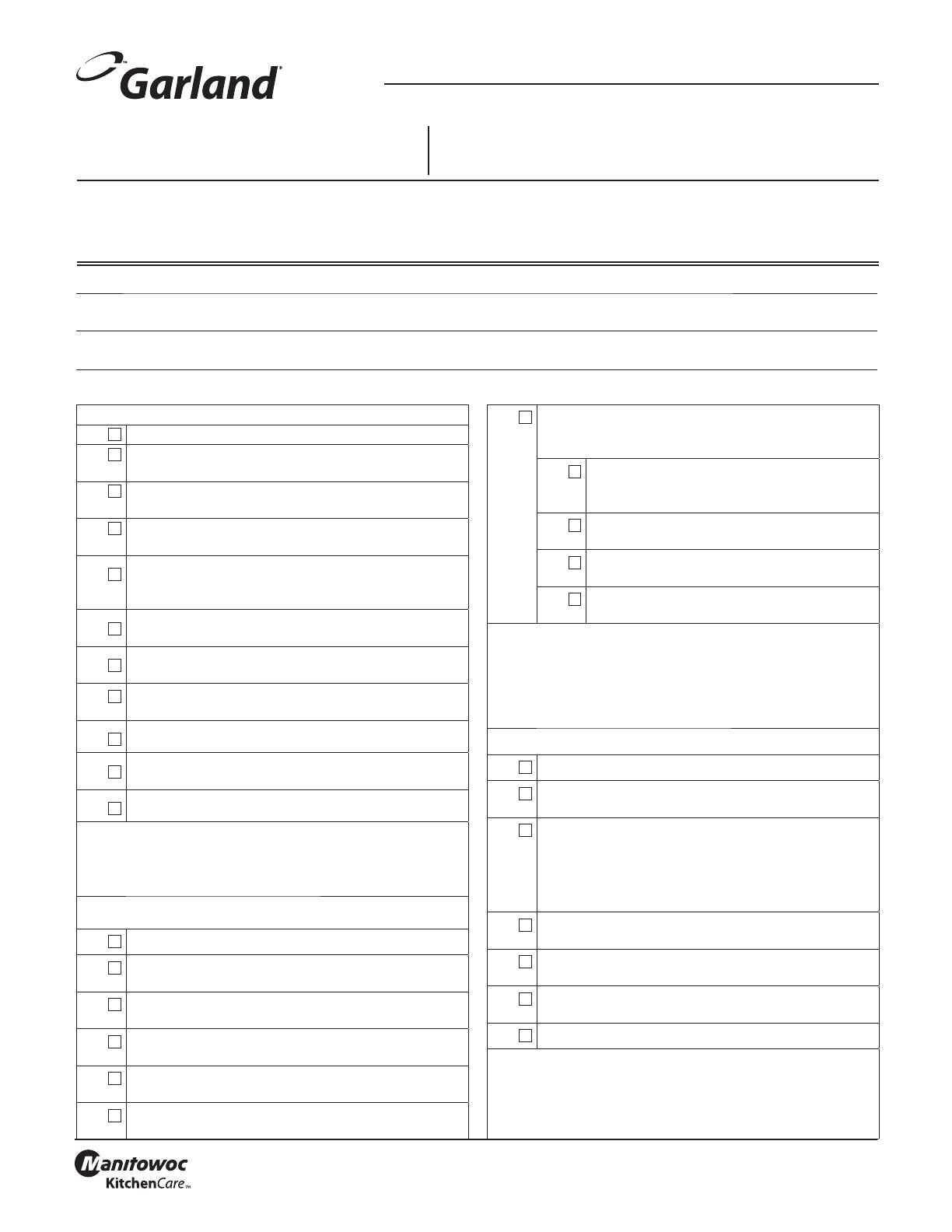

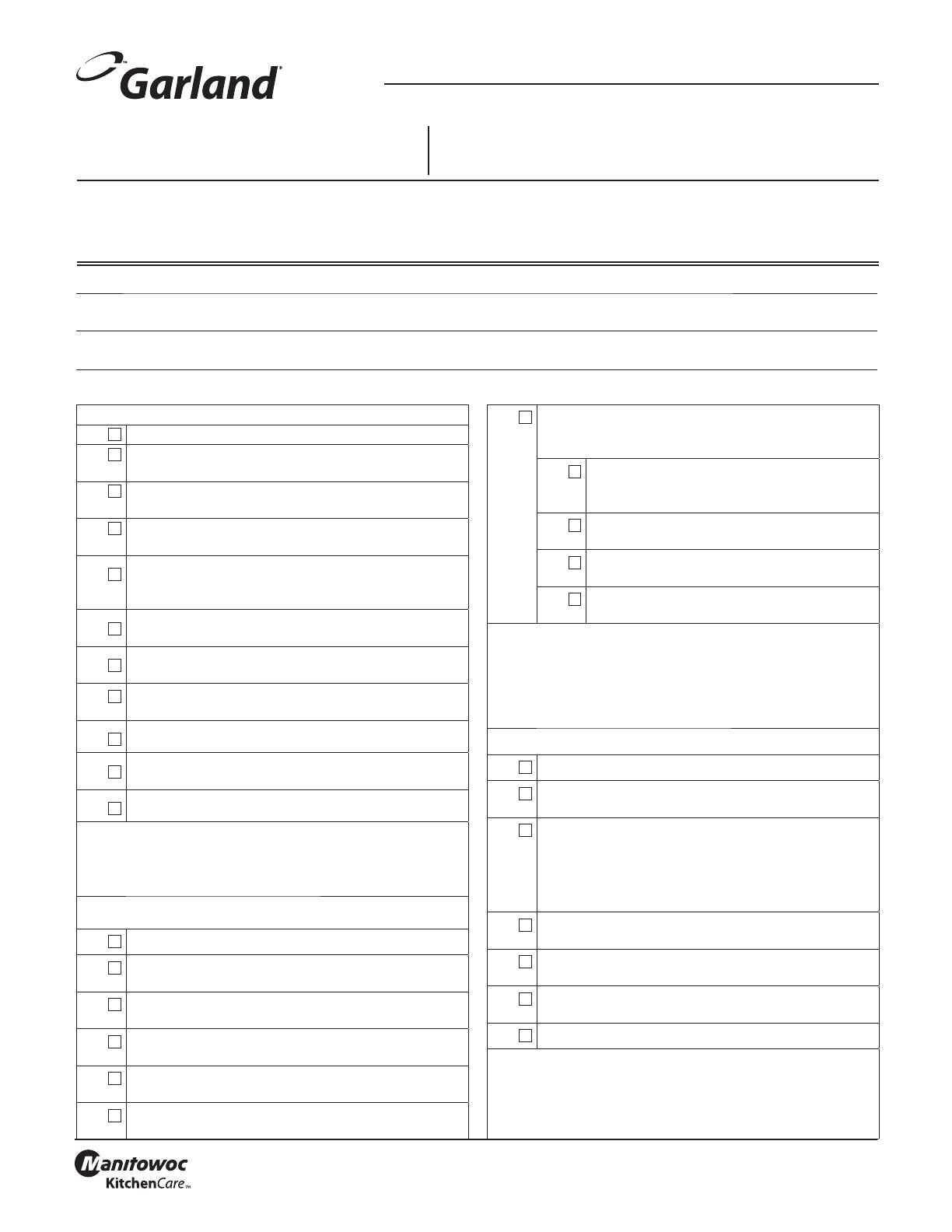

1 of 2

Document Number: GAR_CL_0003_en 5/15

GARLAND

1177 KAMATO ROAD, MISSISSAUGA, ONTARIO, CANADA. L4W1X4

844724CARE 2273

WWW.GARLANDGROUP.COM

Induction Generator

1.

All cables at the device are labelled?

2.

All cables are connected and the screws on the plugs are

fastened?

3.

The tongue from the RJ45 cable is snapped into the

generator socket?

4.

Coil and supply cables are routed separately and sorted

from other low voltage and communication cables?

5.

The installation clearances are maintained — air intake

and exhaust vents, at least 40mm(1.6”) and all sides, at

least 10 mm(0.4”)?

6.

Is there adequate ventilation? For example, separated

paths for fresh air and exhaust air?

7.

Ambient air temperature around the generator is

≤ 40°C (104

o

F) when it is in operation?

8.

Ensure there is no moisture, hot or grease laden air that

goes through the air inlet?

9.

The generator is easily accessible for service?

10.

It is highly recommended to install grease filters to clean

the intake air. Are grease filters installed?

11.

Grease filters can be removed easily for cleaning?

Comments:

Control Unit

12.

All cables at the device are labelled?

13.

All cables are connected and the screws on the plugs are

fastened?

14.

The tongue from the RJ45 cable is snapped into the

control unit socket?

15.

Control unit is mounted securely (mounting brackets

provided)?

16.

Service interface (IR window) is accessible for service?

Installation clearance, minimum 38 mm (1.5”).

17.

Ambient air temperature around the control unit is

≤ 40°C (104

o

F) when it is in operation?

18.

(Outside of the USA/Canada) If a Sicotronic energy

