Toshiba RAV-SM1603ATZ-E User manual

- Category

- Split-system air conditioners

- Type

- User manual

This manual is also suitable for

R410A

PRINTED IN JAPAN, Jun, 2008 ToMo

FILE NO. A07-009

SERVICE MANUAL

AIR-CONDITIONER

SPLIT TYPE

OUTDOOR UNIT <DIGITAL INVERTER>

RAV-SM1603AT-E

RAV-SM1603ATZ-E

RAV-SM1603ATZG-E

INDOOR UNIT <DIGITAL INVERTER>

RAV-SM1403DT-A

RAV-SM1603DT-A

∗ Refer to the Service Manual with File No. A06-010 for Model RAV-SM1403AT-E, and refer to the

Service Manual with File No. A07-003 for Model RAV-SP1403AT-E, respectively.

– 2 –

Adoption of New Refrigerant

This Air Conditioner is a new type which adopts a new refrigerant HFC (R410A) instead of the conventional

refrigerant R22 in order to prevent destruction of the ozone layer.

WARNING

Cleaning of the air filter and other parts of the air filter involves dangerous work in high places, so be sure to

have a service person do it. Do not attempt it yourself.

The cleaning diagram for the air filter is there for the service person, and not for the customer.

CONTENTS

SAFETY CAUTION ............................................................................................ 4

1. SPECIFICATIONS ...................................................................................... 9

1-1. Indoor Unit........................................................................................................... 9

1-2. Outdoor Unit...................................................................................................... 21

1-3. Operation Characteristic Curve....................................................................... 22

2. CONSTRUCTION VIEWS (EXTERNAL VIEWS) ...................................... 23

2-1. Indoor Unit......................................................................................................... 23

2-2. Outdoor Unit...................................................................................................... 24

3. SYSTEMATIC REFRIGERATING CYCLE DIAGRAM .............................. 27

3-1. Indoor Unit......................................................................................................... 27

3-2. Outdoor Unit...................................................................................................... 29

4. WIRING DIAGRAM................................................................................... 30

4-1. Indoor Unit......................................................................................................... 30

4-2. Outdoor Unit...................................................................................................... 32

4-3. Fan Characteristics .......................................................................................... 33

5. SPECIFICATIONS OF ELECTRICAL PARTS .......................................... 34

5-1. Indoor Unit......................................................................................................... 34

5-2. Outdoor Unit...................................................................................................... 34

– 3 –

6. REFRIGERANT R410A............................................................................ 35

6-1. Safety During Installation/Servicing ............................................................... 35

6-2. Refrigerant Piping Installation....................................................................... 35

6-3. Tools .................................................................................................................. 39

6-4. Recharging of Refrigerant................................................................................ 39

6-5. Brazing of Pipes................................................................................................ 40

6-6. Instructions for Re-use Piping of R22 or R407C ............................................ 42

6-7. Tolerance of Pipe Length and Pipe Head........................................................ 46

6-8. Additional Refrigerant Amount........................................................................ 48

6-9. Piping Materials and Sizes............................................................................... 50

6-10. Branch Pipe....................................................................................................... 51

6-11. Distributor ......................................................................................................... 51

7. INDOOR CONTROL CIRCUIT ................................................................. 52

7-1. Indoor Controller Block Diagram..................................................................... 52

7-2. Control Specifications...................................................................................... 53

7-3. Optional Connector Specifications of Indoor P.C. Board.............................. 59

7-4. Indoor Print Circuit Board................................................................................ 60

7-5. Outdoor Print Circuit Board............................................................................. 61

8. CIRCUIT CONFIGURATION AND CONTROL SPECIFICATIONS........... 64

8-1. Outdoor Controls.............................................................................................. 64

9. INDOOR UNIT TROUBLESHOOTING...................................................... 69

9-1. Summary of Troubleshooting........................................................................... 69

9-2. Troubleshooting................................................................................................ 70

10. OUTDOOR UNIT TROUBLESHOOTING.................................................. 83

10-1. Summary of Troubleshooting........................................................................... 83

10-2. Troubleshooting................................................................................................ 85

11. REPLACEMENT OF SERVICE P.C. BOARD ......................................... 112

11-1. Indoort Unit ..................................................................................................... 112

12. SETUP AT LOCAL SITE AND OTHERS................................................ 116

12-1. Indoor Unit....................................................................................................... 116

