Page is loading ...

'l

G{ ltr

lr!

ll

'

J11.,,,

eE[$'uujRlj0

i"ili \ilI'I-lr',

t-i

vY

(llr

PERFORMANCE

-

SPECIFICATIONE

Two Ten Centlrlnnl

cROsS

WEIGHT

.

34OO

tb8

SPEED,

BEST

POWER

MXTIJRE:

Top

Speed

at

Sea Level

. .il.

.

,

.

2OO

mph

RANGE,

NORMAL

LEAN

MD(TURE:

Cruise,

?570 Power

at 6500

ft

. ?g5

mi

64

Gallons,

No Reserve

4. 1

trrs

cruise,

?b7o

power

at 6boo

n

lSidill

89

cqllons,

No

Reserve

S.

? hrg

/

/

191

mph

ogidlf

Ranse

at to,Ooo

ft

.

. 980

mr

,

I

64

Gtllons,

No

Reserve

6.9

hr8

_.t

142

mph

Optl4um

Range

at 10,000

tt

.

tg6o

;l

89

$allons,

No

Reservc

9.

6

hrs

Ar sEA

LB'EL

lf8di3l"

c.

.ls,sodft

Run

.

800

ft

,.....ovvlt

Distance

Over 5o-foot

Obstacle

,

l36E

lt

/Lanfing

RoU

. 6zE

ft

Toti.l

Distance

Over

so-foot

Obstacle

.

......l3btit

EMPJY

WEIGHT (Approximate)

. . 1960

tbg

WINq

LOADING:

pounds/Sq

Foot

....ig.I

POWER

TOADING:

Pounds/HP

.

1r.g

FUEL

CAPAoITY:

Total -.

. 90

gal,

OIL CAPACITY:

.

12

its

ENGINE:

Continental

Fuel

Injectton

Englne.

.,,.

. IO_O2O-A

285

rated

BHp

ar

2?00

RpM

i

'-

.'

'I

Pertormance

vrith

a 3-blolded propeller

18

essen

ally the

same

as

ibove,

*This

manual

covers

op8ration

of,ihr

Two lon

Ccnturion vlhich

is

cedilicated

'\

as M0del

2l0H

under tAA

lyp!.

garflfh!t0

No,

i

:t'

D551-

L3-RPC-r00_7/7F

)

3A21,

CONGRATULATIONS

. . .

. .

.

:

wilcome

to the

ranks of Cessna

Owners

! Your

Cessna

has been

deBigned

,na

"on"tru"t"a

to

give you

the

moat

in

performance, economy'

and

co4-

fort. It

is our

desire

that

you

wiu

find

flying

it, either

lor business

or

i

pleasure,

a

pleasant

and

profitable

experience.

{

This Owner's

Manual

has been

prepared

as

a

guide

[o help

you get

the

most'pleasure

and

utility

Ircm

your

TWO

TEN CENTURIONT

It

contains

information

about

your

cesena's

equipment,

operating

procedureB,

and

perforniance; and suggestions

for

its servicing

afid

car€.

we

urge

you

io read it

from

cover to

covef and

to

reler to

it fTequently.

FACTORY

TRAINED

PERSONNEL

to

provide

you

with courteouE:

expert

service.

'

l

FACToRY APPROVED

SERVICE

EQIIIPMENT

to

provide

you

.

with

the

most eflicient

and

accurate workmanship

possible.

A

STOCK

OF

GENUINE

CESSNA

SERVICE

PARTS

OII

h

Id

when

you

need them.

TIIE LATEST AUTHORITATIVE

INFORMATION

FOR SERV-

ICING

CESSNA

AIRpLANES,

since

Cessna

Dealers

have all

oI

the service

Manuals

and

Parts Cata.logs,

kept

currert

by

Service

Letters

and

Service

News

Letters,

published

by

Cessna

AircraJt CompanY.

We

urye all Cessna

owners

to

use the Cessna

Dealer Organization

to the

fullest-

A ei[rent

Pessna

Dealer

Directory

accompanies

your

ne{' airplare.

The

Directory

is revised

frequently,

and a

curlent copy

can be obtained

from

your

Cessna

Dealer,.

Mahe

your

Directory

one oI

your

cross-country

itight

ptanning

aids;

a

warm

welcome

a\rraits

you

at every

cessna

Dealer.

,''

:

i

t

!

I

11

tii

TABLE OF CONTENTS

Page

=

SECTION

I

-

OPERATING CHECK LIST

--------

I.I

SECTION

II

.

DESCRIPTION

AND

OPERATING DETAILS

--.----------

2-I

SECTION III

-

EMERGENCY PROCEDURES----- 3-I

SECTION

IV

-

OPERATING

LIMITATIONS..---.-.

4.I

SECTION V

-

CARE OF

THE AIRPLANE-----.--

5r

owNER FOLLOW-UP SYSTEM

-______________

5-10

SECTION Vl

-

OPERATIONAL DATA-------------- 6-r

SECTION Vll- OPTIONAL SYSTEMS--------------

7-t

ALPHABETICAL

INDEX---

--------

tndex-l

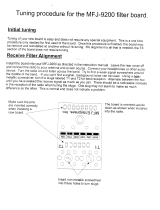

EXIER'OR

'NSPECI'ON

Tum o nast€r sult.h

and.lrock

ro.l

q!rn0

-

ty tndcrtors, ti.n turn malt.r 6yttch

'loff, "

Check lsntllo.

tqltch

"OtF."

Check

that lu€l

bny *I€ctor volvc hlndlo l.

Remov€ conlrol whe.l lo.k.

che.k bagg.{e door lor 6ecurlty.

Inspect atrcp€€d .tatlc source hol.! on .1d..

oI l$.laAe r.lkon€ lor stoppase.

Redde rdd€r

eu.t

lock,

tr lndt

ll€d,

DiscdnDecl tail ile-dwn,

check ruel bay venl op€nrna

Gt

sha tlp trril-

Disconnect {tng tt.-doen.

!.lore the lrlst lrlght ol ihe day and rlt.r

each

.efueling. us€ sampl€r cup

ad d[1.

snall anount of fuel l.om

quick-drrtn

v.lv€ in tuel bay to rmde

po.stbl€

u.l.r

and *dlme.r. check drain v.tve clo..d,

check main whe€l tire lor

proper

lnilruo[

NOTE

Vlsu.ltyche.k ruel r ler

caps.

lrupection

plales,

and

gener.l

al.oalt condition durlnC Mlk-

U ntght flight ts

planne4

cbek

oper.tlon ol an lishtsj

ud

roke 3ure a rlashlisht is

avail-

Ch.c*

prop€lI€r

and spinn€r

lor nicks and

.eclrlty, and

properl€r

Ior oil lea](s.

Check oo6e

vhe€l strut and tt.. Io!

proper

Dtsconnect noBe

rie-doe.,

Ch.cl oll lcvel, Do not

operale vith le53

thon nlne

querts.

Illl for dtended

ltishi-

Beiore

the ltrs! tu3ht ol the d.y and alt€r

o&h

retuell.g,

glll

out shaln€r dr.in

kmb Io. aboul

lour s€con& to clear fuel

.tmlne. of

Doasible

*ater and sedlnent.

Chcck

slr ner d.ain closed.

Il €ter is

ob[rv.d. lh.r€ ls a

possibility

thit the

luol b{y

sunl)s conlaln wate.. h .ddition

to oho(klnT

th€ Iuer bey sumps as @tliled

in

rloD s rbovo,

the Iu€l rdelvotl dl.in

ptugE

.hould

ho romov€d

to

check

lor lhe

presenc€

o-

o"

@"

o"

@'

x;*ru*'ll,*r,::r""Jr,ir

.liis*!:

""'

i'tgur€ l-1,

TFI

fettion I

E-

I-

L--

OPERATING

CHECK LIST

One oI

the

lirst

step€

in

obtaining

the

utmost

performance,

serYice,

and

flying enjoyment

from

your

Cessna

is to familiarize

yourself

with

your

airplane's

equipment, systems, and

cortrols.

