Page is loading ...

SALON™ SPA

AIR BATH AND WHIRLPOOL

INSTALLATION AND OPERATING INSTRUCTIONS

©2006 Jacuzzi Whirlpool Bath EL21000B 10/06

Installer: Leave this manual for homeowner.

Homeowner: Read this manual and keep for future reference.

Owner's Record

Save These Instructions for Future Use.

Complete and mail-in the product registration card provided with your unit.

Write and save the model and serial number of your unit below.

Date Purchased ____________________________________________________________

Purchased From ____________________________________________________________

Installed By ________________________________________________________________

Serial Number ______________________________________________________________

Model _____________________________________________________________________

ENGLISH

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

INSTRUCTIONS PERTAINING TO A RISK OF FIRE, ELECTRIC

SHOCK, OR INJURY TO PERSONS

WARNING — WHEN USING THIS UNIT, BASIC PRECAUTIONS SHOULD ALWAYS BE FOLLOWED,

INCLUDING THE FOLLOWING:

DANGER: — TO REDUCE THE RISK OF INJURY, DO NOT PERMIT CHILDREN TO USE THIS UNIT

UNLESS THEY ARE CLOSELY SUPERVISED AT ALL TIMES.

WARNING — USE THIS UNIT ONLY FOR ITS INTENDED USE AS DESCRIBED IN THIS MANUAL. DO

NOT USE ATTACHMENTS NOT RECOMMENDED BY THE MANUFACTURER.

WARNING — NEVER DROP OR INSERT ANY OBJECT INTO ANY OPENING.

WARNING — DO NOT OPERATE THIS UNIT WITHOUT THE GUARD OVER THE INTAKE FOR THE

CIRCULATION PUMP (SUCTION COVER/STRAINER).

WARNING — THIS UNIT MUST BE CONNECTED ONLY TO A SUPPLY CIRCUIT THAT IS PROTECTED

BY A GROUND FAULT CIRCUIT INTERRUPTER (GFCI). SUCH A GFCI SHOULD BE PROVIDED BY THE

INSTALLER AND SHOULD BE TESTED ON A ROUTINE BASIS. TO TEST THE GFCI, PUSH THE TEST

BUTTON. THE GFCI SHOULD INTERRUPT POWER. PUSH THE RESET BUTTON. POWER SHOULD

BE RESTORED. IF THE GFCI FAILS TO OPERATE IN THIS MANNER, THE GFCI IS DEFECTIVE. IF

THE GFCI INTERRUPTS POWER TO THE BATHTUB WITHOUT THE TEST BUTTON BEING PUSHED,

A GROUND CURRENT FLOWING, INDICATING A POSSIBILITY OF AN ELECTRIC SHOCK. DO NOT

USE THIS HYDROMASSAGE BATHTUB. DISCONNECT THE HYDROMASSAGE BATHTUB AND HAVE

THE PROBLEM CORRECTED BY A QUALIFIED SERVICE REPRESENTATIVE BEFORE USING.

WARNING — (FOR PERMANENTLY CONNECTED UNITS) A GREEN COLORED TERMINAL (OR A

WIRE CONNECTOR MARKED “G”, “GR”, “GROUND”, OR “GROUNDING”) IS PROVIDED WITHIN

THE TERMINAL COMPARTMENT. TO REDUCE THE RISK OF ELECTRIC SHOCK, CONNECT THE

TERMINAL OR CONNECTOR TO THE GROUNDING TERMINAL OF YOUR ELECTRIC SERVICE

OR SUPPLY PANEL WITH A CONDUCTOR EQUIVALENT IN SIZE TO THE CIRCUIT CONDUCTORS

SUPPLYING THIS EQUIPMENT.

OPERATING

WARNING — PROLONGED IMMERSION IN HOT WATER MAY INDUCE HYPERTHERMIA. HYPER-

THERMIA OCCURS WHEN THE INTERNAL TEMPERATURE OF THE BODY REACHES A LEVEL

SEVERAL DEGREES ABOVE THE NORMAL BODY TEMPERATURE OF 98.6°F. THE SYMPTOMS OF

HYPERTHERMIA INCLUDE AN INCREASE IN THE INTERNAL TEMPERATURE OF THE BODY, DIZZI-

NESS, LETHARGY, DROWSINESS AND FAINTING. THE EFFECTS OF HYPERTHERMIA INCLUDE:

A) FAILURE TO PERCEIVE HEAT

B) FAILURE TO RECOGNIZE THE NEED TO EXIT THE SPA OR HOT TUB,

C) UNAWARENESS OF IMPENDING HAZARD,

D) FETAL DAMAGE IN PREGNANT WOMEN,

E) PHYSICAL INABILITY TO EXIT THE SPA OR HOT TUB, AND

F) UNCONSCIOUSNESS RESULTING IN DANGER OF DROWNING.

WARNING — THE USE OF ALCOHOL, DRUGS OR MEDICATION CAN GREATLY INCREASE THE

RISK OF FATAL HYPERTHERMIA.

WARNING — DO NOT TAMPER WITH USER-OPERATED CONTROLS OR SUCH DEVICES.

2

Jacuzzi Whirlpool Bath EL21000B 10/06

ENGLISH

PRODUCT SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

USE INSTALLATION INSTRUCTIONS SUPPLIED WITH PRODUCT.

The Company has obtained applicable code (standards) listings generally available on a national basis for products of this type.

It is the responsibility of the installer/owner to determine specifi c local code compliance prior to installation of the product. The

Company makes no representation or warranty regarding, and will not be responsible for any code compliance.

NOTE: This is a professional grade product. A knowledge of construction techniques, plumbing and electri-

cal installation according to codes are required for proper installation and user satisfaction. We recommend

that a licensed contractor perform the installation of all Jacuzzi Whirlpool Bath products. Our warranty does

not cover improper installation related problems.

PRECAUTIONS

! Do not operate the hydromassage system unless the bath is fi lled with water to at least 1" to 2" (25,4 - 50,8 mm) above

the highest jet.

! Do not immerse the control panel by overfi lling the bath.

! Do not use oil-based bath additives in your hydromassage bath.

! When cleaning your bath, do not use abrasive substances which will damage the bath's surface.

! To prevent discoloration of the acrylic fi nish, do not fi ll the bath with water in excess of 140°F (60°C).

WARNING — WHEN USING THIS UNIT, BASIC PRECAUTIONS SHOULD ALWAYS BE FOLLOWED, IN-

CLUDING THE FOLLOWING:

DANGER — RISK OF ELECTRIC SHOCK. CONNECT ONLY TO A CIRCUIT PROTECTED BY A GROUND

FAULT CIRCUIT INTERRUPTER (GFCI).

CAUTION — TEST THE GROUND FAULT CIRCUIT INTERRUPTER PROTECTING THIS APPLIANCE PE-

RIODICALLY IN ACCORDANCE WITH MANUFACTURER’S INSTRUCTIONS.

WARNING — USE THIS UNIT ONLY FOR ITS INTENDED USE AS DESCRIBED IN THIS MANUAL. DO NOT

USE ATTACHMENTS NOT RECOMMENDED BY THE MANUFACTURERS.

WARNING — TO AVOID INJURY, EXERCISE CAUTION WHEN ENTERING OR EXITING THE HYDROMAS-

SAGE BATHTUB.

WARNING — KEEP BODY AND HAIR A MINIMUM OF 6" (15,2 cm) AWAY FROM SUCTION FITTING AT

ALL TIMES WHEN THE HYDROMASSAGE SYSTEM IS OPERATING. HAIR LONGER THAN SHOULDER

LENGTH SHOULD BE SECURED CLOSE TO THE HEAD.

