77-3090-R2 (9/2019) 1 / 12 www.carlisleft.com

240-3119-1 (ONE GUN)

240-3119-2 (TWO GUNS)

GUN FLUSH BOX KIT

INSTALLATION INSTRUCTIONS

EN

OPERATION MANUAL

GLOBAL ELECTRONIC MIX SOLUTIONS

PLURAL COMPONENT MIXING SYSTEM

EN

77-3090-R2 (9/2019)2 / 12www.carlisleft.com

LOCK OUT / TAG-OUT

Failure to de-energize, disconnect, lock out and tag-out all power

sources before performing equipment maintenance could cause

serious injury or death.

OPERATOR TRAINING

All personnel must be trained before operating finishing

equipment.

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture,

malfunction, or start unexpectedly and result in serious injury.

PROJECTILE HAZARD

You may be injured by venting liquids or gases that are released

under pressure, or flying debris.

PINCH POINT HAZARD

Moving parts can crush and cut. Pinch points are basically any

areas where there are moving parts.

INSPECT THE EQUIPMENT DAILY

Inspect the equipment for worn or broken parts on a daily basis.

Do not operate the equipment if you are uncertain about its

condition.

In this part sheet, the words WARNING, CAUTION and NOTE are used to

emphasize important safety information as follows:

Hazards or unsafe practices which

could result in minor personal injury,

product or property damage.

!

CAUTION

Hazards or unsafe practices which

could result in severe personal

injury, death or substantial property

damage.

!

WARNING

Important installation, operation or

maintenance information.

NOTE

Read the following warnings before using this equipment.

READ THE MANUAL

Before operating finishing equipment, read and understand all

safety, operation and maintenance information provided in the

operation manual.

WEAR SAFETY GLASSES

Failure to wear safety glasses with side shields could result in

serious eye injury or blindness.

NEVER MODIFY THE EQUIPMENT

Do not modify the equipment unless the manufacturer provides

written approval.

IT IS THE RESPONSIBILITY OF THE EMPLOYER TO PROVIDE THIS INFORMATION TO THE OPERATOR OF THE EQUIPMENT.

FOR FURTHER SAFETY INFORMATION REGARDING THIS EQUIPMENT, SEE THE GENERAL EQUIPMENT SAFETY BOOKLET (77-5300).

KNOW WHERE AND HOW TO SHUT OFF THE EQUIPMENT

IN CASE OF AN EMERGENCY

PRESSURE RELIEF PROCEDURE

Always follow the pressure relief procedure in the equipment

instruction manual.

NOISE HAZARD

You may be injured by loud noise. Hearing protection may be

required when using this equipment.

STATIC CHARGE

Fluid may develop a static charge that must be dissipated through

proper grounding of the equipment, objects to be sprayed and all

other electrically conductive objects in the dispensing area. Improper

grounding or sparks can cause a hazardous condition and result in

fire, explosion or electric shock and other serious injury.

WEAR RESPIRATOR

Toxic fumes can cause serious injury or death if inhaled.

Wear a respirator as recommended by the fluid and solvent

manufacturer’s Material Safety Data Sheet.

TOXIC FLUID & FUMES

Hazardous fluid or toxic fumes can cause serious injury or death if

splashed in the eyes or on the skin, inhaled, injected or

swallowed. LEARN and KNOW the specific hazards or the fluids

you are using.

KEEP EQUIPMENT GUARDS IN PLACE

Do not operate the equipment if the safety devices have been

removed.

!

WARNING

AUTOMATIC EQUIPMENT

Automatic equipment may start suddenly without warning.

FIRE AND EXPLOSION HAZARD

Improper equipment grounding, poor ventilation, open flame or

sparks can cause a hazardous condition and result in fire or

explosion and serious injury.

PLURAL COMPONENT MATERIALS HAZARD

Because of the vast number of chemicals that could be used and

their varying chemical reactions, the buyer and user of this

equipment must determine all facts relating to the materials used,

including any of the potential hazards involved.