Ihis can best be

done

by reviewing this equipment while

sitting

in the airplane. Ihose

items

u/hose

function

ard opeaation

are not obvious

are

covered in

Section

tr.

Section I

lists, in Pilot's

Check

List form,

the steps necessary to

operate

your

airplane

efficiently and saJely. It

is not a check Ust in its

true form

as it is considerably longer, but

it

does

cover briefly aII of

the

points

that

you

should know for a typtcal

flight.

The flight ard operatlonal characteristics of

your

airplare are nor-

mal in all

respects. There

are

no

"unconventional"

characteristics or

operations

t}Iat [eed to be mastered. AII controls

respond in the normal

way within

the entire rar8e of operation. A1l airspeeds

mentioned ir

Sections

I, tr, ard Itr

are indicated

airspeeds

unless otherwise

noted.

Corresponding

calibrated airspeeds

may

be obtained

from the Airspeed

Correction

Table in Section

VI.

BEFORE

ENTERING THE AIRPIANE.

(1)

Make an exterior i[specuoD

in

accorda[ce with

Iigure 1-1.

BEFORE SIARTING THE ENGINE.

I

il

I

(1)

Pilot's Check

List -- Revievt/ check

list

on

IeIt front doorpoat.

(2)

Seats

and Seat Belts

--

Adjust and lock,

(3)

Bmhes

-- Test and set.

(4)

Master Switch

--

rtON. rr

(5)

Landing Gear

--

Handle neutral

a.nd down light

green.

(6)

Landing Gear

Lights and Horn

--

Push to test,

(?)

colrl llaps

--

"oPEN. "

(Move

lever out of

locking hole to lepo6ition.)

1-1

(8)

Fuel Selector

--

Futlest bay.

(9)

Turn all radio

swttches

"OFF.

"

STARIING ENGINE.

(1)

Mixture

--

FulI

Rich.

(2)

Prcpeller

--

High RPM.

(3)

Throttle

-- Closed.

(4)

Auxiuary

Fuel Pump

Switch

-- On

,,I,o,

,,

NOTE

Itre auxiliary

fuel

pumf

wtU

not

operate

until

ttre

'

igrdtion

switch is turned

to the

"START,'

posiuon.

(5)

Ignition

Key

--

"START.'i

(6)

Slou'ly advance

throtue.

.(?)

Releadb tgnition

key

when englne

starts.

.-

NOTE

II engine

falls to contlnue

runring, start again

from

st€p

(3).

(8)

Reset tlrcttle

to desired

ldle

speed.

(9)

Auxiuary

Fuel Pump

Svttch

--Off.

BEFORE TAKE-OFF.

(1)

ParklnC

Brake

-- Set.

(3)

Throttle

Setttng

--

1?00

RpM,

(4)

Magnetos --

Check

(50

RPM murtmum

dtfferenual

between

magnetos.

)

(5)

PropeUer

-- Cycle from

hlgh

to lou'

RpM;

return

to high

RpM

(full

in).

(9)

Engine

Instruments

--

Chsck,

{

(?)

Ammeter

-- Check.

(8)

Suction

C,age --

Check

(4.

0 to

6,

{

tnchss of mercurv).

(9)

FUght

Instrumenta

and

Rrdtor -"

get,

(10)

Elevator

and Rudder

Trtm

--

Tlk!-dt s€ttings,

(11)

Flight

Controls

--

Chock.

(12)

Optional Autopilot

or Wlng

L€volar --

'OfE."

(13)

Cabin Door8

and wind@,

--

Clotcd and lookad.

t-2

TAKE.OFF.

NOR

'YlAT

TAKE.OFF.

(1)

wine Flaps

--

0'to 20".

(2)

Power

--

Full

throttle and

2?00 RPM.

(3)

Mir.ture --

Lean

for field etevation

per

fuel flo1l,

indicato!

placard'

(4)

Elevator

control

--

Lift nosewheel dt

60 MPH.

(5)

Climb

Speed

--

105 MPH untll a1l

obstacles are

cleared,

then

set

up climb

speed as shown

in

"NORMAL

CLIMB"

paragraph.

(6)

Brakes

--

App1y momentarily

(when

airborne).

(?)

Landing Gear

-- Retract

(in

climb

out).

(8)

Wing FlapB --

Retract

(if

extended) aJter

obstacles are

cleared.

ffIAXI'VIU'VI

PERIORiAANCE

TAKE.OFF.

(1)

wing

Flaps

--

20'.

(2)

Brales

--

Apply.

' (3)

Power

--

Full throttle ard

2?00

RPM.

(4)

tr,Iixture

--

I-€an

for

fietd elevation

per

fuel flow indicator

placard.

(5)

Brales

--

Release.

(6)

Elevator

Control

--

Maintain slightly

tail-low attitude.

(?)

Climb

Speed

--

70 MPH

until all obstacles

are cleare4

then set

up climb speed

as shown

in

'MAXIMITM

PERFORMANCE

CLIMB"

paragraph.

(8)

Landing Gear

and

*ing Flaps -- Retract

(alter

obstacles

are

cleared).

cUMB.

NOR'r At Cit

rvl B.

(1)

Airspeed --

120 to

140 MPE.

(2)

Power

--

24

tnches

and

2500 RPM'

(g)

mxture

--

r,ean to

16. 5

gavhr.

tuel

flow.

(4)

Cowl

Flaps

--

open

as required.

,f,I

AXIiA

U M PERFOR'YTANCE

CtIM B.

.

(1)

Airspeed

--

108 MPII

(sea

level) to

100

MPE

(10,000

feet).

(2)

Power

-- Full

throt e

and 2?00 RPM.

.

,i

,

(3)

Mixture --

Lean for altttude

pef

fuel

flow indicsto!

pla'card.

INSTRUMENT

PANEL

1. Ma*er Beacon In.licator

LightB

and Swiiches

(opt.

)

Z. ! light Instlument

Group

3.

Radlos

(opt.

)

4. Radio S€recto! Switches

(Opt.

)

5. Rear view Mirro!

(opt.

)

6.

Manirold Pres6lrelnrel

Ftow

?. Fuel

Quartity

Indicatols

L Cylinde! Eead

Tempelatule, Oil

Temperature

and Oil

Presrurc

Gages

11. rlght Hour

Recoldel

(Opt.

)

26. Larding

Cear

Positiotr Ilandle

12. Opttonel

In8trument 6pace z?.Miclophore

13,

Rrdlo

(Opt.

)

28. Elevator Trim

C

ontlol wheel

14. Map Compdtmont

2g.Etectric Elevlto! Trim

15. Cabtn

Al!

rnd

fl€rt Conllol8 Cilcult Bleake! s{,ttch

(Opt.

)

16. Clgar

Llght€!

3o.Throttle

U.ll/lng

Fl.p

swttch

18.Mlxhro Coitrol

l(nob

10. Plopsll€! Contlol

Knob

2o,coel Fla.p

Control Hrndlo

21.'R€s€Ivol!

Slght Wlndow

22. Enslno

Prlmor

(Opt,

)

23.Emglgoocy Hrhd hmp

24.Fu€l Soloctor Valva Hrndlo

31

. Autopilot Conhor Unit

(Opt.

)

S2,

LanaUnA Gear

Position

Lights

33. Electlical switcheE

34. Palking Brake flanrUe

35.Ctrcult Breakers

10,

knltion/starte!

Sx,itch

3?.

Auxlltary

tuel Pump

Sxritch

38. Mrst6! Switch

Economy Mixtule lndcato!