WARNING — RISK OF ELECTRICAL SHOCK; DO NOT PERMIT ELECTRICAL APPLIANCES (SUCH AS

HAIR DRYER, LAMP, TELEPHONE, RADIO OR TELEVISION) WITHIN 60" (1,5 m) OF THIS HYDROMAS-

SAGE BATHTUB.

WARNING — RISK OF ACCIDENTAL INJURY OR DROWNING; DO NOT USE DRUGS OR ALCOHOL BE-

FORE OR DURING THE USE OF HYDROMASSAGE BATHTUB EQUIPPED WITH A HEATER TO AVOID

UNCONSCIOUSNESS AND POSSIBLE DROWNING.

WARNING — RISK OF FETAL INJURY; PREGNANT OR POSSIBLY PREGNANT WOMEN SHOULD CON-

SULT A PHYSICIAN BEFORE USING A HYDROMASSAGE BATHTUB EQUIPPED WITH A HEATER.

WARNING — RISK OF HYPERTHERMIA AND POSSIBLE DROWNING; DO NOT USE A HYDROMASSAGE

BATHTUB EQUIPPED WITH A HEATER IMMEDIATELY FOLLOWING STRENUOUS EXERCISE.

WARNING — RISK OF HYPERTHERMIA AND POSSIBLE DROWNING; WATER TEMPERATURE IN EXCESS

OF 104°F (40°C) MAY BE INJURIOUS TO YOUR HEALTH. CHECK AND ADJUST WATER TEMPERATURE

BEFORE USE.

WARNING — RISK OF HYPERTHERMIA; PEOPLE USING MEDICATIONS AND/OR HAVING AN ADVERSE

MEDICAL HISTORY SHOULD CONSULT A PHYSICIAN BEFORE USING A HYDROMASSAGE BATHTUB

EQUIPPED WITH A HEATER.

FOR BUILT-IN AND DROP-IN UNITS, INSTALL TO PERMIT ACCESS FOR SERVICING.

THIS UNIT SHOULD BE ELECTRICALLY GROUNDED AND INSTALLED BY A LICENSED CONTRACTOR,

ELECTRICIAN, AND PLUMBER.

BUILDING MATERIALS AND WIRING SHOULD BE ROUTED AWAY FROM THE MOTOR/PUMP OR

BLOWER OR OTHER HEAT PRODUCING COMPONENTS OF THIS UNIT.

A PRESSURE WIRE CONNECTOR IS PROVIDED ON THE EXTERIOR OF THE MOTOR/PUMP AND

HEATER TO PERMIT CONNECTION OF AN NO. 8 AWG (8.4 mm) SOLID COPPER BONDING CONDUCTOR

BETWEEN THIS UNIT AND ALL OTHER ELECTRIC EQUIPMENT AND EXPOSED METAL IN THE VICINITY,

AS NEEDED TO COMPLY WITH LOCAL REQUIREMENTS.

SAFETY INSTRUCTIONS - INSTALLATION

3

Jacuzzi Whirlpool Bath EL21000B 10/06

ENGLISH

CONTENTS

Safety Instruction ______________________________________________________________________ 2-3

Contents _____________________________________________________________________________ 4

Specifi cations _________________________________________________________________________ 5-8

Roughing-in Reference __________________________________________________________________ 9-12

Framing and Support ___________________________________________________________________ 13

Service Access ________________________________________________________________________ 13

Electrical Connections ___________________________________________________________________ 14-15

Fuzion control Panel Installation ___________________________________________________________ 15

Plumbing and Water Supply ______________________________________________________________ 16

Fuzion Overfl ow Installation ______________________________________________________________ 16

Clean Up After Installation _______________________________________________________________ 16

Operating Instructions __________________________________________________________________ 17-21

Salon Control Panel __________________________________________________________________ 18-19

Salon Control Panels (for Mito™ 6) ______________________________________________________ 20

Maintenance Instructions _________________________________________________________________ 22-23

General Troubleshooting Guide ____________________________________________________________ 24

Authorized Service _____________________________________________________________________ 25

Warranty _____________________________________________________________________________ 27-28

NOTE: To obtain a referral for a service agent in your area call 1-800-288-4002. You may also visit our web site at

http://www.jacuzzi.com/. To fi nd service agent listings for:

Electrical or Mechanical Repairs visit http://jacuzzi.com/pdf/ASA.PDF

Finish, Surface, or Shell-Related Repairs visit http://jacuzzi.com/pdf/AFC.PDF

Repair Parts or Accessories visit http://jacuzzi.com/pdf/MPD.PDF

4

Jacuzzi Whirlpool Bath EL21000B 10/06

ENGLISH

SPECIFICATIONS

Important: Read complete instructions before beginning installation.

Each bath arrives ready for installation, completely equipped with blower motor, pump/motor assembly, heater, and plumbing

necessary for operation.

Remove the bath from the carton. Retain the shipping carton until satisfactory inspection of the product has been made. Do

not lift the bath by the plumbing or wiring at any time; handle by the shell only.

Immediately upon receipt, inspect the shell before installing. Should inspection reveal any damage or defect in the fi nish,

do not install the bath. Damage or defect to the fi nish claimed after the bath is installed is excluded from the warranty. Jacuzzi

Whirlpool Bath's responsibility for shipping damage ceases upon delivery of the products in good order to the carrier. Refer any

claims for damage to the carrier. For defi nitions of warranty coverage and limitations, refer to the published warranty information

packed with the product.

All bath units are factory tested for proper operation and watertight connections prior to shipping. NOTE: Prior to installa-

tion, the bath must be fi lled with water and operated to check for leaks that may have resulted from shipping damage

or mishandling. Jacuzzi Whirlpool Bath is not responsible for any defect that could have been discovered, repaired, or avoided

by following this inspection and testing procedure.

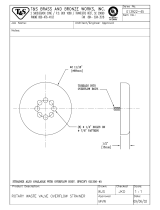

DRAIN/OVERFLOW

A

B

RECTANGULAR BATHS

5

Jacuzzi Whirlpool Bath EL21000B 10/06

END VIEW

SIDE VIEW

2"

(Inlet Heater)

(Motor)

(51 mm)

(Blower)

L

W

H

BELLAVISTA™

END VIEW

H

W

SIDE VIEW

L

1/2"

(13 mm)

(Motor)

(Inlet Heater)

(Blower)

ELARA

B

A

FUZION™

DRAIN/OVERFLOW

72"

26-1/2"

2"

1"

47"

SIDE VIEW

END VIEW

(51 mm)

(Inlet Heater)

(Motor)

(Blower)

(25 mm

SABELLA™

END VIEW

25"

42

"

SIDE VIEW

72

"

2"

(51 mm)

(Inlet Heater)

(Motor)

(Blower)

REÁL™

(

133 mm

)

5-1/4"

SIDE VIEW END VIEW

70-11/16"

(Motor)

(Inlet Heater)

25-1/4"

35-3/8"

(Blower)

FUZION™ 7236 with wood

SIDE VIEW END VIEW

(Motor)

(Inlet Heater)

24"

(

102 mm

)

4"

(Blower)

70-11/16"

35-3/8"

FUZION™ 7236 undermount

6-1/4" (159 mm)

SIDE VIEWEND VIEW

(Motor)

(Inlet Heater)

72"

25-1/4"

60"

(Blower)

FUZION™ 7260 with wood

SIDE VIEWEND VIEW

(Motor)

(Inlet Heater)

72"

24"

60"

5" (127 mm)

(Blower)

FUZION™ 7260 undermount

END VIEW

SIDE VIEW

72"

2"

(51 mm)

(Heater Blank)*

42"

21-1/2"

(Blower)

(Motor)

MITO™ 6

*MITO™ 6 COMES WITH HEATER BLANK ONLY.

INLINE HEATER MUST BE PURCHASED SEPARATELY.

