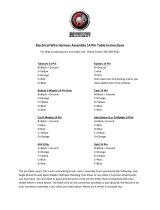

Table of Contents

LTV

wc_bo5100030216_05TOC.fm

10

15.7 LTV—Metal Halide Lights Module ............................................................. 112

15.8 Components ............................................................................................... 112

15.9 LTV—120V / 30A Receptacle Module ....................................................... 113

15.10 Components ............................................................................................... 113

15.11 LTV—8 kW GFCI Receptacle Module ....................................................... 114

15.12 Components ............................................................................................... 114

15.13 LTV—Trailer ............................................................................................... 115

15.14 Components ............................................................................................... 115

15.15 LTV—Kubota Engine ................................................................................. 116

15.16 Components ............................................................................................... 117

15.17 LTV—Power Winch .................................................................................... 118

15.18 Components ............................................................................................... 118

15.19 LTV—LED Lights Module .......................................................................... 119

15.20 Components .............................................................................................. 119

15.21 LTV—Auto Start Module ............................................................................ 120

15.22 Components ............................................................................................... 120

15.23 LTV—Shore Power Module ....................................................................... 121

15.24 Components ............................................................................................... 121

15.25 LTV—Controller-Kubota D2005 / D1105 ................................................... 122

15.26 Components ............................................................................................... 123

15.27 LTV—230V / 50 HZ Module ....................................................................... 124

15.28 Components ............................................................................................... 124

15.29 LTV—Containment Switch ......................................................................... 125

15.30 Components ............................................................................................... 125

15.31 LTV—URI Telematics ................................................................................ 126

15.32 Components ............................................................................................... 126

16 Appendix I 127

16.1 Standard Racked Assembly ....................................................................... 127

16.2 Installing the Axle ....................................................................................... 128

16.3 Installing the Fenders ................................................................................. 129

16.4 Installing the Wheels .................................................................................. 130

16.5 Installing the Outriggers and Swivel Jacks ................................................ 131

16.6 Installing the Tongue Assembly ................................................................. 132

16.7 Installing the Mast ...................................................................................... 134

16.8 Installing the Standard Winch .................................................................... 135

16.9 Installing the Power Winch ......................................................................... 137

16.10 Installing the Light Support Bracket and Light Bar ..................................... 139

16.11 Installing the Lights—240W Metal Halide or 300W LED ............................ 140

16.12 Installing the Lights—240W LED ............................................................... 141

16.13 Connecting the Wiring at the Junction Box ................................................ 142