12-2. Setup at Local Site / Others ........................................................................... 123

12-3. How to Set up Central Control Address Number ......................................... 125

13. ADDRESS SETUP.................................................................................. 127

13-1. Address Setup Procedure.............................................................................. 127

13-2. Address Setup & Group Control.................................................................... 128

13-3. Address Setup (Manual Setting from Remote Controller)........................... 131

14. DETACHMENTS ..................................................................................... 133

14-1. Indoor Unit....................................................................................................... 133

14-2. Outdoor Unit.................................................................................................... 141

15. EXPLODED VIEWS AND PARTS LIST .................................................. 150

15-1. Indoor Unit....................................................................................................... 150

15-2. Outdoor Unit.................................................................................................... 153

– 4 –

SAFETY CAUTION

The important contents concerned to the safety are described on the product itself and on this Service Manual.

Please read this Service Manual after understanding the described items thoroughly in the following contents

(Indications/Illustrated marks), and keep them.

[Explanation of indications]

∗ Property damage : Enlarged damage concerned to property, furniture, and domestic animal/pet

[Explanation of illustrated marks]

[Confirmation of warning label on the main unit]

Confirm that labels are indicated on the specified positions

(Refer to the Parts disassembly diagram (Outdoor unit).)

If removing the label during parts replace, stick it as the original.

Indication

DANGER

WARNING

CAUTION

Explanation

Indicates contents assumed that an imminent danger causing a death or serious injury of

the repair engineers and the third parties when an incorrect work has been executed.

Indicates possibilities assumed that a danger causing a death or serious injury of the repair

engineers, the third parties, and the users due to troubles of the product after work when

an incorrect work has been executed.

Indicates contents assumed that an injury or property damage (∗) may be caused on the

repair engineers, the third parties, and the users due to troubles of the product after work

when an incorrect work has been executed.

Mark Explanation

Indicates prohibited items (Forbidden items to do)

The sentences near an illustrated mark describe the concrete prohibited contents.

Indicates mandatory items (Compulsory items to do)

The sentences near an illustrated mark describe the concrete mandatory contents.

Indicates cautions (Including danger/warning)

The sentences or illustration near or in an illustrated mark describe the concrete cautious contents.

Turn off breaker.

Execute discharge

between terminals.

Prohibition

Turn “OFF” the breaker before removing the front panel and cabinet, otherwise an electric

shock is caused by high voltage resulted in a death or injury.

During operation, a high voltage with 400V or higher of circuit (∗) at secondary circuit of the

high-voltage transformer is applied.

If touching a high voltage with the naked hands or body, an electric shock is caused even if using an

electric insulator.

∗ : For details, refer to the electric wiring diagram.

When removing the front panel or cabinet, execute short-circuit and discharge between high-

voltage capacitor terminals.

If discharge is not executed, an electric shock is caused by high voltage resulted in a death or injury.

After turning off the breaker, high voltage also keeps to apply to the high-voltage capacitor.

Do not turn on the breaker under condition that the front panel and cabinet are removed.

An electric shock is caused by high voltage resulted in a death or injury.

DANGER

– 5 –

Check earth wires.

Prohibition of modification.

Use specified parts.

Do not bring a child

close to the equipment.

Insulating measures

No fire

Refrigerant

Assembly/Cabling

Before troubleshooting or repair work, check the earth wire is connected to the earth

terminals of the main unit, otherwise an electric shock is caused when a leak occurs.

If the earth wire is not correctly connected, contact an electric engineer for rework.

Do not modify the products.

Do not also disassemble or modify the parts. It may cause a fire, electric shock or injury.

For spare parts, use those specified (

∗∗

∗∗

∗).

If unspecified parts are used, a fire or electric shock may be caused.

∗: For details, refer to the parts list.

Before troubleshooting or repair work, do not bring a third party (a child, etc.) except

the repair engineers close to the equipment.

It causes an injury with tools or disassembled parts.

Please inform the users so that the third party (a child, etc.) does not approach the equipment.

Connect the cut-off lead wires with crimp contact, etc, put the closed end side upward

and then apply a water-cut method, otherwise a leak or production of fire is caused at

the users’ side.

When repairing the refrigerating cycle, take the following measures.