ENGLISH

SPECIFICATIONS

(Rectangular) RH = RIGHT HAND

NOTE: The overall dimensions are nominal with a tolerance of +0 and -1/4" (6,4 mm).

FOR MITO™ UNIT: Electrical Service Requirements: It requires a dedicated GFCI protected separate circuit.

Blower and Motor/Pump: 120 VAC, 20 AMP, 60 Hz. dedicated GFCI protected separate circuit.

BELLAVISTA™

6

RH

BELLAVISTA™

5

RH

BELLAVISTA™

5.5

RH

72” (1829 mm) L

42” (1067 mm) W

26” ( 660 mm) H

60” (1524 mm) L

42” (1067 mm) W

26” ( 660 mm) H

66” (1676 mm) L

42” (1067 mm) W

26” ( 660 mm) H

Not Available

Not Available

180 lb

(81.8 kg)

157 lb

(71.3 kg)

85 U.S. gal

(322 liters)

177 lb

(80.5 kg)

Not Available

1025 lb

(466 kg)/

59 lb/ft

2

(287 kg/m

2

)

1186 lb

(539 kg)/

61.57 lb/ft

2

(299.8 kg/m

2

)

1231 lb

(560 kg)/

59 lb/ft

2

(228 kg/m

2

)

20” (508 mm) A

11-3/4” (298 mm) B

20” (508 mm) A

11-3/4” (298 mm) B

20” (508 mm) A

11-3/4” (298 mm) B

Template

Provided

P/N

P187000

Template

Provided

P/N

P187000

Template

Provided

P/N

P187000

Factory Installed

(BN60000 HEATER 230V)

MODEL

PRODUCT

WEIGHT

OPERATING

GALLONAGE

TOTAL WEIGHT/

FLOOR LOADINGDIMENSIONS DRAIN/OVERFLOW

SKIRT &

MOUNTINGCUTOUT

HEATER

Factory Installed

(BN60000 HEATER 230V)

Factory Installed

(BN60000 HEATER 230V)

6

Jacuzzi Whirlpool Bath EL21000B 10/06

ELARA™ 6636

RH

ELARA™ 6042

RH

66” (1676 mm) L

36” ( 914 mm) W

26” ( 660 mm) H

60” (1524 mm) L

42” (1067 mm) W

26” ( 660 mm) H

Not Available

164 lb

(74.5 kg)

170 lb

(77 kg)

Not Available

942 lb

(428 kg)/

53.8 lb/ft

2

(262 kg/m

2

)

847 lb

(385 kg)/

51.3 lb/ft

2

(250 kg/m

2

)

18-1/2” (470 mm) A

9.6” (269 mm) B

18-1/2” (470 mm) A

9.6” (269 mm) B

58” x 40”

(1473 mm x 1016

mm)

Umt Template

Provided

P/N DQ50000

64” x 34”

(1626 mm x 864

mm)

Umt Template

Provided

P/N DQ51000

Factory Installed

(BN60000 HEATER 230V)

Factory Installed

(BN60000 HEATER 230V)

ELARA™ 7242

RH

72” (1829 mm) L

42” (1067 mm) W

26” ( 660 mm) H

Not Available178 lb

(81 kg)

1060 lb

(482 kg)/

50.5 lb/ft

2

(246 kg/m

2

)

18-1/2” (470 mm) A

9.6” (269 mm) B

70” x 40”

(1778 mm x 1016

mm)

Umt Template

Provided

P/N BZ50000

Factory Installed

(BN60000 HEATER 230V)

SABELLA™

RH

REÁL™

RH

72” (1829 mm) L

47” (1194 mm) W

26-1/2” ( 673 mm) H

72” (1829 mm) L†

42” (1067 mm) W

26” ( 660 mm) H

Not Available179 lb

(81.4 kg)

Not Available

1230 lb

(559 kg)/

58.83 lb/ft

2

(287 kg/m

2

)

1302 lb

(592 kg)/

55.3 lb/ft

2

(269 kg/m

2

)

20 “ (508 mm) A

14 “ (356 mm) B

20 “ (508 mm) A

14” (356 mm) B

70” x 40”

(1778 mm x

1016 mm)

Template

Provided

P/N

P187000

Factory Installed

(BN60000 HEATER 230V)

Factory Installed

(BN60000 HEATER 230V)

FUZION™ 7260

WITH TEAK or

WENGE

RH

FUZION™ 7236

WITH TEAK or

WENGE

RH

FUZION™ 7236

UNDERMOUNT

RH

72” (1829 mm) L

60” (1524 mm) W

25-1/4” ( 641 mm) H

70-11/16” (1795 mm) L

35-3/8” ( 899 mm) W

25-1/4” ( 641 mm) H

70-11/16” (1795 mm) L

35-3/8” ( 899 mm) W

24” ( 610 mm) H

Not Available

Not Available

Min - 145 U.S. gal

(549 liters)

Max - 192 U.S. gal

(727 liters)

274 lb

(125 kg)

Min - 70 U.S. gal

(265 liters)

Max - 94 U.S. gal

(360 liters)

200 lb

(75 kg)

Min - 70 U.S. gal

(265 liters)

Max - 94 U.S. gal

(360 liters)

165 lb

(75 kg)

Not Available

1180 lb

(536 kg)/

65.6 lb/ft

2

(319 kg/m

2

)

1145 lb

(520.4 kg)/

63.7 lb/ft

2

(310 kg/m

2

)

1805 lb

(820 kg)/

60 lb/ft

2

(292 kg/m

2

)

16-3/4” (425 mm) A

12-1/16” (306 mm) B

17” (432 mm) A

10-1/4” (260 mm) B

17” (432 mm) A

10-1/4” (260 mm) B

69-1/2” x

34-3/8”

(1765 mm x

873 mm)

Template

Provided

P/N

DD42000

71” x 59”

(1803 mm x

1499 mm)

Factory Installed

(BN60000 HEATER 230V)

Factory Installed

(BN60000 HEATER 230V)

Factory Installed

(BN60000 HEATER 230V)

FUZION™ 7260

UNDERMOUNT

RH

72” (1829 mm) L

60” (1524 mm) W

24” ( 610 mm) H

Min - 145 U.S. gal

(549 liters)

Max - 192 U.S. gal

(727 liters)

199 lb

(90.5 kg)

Not Available1730 lb

(786 kg)/

57.6 lb/ft

2

(280.5 kg/m

2

)

16-3/4” (425 mm) A

12-1/16” (306 mm) B

Template

Provided

P/N

DD44000

Factory Installed

(BN60000 HEATER 230V)

SPECIFICATIONS

90 U.S. gal

(341 liters)

80 U.S. gal

(303 liters)

Min - 75 U.S. gal

(284 liters)

Max - 83 U.S. gal

(314 liters)

Min - 83 U.S. gal

(314 liters)

Max - 92 U.S. gal

(348 liters)

Min - 95 U.S. gal

(360 liters)

Max - 105 U.S. gal

(398 liters)

98 U.S. gal

(371 liters)

184 lb

(84 kg)

MITO™ 6

RH

72” (1829 mm) L

42” (1067 mm) W

21-1/2” ( 546 mm) H

Not Available155 lb

(70.5 kg)

1197 lb

(544 kg)/

57 lb/ft

2

(278 kg/m

2

)

17-1/2” (445 mm) A

11-7/8” (302 mm) B

70” x 40”

(1778 mm x

1016 mm)

HEATER READY FOR FIELD

INSTALLATION

(S750000 HEATER 120V KIT)

Min - 62 U.S. gal

(235 liters)

Max - 90 U.S. gal

(341 liters)

Min - 62 U.S. gal

(235 liters)

Max - 90 U.S. gal

(341 liters)

† Add 1/4” (6,4 mm) to this dimension when roughing-in for 3-wall niche.

