool Cycle Timer

• MV Fan 1

5

• Stage 6 Cool/Heat

2

• Stage 3 Cool

6

• Stage 7 Cool/Heat

3

• Stage 4 Cool

7

• None

4

• Stage 5 Cool

8

• None

• Alarm

Output

Options

TRIAC

• Variable Fan 1 (Stage 1 Cool)

Table 4: 5222 Relay Options

Relay

Options

Relay

Options

1

• Not Available

5

• None

• Stage 4 Cool

2

• None

6

• None

• Stage 5 Cool/Heat

3

• None

7

• None

• Stage 6 Cool/Heat

4

• None

• Stage 3 Cool

8

• None

• Alarm

© Munters AB, 2013

9

Output

Options

TRIAC

• Variable Fan (Stage 1 Cool)

TRIAC

• Variable Fan (Stage 2 Cool)

NOTE The last available Cool Stage can be set as Misting. For example, in a 5222 or 5124, if Stage

7 is set to heat and Stage 6 is set to cool, Stage 6 can be defined as Misting.

2.1 User interface

•

LED indicator:

ON/OFF state of LED indicates whether the relay is operating or idle.

•

<CHANGE>

key:

Navigates to the parameters in main menus and edit parameters. Press once

to enter edit mode; press again to exit edit mode).

•

Down / Up arrow keys:

Serve to increase/decrease parameter values, navigate Hot Keys

(see

Hot Keys

section) and menus.

•

<MENU>

key:

Navigates in and out of main screen and menus (Press once to enter main

menus, press again to exit).

2.2 Hot keys

The

CCU5000

incorporates keys enabling quick access to different parameters. On the Main screen,

press the ▼▲ keys. The following hot keys are displayed.

1.

4.

2.

5.

3.

6.

1. Individual temperature sensors readings

2. Current temperature, set point temperature and current day

3. CCU Model

4. Misting cycle time: the time shown is the cycle values.

NOTE This screen only appears if misting stage has been defined for one of the relays.

5. Current and previous day's water and feed count

• T.W: Today's

water

• T.F: Today's feed • Y.W: Yesterday's

water

• Y.F: Yesterday's

feed

6. Current variable fan speed and cycle on/off timer states/values. The time shown is a countdown until

the cycle switches between functions.

V. Fan:

MN Fan Cycle: Off: 250

CCU5026

T.W: 250.5 T.F: 100.8

Y.W: 244.5 Y.F: 97.8

Temp: 25.5° Day: 3

Targ. 26.2°

Misting

MS Cy On: 60 Off: 0

T1: 25.5° T2: 24.0°

T3: 25.7°

© Munters AB, 2013

10

2.3 Menu structure

• The Main screen is in the root, the main menus are on the next line. To return to the main screen

at any point, press and hold

MENU

.

• To reach a main menu (the level below the Main screen), press

MENU

.

• To reach any level below the main menus, press

CHANGE.

For example, to view the Alarm Reminder parameter, press:

MENU > ARROW KEYS >

ALARMS > CHANGE > ARROW KEYS.

, until the desired parameter is displayed.

•

X

represents a number. For example,

Growth Day: xxx

means a specific growth day number,

such as the 9

th

day.

1.

6.

2.

7.

3.

8.

4.

9.

5.

10.

NOTE The Humidity Menu only appears if a humidity sensor has been installed.

2.4 18BMain screen features

• To change the Main screen display, click the last Hot Key.

• If a screen other than the Main screen is displayed for five consecutive minutes, the system

returns to the Main screen display automatically (in menus only, not including Hot Keys).

• When changing value using the arrow keys (either ▲ or ▼), the changes occur at a rate of 2

changes per second. After holding down an arrow key for 3 seconds, the changes will occur

at a rate of 10 changes per second.

• If the system displays one of the Hot Keys and no alarms arise, the screen will be refreshed

every second. If the system displays a Hot Key screen and alarms arise, both the Hot Key

screen and the alarm will be displayed alternately every three seconds. If more than one alarm

is activated, the Hot Key screen will display the different alarms alternately.