1) Be attentive to fire around the cycle. When using a gas stove, etc, be sure to put out fire

before work; otherwise the oil mixed with refrigerant gas may catch fire.

2) Do not use a welder in the closed room.

When using it without ventilation, carbon monoxide poisoning may be caused.

3) Do not bring inflammables close to the refrigerant cycle, otherwise fire of the welder may

catch the inflammables.

Check the used refrigerant name and use tools and materials of the parts which

match with it.

For the products which use R410A refrigerant, the refrigerant name is indicated at a position

on the outdoor unit where is easy to see. To prevent miss-charging, the route of the service

port is changed from one of the former R22.

For an air conditioner which uses R410A, never use other refrigerant than R410A.

For an air conditioner which uses other refrigerant (R22, etc.), never use R410A.

If different types of refrigerant are mixed, abnormal high pressure generates in the

refrigerating cycle and an injury due to breakage may be caused.

Do not charge refrigerant additionally.

If charging refrigerant additionally when refrigerant gas leaks, the refrigerant composition in

the refrigerating cycle changes resulted in change of air conditioner characteristics or

refrigerant over the specified standard amount is charged and an abnormal high pressure is

applied to the inside of the refrigerating cycle resulted in cause of breakage or injury.

Therefore if the refrigerant gas leaks, recover the refrigerant in the air conditioner, execute

vacuuming, and then newly recharge the specified amount of liquid refrigerant.

In this time, never charge the refrigerant over the specified amount.

When recharging the refrigerant in the refrigerating cycle, do not mix the refrigerant

or air other than R410A into the specified refrigerant.

If air or others is mixed with the refrigerant, abnormal high pressure generates in the

refrigerating cycle resulted in cause of injury due to breakage.

After installation work, check the refrigerant gas does not leak.

If the refrigerant gas leaks in the room, poisonous gas generates when gas touches to fire

such as fan heater, stove or cocking stove though the refrigerant gas itself is innocuous.

Never recover the refrigerant into the outdoor unit.

When the equipment is moved or repaired, be sure to recover the refrigerant with recovering

device. The refrigerant cannot be recovered in the outdoor unit; otherwise a serious accident

such as breakage or injury is caused.

After repair work, surely assemble the disassembled parts, and connect and lead the

removed wires as before. Perform the work so that the cabinet or panel does not

catch the inner wires.

If incorrect assembly or incorrect wire connection was done, a disaster such as a leak or fire

is caused at user’s side.

WARNING

– 6 –

After the work has finished, be sure to use an insulation tester set (500V Megger) to

check the resistance is 2M

ΩΩ

ΩΩ

Ω or more between the charge section and the non-charge

metal section (Earth position).

If the resistance value is low, a disaster such as a leak or electric shock is caused at user’s

side.

When the refrigerant gas leaks during work, execute ventilation.

If the refrigerant gas touches to a fire, poisonous gas generates.

A case of leakage of the refrigerant and the closed room full with gas is dangerous because

a shortage of oxygen occurs. Be sure to execute ventilation.

When checking the circuit inevitably under condition of the power-ON, use rubber

gloves and others not to touch to the charging section.

If touching to the charging section, an electric shock may be caused.

When the refrigerant gas leaks, find up the leaked position and repair it surely.

If the leaked position cannot be found up and the repair work is interrupted, pump-down and

tighten the service valve, otherwise the refrigerant gas may leak into the room.

The poisonous gas generates when gas touches to fire such as fan heater, stove or cocking

stove though the refrigerant gas itself is innocuous.

When installing equipment which includes a large amount of charged refrigerant such

as a multi air conditioner in a sub-room, it is necessary that the density does not the

limit even if the refrigerant leaks.

If the refrigerant leaks and exceeds the limit density, an accident of shortage of oxygen is

caused.

For the installation/moving/reinstallation work, follow to the Installation Manual.

If an incorrect installation is done, a trouble of the refrigerating cycle, water leak, electric

shock or fire is caused.

After repair work has finished, check there is no trouble.

If check is not executed, a fire, electric shock or injury may be caused.

For a check, turn off the power breaker.

After repair work (installation of front panel and cabinet) has finished, execute a test

run to check there is no generation of smoke or abnormal sound.

If check is not executed, a fire or an electric shock is caused.

Before test run, install the front panel and cabinet.

Check the following items after reinstallation.

1) The earth wire is correctly connected.