((ht.

)

25. Ituddor Tltm Control

Wh.sl

39 , Wtng Leveler Control Knob

Figure 8-l.

1-6 2-t

Iection

II

-L

L-

DESCRIPTION

AND

OPERATING

DETAILS

The

following

paragraphs

describe

the systems

ard equipment

n'hose

function

and operauon

is not obvious

when sitting

in the airplane.

This

section

also

covers

in someu,hat

greater

detail some

of

the ltems

listed

in Check

List form

in Section

I that

require

iurther explarEtion.

FUET

SYSTEM.

Fuel

is

supplied

to

the engine

from

two integral

fuel bays,.

o-ne

in each

wiug.

usable

fuel

in each

bay,

for

all flight

conditions,

is

44'5

gallons

when

completely

filled.

The

fuel

capacity

of

thls aircraft

has been

designed

to

provide

the

owner

with

a ctroice

ot long

range capability

with

partial

cabin

loading

or

reduced

range with

fuII cabin

loadlng.

For example,

with

iull cabin

load-

ins.

it norm;Ilv

wilt

be

necessary

to

reduce

the fuel

load

to keep the

air-

".Irit

*itt in approved

weight

and balance

Limits,

Refer

to section

IV

lor

veight

and balance

contxol

procedures'

NOTE

Unusable

fuel

is at a

minimum

due

to the design

of

the

fuel system.

However,

when

the

fuel bays

are

1/4 full

or less,

prolonged uncoordturated

flight such

as slips

or

skids can

uncover

the fuel bay

outlets,

causing

fuel

star-

vation

and engine

stoppage.

Therefore,

v,rith

low

fuel

re-

serves,

do

not allow

the aircraft

to remain

in uncoordinated

flight

for

periods

in excess

of one

minute'

Fuel

from each

wing

fuet bay

flows

through a

reservoir

tank

to the IueI

selector

valve.

Depending

upon

the setting

of

the selector

valve,

{uelfrom

the

left or

righi

fuel bay and

reservoir

tank flows

through

a strainer

and-

-

by-pass

in

th; electric

auxiliary

fuel

pump

(when

it is not

op€rating)

to

the

e-ngine-driven

fuel

pump.

From

here

fuel is distributed

to the engine

cyl-

indera

via

a control

unit and

manifold'

NOTE

Fuel

cannot

be used

irom both

iuel bays

simultaneously.

LEFT FUEL BAY

RIGHT FUEL BAY

CTIECI< VALVE

THRoTTLE

FIINL

SIEAINER

lE!@n

FUEL SUPPLY

@m&Y^gffi#&

Ell

vsrr

EIIGINE

rUEL PUMP

FUEL

CONTROL

UNIT

,'---@ffi

ro

MD'TURE

CONTROL

FUEL SYSTElvl

SCHEMAIIC

FDEL FI'UI

INDICATOB

(Right

Eall ol DurI

In.trum.nt)

rleure

2-2,

2-2

Vapor

and excess

fuel from

the engine-driven

luel

pump

and

fuel control

unit are returned tV

way of

the selector valve

to the

reaervoir tank

of the

wing fuel bay system

being

used

AUXITIARY

FUEI.

PUIAP

SWIICH.

The

right

haI of the

auxiliary

fuel

pump

s,ritch,

Iabeled'll.o,"

,:

used

for starting. with

the switch

position'

and the

ignition-

starter

switch

turned

to

"START,

"

the auxiliary

fuel

pump

will

operate

at a

lovu llow

rate

(providing

proper

fuel mixture

for starting)

as tlre

engine

is being turned

over with

the starter.

NOTE

The

auxiuary

luel

pump

will

not operate

in

the

"LO"

position

until the

ignition switch

is turned to

the

"START'

position.

The

lelt hau of

the switch,

Iabeled

"HI, "

is

used for engine

opera.tion

if

t}te engine-driven

pump

should

fail.

when

the switch

is in this

position'

the

pump

operates

at o.ne oI

two IIow

rates depending

upon the setting

of

the throtUe. WitI

the throttle

at a cruise setting,

the

pump

is operating

at maximum

capacity, supplying

sufficient

fuel flow to

maintain flight.

When

the

throttle

is moved tov,rard

the closed

position

(as

during let-down,

Ianding and

taxiing),

the

auxiUary

fuel

pump

floq, rate is automaucally

reduced,

preventing

an excessively

rich

mixture durtng

theee

periods

of

reduced engine

speed.

The

auxiliary

fuel

pump

is not

to be turned

on

"Itr"

during

normal

operation,

uecause, wilh

ttre engine-driven

pump

Iuncuoning,

a Iuel/air

aatio

considerably

rj.cher

than best

pourer

is

produced.

NOTE

Turn

auxiliary

fuel

pump

switch

on

"HI"

when

switch-

ing

from empty

bay

to bay containing

fuel.

NOTD'

II

the auxitiary

IueI

pump

switch

is. accidentally

turned

on

"I["

(with

master

switch

on) with

the engine

stopped,

the

intake

manilolds

will

be

flooded.

ELECIRTC4!

SYSTEM.

Electrical

energy

is

suppued

by a

14-volt,

direct-current

system

powered

by an engine-ariven

alternator

(see

figure

2-3). The

12-volt

2-3

ELEqTRICAL SYSTEM

SCHE'IIATIC

CONIROT WHEEL

AiIAP

TO NAVIGATION

TIGHIS

TO

Orr DTLU',IION SYSTET

IOPO

TO

HEA'IED PITOT T. SIAII.

waiNrNG

sYsTEMloPtl

IO

FUEI AUANIITY IND.

a cYt. tlAD tEr P. 6A6E

TANDING

GEAT INO tI6HIS

lGNllroN-srAnrtR

swrlcH

IO

SIAI.T WARNING

AND

LANDING

CEAR

WA[NING

TO

TUIN COOTDINAION

,UIN.AND.IANX

INDICATOR

TO INSTRUMENI LIGHIS

E OPI COUI'IESY TIOHTS

lo r AP UGHTS

lOP0

TO

INSITU'IAENT PANET POST

& 3AC( UGHTNG

{OPl

to wrNG

ftAP sYsrE/,^

lo aulru^eY rurr

pu

P

IO TANOING

CEAN DOOR

TO IIASHTNG iEACON

to AlJDro A

PUFTCT (oPr)

TO AUTOMATTC nrot

loPll

Ht,

-R$7^"."n^'o*

COD:

S1

c'*cu'r

e r r^*.r

rorro,rrr.r1

O)

cr.curr BnE^(ER

lPurH,rEsfl,

@

cncur ar:rxtn swrrcx

!

ruse

.l+

Droor

caPAcrToR

4iA,

REsrsror

Figurs 2-3.

2-4

battery

is

located on the upper

left-hand forward

portion

of the firewail.

Power is

supplied

to

all electrical circuits through

a split

bus bar, one

side containing

electronic system circuits

and

the

other side

having

gen-

eral electrical system

circuits. Both sides

of

the

bus are on

at all

times

except when either

an external

power

source

is

comeoted or the

starter

switch

is

turned on; then

a

power

contactor is

autoEatically activated to

open the circuit to the

electronics bus. Isolating the

electronic circuits

in this marurer

prevents

harmful transient

voltages from damaging the

semi-conductors in the

electxonics

equipment,

ANA'VT

ET ER.

The

ammeter

indicates flow

of

current, in'amperes,

from

the alterna-

tor to tlle battery or from the battery

to the aircmJt electrical

system.

When the engine is operating

and

the master

switch is

"ON, "

the

ammeter

indicates the charging rate

applied to the battery. In the

event the alterna-

tor is not functj.oning

or

the

electrica-l

load

exceeds

the output of the

a1-

ternator,

the ammeter indicates

the

discha/ge

rate

od the battery.