10 Main Menu

Stage 1

5 Main Menu

Alarms

9 Main Menu

System

4 Main Menu

Min/Max

8 Main Menu

Calibration

3 Main Menu

Cycle On: Off:

On

7 Main Menu

Test

2 Main Menu

Humidity: 75%

56 Main Menu

Growth Day: 3

1 Main Menu

Targ Temp: 25.9

© Munters AB, 2013

11

2.5 Alarms

Table 1

shows the list of alarms. The alarms can be viewed on the main screen. The main screen shows

the alarms and the main screen display alternately.

CCU5000

navigates between the alarms

automatically.

Table 5: Alarm Messages

Alarm Display

Explanation

Possible Alarm Reason

T1 SNS ERR

Error in temperature

sensor 1

Temperature sensor number 1 is out of order,

disconnected or shorted

T2 SNS ERR

Error in temperature

sensor 2

Temperature sensor number 2 is out of order,

disconnected or shorted

T3 SNS ERR

Error in temperature

sensor 3

Temp sensor number 3 is out of order, disconnected or

shorted

HUM SNS ERR

Error in humidity sensor

Humidity sensor number 1 is out of order or

disconnected

HI TEMP

High temperature

The average temperature in the building is higher than

the temperature set as the alarm's temperature.

LOW TEMP

Low temperature

The average temperature in the building is lower than

the temperature set as the alarm's temperature.

Press

MENU

(on the main menu) to reset the alarm relay. The alarm messages continue to be displayed

until the problem is resolved.

If you remove a sensor deliberately, the sensor error alarm can be disabled via the Calibration menu (see

Calibrating the sensors, page 22).

© Munters AB, 2013

12

3 Installation

CAUTION If any problem arises with the hardware, do not open the box. Contact an authorized

electrician.

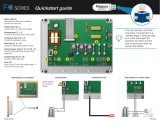

Figure 4: Board Layout

© Munters AB, 2013

13

Figure 5: Wiring Diagram of Low Voltage Section

Terminal Number

Possible Connections

11 - 12 Temperature sensor

11 - 13 Temperature sensor

11 - 14 Temperature sensor

15 - 16 Water meter

15 - 17 Feed pulse

18 - 20 Humidity sensor

© Munters AB, 2013

14

Figure 6: Wiring Diagram of Main Voltage Section

© Munters AB, 2013

15

Figure 7: Wiring Diagram of Main Voltage Section having Protection and Isolation

NOTE Munters recommends installing a line protector to protect against surges and lightning, and an

isolation transformer to prevent interference caused by excess power line noise.

© Munters AB, 2013

16

Figure 8: RS-232 Communication Wiring Diagram

© Munters AB, 2013

17

Figure 9: RS-485 Communication Wiring Diagram

© Munters AB, 2013

18

3.1 Connection the mains voltage

The input power of the controller should be connected to one or a few circuit breakers in the electrical

enclose (fuse box).

• Single wire supply is recommended for applications in which the controller's outputs are

connected to low power contactors. In this case one 18 AWG cable should be used for the

Phase and for the Neutral.

• Multi wire supply is recommended for high power applications in which the outputs supply up

to 5Amp each. In this case a separate 18AWG wires should be connected from each circuit

breaker in the electrical enclose (fuse box) to each output, and to the variable speed fan. All

the wires (from the separate circuit breakers) are from the same single phase.

WARNING!

Multi wire supply! Up to nine independent mains input may present in CCU5000. Be

sure that all appropriate circuit breakers are in position OFF before servicing.

3.2 Electrical grounding for controllers

Electrical equipment can be destroyed or slowly damaged by voltage spikes, lightning hits, etc. Proper

electrical grounding in combination with the CCU5000 internal protections is essential to protect the

system, reduce the risk of damage and prolong its lifetime. Correct selection and installation of equipment

will protect your system and reduce the risk of human injury.

