Page is loading ...

Permission is hereby given for the use of this artwork and verbiage by Kent Marine distributors and their customers for the advertisement of the products of Kent

Marine. "Copyright Kent Marine" and date must be shown with each use . Any modification so as to allow advertising another brand is expressly forbidden and will

be legally pursued.

Kent Marine

MAXXIMA & MAXXIMA Hi-S

™

Combination Reverse Osmosis / Deionization Filter Instructions

™™

KENT

E

MARIN

TM

e

r

t

a

a

n

w

d

h

s

M

e

a

r

r

F

i

n

e

e

n

i

A

F

q

f

u

o

a

r

i

s

u

r

m

e

r

u

t

S

c

u

a

p

f

p

u

l

n

i

e

a

s

M

Stage 3

Membrane Filtration

Waste

Water

Out

MAX24, MAX50 Parts List:

MAX35HIS, MAX60HiS Parts List:

Part#

CF1M

1 Micron

Sediment

Filter

Part#

GHF

Garden

Hose

Fitting

Part#

GHF

Garden

Hose

Fitting

Part#

CFCE

Matrix

Carbon

Filter

Part#

CFI

Mixed-Bed

Deion

Resin

Cartridge

Part#

SILICAMAX

High

Silicate

Removal

Deion

Resin

Cartridge

Part#

CFCE

Matrix

Carbon

Filter

Part#

CF1M

1 Micron

Sediment

Filter

Canister Wrench

Canister Wrench

Part #: MTFC50, MTFC24

Membrane

Part #: MHIS35, MHiS60

Membrane

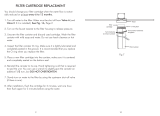

Membrane Insertion:

Disconnect the yellow tube that runs from the prefilter to the

membrane housing’s cap. Unscrew this cap, and, if needed,

re-seat the housing’s o-ring(see diagram 2). Remove

membrane from protective plastic bag. DO NOT REMOVE

PROTECTIVE TAPE FROM AROUND MEMBRANE! The

membrane has a plastic pipe located in the center of the

membrane material. At one end of the pipe, there are two

small black o-rings. Hold the housing vertically and insert the

membrane with the two small, black o-rings first(see diagram

2). It will stop at the large black gasket seal located on the

outer edge of the membrane material. Take the palm of your

hand and push the membrane into the housing. This is

sometimes a tight fit so push with adequate force. You will

feel it “seat” into the housing.

Diagram 1

Membrane

Housing

Housing

O-Ring

Membrane

Diagram 2

Once the membrane is “seated”,

you can check to make sure it is all

the way in. From the top of the

membrane material to the edge of

the housing lip should measure

about 3/4 of an inch(see diagram

3). If it is not this far in, you will

have to either, re-insert the

membrane, or try to push it farther

inside. Once the membrane is

seated properly, screw the housing

cap onto the housing and re-attach

the yellow tube as before.

3/4“ Space

Stage

1

Stage

2

Stage 4

™

CFI or SILICAMAX(Hi-S )

Tap Water In

Product

Water

Out

Model #

MAX24, MAX50

MAXHIS35, MAXHiS60

Front View

Rear View

1

1

1

1

1

1

1

1

1

1

1

1

Diagram 3

Waste Water (Orange tubing)

Product Water (Yellow Tubing)

Membrane Housing

Flow Restrictor Diagram

This is shown for reference only.

All units have their flow restrictors PRE-

®

INSTALLED at Kent Marine This

component has no adjustment and

should not be removed or tampered with

Housing Cap

Prefiltered

Water In

The Membrane Housing

JacoNut

Orange Tubing

Split

Compression

Ring

Compression

Collar

REV. 2

®

Copyright 1999, Kent Marine , Inc.

®

Copyright 1999, Kent Marine , Inc.

MAXXIMA , MAXXIMA Hi-S

™ ™

OVERVIEW:

Maxxima unit incorporates a TFC or Hi-S membrane so it can be run on municipal or

™ ™

well water systems. Chlorine can damage a TFC membrane, so proper maintenance is

essential. The water in our taps is filled with all sorts of toxic materials. Among these can

be lead, mercury, arsenic, chromium, pesticides, herbicides, industrial pollutants (carbon

tetrachloride, vinyl chloride, benzine etc.), gasoline, and trihalomethanes (from reactions

between organic matter and chlorine), chlorine, radium, and radon gas to name just a few.