2) The power cord is not caught in the product.

3) There is no inclination or unsteadiness and the installation is stable.

If check is not executed, a fire, an electric shock or an injury is caused.

Insulator check

Ventilation

Be attentive to

electric shock

Compulsion

Check after repair

Check after reinstallation

WARNING

Put on gloves

Cooling check

Be sure to put on the gloves (∗) and a long sleeved shirt:

otherwise an injury may be caused with the parts, etc.

(∗) Heavy gloves such as work gloves

When the power was turned on, start to work after the equipment has been

sufficiently cooled.

As temperature of the compressor pipes and others became high due to cooling/heating

operation, a burn may be caused.

CAUTION

– 7 –

• New Refrigerant (R410A)

This air conditioner adopts a new HFC type refrigerant (R410A) which does not deplete the ozone layer.

1. Safety Caution Concerned to New Refrigerant

The pressure of R410A is high 1.6 times of that of the former refrigerant (R22).

Accompanied with change of refrigerant, the refrigerating oil has been also changed.

Therefore, be sure that water, dust, the former refrigerant or the former refrigerating oil is not mixed into the

refrigerating cycle of the air conditioner with new refrigerant during installation work or service work.

If an incorrect work or incorrect service is performed, there is a possibility to cause a serious accident.

Use the tools and materials exclusive to R410A to purpose a safe work.

2. Cautions on Installation/Service

1) Do not mix the other refrigerant or refrigerating oil.

For the tools exclusive to R410A, shapes of all the joints including the service port differ from those of

the former refrigerant in order to prevent mixture of them.

2) As the use pressure of the new refrigerant is high, use material thickness of the pipe and tools which are

specified for R410A.

3) In the installation time, use clean pipe materials and work with great attention so that water and others do

not mix in because pipes are affected by impurities such as water, oxide scales, oil, etc.

Use the clean pipes.

Be sure to brazing with flowing nitrogen gas. (Never use gas other than nitrogen gas.)

4) For the earth protection, use a vacuum pump for air purge.

5) R410A refrigerant is azeotropic mixture type refrigerant.

Therefore use liquid type to charge the refrigerant. (If using gas for charging, composition of the

refrigerant changes and then characteristics of the air conditioner change.)

3. Pipe Materials

For the refrigerant pipes, copper pipe and joints are mainly used.

It is necessary to select the most appropriate pipes to conform to the standard.

Use clean material in which impurities adhere inside of pipe or joint to a minimum.

1) Copper pipe

<Piping>

The pipe thickness, flare finishing size, flare nut and others differ according to a refrigerant type.

When using a long copper pipe for R410A, it is recommended to select “Copper or copper-base pipe

without seam” and one with bonded oil amount 40mg/10m or less.

Also do not use crushed, deformed, discolored (especially inside) pipes.

(Impurities cause clogging of expansion valves and capillary tubes.)

<Flare nut>

Use the flare nuts which are attached to the air conditioner unit.

2) Joint

The flare joint and socket joint are used for joints of the copper pipe.

The joints are rarely used for installation of the air conditioner. However clear impurities when using them.

– 8 –

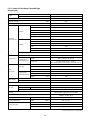

4. Tools

1. Required Tools for R410A

Mixing of different types of oil may cause a trouble such as generation of sludge, clogging of capillary,

etc. Accordingly, the tools to be used are classified into the following three types.

1) Tools exclusive for R410A (Those which cannot be used for conventional refrigerant (R22))

2) Tools exclusive for R410A, but can be also used for conventional refrigerant (R22)

3) Tools commonly used for R410A and for conventional refrigerant (R22)

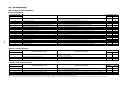

The table below shows the tools exclusive for R410A and their interchangeability.

Tools exclusive for R410A (The following tools for R410A are required.)

Tools whose specifications are changed for R410A and their interchangeability

(Note) When flaring is carried out for R410A using the conventional flare tools, adjustment of projection

margin is necessary. For this adjustment, a copper pipe gauge, etc. are necessary.

General tools (Conventional tools can be used.)

In addition to the above exclusive tools, the following equipments which serve also for R22 are necessary

as the general tools.