NOTE: The overall dimensions are nominal with a tolerance of +0 and -1/4" (6,4 mm).

FOR ALL UNITS: Electrical Service Requirements: All require a dedicated GFCI protected separate circuit.

Blower: 120 VAC, 20 AMP, 60 Hz. dedicated GFCI protected separate circuit.

Motor/Pump and RapidHeat™: 240 VAC, 20 AMP, 60 Hz. dedicated GFCI protected separate circuit.

ENGLISH

7

Jacuzzi Whirlpool Bath EL21000B 10/06

SPECIFICATIONS (Oval and Round) RH = RIGHT HAND

NOTE: The overall dimensions are nominal with a tolerance of +0 and -1/4" (6,4 mm).

FOR ALL UNITS: Electrical Service Requirements: All require a dedicated GFCI protected separate circuit.

Blower: 120 VAC, 20 AMP, 60 Hz. dedicated GFCI protected separate circuit.

Motor/Pump and RapidHeat™: 240 VAC, 20 AMP, 60 Hz. dedicated GFCI protected separate circuit.

DUETTA™ 6636

RH

DUETTA™ 6042

RH

66” (1676 mm) L

36” ( 914 mm) W

26” ( 660 mm) H

60” (1524 mm) L

42” (1067 mm) W

26” ( 660 mm) H

Not Available

160 lb

(72.7 kg)

110 lb

(50 kg)

Not Available

999 lb

(454 kg)/

57.1 lb/ft

2

(278 kg/m

2

)

1027 lb

(467 kg)/

62.3 lb/ft

2

(303 kg/m

2

)

18.4” (467 mm) A

11” (279 mm) B

18.4” (467 mm) A

11” (279 mm) B

Template

Provided

P/N

DA09000

Template

Provided

P/N

DA08000

MODEL

PRODUCT

WEIGHT

OPERATING

GALLONAGE

TOTAL WEIGHT/

FLOOR LOADINGDIMENSIONS DRAIN/OVERFLOW

SKIRT &

MOUNTINGCUTOUT

HEATER

Factory Installed

(BN60000 HEATER 230V)

Factory Installed

(BN60000 HEATER 230V)

DRAIN/OVERFLOW

A

B

OVAL AND ROUND BATHS

VENICIA™

RH

DUETTA™ 6642

RH

DUETTA™ 7242

RH

72” (1829 mm) L

42” (1067 mm) W

26” ( 660 mm) H

66” (1676 mm) L

42” (1067 mm) W

26” ( 660 mm) H

72” (1829 mm) L

42” (1067 mm) W

26” ( 660 mm) H

Not Available

Not Available

90 U.S. gal

(341 liters)

179 lb

(81.4 kg)

117 lb

(53 kg)

130 lb

(59 kg)

Not Available

1106 lb

(503 kg)/

57.5 lb/ft

2

(280 kg/m

2

)

1277 lb

(580.5 kg)/

60.8 lb/ft

2

(296 kg/m

2

)

1230 lb

(559 kg)/

58.83 lb/ft

2

(287 kg/m

2

)

20” (508 mm) A

14” (356 mm) B

18.4” (467 mm) A

11” (279 mm) B

18.4” (467 mm) A

11” (279 mm) B

Template

Provided

P/N

DA07000

Template

Provided

P/N

DA06000

Template

Provided

P/N

P187000

Factory Installed

(BN60000 HEATER 230V)

Factory Installed

(BN60000 HEATER 230V)

Factory Installed

(BN60000 HEATER 230V)

SPECIFICATIONS

END VIEW

H

W

SIDE VIEW

L

1/2"

(13 mm)

(Motor)

(Inlet Heater)

(Blower)

DUETTA

END VIEW

H

W

SIDE VIEW

2"

(Motor)

L

(51 mm)

VENICIA™

(Inlet Heater)

(Blower)

Min - 75 U.S. gal

(284 liters)

Max - 80 U.S. gal

(303 liters)

Min - 77 U.S. gal

(291 liters)

Max - 83 U.S. gal

(314 liters)

Min - 90 U.S. gal

(341 liters)

Max - 95 U.S. gal

(360 liters)

Min - 98 U.S. gal

(371 liters)

Max - 106 U.S. gal

(401 liters)

ENGLISH

8

Jacuzzi Whirlpool Bath EL21000B 10/06

SPECIFICATIONS (Corner) RH = RIGHT HAND

NOTE: The overall dimensions are nominal with a tolerance of +0 and -1/4" (6,4 mm).

FOR ALL UNITS: Electrical Service Requirements: All require a dedicated GFCI protected separate circuit.

Blower: 120 VAC, 20 AMP, 60 Hz. dedicated GFCI protected separate circuit.

Motor/Pump and RapidHeat™: 240 VAC, 20 AMP, 60 Hz. dedicated GFCI protected separate circuit.

FUZION™ 6666

UNDERMOUNT

RH

BELLAVISTA

CORNER

RH

FUZION™ 6666

WITH TEAK or

WENGE

RH

66” (1676 mm) L

66” (1676 mm) W

24” ( 610 mm) H

60” (1524 mm) L

60” (1524 mm) W

25” ( 635 mm) H

66” (1676 mm) L

66” (1676 mm) W

25-1/4” ( 641 mm) H

Not Available

Not Available

Min - 124 U.S. gal

(469 liters)

Max - 176 U.S. gal

(666 liters)

184 lb

(83.5 kg)

110 lb

(50 kg)

Min - 124 U.S. gal

(469 liters)

Max - 176 U.S. gal

(666 liters)

256 lb

(116.4 kg)

Not Available

1165 lb

(530 kg)/

49.6 lb/ft

2

(242 kg/m

2

)

1923 lb

(874 kg)/

72.6 lb/ft

2

(354 kg/m

2

)

1851 lb

(841 kg)/

69.8 lb/ft

2

(340 kg/m

2

)

16-13/16” (427 mm) A

12-1/8” (308 mm) B

18-7/8” (479 mm) A

14” (356 mm) B

16-13/16” (427 mm) A

12-1/8” (308 mm) B

Template

Provided

P/N

P654000

See

Page 12

Template

Provided

P/N

DD43000

Factory Installed

(BN60000 HEATER 230V)

MODEL

PRODUCT

WEIGHT

OPERATING

GALLONAGE

TOTAL WEIGHT/

FLOOR LOADINGDIMENSIONS DRAIN/OVERFLOW

SKIRT &

MOUNTINGCUTOUT

HEATER

Factory Installed

(BN60000 HEATER 230V)

Factory Installed

(BN60000 HEATER 230V)

CORNER BATHS

SPECIFICATIONS

(159 mm)

6-1/4"

SIDE VIEW END VIEW

DRAIN/OVERFLOW

B

A

(Intake Heater)

(Motor)

25-1/4"

66"

66"

(Blower)

FUZION™ 6666 with wood

25"

SIDE VIEW

A

B

DRAIN/OVERFLOW

(Inlet Heater)

(Motor)

(Blower)

60"

END VIEW

2”

(51 mm)

BELLAVISTA™ CORNER

SIDE VIEW END VIEW

DRAIN/OVERFLOW

B

A

(Inlet Heater)

(Motor)

24"

66"

(

127 mm

)

5"

66"

(Blower)

FUZION™ 6666 undermount

Min - 77 U.S. gal

(291 liters)

Max - 83 U.S. gal

(314 liters)

ENGLISH

9

Jacuzzi Whirlpool Bath EL21000B 10/06

ROUGHING-IN REFERENCE

NOTE: 1. THE OVERALL DIMENSIONS ARE NOMINAL WITH A TOLERANCE OF +0 AND -1/4" (6,4 mm).