CIRCUIT

BREAKERs AND FUsES.

Most

electrical circuits in the airplane are

protected

by

'rpush-to-

reset" circuit breakers

mounted

on

the left

side od

the instrument

panel.

Exceptions to this are the battery contactor closing

(external power)

cir-

cuit which has a fug€

mounted near

the

ground

service

plw

receptacle,

ard

t}Ie clock and optiGal flight hour recorder circuits which have a fuse mount-

ed near the battery;

power

for the optional control wheel map light circuit

is taken from a

circuit

breake! and thesystem has a fuse mounted behind

the left

side of

the instrument

panel.

AIso, the cigar lighter is

protected

by a

manually-reset type circuit brea.ker mounted directly

on

the back

of

the lighter behind ttle instrument

parel

-

Autouatically resetting circuit

-

breakers mounted behind the instrument

panel protect

the stall wa-rning and

landing

gear

warning

horn

circuits, the

turn

coordinator or optional turn-

and-bank

indicator circuit,

ard

the

alternator

field

and vdring circuit. The

optional

electric elevator trim system is

protected

by

a switch

type

circuit

breaker

mounted

on

the control

pedestal

by the

elevator trim wheel.

coNrR.ot wHEEt rvtAP uGHT

(oPT).

A map light may be instatled on the bottom oI ttte

pilot's

control

u,heel. The light illuminates tfie lovrer

portion

oJ the cabin

just

forward of

tlre

pllot

ard

is helplul when checking map€

and

otler flight data during

night

operation.

A small knurled rheostat knob

iust

foryard of tlle lower

face of

the control

wheel

is used to turn on the light arrd adjust its intensity,

2-6

:

FTASHING

BEACON.

The flashing

beacon

should not be used

when

ftying through

clouds

or overcasu

the flashing light reflected from

water droplets or

particles

in the atmosplere,

particularly

at night, can

produce

vertigo

and

loss of

orientation.

TANDING

GEAR SYSTEM.

the retractable

tricycle landiug

gear

ls extended and

retracted by

hydrallic actuators,

powered

by

an

engine-driven hydraulic

pump.

Both

the nose ard main

gears

have

positive

mechanical up and down locks,

operated

by

separate

hydraulic

actuetors. The nose

gear

also

has

a

hydraulic

saJety

Iock

within

its

actuator ard

is

actuated

in

the nose

gear

down

position

only,

TVo

position-indicator

lights show that the

gear

is

either

up or down

and locBed. The lights are the

preas-to-test

type.

The

gear-down

indi-

cato! light

(green)

has two test

positions;

with

the light

pushed

in

hau-way

(throttle

plued

out) the

gear

warning

horn Bhould sound intermittently, and

with the light

pushed

full in, the light should illuminate. The

gear

-up in-

dicato! liEht

(amber)

has onl.y one test

position;

with the tight

pushed

fuU

in, lt should illumiDate,

The indicator lights contain dimming shutters

for night operation.

As an additlonal

leminder that

the

gear

is retracted, a warning

horn

sounds lntermlttently u,henever the throttle

is retarded nith

the

gea!

up.

TANDING GEAR POSITION

HANDTE.

The

gea! position

hardle has

two

neutral

positions (slightly

above

cen-

ter for

gear

up,

ard sughtly below center for

gear-down)

which

give

a

me-

chanical indication

oI the

gear

positlon.

From either

positlon,

tlle

handle

must be

pulled

out to clear a detert before lt can be repositionedl operatlon

of the

gear

and doors $rill not begln unttl the handle

has been repositioned.

To

reposition

the

gear,

th; hardle is

pulled

out and moved to the de-

sired

position,

then

released.

Presgure ls created ln the system by the

engine-driven hydraulic

pump

and the

gear

ls actuated to the selected

po-

siuon.

A detent in the

gear

handle

syst€m holds tlle

handle in the

opera-

Ung

position

until the cycle is coEpleted;

then th€

handle automatically

returns

to

neutral

and

pressure

in the

gystem

ls

r61ieved,

2-6

IMPORTANT

I$e landing

gear position

hardle should be

returned

to neu-

tral nEnually

iJ

a

mallunction

occurs

in the hydrauuc system

.

which

preveds

tlrc

gear position

hardle

lrom returning to

neutral

alter a cycle has been

completed. Continuous op-

eration with

t}te hardle out of neutral

keeps the eystem

pres-

surized

aJd

$rill

evedually

result in

overheating

ard damage.

During a

normal cycle, the

gear

locks up or

down ard t}le

position

indicator tight comes on. When

the light illuminates,

hydraulic

pressure

is switched

from tlle

gear

achrators

to the doof actuators

to close the

gear

doors.

W\en

the doors are

closedi

tlle

gear

handle returns

to neu-

tral and the

cy@e is complete. The

iorrral Ume interval between the

in-

dicator Ughting

and the handle

returning to neutralis 3-9 seconds. II the

position

indicator light does

not light, the

gear

do6is

wiII

not close

ard

A sa.fety switch,

actuated

by the nose

gear

strut'

restricts

the

gear

position

handle to

prevent

iladvertent

retraction

whenever

the nose

gear

strut

is

compressed

by the

weight

oI

t}re airplane.

E'{IERGENCY HAND PU'\AP.

For €mergency

use, U the

hydraulic

pump

fails, the hydraulic

control

unit containa a

marual

pump

which

may be used to extend

the

gear'

The sys-

tem reservoir is arranged

to retain sufficient

fluid to extend

the

gear

u,ith

the

hard

prmp

if a

faiture between the engine-driven

pump

ard

resewolr re-

sults

in fluid tross. See Section

m for emergency

operation of

the hand

pump.

OPERATION

OF TANDING GEAR

DOORS

(AIRPI.ANE

ON GROUND).

For

inspection

purposes,

the

landing

gear

doors may be opened and

closed while

the airplane

is on the

ground

with

the engine stopped. Oper

-

ate

t}Ie doors with the

landing

gear

handle in the

"down-neutral"

position.

To open the

doors, turn off

the master switch and operate

the hand

pump

until the

doors open. To close

the doors,

turn the master switch on and

operate

the hand

pump,

NOTE

The

position

of the master switch

lor

gear

door oper-

ation is easily

remembered

by the Iollowing

rule:

OPEN circuit

=

OPEN doors

CLOSED

circuit

=

CLOSED

doors

2-1

CABIN

HEATING,VENTITATING

AND DEFROSIING SYSTEM.

The temperature

and

volume

of airflow into the cabin can be regulated

to

any degree desired by

manipulation of the

push-pull

"CABIN

HEAT" arld

,CABIN

AIR!

knobs. When

partial

cabin heat is desired, blending warm

and

cold air wilf result in improved ventilation and heat distribution

through-

out the cabin. Additional outside

air for summdr ventilation is

provlded

through the heat and vent syatem by

operation of

the

push-puu

'TALIX

CABIN

AIRI knob.

The

rotary type

"DEFROST'i

knob regulates the air-

flow for windshield defrosting.

(

Front cabin heat and ventilating

air

is supplied by outlet holes spaced

across

a cabin manilold

just

lorward of the

pilotrs

and copilotrs feet.

Rear cabin heat and air is supplied by two ducts from the manifold,

one

extending

down each

side oI

the

cabin

to

an outlet at

the front

door

post

at

floor level. Windshield defrost air is also supplied by a duct leading lrom

the cabin

manifold.

Separate adjustable ventilators supply additional air;

two mounted side

by

side in the top

of the cabin

ceiling

just

aft of

the windshield supply air to

the

pilot

and copilot,

ajld

one above each

rear

doorpost

in

the

rear cabin

ceiling supplies

air

to the rear seat

passengers.

STARTING ENGINE.