optimization is connected, check if the yellow wire is

connected at RED.

19.

Switch the induction unit on, put a pot of water

on the field and read the EAMMN_Modul the

status.

20.

LED a On? (It is illuminated if the generator

switched on).

21.

LED b On? (It is illuminated if the potentiometer

is between 8 and 12).

22.

LED c On? (It is illuminated if the generator takes

full energy).

Comments:

Coil Carrier

23.

All cables and CONNECTIONS are labelled?

24.

All cables are connected and the screws on the plugs are

fastened?

25.

Coil assemblies must be pressed against the glass-top

with an even compression or contact pressure. Coil

compression is measured by the coil assembly mounting

bolts protruding below the carrier frame by about 5mm.

Is each mounting bolt protruding about 5mm?

26.

Coil assemblies have an even contact pressure against

the glass-top?

27.

There is no ferromagnetic material (installation and

mounting frame) in proximity to the coil?

28.

There is natural air flow or forced ventilation in the coil

area?

29.

Correct glass-top for the model is installed?

Comments:

Today’s Date:

(Day/Month/Year)

Installation Date:

(Day/Month/Year)

Installation

Company:

Model Number:

Store

Contact:

(Name, Phone#)

Serial Number:

Store Name,

Address:

Voltage:

Checklist

Installation Checklist for Induction RTCS

®

mp

Module-

Line Equipment

• This checklist is designed as an installation inspection tool for Fabricators and Installers.

• Service Technicians can also use this checklist to diagnose any potential installation issues.

• We recommend to use one checklist per appliance installed.

• Inspect and ensure client’s cookware is suitable for cooking on the induction equipment.