2. Measurements inside each unit represent cutout in fl oor to allow for drain/overfl ow.

3. All measurements are in inches. To convert to millimeters, multiply inches by 25.4.

4. Service Access dimensions given are minimum size.

7"

32-1/2"

11-3/4"

6"

30-1/8"

42"

60"

4" x 4"

Motor

12" H x 24" L

Service Access

Heater

Blower

Bellavista™ 5,

(Right Hand Only)

10"

35-1/2"

11-3/4"

6"

30-1/8"

42"

66"

4" x 4"

Motor

12" H x 24" L

Service Access

Heater

Blower

Bellavista™ 5.5

(Right Hand Only)

4" x 4"*

42"

72"

10-1/2"

35-13/16"

11-3/4"

6"

30-1/8"

Motor

12" H x 24" L

Service Access

Heater

Blower

Bellavista™ 6

(Right Hand Only)

36"

42"

72"

11-7/8"

10" x 4"

2"

Motor

12" H x 24" L

Service Access

5-3/8"

Blower

Heater Blank*

MITO™ 6,

(Right hand only)

*MITO™ 6 COMES WITH HEATER BLANK ONLY.

INLINE HEATER MUST BE PURCHASED SEPARATELY.

60"

42"

21"

4.2"

9.6"

12" x 4"

2"

Heater

Motor

Opt. Service

Access

12" H x 24" L

Service Access

Blower

Elara™ 6042,

Right Hand

Elara™ 6636,

Right Hand

66"

36"

18 "

4.2"

9.6"

12" x 4"

Motor

Opt. Service

Access

12" H x 24" L

Service Access

Heater

2"

Blower

Some tubs are supplied with cutout template and/or undermount template. Refer to CUTOUT on pages 6-8 for template part

numbers.

72"

42"

21"

4.2"

9.6"

12" x 4"

2"

Heater

Motor

Opt. Service

Access

12" H x 24" L

Service Access

Blower

Elara™ 7242,

Right Hand

ENGLISH

10

Jacuzzi Whirlpool Bath EL21000B 10/06

ROUGHING-IN REFERENCE

NOTE: 1. THE OVERALL DIMENSIONS ARE NOMINAL WITH A TOLERANCE OF +0 AND -1/4" (6,4 mm).

2. Measurements inside each unit represent cutout in fl oor to allow for drain/overfl ow.

3. All measurements are in inches. To convert to millimeters, multiply inches by 25.4.

4. Service Access dimensions given are minimum size.

Motor

Opt. Service Access

17-11/16''

2''

7''

10-1/4''

12'' x 4"*

Heater

70-11/16''

35-3/8''

12" H x 24" L

Service Access

Blower

Fuzion™ 7236, Right Hand

Opt. Service Access

17-11/16''

2''

7''

10-1/4''

12'' x 4"*

Heater

70-11/16''

35-3/8''

Motor

12" H x 24" L

Service Access

Blower

Fuzion™ 7236 Undermount,

Right Hand

Some tubs are supplied with cutout template and/or undermount template. Refer to CUTOUT on pages 6-8 for template part

numbers.

Motor

Heater

72"

60"

36"

24.19"

12"

8.47"

18-1/2" x 4"

12" H x 24" L

Service Access

Optional

Service Access

Blower

Fuzion™ 7260,

Right Hand

Motor

Heater

72"

60"

36"

24.19"

12"

8.47"

18-1/2" x 4"

12" H x 24" L

Service Access

Optional

Service Access

Fuzion™ 7260 Undermount,

Right Hand

Blower

10-1/2"

36"

14"

5-1/4"

42"

72"

3"

Motor

12" H x 24" L

Service Access

Heater

Blower

18" x 4"*

REÁL™

Right Hand

72"

10-1/4"

36"

3"

1"

3"

3"

1"

7"

47"

13-3/4"

18" x 4"

Motor

12" H x 24" L

Service Access

Heater

Blower

Sabella™

Right Hand

ENGLISH

11

Jacuzzi Whirlpool Bath EL21000B 10/06

ROUGHING-IN REFERENCE

NOTE: 1. THE OVERALL DIMENSIONS ARE NOMINAL WITH A TOLERANCE OF +0 AND -1/4" (6,4 mm).

2. Measurements inside each unit represent cutout in fl oor to allow for drain/overfl ow.

3. All measurements are in inches. To convert to millimeters, multiply inches by 25.4.

4. Service Access dimensions given are minimum size.

11.04"

60"

42"

30"

3.84"

13" x 4"

2"

Motor

Heater

12" H x 24" L

Service Access

Blower

Duetta™ 6042,

Right Hand

11.04"

66"

36"

33"

3.84"

13" x 4"

2"

Motor

Heater

12" H x 24" L

Service Access

Blower

Duetta™ 6636,

Right Hand

11.04"

66"

42"

33"

3.84"

13" x 4"

2"

Motor

Heater

12" H x 24" L

Service Access

Blower

Duetta™ 6642,

Right Hand

72"

42"

36"

11"

3-1/2"

14" x 4"

Motor

Heater

2"

12" H x 24" L

Service Access

Blower

Duetta™ 7242,

Right Hand

10-1/2"

36"

3"

42"

72"

12-1/8"

5-1/4"

29-7/8"

Motor

12" H x 24" L

Service Access

Heater

Blower

18" x 4"

Venicia™,

Right Hand

Some tubs are supplied with cutout template and/or undermount template. Refer to CUTOUT on pages 6-8 for template part

numbers.

NOTE: On oval tubs the motor and blower mounting plates extend beyond the bath rim.

ENGLISH

12

Jacuzzi Whirlpool Bath EL21000B 10/06

ROUGHING-IN REFERENCE

NOTE: 1. THE OVERALL DIMENSIONS ARE NOMINAL WITH A TOLERANCE OF +0 AND -1/4" (6,4 mm).

2. Measurements inside each unit represent cutout in fl oor to allow for drain/overfl ow.

3. All measurements are in inches. To convert to millimeters, multiply inches by 25.4.

4. Service Access dimensions given are minimum size.

46.61"

66"

32.97"

Ref.

69.68"

66"

37.23"

9.29"

40.94"

Fuzion™ 6666,

Right Hand

40.94"

32.97"

20" X 4"

Motor

12" H x 24" L

Service Access

Heater

Blower

60"

60"

77-3/4"

3"

7.5"

34-9/16"

59-1/2" Ref.

Heater

Motor

12" H x 24" L

Service Access

Opt. Service Access

Blower

12" x 4"*

46.61"

66"

32.97"

Ref.

69.68"

66"

37.23"

9.29"

40.94"

32.97"

20" X 4"

40.94"

Fuzion™ 6666 Undermount,

Right Hand

Motor

12" H x 24" L

Service Access

Heater

Blower

48"

65"

32"

Ref.

67-1/2"

65"

32"

Drain

CUTOUT

Fuzion™ 6666,

Right Hand units with Teak or Wenge

Corner Bath Cutout

Some tubs are supplied with cutout template and/or undermount template. Refer to CUTOUT on pages 6-8 for template part

numbers.

ENGLISH

13

Jacuzzi Whirlpool Bath EL21000B 10/06

Framing and Support

The drain/overfl ow of the bath extends below the bottom of the bath. Note that this requires a cutout in the fl oor.

The fl oor structure beneath the bath must be able to support a total weight of bath, water, and bather. Refer to the

table under total weight for your model. The unit must be supported from the bottom of the bath and not from the bath rim

or nailing fl ange. If the subfl oor is level and a continuous surface, no other preparation is necessary. You can proceed to install

the bath. If the subfl oor is not level, you MUST level the entire surface prior to installing the bath. The use of materials that shim

or provide a level installation are allowed provided the method used will insure a level bath that is supported from the bottom.