ELECTRIC SHOCK / GROUNDING

Improper grounding or sparks can cause a hazardous condition

and result in fire, explosion or electric shock and other serious

injury.

HIGH PRESSURE CONSIDERATION

High pressure can cause serious injury. Relieve all pressure before

servicing. Spray from the spray gun, hose leaks, or ruptured

components can inject fluid into your body and cause extremely

serious injury.

EXPLOSION HAZARD

Halogenated hydrocarbon solvents can cause an explosion when

in contact with aluminum components of a pressurized or closed

fluid system.

EN

77-3090-R2 (9/2019) 3 / 12 www.carlisleft.com

MOUNTING

Mount gun ush boxes to a sturdy metal stand,

wall, or support that is connected to an earth

ground. Conductive metal ushing / solvent waste

container should be positioned directly below the

ush box.

Mount box with 4 ea. 1/4” or 6mm diameter screws

using dimensions shown at right. Remove the gun

saddle from the box to make mounting easier.

GUN FLUSH BOX KIT

Gun ush boxes are used to improve safety and minimize solvent usage and time when compared to manual

ushing of spray guns. Higher solvent and air pressures may be used, improving ushing efciency.

Flush boxes may be installed on the GEMS system for one or two guns. In a two-gun installation the system

controller allows either gun 1 or both guns 1 and 2 to ush and load paint. The second gun may be disabled

by the administrator if necessary.

All pneumatic connections to the gun ush box are for 5/32” (4mm) OD tubing.

The gun flush box(es) must be enabled in the system software configuration, accessible only

by distributor. Contact distributor for installation and proper kit functionality.

!

CAUTION

Gun flush box(es) will generate vapors and

mists of paint and solvent and therefore

must be mounted in a spray booth or other

Class 1 Division 1 [Zone 1] Hazardous Area.

The gun flush box and conductive metal

waste container used for flushing must be

bonded to earth ground and continuity

checked with an ohmmeter .

Do NOT operate the gun flush box until

properly grounded.

!

WARNING

GUN BOX MOUNTING HOLE PATTERN

EN

77-3090-R2 (9/2019)4 / 12www.carlisleft.com

GUN BOX PNEUMATIC CONNECTIONS

AIR CONNECTION DESCRIPTIONS

AIR — Supply air needed to operate the Gun Box. 75-100 psi [5-7 bar] required.

GIB — Air signal sent to the controller (GIB1, GIB2) when the spray gun is in

the Gun Box and the lid is closed.

ACO — Triggers the Air Cut Off (ACO) Valve at the Air Flow Switch. Enables /

disables the spray gun’s atomizing air.

TRG — Air signal used to trigger the spray gun in the closed box. Receives signal

from system controller (TRG1, TRG2).

IND – Pneumatic indicator shows when gun is triggered. This input is shared

with TRG via a tee. Only the TRG input must connect to the control.

CONNECTING AIR LINES

After mounting the box, use the supplied pneumatic tubing to connect the ush box to the supply air and

GEMS control. Use a length of black 5/32” tubing to provide supply air to the bulkhead ‘AIR’. Adapt to

tubing size as needed.

Use a length of clear tubing to connect the enclosure bulkhead for GIB1 (or GIB2) to the GIB connection of

the ush box.

The second length of clear tubing should run from the ACO connection of the ush box to the elbow

mounted on the air cutoff valve. The ACO labeled solenoid (in the control enclosure) valve should be

plugged at the valve outlet.

A second length of black tubing should connect the ush box TRG connection to the corresponding TRG1

or TRG2 bulkhead on the back of the enclosure.

Ensure all tubing is free from sharp bends and kinks. Keep tubing clear of sharp edges and hot surfaces.

See the diagram on pp. 6-7 for more information.

CONNECTING AIR CUT OFF VALVE

Mount the Air Cut Off valve(s) to the outlet of the airow

switches as shown at left. For more detail, see 77-3087

Air Cut-off Installation Instructions.

Connect the ACO trigger signal tubing as described above.