Prope!

fuel maragement

and throttle adjustments are

the determining

factors in seculing

ar

easy start from

your

continuous-flow fuel-injection

engine. The

procedure

outlined

in Section I should be followed closely

as

it is effective under

nearly all operating conditions,

including hot

and cold

weather conditions. Slight variations from this

procedure

may be neces-

sary

at

times to compensate for extreme

conditions.

Conveltioral full

rich

mixture and

high RPM

propeller

settings

are

used for starting; the throttle,

however,

should

be fuUy

closed

initially.

When ready to start,

depress

the right half of the auxiliary fuel

pump

switch to

rLO[

and turn

the

ignition-Btarter Bwitch to

"START"

position.

At

the same time t}le starter engages and turns the engine, the auxiliary

fuel

pump

will operate

at a low

flow

rate,

supplying

fuel lor starting.

Whlle crarking, slowly

advance

the

throttle untll

the engine starts.

Slow

throttle advancement is essentia.l slnce the englne wlll start

readily

when

tlle correct

fuel/air ratio is obta{ned.

On ttle other

hand, fast throttle

movement may

prevent

starting slnce an exie8sively rlch mixture wiII be

2-8

TAXIING

DIAGRAM

CODE

NOTE

Strong

quartering

tail wlnds require cauuon,

Avoid sudden

bursts ol the throttle and sharp

braking when

the airplane is in this attitude.

Use

the steerable

noae wheel and rudder

to

malntaln direction.

wrND

DTRECTTON

)

Figure 2-4.

2-g

obtained due to

greater

luel flow

metered by the throttle

position.'

Ir this

case,

anotlrer Etartlng attempt must be made. When the engine

haa

started,

reset tlle tlrottle to tlte desired idle speed and turn the fuel

pump

switch off.

Engine

starting in hot weather or with a hot

engine

1s

sometimea ham-

pered

bv vapor formation in tlle fuel llnes. To

purge

the

vapor,

move

the

mixture control to full rich, open tfre throttle 1 1/2 inches, and

prime'ivith

the auxiliary fuel

prmp

switch in tfre

"HI"

tr)osition

until the luel flow indi-

cator reeds

4 - 6

gal/hr.

Then shut off the fuel

punp

switch and engage

tlle starter.

As the

flooded mixture

becomes

progreasively

leaner, reach-

ing'a comhrstible mixture, the engine

wlll start. If

ttle engine tend6 to die,

turn trle

auxiliary

fuel

pump

switch momentarily

te

"111"

at appropriate

intervals until the

vapor is fully cleared and the engine runs smoothly.

If

prolonged

cranking is necessary, allorr tJle

starter

motor

to

cool at

frequent intervals,

since excessive heat may damage the armature.

IAXIING.

Taxiing over loose

gravel

or cinders should be done at low engi[e

speed to avoid abrasion and stone damage to the

propeller

tips. Refea

to figure

2-4

for

additional

taxiing tips.

BEFORE TAKE-OFF.

Since

ttre engine is closely cowled for efficient

in:flight cooling,

pre-

cautions should be talen to avoid overheating on

the

ground,

FulI throttle

checks on the

ground

are not

recommended unless the

pilot

has

good

reason to suspect that the engine

is

not turning

up

properly.

The

magneto check should

be made at

1700

RPM with

the

propeller

in

flat

pitch

as follon's: Move t}le ignition

gwitch

flr

position

and

note RPM.

Then move switch back to

I'BOTII'

position

to clear the other

set

of

plugs.

Then move switch to

"L"

posltlon

and

note RPM. The

difference

betvreen tlrc two magnetos operEted stngly

should not be

more

thar 50 RPM. U there

is a doubt concsrnlng the operatlon

of the ignition

system, RPM checks at a

highel

etl8ln€ Epeed n'lu

usually

confirm whether

a deficiency exists.

2-to

An absence

oI RPM drop

rnay be an indication of faulty

grounding

of

one side

of the ignition system

or should be cause for suspicion that the

magneto

timing is set

in advance cf the setting speciJied.

It

is important to check

tuIl-throttle engine operation

early in.the

tale-off run. Any signs

of rough engine operation

or sluggish engine

ac-

celeration is

good

cause for

discontinuing the take-off.

FUll tlrottle

runups over loose

gravel

are especially

harrnful to

propeller

tips, When

take-oIfs mustle

made over

a

gravel

surface,

it

is very important

that

the throttle be

a-dvaaced slowly. This allows

the

airplane to start

rolling

before high RPM is

developed, and tlle

gravel

will ba blown

back of the

propeller

rather ttlan

puUed

into lt.

For maximum engine

power,

t}le

dixture should be adjusted durhg

the

initial take-ofI

roll to the fuel llow corresponding

to the field eleva-

tion.

(Refer

to Maximum Pexformance

Take-Off and Climb

Settirgs

placard

located adjacent

to fuel flow

indicator.

)

The

power

increase is

significant above 3000

feet and this

procedure

always should be em-

ployed

for field elevations

greater

than 5000 feet abdve sea level.

Using

20' flaps reduces the

ground

run and

total distarce oYer the ob-

stacle by approximately

10

per

cent. solt lield take-offs are

performed

witl

20'

flaps

by tilting the nose u'heel

oIf the

ground

as

soon as

practical

and

leaving the

ground

in a sUghtly

tail-Iow attitude.

However, the air-

plane

should be

leveled ofI immediately

to accelerate

to

a safe

climb speed.

Ta}e-oiIs

into strong

crosswinds normally

are

performed

witl

the

minimum

flap

setting

necessary for the

field leugth, to minimize the

drift angle

immediately after tal<e-off. The airplane

is

accelerated

to

a speed slightly

higher than lormal,

tlrcn

pulled

off

abruptly to

prevert

possible

settling

back to the

runway

while

drifting.

When

clear of

the

ground.

make a coordinated turn

into

the wind

to correct for drift.

Landing

gear

retraction normally

is

started aJter

reaching

the

point

over

the runway where a wheels-down,

forg€d landing

on that

mnway

would

become

impractical.

Since the

Ianding

gear

swings

downward

approximately

two feet as

it

starts the

retraction cycle,

damage

can

result by retracting it before obtaining at least tiat much

ground

clear-

ance.

In addition, tlle

landing

gear

would extend slowly ln tfie event of

2-LL

an engi-ne

failure

during

tale-off,

and

mlght not

be completely

down

vh[e

a

rheela-down

Iarding

could

sUU be

made

on the runwa].

Before_ retracting

the landing

gear,

the brahes

should

be appued

mom€ntarily

to

stop

wheel rotaUon.

iertrifugal

force

caused

Ly

ttre

rapidly-splnnin_g

wheel srpands

ure

diameter

o1 ure tire.

If there

is

an

accumulation

of

mud

or lce in

the

wheel-uel1s,

the rotating

wheel may

rub

as it is retracted

irto

ttle

wheel well.

?

cun

B.

A

cluising

cumb

at 24 inches

oI manifold pressure,

2bOO

RpM

(ap-

proximately

75$

power)

and 120

to 140

MpH

is recommended

to save

time

and

fuel

for

the

overall

trip.

In addiHon,

this type

of cllmt

provides

bet_

ter

engin€

cooling,

less

engine

wear,

and more-fassenger

cimiort

<tue

to

lower

noise

level.

-

Qrutsing

climbs

should

be

conducted

at approximately

16.8

cpu

up to

6500 feet

and

at

1

GpH

more thar

ttre

normat

tiran tuei

fi&

strJwn

on

trre

Cessna

Power

Computer

at higher

altitudes

and

lower

powei

-'

-

_

If it

ls

neceasary

to

climb rapidiy

to clear

mountains

or

reach

favor_

able winds

at

hlgh

altitudes,

the

best rate-of-climb

speed

shouid

be used

\vrm ma{imum power.