Materials that may be used are a fl oor leveling compound, mortar, plaster or minimal expansion structural foam; however the

bath must remain level in order for it to drain properly and all foam feet must make full contact with the leveling material. Both

sides of a joint or splice of subfl oor should be level to each other.

NOTE: Drop-In Bath units are equipped with metal anchor straps. These straps can be used to secure the unit to the

fl oor or sub-fl oor to reduce movement after installation. If mortar or similar anchoring material is used, these straps

are not necessary.

WARNING: ALL foam feet must contact the fl oor. Anchoring straps and/or other anchoring materials will not properly

anchor unit if ALL foam feet are NOT in contact with a level fl oor. Operating a unit improperly installed may cause ir-

reparable damage to the unit.

The rim of the bath is not designed to support weight. If fi nish material is to overlap or contact the bath, the added weight

must be fully self-supporting.

Install optional trim parts when all installation has been completed.

The protective fi lm liner inside the bath is used to help prevent damage to the fi nish during installation. Before instal-

lation, remove liner to inspect for any defects, reapply and do not remove until fi nal cleanup.

FLUSH TO WALL

SEMI-SUNKEN

TILE

1" X 4" (NOT FOR SUPPORT)

MORTAR OR ADHESIVE

FLASHING

SEALANT

SUB-FLOOR

FLASHING

SEALANT

MORTAR OR ADHESIVE

TILE

TYPICAL INSTALLATIONS

1" X 4" (NOT FOR SUPPORT)

INSTALLATION

NAIL OR SCREW

THROUGH

ANCHOR STRAP

INTO FLOOR

FLOOR

ANCHOR

STRAP

Service Access

For partially or fully sunken installations, allow for access to

service connections. It is the installer's responsibility to pro-

vide suffi cient service access. The recommended minimum

dimensions allowable for service to the bath are shown in the

"Service Access" illustration below.

Provide adequate ventilation for cooling and to supply suf-

fi cient air for the blower. Also provide adequate area around

unit for air circulation for cooling the motor and to supply suf-

fi cient air to the jets.

Do not insulate this area or around blower or motor.

PUMP/MOTOR

24"

PUMP/MOTOR & BLOWER SERVICE ACCESS - REQUIRED

12"

BLOWER

FRONT

HEATER

ENGLISH

14

Jacuzzi Whirlpool Bath EL21000B 10/06

ELECTRICAL CONNECTION - BLOWER

DUPLEX

RECEPT. *

3 PRONG

PLUG

*(NOT PROVIDED)

FLOOR

4" MIN.

OR IN

ACCORDANCE

WITH LOCAL

& BUILDING OR

ELECTRICAL

CODES

Two (2) separate Ground Fault Circuit Interrupter (GFCI)

are required for the Salon™ Spa units (except Mito™ 6).

The Mito™ 6 requires a single Ground Fault Circuit Interrupter

(GFCI). Electrical connections should be performed by a

licensed electrician.

A separate 240 VAC, 20 AMP, GFCI electrical circuit is

required for the heater and pump/motor for all units except

the Mito™ 6. The Mito™ 6 requires a separate 120 VAC, 20

AMP, GFCI electrical circuit.

A separate 120 VAC, 20 AMP, GFCI electrical circuit is

required for the blower (except Mito™ 6).

DANGER: RISK OF ELECTRIC SHOCK. Connect only to a

circuit protected by a Ground Fault Circuit Interrupter.

DANGER: RISK OF COMPONENT OVERHEAT. Do NOT use

electric extension cord to provide power to unit.

CAUTION: Operating the motor/pump without enough

water in the bath can cause leaking and permanent dam-

age to the pump.

NOTE: At initial start up the 8 button electronic control

system enters an automatic self diagnostic program for

15-20 seconds. During the diagnostic program the system

will not accept user commands.

ELECTRICAL CONNECTION - HEATER AND PUMP/MOTOR

T

M

240V GFCI

PROTECTED

CIRCUIT*

HEATER

SUPPLIED POWER CORD

FROM JUNCTION BOX TO

GFCI PROTECTED

CIRCUIT

4" MIN.

OR IN

ACCORDANCE

WITH LOCAL

BUILDING OR

ELECTRICAL

CODES

*(NOT PROVIDED)

Electrical Connections

BLOWER (Except Mito™ 6)

Install a 120 VAC, 20 AMP, GFCI duplex outlet to the stud-

wall underneath the bathtub, at least 4 inches (10,2 cm) above

the fl oor. The duplex outlet is not provided. .

PUMP/MOTOR AND HEATER (Except Mito™ 6)

Install a 240 VAC, 20 AMP RATED GFCI single outlet to the

studwall underneath the bathtub, at least 4 inches (10,2 cm)

above the fl oor. The single outlet is not provided.

Power cords from the heater and the pump/motor are routed

to a fused junction box at the factory. A supplied power cord

from the junction box with a 240 VAC plug connects to the

customer supplied GFCI dedicated circuit.

With a #8 solid copper wire, bond the heater to the house

electrical panel or approved local bond. A bonding lug is

provided on the heater.

At initial start-up and before each use thereafter with power

ON, push the GFCI test button. The reset button should pop

out. Push this button in to reset. If the interrupter fails to

operate in this manner, there is a ground current fl owing or a

device malfunction, indicating the possibility of electrical shock.

Turn OFF power and do not use the bath until the source

of the problem has been identifi ed and corrected.

BLOWER

BLOWER

POWER CORD

TO WATER

SENSORS

TO CONTROL

PANEL

DANGER: RISK OF ELECTRIC SHOCK. Before servicing

these connections disconnect all power supply to both

120 VAC service and 240 VAC service.

JUNCTION

BOX

PLUG INTO

240V 20AMP GFCI RECEPTACLE

FEMALE PLUG

240VAC, 12AMP

(FOR CONTROL BOX)

FEMALE PLUG

240VAC, 15AMP

(FOR HEATER)

FUSES

(DO NOT REMOVE)

FUSES

(DO NOT REMOVE)

JUNCTION BOX CONNECTIONS

DANGER: RISK OF ELECTRIC SHOCK. Before servicing

these connections disconnect all power supply to both

120 VAC service and 240 VAC service.

SALON™ SPA CONTROL BOX CONNECTIONS

TO CONTROL PANEL

TO LED LIGHT(S)

TO MOTOR

(4 PIN CONNECTOR)

TO JUNCTION BOX

(MALE CONNECTOR)

TO WATER LEVEL

SENSOR

TO AIR FLOW VALVES

INSTALLATION

ENGLISH

15

Jacuzzi Whirlpool Bath EL21000B 10/06

INSTALLATION

FUZION™ Control Panel Installation

NOTE: The Fuzion™ control panel is delivered loose and

must be installed during the tub install.

For Fuzion™ drop-in and undermount installations, install

the control panel as shown below.

The control panel cutout opening in the assembled wood

frame and tub and in the assembled counter and tub must be

clear and free of adhesive.

Control panel and wire to be free of defects. Insert wire

into panel connector.

Apply adhesive sparingly around base of control panel.

Thread wire through cutout and to control box. Orientate

control panel so that the Jacuzzi logo is read from the inside

of the tub. Lower control panel in cutout and press fi rmly to

embed adhesive.

Connect wire to control box.

Adhesive

Apply sparingly to

avoid squeeze out

Connect Blower

wire here

(Grey wire)

Connect Control Box

wire here

(Black wire)

Inside of tub

Inside of tub

ELECTRICAL CONNECTION

115 VAC

DUPLEX

RECEPT GFCI

(NOT PROVIDED)

115 VAC

3 PRONG

PLUG FROM

JUNCTION BOX

FLOOR

4" MIN.

OR IN

ACCORDANCE

WITH LOCAL

BUILDING OR

ELECTRICAL

CODES

HEATER BLANK

PUMP/MOTOR AND BLOWER FOR MITO™ 6

The Mito™ 6 unit comes with a blower, a pump/motor, and a heater blank. The Inline Heater must be purchased separately.