EN

77-3090-R2 (9/2019) 5 / 12 www.carlisleft.com

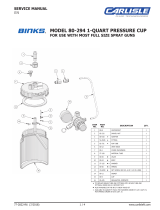

ADJUSTING THE GUN SADDLE

Gun flush box saddles are sold separately. Order the

appropriate saddle for the spray gun to be used on the

system from a Binks distributor. See chart on page 9 for

available saddles.

NOTE

The gun saddle is the plastic part inside the box used to cradle the spray

gun’s front end to ensure proper box operation. Install the gun saddle for

the specic model of spray gun to be used. Two 5/16”-18 screws will pass

through the box side wall and a plastic spacer then thread into the saddle.

The bottom of the gun saddle is threaded with a 2” NPT female thread for

connection to a 2” metal waste drain pipe with mating threads.

The gun saddle should

be adjusted for proper

gun position. Place the

gun in the saddle as

shown, and attempt to

shut the lid. If the lid

does not close all the

way, use the two screws

to adjust the height of

the gun holder so the

lid will shut properly.

Verify that the gun trigger

actuator pin will catch the

“nger side” of the spray gun

trigger when the lid is closed.

If not, the holder may need

to be adjusted again.

Gun trigger actuator pin

ADJUSTMENT STEPS

1. To properly adjust the gun saddle in the gun

box you need the correct saddle for your gun.

2. Place the gun saddle into the gun box by

removing the 5/16-18 cap screws on the right

side of the gun box.

3. Screw in the new saddle for your gun, leaving

the bolts loose for adjustment.

4. Place gun in holder and bring the gun up to the

actuating pin so that the pin goes under the gun

trigger. Secure bolts on right side of gun box.

5. Position the adjustment for the gun handle so it

clears the gun controls on the back of the gun.

6. Close the gun box lid. If the lid triggers the

air output "Gun in Box" (GIB) signal, the box

is ready to use. If the lid does not trigger

the air output "Gun in Box" (GIB) signal,

continue with steps 7-10 below.

7. Adjust the actuation pin location, pull it up, and

secure its screws.

8. To access the screws for the actuator pin,

remove the four screws on the left side of the

gun box and remove the input-output part of

the box.

9. Loosen the two screws on the actuation

slide block and move upward or downward

depending on gun size and shape. Secure the

bolts.

10. Repeat steps (4 to 9) until the gun box GIB

output is working. You are now ready to use

the box.

Gun

saddle

Spacer

Screws

1-1/2"

Adjustment

Adjustment

locations

Adjustment

locations

Adjustment locations

1"

1/2"

Adjustment

3/16" saddle

movement when

gun is closed in box

View of air connections on

back of control enclosure

TO GUN TRIGGER SOLENOID

TO MAIN AIR

TO GUN IN BOX PRESSURE SWITCH

TO AIR CUT OFF SWITCH

EN

77-3090-R2 (9/2019)6 / 12www.carlisleft.com

PNEUMATIC HOSE ROUTING FOR CONNECTING

GEMS TO GUN FLUSH BOX

TO GUN TRIGGER SOLENOID

TO MAIN AIR

TO GUN IN BOX PRESSURE SWITCH

TO AIR CUT OFF SWITCH

EN

77-3090-R2 (9/2019) 7 / 12 www.carlisleft.com

240-3119-X GUN FLUSH BOX

KIT CONTENTS

Part

Number

Description

240-3119-1

Qty.

240-3119-2

Qty.

240-3179-K Gun Flush Box 1 2

240-3118-1 Air Cut Off Kit, single 1 2

77536-01

5/32” tubing black,

50’ cut length

2 4

77536-05

5/32” tubing clear,

50’ cut length

2 4

EN

77-3090-R2 (9/2019)8 / 12www.carlisleft.com

GUN FLUSH BOX GUN OPERATION

With ush box mounted, pneumatic tubing connected, and saddle adjusted for proper operation:

Open valve or regulator to supply the ush box AIR inlet with 75-100 psi [5-7 bar] air.

Power on the GEMS system and adjust ush time and load volumes for each gun to optimize the ushing

and loading processes.