Some substances can be toxic to humans and to aquarium fish. Phosphates and silicates

are very common in tap water, though usually not toxic to humans, these cause

undesirable algae growths in all types of aquariums.

Utilizing Reverse Osmosis will remove the majority of these contaminates from the water.

The Maxxima unit adds a post deionization resin filter to polish the R/O water to 99%

™

removal. This highly filtered water is not recommended for drinking due to its lack of minerals

and possible odd taste. Listed below are typical removal percentages, actual percentages

will vary depending on exact chemistry, temperature, pressure and TDS of your water.

CTA TFC Hi-S Maxxima

™ ™

% % % %

Hardness: 93-95 93-97 99-99.5 --------- 99.9

Heavy Metals: 94-96 95-98 99-99.5 --------- 99.9

Ammonium: 85-90 80-90 98-99 --------- 99.9

Phosphate: 85-97 95-98 99-99.5 --------- 99.9

Nitrate: 50-70 90-95 93-96 --------- 99.9

Silicate: 80-90 92-95 99-99.5 --------- 99.9

Bacteria: N/A >99 >99 --------- >99

There are certain factors that lower product water production. The first is water pressure.

The ideal water pressure should be 65 psi. A water pressure of 45psi will reduce the rated

Gallons Per Day(GPD) by one half. The second condition is water temperature. The ideal

o o o o o

operational temperature should be 70 to 77 F, 21 to 25 C. Low water temperatures like 50

o

F, 10 C restrict the output to half. NEVER run hot or mixed hot/cold water to the unit. Only

run the cold water. The third and final condition is the TDS or Total Dissolved Solids of the tap

water. These units are rated for 200 ppm(parts per million) of TDS. High TDS can also lower

output.

INSTALLATION:

NOTE: THIS UNIT SHOULD BE INSTALLED BY A LICENSED PLUMBER

TO ADHERE TO ALL LOCAL CODES. IT IS THE RESPONSIBILITY OF

THE PURCHASER TO INSURE THAT ALL FITTINGS ARE TIGHT AND

THAT CODES ARE MET.

WARNING: HOUSEHOLD WATER PRESSURE CAN CAUSE LEAKS

AND DAMAGE SURROUNDING BUILDING AND FIXTURES IF NOT

PROPERLY INSTALLED! User must check all fittings for tightness!

KENT MARINE ASSUMES NO RESPONSIBILITY FOR WATER DAMAGE

DUE TO LEAKS! Check the box thoroughly for all parts listed on the other side of these

instructions for the type of unit purchased. All units come standard with a Garden Hose

Fitting(GHF). If the feed water (faucet or sink) does not have ¾ “ garden hose threads, you

will need to purchase an adapter, a FAUS; chrome diverter fitting (fits standard faucet

threads), or use an alternative, under the counter device like a SV. After you have the feed

line(yellow tubing) installed , you need a drain to dispose of the waste water(orange Tubing).

If the unit is going to be portable, you can run the waste line down the sink. If you are installing

the unit permanently, you should purchase our DSAD(drain saddle). This saddle fits standard

sink drain piping. Insert the membrane as shown in diagram 1 & 2 on the opposite side of

these instructions. After membrane insertion, make sure the bottom canisters are tightened

with the supplied canister wrench. Check all compression fittings for proper tightness. Under

normal operation, the full Jaco fitting will not need to be removed from any of the unit's

components. If one is removed, the pipe threads will need to be re-Teflon taped (leaving the

first two threads exposed) prior to installing back into the component. The unit is now ready for

operation. See below for new unit information.

OPERATION AND MAINTENANCE:

When operating the unit for the first time, follow these steps: 1-Remove the cartridge from the

third canister. Store the removed cartridge in an air tight container or bag, this is to prevent the

resin from drying out. 2-Replace the canisters. 3-Turn the tap water source all the way on.

Check the unit thoroughly for leaks and proper membrane operation(test alkalinity, should be

zero). 4-Run the unit and discard the first 10 to 12 gallons of product water. This is to flush the

membrane of the protective fluid as stated on the membrane's heat sealed bag. The

membranes are shipped almost completely dry to preserve them in shipment. Since they are

dry, you might not get your rated GPD at first. After the 10 to 12 gallons have run through,

return the removed cartridge back to the original canister, now the water is ready for use. 10

days of continuous running is required for complete membrane hydration. During this time

the water is still properly filtered and can be used as normal, although output may be low. This

does not mean you have to run the unit for this time period, only that when 10 days of running

is reached by normal operation.