1) Vacuum pump. Use vacuum pump by

attaching vacuum pump adapter. 7) Screwdriver (+, –)

2) Torque wrench 8) Spanner or Monkey wrench

3) Pipe cutter 9) Hole core drill

4) Reamer 10) Hexagon wrench (Opposite side 4mm)

5) Pipe bender 11) Tape measure

6) Level vial 12) Metal saw

Also prepare the following equipments for other installation method and run check.

1) Clamp meter 3) Insulation resistance tester (Megger)

2) Thermometer 4) Electroscope

No.

Q

R

S

T

U

V

W

X

Y

Used tool

Flare tool

Copper pipe gauge for

adjusting projection margin

Torque wrench

Gauge manifold

Charge hose

Vacuum pump adapter

Electronic balance for

refrigerant charging

Refrigerant cylinder

Leakage detector

Usage

Pipe flaring

Flaring by conventional

flare tool

Tightening of flare nut

Evacuating, refrigerant

charge, run check, etc.

Vacuum evacuating

Refrigerant charge

Refrigerant charge

Gas leakage check

R410A

air conditioner installation

Existence of Whether conven-

new equipment tional equipment

for R410A can be used

Yes *(Note)

Yes *(Note)

Yes No

Yes No

Yes No

Yes Yes

Yes No

Yes No

Conventional air

conditioner installation

Whether conventional

equipment can be used

Yes

*(Note)

No

No

Yes

Yes

No

Yes

– 9 –

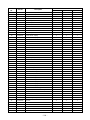

1. SPECIFICATIONS

1-1. Indoor Unit

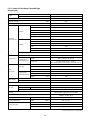

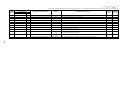

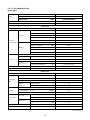

1-1-1. High Static Duct Type

<Single type>

∗ : IEC standard, ∗∗ : AS standard

Model

Indoor unit RAV-

Outdoor unit RAV-

Cooling capacity (kW)

Heating capacity (kW)

Power supply

Running current (A)

Power consumption (kW)

Cooling

Power factor (%)

EER

Energy efficiency class ∗

Electrical

Energy rating ∗∗

Running current (A)

characteristics

Power consumption (kW)

Heating

Power factor (%)

COP

Energy efficiency class ∗

Energy rating ∗∗

Maximum current (A)

Appearance Main unit

Outer

Height (mm)

Main unit Width (mm)

dimension

Depth (mm)

Total weight Main unit (kg)

Heat exchanger

Fan

Standard air flow at 100Pa/HH tap (m³/min.)

Fan unit

Fan speed

Motor (W)

External

Standard (at HH tap) (Pa)

static pressure

Range at HH tap (Pa)

Air filter

Controller (sold separately)

Sound pressure level H (dB•A)

Sound power level H (dB•A)

Gas side (mm)

Connecting pipe Liquid side (mm)

Drain port (mm)

SM1403DT-A SM1403DT-A SM1603DT-A

SM1403AT-E SP1404AT-E SM1603AT(Z)(ZG)-E

12.5 13.0 14.3

14.0 14.0 16.0

1 phase 240V, 50Hz

21.3 18.5 21.97

4.95 4.32 5.01

96.8 97.3 95

2.53 3.01 2.85

(E) (B) (C)

—

16.9 14.5 20.04

3.94 3.38 4.57

97.1 97.1 95.0

3.55 4.14 3.50

(B) (A) (B)

—

22.8 22.8 32.0

Zinc hot dipping steel plate

380

1050

600

57

Finned tube

Centrifugal fan

55 55 58

2

600

100

50 – 250

None (Arranged locally)

Remote controller

49 49 50

64 64 65

15.9

9.5

32 (VP25)

– 10 –

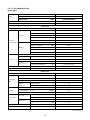

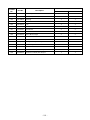

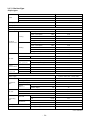

1-1-2. 4-way Air Discharge Cassette Type

<Single type>

Model

Indoor unit RAV-

Outdoor unit RAV-

Cooling capacity (kW)

Heating capacity (kW)

Power supply

Running current (A)

Power consumption (kW)

Cooling

Power factor (%)

EER

Energy efficiency class ∗

Electrical

Energy rating ∗∗

Running current (A)

characteristics

Power consumption (kW)

Heating

Power factor (%)

COP

Energy efficiency class ∗

Energy rating ∗∗

Maximum current (A)

Main unit

Model

Appearance

Ceiling panel

(Sold separately)

Panel color

Height (mm)

Main unit Width (mm)

Outer

Depth (mm)

dimension

Ceiling panel

Height (mm)

Width (mm)

(Sold separately)

Depth (mm)

Total weight

Main unit (kg)

Ceiling panel (Sold separately) (kg)

Heat exchanger

Fan

Fan unit Standard air flow H/M/L (m³/min.)

