7

Have questions? Call us at 1-844-44-ANZZI or visit us at www.ANZZI.com

Fixing slot at the bottom

of the product

Installation steps

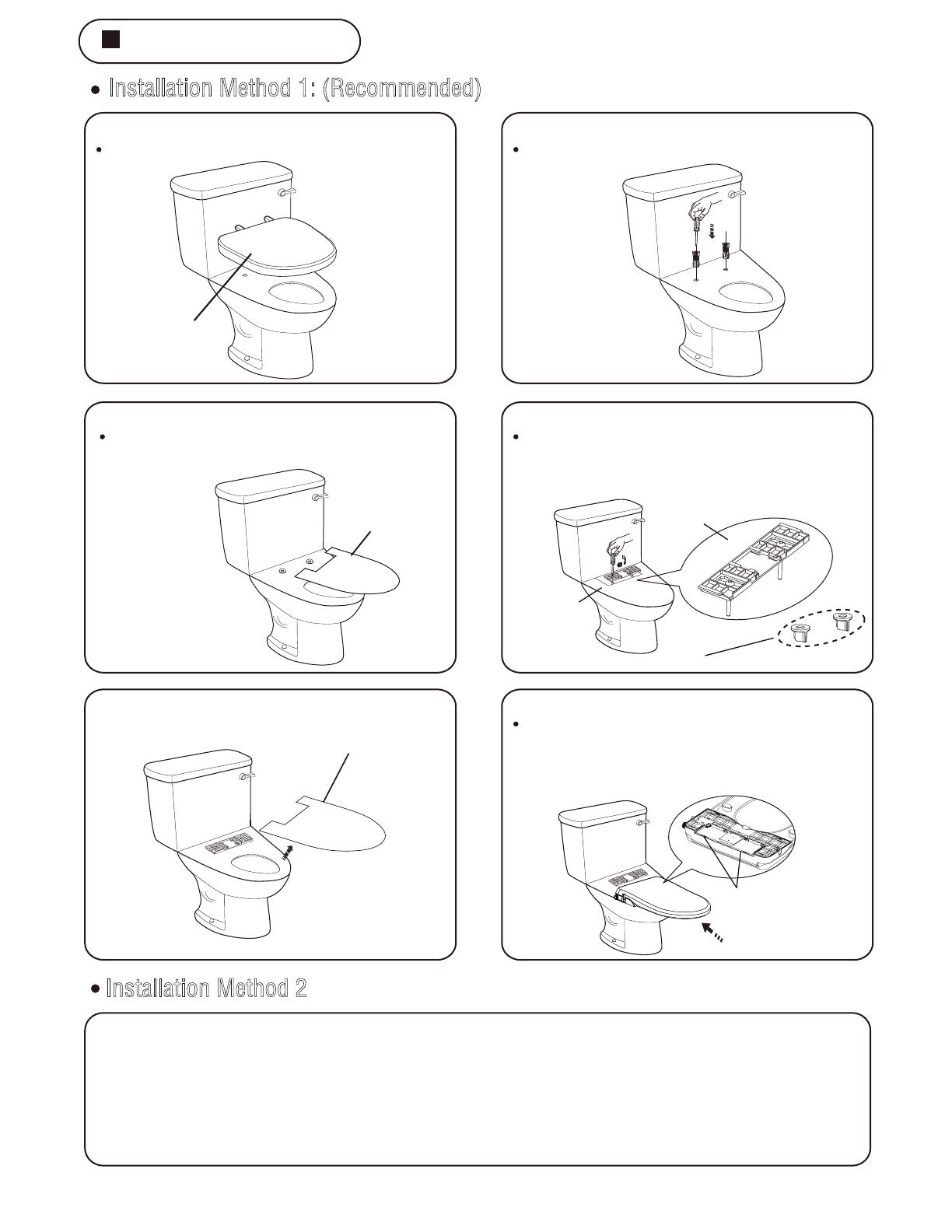

Installation Method 1: (Recommended)

1.Remove the old cover plate.

3.Install the template.

5.Remove the installation template.

6.Install the product.

Cover plate

Install Template

2.Install expansion bolts.

4.Install the fixing plate and lock it.

Loosen nuts linking the cover and remove the

cover.

Press the expansion bolts into the ceramic holes

respectively

as shown in

the figure.

As shown in the figure, place the installation

template on the ceramic.

Align the fixing slot at the bottom of the product

with the fixing plate, push the product in the

direction shown in the figure, push it to the

bottom, and the installation is completed.