Proper grounding provides an easy path for electrical current to return to its source. A grounding system

should tie all non-current carrying conductors to earth ground (0 volts). The grounding system should

present a minimum resistance to current flow. Make sure all items used are in proper condition; for

example, a corroded wire clamp attaching a ground wire to a ground rod might add 100 ohms or more

resistance to a system. Less than 5 ohm will be considered a good ground.

3.2.1 Ground rods

Ground rods are used to efficiently connect the system to earth where current may be dissipated in the

soil.

• Material: Ground rods should be copper clad or galvanized steel.

• Diameter: Minimum 5/8”, preferably 3/4”. Generally the larger the rod diameter, the lower its

resistance to current flow.

• Length: Minimum 2.5 meters (8 feet), preferably 3-meter (10-foot). A longer ground rod will

reach a soil with higher moisture content. Moist soil carries current much better than drier soil.

• Single grounding: It is important that there is only one grounding location where a rod or series

of rods are connected to each other using a ground wire.

• Independent ground rods will increase the risk of current, from a lightning strike for example,

being dissipated through one rod and reentering the system through an adjacent rod.

• Location: Close to the main circuit breaker panel and in moist soil. For example in an area that

is usually wet from a drip or a low spot where water drains. Make sure the area is well

protected from damage by lawnmowers, tractors, etc.

• Rod installation: Drive the rod into the earth until about 10 cm (4 inches) is left above grade. If

it is impossible to drive the rod to the proper depth, it is acceptable to lay the rod horizontally,

80 cm (2.5 feet) below grade.

© Munters AB, 2013

19

• In case the rod is exposed to damage, for example by lawnmowers or tractors, it can be

installed in a hole, about 20 cm (8 inches) deep so that the rod is about 10 cm under grade

and 10 cm above hole level.

The National Electric Code (NEC) mandates two ground rods unless you can show less

than 10 ohms resistance with one rod.

3.2.2 Ground wire

The ground wire is a large copper wire that connects the main circuit breaker panel to the ground rod.

• Material: Ground rods should be copper clad or galvanized steel.

• Diameter: Typically, 16 mm (6-gauge) copper wire is sufficient. If the wire run is greater than

20 feet, 20 mm (4-gauge) wire should be used.

• Length: Minimum 2.5 meters (8 feet), preferably 3-meter (10-foot). A longer ground rod will

reach a soil with higher moisture content. Moist soil carries current much better than drier soil.

The ground wire should be protected from damage by lawnmowers, tractors, etc. It should be buried

minimum 15 cm (6 inches) underground for protection and enter the house as soon as possible. It is

important that the wire not be cut; it should remain continuous.

3.2.3 34BGround clamps

Ground wires should not be merely wrapped around a ground rod. Ground clamps are used to attach a

ground wire to a ground rod. The most common clamp is an acorn clamp. Make sure the ground clamps

you select are rated for outdoor use. Do not use pipe clamps rated for inside water lines or hose clamps

to attach the ground wire.

Figure 10: Ground connection

3.2.4 35BWhat should be grounded?

Any equipment that is or could become energized, even accidentally, should be grounded. Current from

lightning strikes objects in a random fashion. Accounts of lightning strikes reveal scenarios most of us

could not predict.

Electric circuits should be wired with a 3-wire conductor consisting of hot, neutral and grounding wires.

The grounding wire should be attached cleanly and securely to devices or systems to be grounded. The

other end of the grounding wire should be attached to the ground bus on the main panel.

© Munters AB, 2013

20

4 Technical data

Input Power Voltage

One Phase 230 VAC

0.1 Amp, 50-60Hz

Relay Loads

8 x 5.0 Amps, 250 Volts

Alarm relay, NO/NC

Analog Inputs

3 Temperature inputs

1 Humidity input

12 VDC for humidity

0.1 A

Digital Inputs

5 mA @ 5 Volts, Dry Contact

2 inputs (feed pulse, water meter)

Operating Temperature Range

-10° C to +50° C (14° F to 125° F)

Enclosure

Water and Dust Tight

Fuses

Main fuse: 0.100 Amps, 250 Volts

Variable Fan Fuse

15A

Relay Fuse:

5A

/