Motor (W)

Air filter

Controller (sold separately)

Sound pressure level H/M/L (dB•A)

Sound power level H/M/L (dB•A)

Gas side (mm)

Connecting pipe Liquid side (mm)

Drain port (mm)

SM1604UT-E

SM1603AT(Z)(ZG)-E

14.0

16.0

1 phase 230V (220 – 240V) 50Hz

21.38 – 19.69

4.49

95

3.12

(B)

—

21.20 – 19.43

4.43

95

3.61

(A)

—

29.7

Zinc hot dipping steel plate

RBC-U31PG (W, WS)-E,

RBC-U31PGS (W, WS)-E

W: Moon-white (2.5GY 9.0/0.5),

WS: Stripe-white (2.5GY 9.0/0.5 (Gray: 8B 3/0.3))

319

840

840

30

950

950

24

4.2

Finned tube

Turbo fan

35.5 / 25 / 21

72

Standard filter attached (Long life filter)

RBC-AMT32E, AMS41E,

AS21E2, AX31U (W)-E

45 / 40 / 36

60 / 55 / 51

15.9

9.5

32 (VP25)

∗ : IEC standard, ∗∗ : AS standard

– 11 –

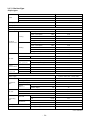

<Twin type>

Indoor unit 1 RAV- SM804UT-E

Model Indoor unit 2 RAV- SM804UT-E

Outdoor unit RAV- SM1603AT(Z)(ZG)-E

Cooling capacity (kW) 14.0

Heating capacity (kW) 16.0

Indoor unit

Power supply 1 phase 230V (220 – 240V) 50Hz

Running current (A) 21.48 – 19.69

Power consumption (kW) 4.49

Cooling Power factor (%) 95

EER 3.12

Electrical

Energy efficiency class ∗ (B)

characteristics

Running current (A) 21.20 – 19.43

Power consumption (kW) 4.43

Heating Power factor (%) 95

COP 3.61

Energy efficiency class ∗ (A)

Fan Turbo fan

Fan unit Standard air flow H/M/L (m³/min.) 20.5 / 16.0 / 13.5

Motor (W) 20

Sound pressure level H/M/L (dB•A) 35 / 31 / 28

Sound power level H/M/L (dB•A) 50 / 46 / 43

Outdoor unit

Power supply 1 phase 230V (220 – 240V) 50Hz

Standard length (m) 7.5

Refrigerant

Min. length (m) 5

Max. total length (m) 50

pipe

Height

Outdoor lower (m) 30

difference

Outdoor higher (m) 30

Fan Propeller fan

Fan unit Standard air flow volume (m³/min.) 103

Motor (W) 100 + 100

Gas side

Main (mm) 15.9

Connecting

Sub (mm) 15.9

pipe

Liquid side

Main (mm) 9.5

Sub (mm) 9.5

Sound pressure level Cooling/Heating (dB•A) 51 / 53

Sound power level Cooling/Heating (dB•A) 68 / 70

∗ : IEC standard

– 12 –

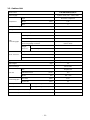

<Triple type>

Indoor unit 1 RAV- SM564UT-E

Model

Indoor unit 2 RAV- SM564UT-E

Indoor unit 3 RAV- SM564UT-E

Outdoor unit RAV- SM1603AT(Z)(ZG)-E

Cooling capacity (kW) 14.0

Heating capacity (kW) 16.0

Indoor unit

Power supply 1 phase 230V (220 – 240V) 50Hz

Running current (A) 21.48 – 19.69

Power consumption (kW) 4.49

Cooling Power factor (%) 95

EER 3.12

Electrical

Energy efficiency class ∗ (B)

characteristics

Running current (A) 21.20 – 19.43

Power consumption (kW) 4.43

Heating Power factor (%) 95

COP 3.61

Energy efficiency class ∗ (A)