This speed

is l0g

MpH

at sea

level,

decreasilg

approximately

4

MPH

for

each

b000 feet

above

eea level.

ihe mixture

should

be

leaned

as

shown

W

the

Maximum

performance

Take_Off

and

Climb Settings placard

located

adacent

to the

fuel flow

irdicator.

.

II. an

obstructiqr

ahead

requires

a

steep

climb angle,

the

airplane

ehould be_tlown

at the

best angle

of cUmb witi

ltaps up

and maximum

power.

This

speed

is

80 MpH

at sea level,

increisilg

l/2 :ItrPIH

tor

each 1000

feet

above

sea leyel.

-

11

a bakeq

Landing

(go-around)

climb,

the

wing

ftap

setting

shoutd

be redrced

to

20' immediately

alter

full

power

is appliira.

Aft-er

a[

obstacles are

cleared

and

a safe

altitude

and

airspeed

are

obtained,

the

uring flape

shoutd

be retracted.

CRUISE.

Normal

cruising

is done between

6$%and ?E%power.

The

power

aet-

2-12

il

,,1

OPTIMUM CRUISE PERFORMANCE

%

BHP

GAT/HR

ATTITUDE

IRUE

AIRSPEEO

RANGC

89OAI.FUE!

15

?0

65

15. ?

14.6

13.

6

6500

8000

10, 000

191

189

18?

1090

1155

Lzt5

.

Figure 2-

5r.

tings

required

to obtain these

powers

at varioua altitudes and

outside air

temperatures can be determined

by usirg

your

Cessna Power

Computer or

the OPERATIONAL DATA,

Section

YI.

The

Optimum

Cruise Performance

table

(figure

2-5)

shows that cruls-

ing can be done most

efficienUy at higber altitudes

because very nearly the

same cruising

speed

can

be maintained at much

less

power.

For

greater

cruising range

at a

given

throttle settlng,

select the low-

est eugine RPM

in tJre

green

arc range tIEt wiU

give

smooth

engine oper-

ation.

Cowl

flaps

should

be

adjusted

to malntain

the cylinder head

tempera-

ture at approximately

two-thirds

of

the

normal operating

(green

arc)

rarge

to

assure

prolonged

engine life.

The

fuel

iniection

system employed on tllis engine la

considered to be

non-icing. In the event that unugual conditions

cause the intake

air filter

to become clogged or

iced

over,

an alternate intake air

valve opens

auto-

matically for the

l!1o6t

efficient use of eitller normal

or,alternate

air, de-

penditrg

on the amount of lilter blockage. Due

to the lower intake

presaure

available through the alternate air valve

or a

partially

blocked

fllter, fult

throttle manilold

paessure

can decreaae

approxlmately 1,5 in.

Hg.

STArrS.

The stall

characterieucs

are conventional

and aural

warning is

pro-

2-13

vided by

a stall

warning

horn

nhich aounds between

5 and

10

MPH above

the stall in aU conJigurations.

Power.pff

sta.ll

speeds at maximum

gross

weight and aIt c.

g. position

are

presented

on

page

6-2 as calibrated

airspeeds since indicated airspeeds

are unreliable

near the

stau.

sPlNS.

Intentional

spins

are

prohibited

in ttris

airplane. Should an lnadvertent

spiu occur,

standard light

plane

recovery

technique8

should

be used,

BEFORE tANDING.

In

view

of the relatively

lov drag of the extended landing

gear

and

the

high allowable

gear-down

speed

(160

MPH), the landing

gear

should be

ex-

tended

before entering the traffic

pattern.

This

practice

will

allow

more

time to

confirm that the

landing

gear

is

dou,n and locked. As a further

precaution,

leave the landing

gear

extended

in

go-around

procedures

or

traffic

patterns

for touch-and-go

landing.

Landing

gear

extension can be detected by

illumination of the

gea.r

down indicator light

(green),

absence ol a

gear

warnlng

horn vith tlle

throttle retarded below 12

inches of manifold

pressure,

and visual in-

spection of the main

gear

position.

Should ttle

gear

indicator light fail

to illuminate, the light

should be checked

for a burned-out bulb by

push-

ing to test.,J*A

burned-out bulb

can

be replaced

in flight with the

bulb from

the compad$tlight

or the landing

gear

up

(amber)

irdicator light,

''

i

,,,

'-r{,

tANDINGS.

Landings

are usually made

on the main

wheels

first to reduce

the

landing

speed and subsequent need for

brahing in the landing roll.

Tlle

,r

nose

wheel

is lotrrered

to the runway

after the speed has dimini.shed to

avoid unnecessary

nose

gear

load.

This

procedure

is especially im-

portant

in rough field

landings.

,

For short lield

landings, make

a

power

-off

approach

at ?8 MPH with

2-14

30" flaps and land

on

main

wheels

fhst. Immediately

after touchdonn,

Iover

the nose

gear

and

apply heavy braking as

required. For thaximum

brake effectiveless

after all

three wheels are

on the

ground,

retract the

Ilaps, hold

full nose up elevator

and apply

majdmum

possible

bE:ake

pres-

sure without

sliding

the tires.

At light

operating

weights,

during

ground

roU

with

full flaps, hold the

control vrheel

full back

to in€ure maximum weight on

the main

wheele

for

bra.king. Under

these conditions,

fuIl nose down elevator

(control

wheel

full forwaid)

will

ralse tfie

main

wheels off ttre

ground.

^V

COLD

WEAIHER

OPERAIION

The

use

of

an external

pre-heater

and an etdernal

power

source

is

recommended whenever

possible

to

reduce wear ard

abuse to

the engine

and the

electrical system.

If external

preheat

is not available'

tfre oil

should

be diluted before

stopping

the engine when

very

cold temperaturea

are anticipated.

Pre-heat wiU

thaw

the oil

tmpped

in the oil cooler, which

probably

will

be

congealed

prior

to

starting

ln ortremely

cold temperatures.

When

using ar

exterual

power

source,

the

positiol

of the

master switch ls im-

portant.

Refer

to Section

VII,

palagraph

GROUND SERVICE

PLUG RE-

CEPTACLE,

for operaung

details.

In very cold

y/eather,

no oil temperature

indication

need be apparent

belore take-off.

After a suitable

warm-up

period

(2

to 5 minutes

at 1000

RPM),

the engine

is ready for take-off

iJ it accelerates

smoothly and

the

oil

pressure

is normal and steady.

During

let-down, obsenre

engine temperatures

closely and carry sul-

ficient

power

to

maintaiu them

in the recommended

operating

range.

Refer

to

Section

VII

for discussion

of additional

col&{ eather equipment.

2-13

flection III

L

L--

EMERGENCY

PROCEDURES

SYSIEM

EMERGENCY

PROCEDURES.

I.ANDING GEAR-E'VIERGENCY

OPERATION..

When

the

landing

gear

v/tll not extend

nolmally, it may

be

extended

manually

as

follows:

NOTE

Prior to

following emergency

procedures,

it is

recom-

mended that

the landing

gear

handle be moved from

"UP"

to

"DOWN'

several times. In

certain cases, this

pro-

cedure

can dislodge

foreign matter

which

may

be caus-

ing the

malfuncHon.

(1)

Place

the

gear

handle in the

position.

(2)

PuU the emergency

hand

pump

out to

its full extension.

(3)

Operate

the

harrd

pump

up and

dov{n until the down indicator

(green)

light comea on,

and continue

pumping

until the landing

gear

handle returns to

neutral.

NOTE

Retraction of the

landing

gEar

rnanually will require use

of

the

emergency

hand

pump,

therefore, il the

gear

will

not retract normally, extend

the

gear,

land, and have

the malfunction corrected.

LANDING

EMERGENCIES

(Except

Ditchins).