Follow the installation instructions provided with the Inline Heater if an Inline Heater has been purchased separately and is to be

installed at this time. The blower and pump motor are connected to a 120 VAC junction box.

Install a 120 VAC, 20 AMP RATED GFCI single outlet to the studwall underneath the bathtub, at least 4 inches (10,2 cm)

above the fl oor. The single outlet is not provided. A supplied power cord from the junction box with a 120 VAC plug connects to

the customer supplied GFCI dedicated circuit.

At initial start-up and before each use thereafter with power ON, push the GFCI test button. The reset button should pop

out. Push this button in to reset. If the interrupter fails to operate in this manner, there is a ground current fl owing or a device

malfunction, indicating the possibility of electrical shock. Turn OFF power and do not use the bath until the source of the

problem has been identifi ed and corrected.

JUNCTION

BOX

PLUG INTO

120V 20AMP GFCI RECEPTACLE

FEMALE PLUG

120VAC, 7AMP

(FOR CONTROL BOX &

PUMP/MOTOR)

FEMALE PLUG

120VAC, 12AMP

(FOR BLOWER)

FUSE

(DO NOT REMOVE)

FUSE

(DO NOT REMOVE)

JUNCTION BOX CONNECTIONS

DANGER: RISK OF ELECTRIC SHOCK. Before servicing

these connections disconnect all power supply to 120

VAC service.

Electrical Connections (continued)

ENGLISH

16

Jacuzzi Whirlpool Bath EL21000B 10/06

Drain Information

A drain/overfl ow assembly (sold separately) must be installed

on the bath, water tested, and connected to the sanitary system

of the house. After opening the carton, inspect for damage and

verify that the kit is of the proper fi nish. In the Jacuzzi Whirlpool

Bath drain/overfl ow kit (supplied with some models), note that

the waste fl ange, strainer, overfl ow cover and cover screws

are packaged in a separate package within the kit to protect

the trim fi nish. Follow the installation instructions provided

with the drain/overfl ow kit. After the drain is fully installed,

test for proper drainage. If the unit does not drain properly,

rectify this condition before proceeding with the installation.

Jacuzzi Whirlpool Bath is not responsible for removal and or

reinstallation costs.

NOTE: Watertight installation of the drain is the installer’s

responsibility. Drain leakage is excluded from the Jacuzzi

Whirlpool Bath warranty of this product.

NOTE: FUZION™ TUBS ONLY - The supplied overfl ow

fi tting of the drain/overfl ow assembly MUST be installed

before the wood frame or (for undermount tubs) the

counter is installed.

Plumbing and Water Supply

Plumbing

Pump, jets, and suction fi ttings for the whirlpool system are

factory plumbed in schedule 40 PVC piping.

All Jacuzzi Whirlpool Salon™ Spa Bath products are factory

tested for proper operation and watertight connections prior to

shipping. If leaks are detected, notify your Jacuzzi Whirlpool

Bath Dealer. Do not install the unit.

Water Supply

Consult local authorities for plumbing code requirements

in your area.

IMPORTANT: Proper installation of the fi ll spout plumbing

and compliance with local codes are the responsibility

of the installer. Jacuzzi Whirlpool Bath does not war-

rant connections of water supply fi ttings and piping, fi ll

systems, or drain/overfl ow systems. Nor is it responsible

for damage to the bath which occurs during installation.

CAUTION: A nonfl ammable protective barrier must be

placed between soldering work and bath unit to prevent

damage to the bath.

*ANTI-SIPHON VALVE

BATH RIM

6"

* NOT

PROVIDED

Anti-Siphon Valve (Optional)

Optional Anti-Siphon valve installation. The Anti-Siphon

valve is not supplied with the tub. Consult your local plumb-

ing code requirements for the minimum height above the tub

rim.

Fuzion™ Overfl ow Fitting Installation

The supplied overfl ow fi tting of the drain/overfl ow assembly

MUST be installed before the wood frame or (for undermount

tubs) the counter is installed.

Remove and open the overfl ow fi tting from the drain kit (sup-

plied). Remove washers and nuts from the overfl ow fi tting.

Place a small bead of plumbers putty, silicone, or similar

approved sealant around the underside of the top fl ange. Place

the overfl ow fi tting into the overfl ow hole of the tub.

From the underside of the unit, place the rubber washer

then locknut on the fi tting and tighten securely. Be careful

not to over tighten.

The 1-1/2" (38 mm) overfl ow fi tting connects with standard

drain plumbing fi ttings widely available at local hardware and

plumbing stores. Assemble in accordance with local plumbing

or building codes.

After the drain is fully installed, test for proper drainage. If

the unit does not drain properly, rectify this condition before

proceeding with the installation. Jacuzzi Whirlpool Bath is not

responsible for removal and or reinstallation costs.

NOTE: Watertight installation of the drain is the installer’s

responsibility. Drain leakage is excluded from the Jacuzzi

Whirlpool Bath warranty of this product.

Clean-Up After Installation

To avoid dulling and scratching the surface of the bath,

never use abrasive cleaners. A mild liquid detergent and warm

water will clean soiled surfaces.

Remove spilled plaster with a wood or plastic edge. Metal

tools will scratch the surface. Spots left by plaster or grout

can be removed if lightly rubbed with detergent on a damp

cloth or sponge.

Paint, tar, or other diffi cult surface stains can be removed

with paint thinner, turpentine, or isopropyl alcohol (rubbing

alcohol). NOTE: Use these chemicals only on SURFACE

stains.

Minor scratches which do not penetrate the color fi nish can

be removed by lightly sanding with 600-grit wet/dry sandpaper.

You can restore the glossy fi nish to the acrylic surface of the

bath with a special compound, Meguiar's #10 Mirror Glaze.

If that is not available, use automotive rubbing compound fol-

lowed by an application of automotive paste wax.

Major scratches and gouges which penetrate the acrylic

surface will require refi nishing. Ask your Jacuzzi Whirlpool

Bath dealer for special instructions or visit our web site at

http://www.jacuzzi.com/ to fi nd a service agent listing for Sur-

face or Shell-Related Problems.

O

VERFL

O

W

FITTING

APPLY

PUTTY/SEALANT

(NOT PROVIDED)

FLAT RUBBER WASHER

LOCKNUT

TIGHT

WASTE ELBOW

(NOT PROVIDED)

ENGLISH

17

Jacuzzi Whirlpool Bath EL21000B 10/06

TYPICAL BATH FITTINGS

Operation

NOTE: These instructions pertain to all bath products manufactured by Jacuzzi Whirlpool Bath. Not all features dis-

cussed in this instruction pamphlet apply to all baths.

All baths manufactured by Jacuzzi Whirlpool Bath are designed for "fi ll and drain," which means the bath should be drained

after each use and fi lled with fresh water by the next bather. This is a health precaution, as these baths are not designed to hold

water continuously like pools or spas. If you want a unit designed to continuously hold water, see your Jacuzzi Whirlpool Bath

dealer for the complete line of spas available.

Once the bath is installed, remove any residue or foreign materials left over from construction. Paint, tar, or other diffi cult surface

stains can be removed with paint thinner, turpentine, or isopropyl alcohol (rubbing alcohol). NOTE: Use these chemicals only on

SURFACE stains. Other dirt can be cleaned off with a mild liquid detergent on a damp cloth. Scrape off plaster with a wooden

or plastic edge; do not use metal scrapers, wire brushes or other metal tools, as they will damage the bath's surface.

Water Level

Close the drain and fi ll the bath until water is at least 1" to 2" (25,4 to 50,8 mm) above the highest jet (see water line indicated

in the illustration). Do not turn on the whirlpool system at any time if the jets are not completely immersed in water.