Reverse Osmosis membranes simulate the membranes within our bodies, so they are

delicate. The membranes, once hydrated, cannot be allowed to dry out. When a membrane

dries, it is no longer able to purify the water and would need to be replaced. When the unit is

not operating, the membrane housing MUST stay wet. If the unit is portable and makes water

once or so a month, store the unit with the tubing above the membrane housing to prevent

draining. If the unit is not going to produce water for over 4 weeks, the membrane needs to be

removed from the membrane housing and stored in a plastic, air tight bag with 2 tablespoons

of product water and placed in the refrigerator. Doing this will prolong the membrane life. Do

not let the membrane freeze. Regular maintenance of the R/O unit consists of keeping track of

about how much water the unit is producing. This can be estimated. The following chart is the

recommended change times for all the filters.

Prefilter

st

1 canister- CF1M- 1 micron string wound filter:

Change every 6 months or earlier if filtering heavy sediment, looks

dirty or unit loses flow.

nd

2 canister- CFCE-solid block carbon matrix filter: Change

every 3,750 gallons of product water at 2 ppm chlorine,

or every 6 months.

Post Filter

rd

3 canister- CFI- or SILICAMAX:

post deionization resin cartridge or Hi-S™

High Silica removal resin: These resins are color indicated,

exhaustion starts from bottom up. Once color change is one inch

from the top, the cartridge needs replacing.

Membranes for all Units

Membrane-MTFC??( rated gpd)-Thin Film Composite, MHiS35, MHiS60:

Under average conditions this membrane can filter

25,000 gallons or around 3 to 5 years of service. The

existence of fouling chemicals in the tap water like Iron,

Calcium, or Magnesium, will reduce the membrane

life exponentially. Kent Marine makes an add-on called

the FLUSHKIT. Adding this kit will greatly decrease

the chances of the fouling chemicals from destroying

the membrane.

Kent Marine makes add on kits to enhance the performance of these units. Here are some

examples. The FVKITKENT is a complete kit for filling up a reservoir container or sump and

shutting off the R/O unit by the means of a plastic float valve. We also have a drinking water

system called the COMKITPLUS. This system includes a 2.5 gallon pressurized tank and bar

faucet for dispensing filtered water and the solenoid to shut off the unit(drinking water from a

Maxxima unit must be taken before resin filtration). For more information about all our kits,

™

either call your supplier or look up our web site at www.kentmarine.com.

TROUBLESHOOTING:

Too much product water, little waste or resin exhausts quickly: Cause: the membrane is

not fully seated in the housing. See diagram 1 & 2 from opposite side of these instructions.

Not enough product water, lots of waste: Cause: Check the TDS, Temperature, PSI as stated

in the Overview section. Make sure you have given the membrane enough time to completely

®

hydrate. If all the common problems have been ruled out, contact Kent Marine 's Technical

Department for further assistance.

LIMITED WARRANTY:

®

Kent Marine warrants this product to be free from defects in material and workmanship under

normal use and conditions for a period of 90 days from the date of original purchase. Gallons

per day is not warranted since it is dependent on the users water conditions (i.e., temperature,

pressure, and total dissolved solids).

Should service be necessary under this warranty due to a manufacturing defect or malfunction

®

during the 90 day warranty period, Kent Marine will, at our option, repair or replace the unit

and pay transportation charges back to purchaser. Purchaser is responsible for transportation

®

to Kent Marine , in any event. If the unit is determined to be damaged due to incorrect

installation, poor water conditions from users tap, or other unwarrantable condition, Purchaser

will be billed for repair charges and return shipping charges.

Note: The warranty is void if the product is: 1) Damaged through negligence, misuse, abuse,

or accident. This includes, but is not limited to failure to regularly replace carbon and sediment

filters. 2) Damaged by poor local tap water conditions. 3) Damaged due to connection of

®

equipment other than supplied by Kent Marine , or modification by the user.

This warranty is valid only in the U.S., is non-transferable and applies to original purchaser

only. No other warranties are expressed or implied and any other warranties required by law

are limited in duration to 90 days. This product is not warranted for any specific purpose. Kent

®

Marine will not be responsible for consequential damages arising from installation or use of

the product, including any flooding which may occur due to malfunction or faulty installation

including, but not limited to failure of installer to tighten all fittings.

IMPORTANT!!: Most phosphate and nitrate test kits cannot read R/O, Deionized water

properly. If testing for these, they will give a FALSE positive reading.

ATTENTION! Please read these instructions thoroughly before

installation.

/