FORCED LANDING

(Precoutionory

Londing

wirh Power).

(1)

Drag

over selected

field with flaps 20'

and

90

MPH airspeed,

nottng type of

terrain ard obsttuction.

(2)

Jf

surface

is smooth and hard

(pasture,

Irozen lake, etc.

),

plar

8-1

.

a

urheels-down

landing using full flaps

and keeping nose

r[heel

oIf

grourd

aa

long as practical.

(3)

U surface is rough or soft,

plan

a u,heels-up landing as follows:

a. Approach with flaps dosn at 80

to

90 MPH.

b. Turn off all switches except

ignttion

switch.

c. Unlatch c2bin

doors

prior

to

flare-out.

d.

Redrce

pover

to a minimum during flare-out.

e. Prior to contact, turn ignition

switch

"OFF, "

I.

Lard

in

a slightly

tail-low

i.ttitude.

g.

Attempt to

hold

the tail

low throughout slide.

FORCED LANDING

(Engine

Our).

Iu the event of a complete

engine

failure, maximum

gliding

distance'

can

be obtained by maintaining 90 MPH

(at

3400

pounds gross

weight) with

the landing

gear

and wing

flaps retlacted.

Refer to Maximum

Glide,

fig-

ure 3-1,

for maximum

glide

alata and speed

variation with welght.

(1)

PuU mixture control knob to idle cut-off.

(2)

Turn

fuel

selector valve handle to

"BOTH

OFF.

"

(3)

Turn off

all s$dtches except master switch.

(4)

Approach

at

90 to 100

MPfl.

(5)

ff Iield is

smooth and hard, extend landing

gear

within

gliding

distarce of field.

(6)

If electrical

pouier

is

available, extend flaps as necessary within

gliding

distance of field.

(7)

Turn olf master switch.

(8)

Make a normal

landing, keeping nose wheel oft

ground

as long as

practical.

(9)

ff terraln is rough or

soft,

plan

a wheels-up landing as follows:

a. Approach

at

90 to 100 MPH

with

gear

and flaps

retracted.

b. If

practical,

extend flaps within

gliding

distance of field.

T\rrn off master

switch.

Unlatch cabin doors

prior

to flare-out.

Land in

a slightly

tail-lou,

attitude,

Attempt to

hold tail low throughout s1ide.

IANDING WITHOUT

POSITIVE INDICATION

OF GEAR

I.OCKING.

Should a

flickering, unsteady,

or

inoperative

gear-do\r,n

(green)

light

be

obtained, and observers verffi, tlat tlre

gear

is down

and

apparently in

tlle locked

position, proceed

as

follows:

3-2

c.

d.

e.

f.

F

z

4

I

o

o

I

I

I

ro 15 20 25 30

GROUND DTSTANCE

(SrArUrE

irlrEs)

Figure

3-1.

(1)

Make

a normal full-Ilaps approach.

(2)

Hotding

the landing

gear

handle in the

"DOWN'

position

and

maintainirg

a minimum of

1000

RPM,

complete the

laudiug and taxi

clear of.the

runway.

NOTE

Maintaining

1000

RPM ard

holding the

gear

handle

TTDOWN''

3-3

secureB the-Ianding

gear

in the extended

position

by hydrau-

lic

pressure.

(3)

BErORE

reducing engine RPM or releaslng

gear

handle, have

ground

personnel

depress the tail until nose

gear

is

ofl

ground.

The nose

gear

requires hydraulic

pressure

to

hold it in

the

'TDOWN'

position

if it is not mechanically

locked.

(4)

Stop

tie engine and determine that the nose

gear

is mechanically

locked

down BEFORE lowering the nose wheel to tfle

ground.

TANDING WIIH DEFECTIVE

NOSE

OEAR.

U the

nose

gear

does not extend or only

partiauy

extends, and observers

verify

that

it is not down,

prepare

for

a wheels-down

landing as follows:

(1)

Transfer

movable load to baggage area, and

front

seat

Euisenger

to

rear seat if a rear seat

position

is unoccupied.

(2)

Select

a hard-surfaced or smooth

sod run$ay.

NOTE

Il terrain is rough or soft,

plan

a wheels-up

landiag as

presented

under

"FORCED

LANDING

(Precautionary

Landing with Power)"

in lieu

of

the Iollowing steps.

Place landing

lear

hardle

iDOWN.

'

Extend flaps to

30'.

Turn off master switch.

Land in a slightiy tail-low attitude.

Pull

mixture control knob to

idle cut-off.

T\rrn igniuon switch

"OFF. "

Hold nose off the

ground

as

long

as

1rcssible.

I\rrr fuel selector valve

handle to

"BOTII

OFF.

"

Evacuate

t}Ie airplane as eoon as

it

stops.

(3)

(4)

(5)

(6)

(?)

(8)

(e)

(10)

(11)

3-4

4-t

r-

-L

Iettion Il

L=

OPERATING LIMITATIONS

OPERATI ONS AUTHORIZED.

Your Cessna exceeds the requirements fer

airworthindss

as

set forth

by the

United States covernment,

and

is certilicated

under FAA Type

Cer-

tificate No. 3A21.

With stardard

equipment, the airplane is

approved

for

day and night

opelation under

VFR. Additional optional

equipment

is

available to in-

crease its utility

and

to make

it authorized for use under

IFR day and

night. An owner

of a

properly

equipped

Cessna is eligible to obtain

ap-

proval

for its

operation on single-elgine

scheduled airline service

under

VFR. Your Cessna Dealer will

be happy

to

assist

you

in selecting

equip-

ment

best suited to

your

needs.

MANEUVERS

_,

NORMAT CAIEGORY.

The

airplane

is

certificated in tlle normal

category. The normal

category is

applicable to airplanes intended for non-aerobatic

operations.

These

include

any maneuvers incidental to normal

flying, staUs

(except

whip staus) and turns in which the angle

of bank is not more tlran

60". In

connection with the foregoing, the following

gross

weight

and

flight

load

.factors apply:

Gross Weight

.

3400

lbs

Flight Load

Factor

*Ftraps

Up +3.8

-7,52

Flight Load

Factor

*Flaps

Down

. . r3.0

*The

deBign load factors

are

150%

of the above,

and in

all

cases, the

structure meets or exceeds

design loads.

Your airplane

must

be opeaated in

accordance with a1l

FAA-approved

markings,

placards

and check lists in the

airplane. If there is

aIur tufor-

rnation in

this section which

contradicts the FAA-approved markings,

placards

and check lists, it is to

be disregarded.

AIRSPEED I.lMITATIONS.

The

following are the certificated

calibrated

airspeed limits for

your

Cessna;

Never

Exceed

(Glide

or dive, smooth air) , .

225

MPH

(red

line)

Caution

Range

.

190-225

MPH

(yellow

arc)

Maximum Structural Cruising

Speed

190 MPII

(Level

flight

or climb)

.

Normal

Operating

Range

.

?4-190 MPH

(green

arc)

Maximum Speed, Gear

Extended

160

MPH

Maximum Speed,

Flaps Extended

Flaps

10'

160 MPH

Ihps

10'

-30'

110 MPH

FIap Operating

Range ,

.

63-110 MPH

(white

arc)

Maneuvering Speed+ .

135 MPH

tThe

maximum speed at which abrupt

control

travel

can.be

used

without

exceeding

the design load

factor.

ENGINE

OPERATION

TIMITAIIONS

Empty

(0.

5

gallon

unusable each

fuel bay)

2200- 2500

RPM

(green

arc)

2700

RPM

(red

Une)

E

(red

line)

7. 0-17.0

gal/hr

(green

arc)

3. 5

and 18. 5

psi

(24.

2

gal/hr)(red

lines)

NOTE

IACHOIVIETER

Normal

Operating Range , .