Running the whirlpool system when there is insuffi cient water in the bath could result in water spraying outside the bath area.

Running the whirlpool system without water will damage the recirculating pump.

IMPORTANT: When exiting the bath, the water level will drop below the jets which could result in water being sprayed out of the

unit. To prevent this, you must turn unit OFF before exiting bath.

OPERATING INSTRUCTIONS

1" - 2"

FILL TO AT LEAST

1" - 2" ABOVE HIGHEST JET

DRAIN/OVERFLOW

T

YPICAL SALON™ SPA FITTINGS

SALON

CONTROL PANEL

AIR JETS

FULLY

ADJUSTABLE

SIDE JETS

FULLY

ADJUSTABLE

BACK JETS

WATER LEVEL

SENSORS

SUCTION COVER

ENGLISH

18

Jacuzzi Whirlpool Bath EL21000B 10/06

Electronic Control Panel Operation (with standard Chromatherapy lighting)

All tubs in this product line (except the Mito™ 6) come with electronic controls and standard Chromatherapy lighting. Read

and follow the operation instructions for the control system of your unit.

General Functions

This Jacuzzi tub is equipped with a eight button electronic control panel. The eight button panel controls a two speed pump/

motor, Chromatherapy lighting, air controls, blower, and wave control. LED lights (on the control panel) indicate function levels.

When switching between functions, the LED for the inactive functions will dim and the active function will brighten.

The bath is equipped with two water level sensors. When the water level is below the sensors, the pump/motor can not be

activated. If the ON/OFF pump/motor button is pressed at this time, the pump/motor will not operate. When the water goes

above the water level sensor, the pump/motor can be activated. If the water level drops below the level sensor, the pump/motor

will shut OFF. To restart the pump/motor after the water level goes above the level sensor, the ON/OFF pump/motor button must

be pressed. The pump/motor will automatically shut off 30 minutes after the pump/motor was turned on.

When the water level is below the sensors, the blower cannot be activated using the control panel. The blower will activate

a Drain cycle and a Purge Cycle when two conditions are met: the water level is below the sensors and the controls have been

shut down. See Drain Cycle - Air Bath on page 21 for an explanation of these cycles.

NOTE: Ensure the water level sensors located inside the bath are free of any soap or dirt buildup.

CONTROL PANEL OPERATION (WHIRLPOOL AND AIR BATH) [EXCEPT MITO™ 6]

ENGLISH

19

Jacuzzi Whirlpool Bath EL21000B 10/06

Normal Operation (with the bath fi lled to the proper level)

Bath Light

Right Air Valve

Left Air Valve

Left Air Valve

Status LEDs

Right Air Valve

Status LEDs

Pump/Motor

Status LEDs

ON/OFF

Pump/Motor

Wave

Function

Toggle

Switches

Air Bath

Blower Status

LEDs

Wave Function Switch (ON/OFF )

Pressing this

button activates wave action by opening

and closing air valves. Pressing a second time will turn OFF

the wave action.

• When pressing this button after pressing the Pump/Mo-

tor button or the Air Valve button the wave action will

work on both Right and Left Air valves.

Air Bath Switch

Pressing this

button will activate the blower using the

Toggle buttons to increase/decrease air fl ow from the blower.

Blower air can be adjusted from low air to maximum air.

Air Bath Status LED

The Air Bath Status LED will show four LED lights at maxi-

mum air and only one LED light when the air is turned OFF.

Each additional LED indicates more air fl ow.

Toggle Switches

The Toggle buttons, up

and down , act on each

of the other switches to increase, decrease, or modify func-

tionality. Use the up arrow to increase and the down arrow

to decrease.

• Pressing a toggle button after pressing the Pump/Motor

button will increase or decrease speeds on the Pump/Mo-

tor. If the pump/motor is on HIGH speed press the down

arrow to select LOW speed. If the pump/motor is on LOW

speed press the up arrow to select HIGH speed.

• Pressing an up or down toggle button after pressing the

Bath Light button once will increase or decrease the white

light brightness. Pressing an up or down toggle button after

pressing the Bath Light button twice will begin cycling the

light colors. Leave the colors cycling or press the same

toggle button again to stop the color cycling. With the lights

stopped on a color pressing the Bath Light button a third

time will turn OFF the light. (A favorite color will be saved

ONLY when the cycling has been stopped on that color

and then turned OFF.)

• Pressing a toggle button after pressing both the Pump/

Motor button fi rst and then the Wave Function button

will increase or decrease wave action on both air valves.

Pressing a toggle button after pressing either Air Valve but-

tons increase or decrease wave action on that air valve.

• Pressing a toggle button after pressing the Air Bath Switch

increase or decrease the air fl ow through the bottom air

channels.

Pump/Motor Switch (ON/OFF )

Pressing the

button will turn ON the two speed pump/

motor at HIGH speed. Pressing a second time will turn OFF

the pump/motor. To change speeds use the Toggle buttons.

Pump/Motor Status LED

When the pump/motor is ON at HIGH speed all four LED

indicator lights will be lit. When the pump/motor is ON at LOW

speed the bottom LED indicator light will be lit.

Left Air Valve Switch

Pressing this

button will activate the left air valves

using the Toggle buttons to increase/decrease air fl ow to the

left set of jets. The air fl ow can be adjusted from no air to

maximum air.

Left Air Valve Status LED

The Left Air Valve Status LED will show four LED lights at

maximum air and only one LED light when the air is turned

OFF. Each additional LED indicates more air fl ow.

Right Air Valve Switch

Pressing this

button will activate the right air valves.

Use the Toggle buttons to increase/decrease air fl ow to the

right set of jets. The air fl ow can be adjusted from no air to

maximum air.

Right Air Valve Status LED

The Right Air Valve Status LED will show four LED lights

at maximum air and only one LED light when the air is turned

OFF. Each additional LED indicates more air fl ow.

Bath Light Switch (ON/OFF )

Pressing this

button will turn ON the white bath light(s).

Pressing the Toggle buttons at this time will increase or de-

crease light intensity. Pressing the

button a second time

will access the saved favorite color. To cycle lighting colors

use the Toggle button. Pressing the Toggle button again will

stop the light cycling. The color displayed when the cycle has

been stopped will be saved as your favorite color. Pressing

the

button a third time to turn OFF the light.

NOTE: When switching between functions, the LED for the in-

active functions will dim and the active function will brighten.

ENGLISH

Control Panel Operation, Mito™ 6 Air Bath Controls

General Functions

Normal Mode: Press this button to turn the blower ON. The blower will be on for 20 minutes. The intensity may be changed

by using either the up arrow button or the down arrow button. Pressing this button a second time will turn the blower OFF. When

the blower is turned off the blower will continue to run for 10 seconds to allow the heater element to cool.

Wave Mode: Press this button to change the blower's power from a minimum to a user defi ned maximum. Press this button

a second time to return to normal mode where the blower's power is constant.

In the Normal mode with the blower power constant, press the UP arrow to increase or the DOWN arrow to decrease. In

Wave mode these buttons change the blower's power to a user defi ned maximum.

Control Panel Operation, Mito™ 6 Whirlpool Controls

General Functions

The Electronic Control ON/OFF Switch, conveniently located on the bath, allows you to turn the whirlpool system on and

off while in the bath. Simply push down on the switch button to turn on the whirlpool system. To turn the system OFF, push

down on the button again.

The control switch will automatically shut OFF after 20 minutes. Push down on the switch button to restart the whirlpool system

again.

20

Jacuzzi Whirlpool Bath EL21000B 10/06

CONTROL PANEL OPERATION (WHIRLPOOL AND AIR BATH FOR MITO™ 6]

The Mito™ 6 has two control panels, one Air Bath and one Whirlpool.

/