Place the spray gun in the box and close the lid. The atomizing air will exhaust through the ACO valve, and

the trigger actuating pin will extend to the front of the gun trigger.

Select the GEMS Color Change screen. Load a desired paint color. The system will perform the appropriate

ush / load sequence.

The gun flush box must be enabled in the system software configuration, accessible only by

distributor. Contact distributor for installation, configuration, and safety procedures. The GEMS

system will NOT operate the gun flush box until software configuration is correct.

!

CAUTION

The Go button on the color change screen will not display if:

• The spray gun(s) are not in the gun box(es).

• The gun box lids are not closed.

A color change fault will occur if the flush box lid is opened before the

flush / load process is complete.

NOTE

When paint is loaded the system will return to the home screen and make a sound. The AE valve will close.

Open the gun ush box and remove the spray gun. Close the ush box lid. Spray parts.

When spraying is complete, open the ush box lid and place the gun back into the box, then close the lid.

If desired, select the GEMS color change screen to ush or load the next color. Pot life will continue to

count down until it expires or a ush is performed.

EN

77-3090-R2 (9/2019) 9 / 12 www.carlisleft.com

PART NO. DESCRIPTION

240-3198-C Gun Holder — Binks 2100 Gun

240-3198-D Gun Holder — Binks Trophy Touch Up Gun

240-3198-G Gun Holder — DeVilbiss JGA / JGHV Gun

240-3198-H Gun Holder — Ransburg Vector Gun

240-3198-J Gun Holder — DeVilbiss GTi Pro Lite Gun (not available in NA)*

240-3198-K Gun Holder — DeVilbiss Advance HD Gun (not available NA)*

240-3198-L Gun Holder — Ransburg Ransex Electrostatic Gun

240-3198-M Gun Holder — Binks Trophy Gun

*These guns are not available in North America

TROUBLESHOOTING

Most problems associated with gun ush box operation may be easily checked:

• For ushes / color changes

• Is gun positioned properly in the box with the lid closed?

• Is air pressure to the box between 75-100 psi [5-7 bar]? Are there kinks in any of the air lines?

• Is the gun saddle height properly adjusted?

• Are the air switches functioning properly?

• For spraying

• Is the ush box lid closed?

• Is air pressure to the box between 75-100 psi [5-7 bar]? Are there kinks in any of the air lines?

• Are the air switches functioning properly?

Check these items in the order shown. Contact distributor if these checks do not resolve the issue.

GUN FLUSH BOX GUN SADDLES

A number of saddles are available to t Binks, DeVilbiss, and Ransburg spray guns. See the table below for

available gun holders and the corresponding part number. Contact your local Binks representative to order

these accessories.

Use the correct saddle for the spray gun installed on the GEMS system. Using an incorrect or

poorly fitting saddle may result in faulty flush box operation and / or paint and solvent blowing

back into the flush box during flushing.

!

CAUTION

Right Side View

Left Side View

Front View

EN

77-3090-R2 (9/2019)10 / 12www.carlisleft.com

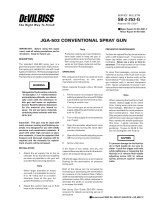

GUN FLUSH BOX COMPONENTS

240-3179-K

EN

77-3090-R2 (9/2019) 11 / 12 www.carlisleft.com

NO. PART NO. DESCRIPTION QTY.