Maximum

(Eugine

rated speed).

FUEI.

QUAN'ITY

INDICATORS

FUEI FIOW INDICATOR

Normal Operating

Range.

Minimum

and Maximuql .

A

placard,

located adjacent to the iuel llow indicator,

provides

maximum

performance

(full

tirottle aJId

2?00 RPM) take-off and climb fuel flow settings at

altitude.

These settings, as called out on

t}le

placard,

are as follorrs:

Sea Level

4000

Feet

8000 Feet

22

gal/hr

20

gal/ht

18

gallhr

Power and Speed .

.285

ENGINE

INSIRUMENT

MARKINGS.

OIt

TEIVIPERATURE GAGE

Normal

Operating Range

Do

Not Exceed

OIt PRISSURE GAGE

Idling Pressure

Normal Operating

Range

Iuaximum Preasure

ITIANITOTO

PRESSURE GAGE

Normal Operating

Range

BHP

at

2?OO

RPM

'

. ,

Green

Arc

240' F

(red

line)

,

.

10

psi (red

line

30-60

psi

(green

arc

100

psi

(red

line

15-24.5 in.

IIg

(green

arc)

WEIGHT AND BAIANCE.

The following inlormation

v/ill

enable

you

to operate

your

Cessna

within

the

prescribed

lieight

aJId center of

gravity

limitations. To fieirre

t}le

weight

and balance for

your particular

airplane, use the

Sample

Problem, Loading Gmph,

adrd

Center oI Grayity

Moment

Envelope,

as

foll.ows:

\

Take the

licensed

Empty

Weight

ard Moment/1000 lrom tlle

Weight

and Balance Data sheet,

plus

any changes noted

on

forms

FAA-337

carried

in

your

airplane, and

write

them down in the

proper

colurnDa.

Using

the Loading

Graph,

determine

the moment/1000 of each item to

be carded.

Total

the

weights and

moments,/1000

and use the Center

of Gravity Moment

Envelope

to determine

whether the

point

faUs

with-

in the envelope,

and

iI the loading is

acceptable.

CYTINDER

HEAD TE'IAPERATURE

GAGE

Normal Operating nange

.,

2OO-460'F

(green

arc)

DoNotExieed. . .

. .

'

460'F(redllne)

4-2

l-3

v,

tsl

o

z

A

z

I

I

o

z

E]

o

^e

j

N

BAGGAGE TIE-DOWN

Two

adjustable tie-down

straps

are

provided

to secrre

baggage in the

baggage

area. The straps

are Iitted

with a hook

on each end

and

have a

buckle

for strap length adjustment.

The straps fasten

into lour

tie-down

Iings in

the baggage area,

two at the flont

edge of ihe

baggage area

floor

and t$/o at the

rear.

44

lrb!.

)

/

!0001

(1b3.)

(lb.,iir.

/r0001

L Li<..r6d Enpiy

Weight

lSqnpl.

Ai.pl6nal

--

2. Oil -

r2

0r!.

3.

Pilor

&

Fr..l Po.!.ns6r

----------

a. F!.1

-

lPo.tiol

Cop. -

64 Gol. ot 6SlGol.l--

llorol

Cop.

-

89 Gol. oi 6rlcol.l

5.

n.o, Po!r.ns.r3 -

lstd.S.otinsri

6. Reor Po33€ns.B

.

lOpr.S.otins)i------

7.

Child'i

S€ot Po$.ns.r3

lOr

gd99os.

___

in Soh6 A160l

-

(trd. seorins)l

B. B.seos.

{Afi

.l Ct'ild! s.otl-{Srd.

tedins)I

----

9. Boss oe.

{Opl.

Seolins)t----------

2071

78 t

71

-

0.,1 22

-0.4

3a0 12.2

384

340

23.4

1!0 I

3.2

t03 11.7

10. Iotol

AirGroh

woiqht

lLood.d)

3,100 156.2

ililil

ll.

!o.ot.

rhi3

poirt

l34OO

oi

156.2) o.

th6 ..nt.r ol

srovirv

.nv6loPe, ond 3in.a

thi!

point

folli rithin ih€

€nv6lop. th. loodi.s

i! o..6Ptobl.

I

No..otty,

lull oil moy bo.q3ium.d

,or oll llighrs.

**

tto,i.u^

ollowobl. lood is 1,rc lb5.

Ior.och,.ot.

ll torol or.o i3 u3.d lor

booEoqc, morinun ollo*ob16

lood i! 280

lbs. Ule teol belrs

to secura bossose.

Morimum

ollowoblc lood ir

120 lb3. Conbi.€d

lood ii child 3 seo, ond boggose

or.o

musl .ot o,...d

280 lb,. lorol.

Morim{m ollowoblc bogsoee

ir 280 lb!.

lslondord

s€.tins <on.isrs ol loot

Iull-5ize

seots ond rvo

.hild sedls:

Opri6ndl seori.s it four-plo..

veroion

wilh.or

(hild

seor

p.ovisionr.

o

o

SqNIIOd

-

JIDIS,II

CVO'T

4-5

n

z

5

R

I

ET

r,I

B

E.

o

A

r'I

o

o

,l

L

fertion /

I:

L_-

.

CARE OF

THE AIRPLANE

U

your

airplane

is to retain that new-plane

performance

and

dependa-

bility, certain inspection and

maintenance requirements

must

be

followed.

It is wise to follow a

planned

schedule

of lubrication ard

preventative

main-

tenance based on

climatic

aJd

flying conditions encormtered

in

your

locality.

Keep

iu

touch vrith

your

Cessna Dealer, and tale advantage

of his know-

ledge aJId experience, He

knov'rs

your

airplane

and how to maintain

it.

He

will

remind

you

when

lubrications

ard oil

changes are necessary, and about

other seasonal

and

periodic

seryices.

s0 60 ?o 80 90

1oo 110'

120 130

140

150

160

1OADED

AIRCRAFT

MOMENT,/IOOO

-

POUND.INCHES

oRoutto

HANDUNG.

The airplane

is most easily and sa.fely

maneuvered during

ground

handling by ttle tow bar attached to the nosewheel.

NOTE

When

using the tow bar, do not exceed the nosevrheel

turning angle of

30o either side of center.

MOORING YOUR AIRPIANE.

Proper

tie-down

procedure

is

your

best

precaution

against

damage to

your

parked

airplane

by

gusty

or strong wind6, To tie

dou,n

your

airplane

securely,

proceed

as follows:

(1)

Set the

parking

brake and instatl

the

control vrheel lock.

(2)

Install

a surface control lock over the fiu and

rudder.

(3)

Tie suJiiciently strong

ropes or chains

(700

pounds

tensile

strength)

to the

wing

and tail tie-down fittings and nose

gear

torque

Itnk, and

secure each rope to a ramp tie-dov/n,

(4)

Install

a

pitot

tube cover.

4-6

5-1

i

{

wlNDsHlEtD-wlNDows.

The

plastic

$.indshield

and Y,rindows

should be

cleaned with an

aircraft

vrindshield

cleaner.

Apply the cleaner

sparingly

with soft cloths,

and

rub

vith moderate

pressure

until all dirt,

oil scum and

bug stains

are

re-

moved.

Allow

the cleaner

to

dry,

then wipe

it off with soft

flannel

cloths.

If

a windshield

cleaner

is not available,

the

plastic

can be cleaned

with

soft cloths moistened with Stoddard

solvent

to remove

oil ind

grease.

NOTE

rygllgl_glg

gasoline,

benzine, alcohol,

acetone,

carbon

tetiachloride,

fire extinguisher

or arti-ice

flui4 lacquer

thirmer

or

glass

cleaner

to clean

the

plastic'

These

ma-

terials will

attack the

plastic

and

may cause

it to craze.

Follov

by carefully washing

with a