Align the fixing plate with the ceramic hole as

shown in the figure, then adjust the positions

of the connecting bolt and the adjusting piece

to align the connecting bolt with the expansion

bolt, and lock the fixing plate.

Text FRONT Forward

Install Template

Install template

Hiperfly nuts are used for the second mounting mode

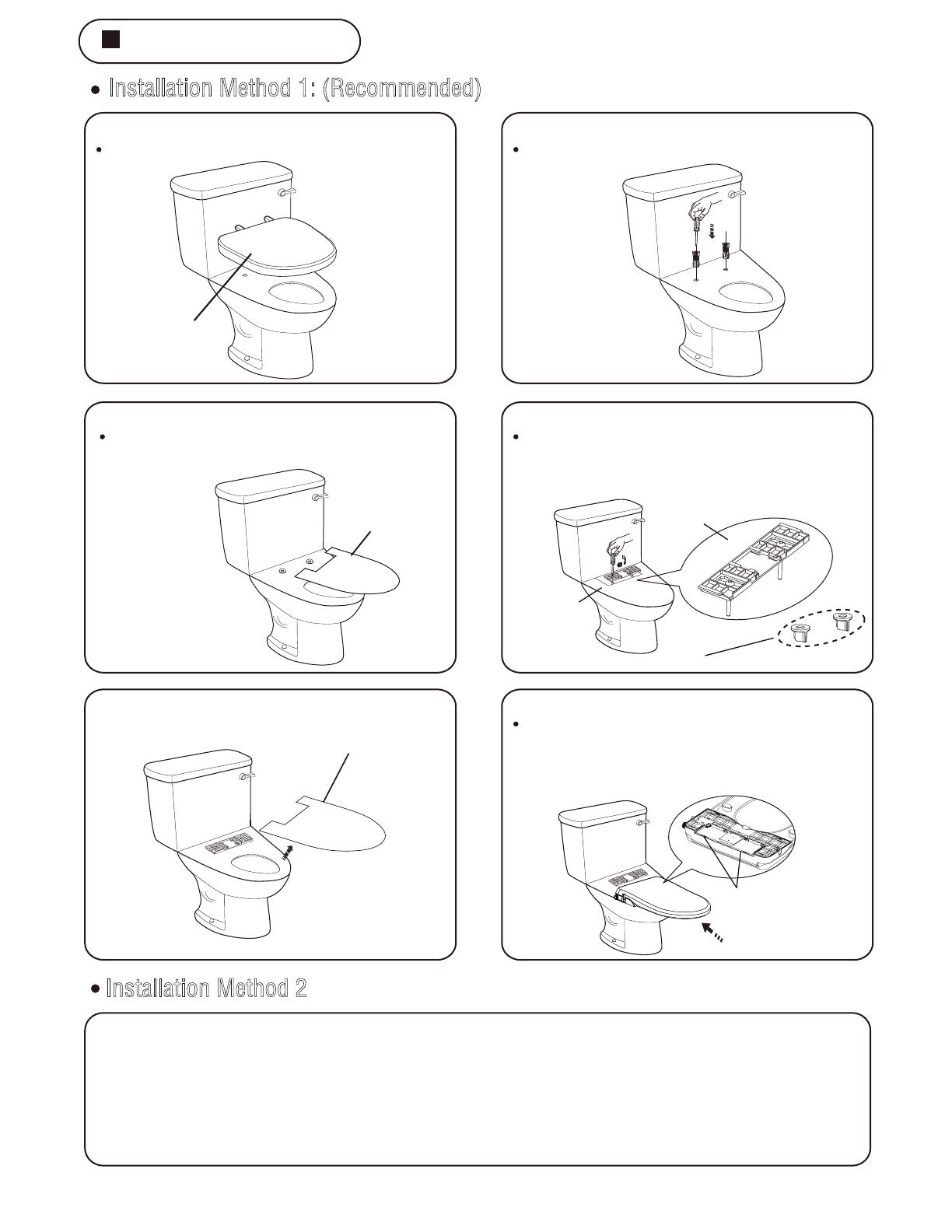

Installation Method 2

1.Remove the old toilet lid and toilet seat and place the installation template on ceramic

(see Article 1 and 3 of the first method).

2.Align the fixing plate as shown in the figure (the fourth point of the first method is shown in the figure)

with the ceramic hole, then adjust the positions of the connecting bolt and the adjusting piece, lock the

hiperfly nut from the lower end of the ceramic to the upper end, and fix the fixing plate.

3.For the rest of the installation steps, see Article 5 and 6 of the first method to complete the installation.