1 E22-1501 GUN BOX BODY 1

2 E22-1502 COVER 1

3 E22-1503 LID ASSEMBLY 1

4 E22-1504 GUN IN BOX BRACKET 1

5 E22-1505 TOGGLE PLATE 1

6 E22-1506 BLOCK 1

7 E22-1507 ARM 1

8 E22-1508 GUN SEAT 1

9 E22-1509 HINGE 1

10 E22-1510 PUSH CAP 1

11 E22-1511 TRIGGER CAP 1

12 E22-1512 HANDLE 1

13 E22-1513 HANDLE ADAPTER 1

14 SEE PAGE 9 GUN SUPPORT 1

15 E22-1515 SPRING SPACER 3

16 E22-1516 SUPPORT SPACER 1

17 E22-1517 TRIGGER CYLINDER 1

18 E22-1518 PUSH CYLINDER 1

19 E22-1519 AIR PILOTED SWITCH VALVE 1

20 E22-1520 AIR PILOT 1

21 E22-1521 5/32" TUBE Y ADAPTER 1

22 E22-1522 5/32" TUBE X 1/8" NPT TEE FITTING 1

23 E22-1523 5/32" TUBE X 1/8" NPT ELBOW 5

24 E22-1218 5/32" TUBE X #10-32 ELBOW 1

25 E22-1525 AIR SWITCH 2

26 E22-1526-K2 TORSION SPRING 1

27 E22-1527 COMPRESSION SPRING 1

28 E22-1528-K2 GROMMET 1

29 E22-1529 S.S. CHAIN LINK 4

30 E22-1530 S.S. CHAIN CONNECTOR 2

31 E22-1531-K2 SPRING PLUNGER 1

32 E22-1532-K2 1/4" X 1" S.S. DOWEL 1

33 E22-1533 PRESSURE INDICATOR 1

34 E22-1534 5/32" TUBE TEES 1

35 E22-1535 5/32" TUBE BULKHEAD 5

36 E22-1536 AIR CUT OFF VALVE 1

37 E22-1537 #4-40 X 3/4" SHCS SS 1

SOURCE

PARTS

LOCALLY

38 E22-1538 #8-32 X 5/8" SHCS SS 2

39 E22-1539 #8-32 X 1" SHCS SS 4

40 E22-1540 #8-32 NUT SS 4

41 E22-1552 #10-32 X 1/2" SHCS SS 4

42 E22-1542 5/16" LOCK WASHER SS 4

43 E22-1543 5/16" WASHER SS 4

44 E22-1544 5/16"-18 X 1/2" BHCS SS 2

45 E22-1545 5/16"-18 X 3/4" BHCS SS 2

46 E22-1546 5/16"-18 X 3" BHCS SS 2

47 E22-1547 3/8" LOCK WASHER SS 1

48 E22-1548 3/8" WASHER SS 2

49 E22-1549 3/8" LOCK NUT SS 1

50 E22-1550 3/8"-16 X 1/2" BHCS SS 2

51 E22-1551 5/8" X 1-1/2" X 1/16" WASHER SS 2

12.2: GUN BOX PARTS LIST

EN

77-3090-R2 (9/2019)12 / 12www.carlisleft.com

WARRANTY POLICY

This product is covered by Carlisle Fluid Technologies’ materials and workmanship limited warranty.

The use of any parts or accessories, from a source other than Carlisle Fluid Technologies,

will void all warranties. Failure to reasonably follow any maintenance guidance provided

may invalidate any warranty.

For specic warranty information please contact Carlisle Fluid Technologies.

For technical assistance or to locate an authorized distributor,

contact one of our international sales and customer support locations.

Region Industrial/Automotive Automotive Renishing

Americas

Tel: 1-800-992-4657 Tel: 1-800-445-3988

Fax: 1-888-246-5732 Fax: 1-800-445-6643

Europe, Africa,

Middle East, India

Tel: +44 (0)1202 571 111

Fax: +44 (0)1202 573 488

China

Tel: +8621-3373 0108

Fax: +8621-3373 0308

Japan

Tel: +81 45 785 6421

Fax: +81 45 785 6517

Australia

Tel: +61 (0) 2 8525 7555

Fax: +61 (0) 2 8525 7575

Carlisle Fluid Technologies is a global leader in innovative nishing technologies.

Carlisle Fluid Technologies reserves the right to modify equipment specications without prior notice.

DeVilbiss

®

, Ransburg

®

, ms

®

, BGK

®

, and Binks

®

are registered trademarks of Carlisle Fluid Technologies, Inc.

©2019 Carlisle Fluid Technologies, Inc.

All rights reserved.

For the latest information about our products, visit www.carlisleft.com

/