Fan Turbo fan

Fan unit Standard air flow H/M/L (m³/min.) 17.5 / 14.5 / 13.0

Motor (W) 14

Sound pressure level H/M/L (dB•A) 32 / 29 / 28

Sound power level H/M/L (dB•A) 47 / 44 / 43

Outdoor unit

Power supply 1 phase 230V (220 – 240V) 50Hz

Standard length (m) 7.5

Refrigerant

Min. length (m) 5

Max. total length (m) 50

pipe

Height

Outdoor lower (m) 30

difference

Outdoor higher (m) 30

Fan Propeller fan

Fan unit Standard air flow volume (m³/min.) 103

Motor (W) 100 + 100

Gas side

Main (mm) 15.9

Connecting

Sub (mm) 12.7

pipe

Liquid side

Main (mm) 9.5

Sub (mm) 6.4

Sound pressure level Cooling/Heating (dB•A) 51 / 53

Sound power level Cooling/Heating (dB•A) 68 / 70

∗ : IEC standard

– 13 –

1-1-3. Concealed Duct Type

<Twin type>

Indoor unit 1 RAV- SM802BT-E

Model Indoor unit 2 RAV- SM802BT-E

Outdoor unit RAV- SM1603AT(Z)(ZG)-E

Cooling capacity (kW) 14.0

Heating capacity (kW) 16.0

Indoor unit

Power supply 1 phase 230V (220 – 240V) 50Hz

Running current (A) 24.50 – 22.46

Power consumption (kW) 5.12

Cooling Power factor (%) 95

EER 2.73

Electrical

Energy efficiency class ∗ —

characteristics

Running current (A) 22.44 – 20.57

Power consumption (kW) 4.69

Heating Power factor (%) 95

COP 3.41

Energy efficiency class ∗ —

Fan Centrifugal fan

Standard air flow H/M/L (m³/min.) 19.0 / 16.2 / 13.3

Fan unit Motor (W) 120

External

Standard (at shipment) (Pa) 40

static pressure

Set up for tap exchange (Pa) 20 / 40 / 70 / 100

Sound pressure level H/M/L (dB•A) 40 / 37 / 34

Sound power level H/M/L (dB•A) 55 / 52 / 49

Outdoor unit

Power supply 1 phase 230V (220 – 240V) 50Hz

Standard length (m) 7.5

Refrigerant

Min. length (m) 5

Max. total length (m) 50

pipe

Height

Outdoor lower (m) 30

difference

Outdoor higher (m) 30

Fan Propeller fan

Fan unit Standard air flow volume (m³/min.) 103

Motor (W) 100 + 100

Gas side

Main (mm) 15.9

Connecting

Sub (mm) 15.9

pipe

Liquid side

Main (mm) 9.5

Sub (mm) 9.5

Sound pressure level Cooling/Heating (dB•A) 51 / 53

Sound power level Cooling/Heating (dB•A) 68 / 70

∗ : IEC standard

– 14 –

<Triple type>

Indoor unit 1 RAV- SM562BT-E

Model

Indoor unit 2 RAV- SM562BT-E

Indoor unit 3 RAV- SM562BT-E

Outdoor unit RAV- SM1603AT(Z)(ZG)-E

Cooling capacity (kW) 14.0

Heating capacity (kW) 16.0

Indoor unit

Power supply 1 phase 230V (220 – 240V) 50Hz

Running current (A) 24.50 – 22.46

Power consumption (kW) 5.12

Cooling Power factor (%) 95

EER 2.73

Electrical

Energy efficiency class ∗ —

characteristics

Running current (A) 22.44 – 20.57

Power consumption (kW) 4.69

Heating Power factor (%) 95

COP 3.41

Energy efficiency class ∗ —

Fan Centrifugal fan

Standard air flow H/M/L (m³/min.) 13.0 / 11.9 / 9.8

Fan unit Motor (W) 120

External static pressure (Factory setting) (Pa) 40

External static pressure (Pa) 20 / 40 / 70 / 100

Sound pressure level H/M/L (dB•A) 40 / 37 / 33

Sound power level H/M/L (dB•A) 55 / 52 / 48

Outdoor unit

Power supply 1 phase 230V (220 – 240V) 50Hz

Standard length (m) 7.5

Refrigerant

Min. length (m) 5

Max. total length (m) 50

pipe

Height

Outdoor lower (m) 30

difference

Outdoor higher (m) 30

Fan Propeller fan

Fan unit Standard air flow volume (m³/min.) 103

Motor (W) 100 + 100

Gas side

Main (mm) 15.9

Connecting

Sub (mm) 12.7

pipe

Liquid side

Main (mm) 9.5

Sub (mm) 6.4

Sound pressure level Cooling/Heating (dB•A) 51 / 53

Sound power level Cooling/Heating (dB•A) 68 / 70

∗ : IEC standard

– 15 –

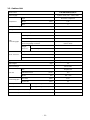

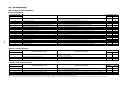

1-1-4. Under Ceiling Type

<Twin type>

Indoor unit 1 RAV- SM802CT-E

Model Indoor unit 2 RAV- SM802CT-E

Outdoor unit RAV- SM1603AT(Z)(ZG)-E

Cooling capacity (kW) 14.0

Heating capacity (kW) 16.0

Indoor unit

Power supply 1 phase 230V (220 – 240V) 50Hz

Running current (A) 23.88 – 21.89

Power consumption (kW) 4.99

Cooling Power factor (%) 95

EER 2.81

Electrical

Energy efficiency class ∗ —

characteristics

Running current (A) 22.44 – 20.57

Power consumption (kW) 4.69

Heating Power factor (%) 95

COP 3.41

Energy efficiency class ∗ —

Fan Centrifugal fan

Fan unit Standard air flow H/M/L (m³/min.) 18.5 / 16.7 / 14.6

Motor (W) 60

Sound pressure level H/M/L (dB•A) 38 / 36 / 33

Sound power level H/M/L (dB•A) 53 / 51 / 48

Outdoor unit

Power supply 1 phase 230V (220 – 240V) 50Hz

Standard length (m) 7.5

Refrigerant

Min. length (m) 5

Max. total length (m) 50

pipe

Height

Outdoor lower (m) 30

difference

Outdoor higher (m) 30

Fan Propeller fan

Fan unit Standard air flow volume (m³/min.) 103

Motor (W) 100 + 100

Gas side

Main (mm) 15.9

Connecting

Sub (mm) 15.9

pipe

Liquid side

Main (mm) 9.5

Sub (mm) 9.5

Sound pressure level Cooling/Heating (dB•A) 51 / 53

Sound power level Cooling/Heating (dB•A) 68 / 70

∗ : IEC standard

– 16 –

<Triple type>

Indoor unit 1 RAV- SM562CT-E

Model

Indoor unit 2 RAV- SM562CT-E

Indoor unit 3 RAV- SM562CT-E

Outdoor unit RAV- SM1603AT(Z)(ZG)-E

Cooling capacity (kW) 14.0

Heating capacity (kW) 16.0

Indoor unit

Power supply 1 phase 230V (220 – 240V) 50Hz

Running current (A) 23.88 – 21.89

Power consumption (kW) 4.99

Cooling Power factor (%) 95

EER 2.81

Electrical

Energy efficiency class ∗ —

characteristics

Running current (A) 22.44 – 20.57

Power consumption (kW) 4.69

Heating Power factor (%) 95

COP 3.41

Energy efficiency class ∗ —

Fan Centrifugal fan

Fan unit Standard air flow H/M/L (m³/min.) 13.0 / 11.2 / 10.0

Motor (W) 60

Sound pressure level H/M/L (dB•A) 36 / 33 / 30

Sound power level H/M/L (dB•A) 51 / 48 / 45

Outdoor unit

Power supply 1 phase 230V (220 – 240V) 50Hz

Standard length (m) 7.5

Refrigerant

Min. length (m) 5

Max. total length (m) 50

pipe

Height

Outdoor lower (m) 30

difference

Outdoor higher (m) 30

Fan Propeller fan

Fan unit Standard air flow volume (m³/min.) 103

Motor (W) 100 + 100

Gas side

Main (mm) 15.9

Connecting

Sub (mm) 12.7

pipe

Liquid side

Main (mm) 9.5

Sub (mm) 6.4

Sound pressure level Cooling/Heating (dB•A) 51 / 53

Sound power level Cooling/Heating (dB•A) 68 / 70

∗ : IEC standard

– 17 –

1-1-5. High Wall Type

<Twin type>

Indoor unit 1 RAV- SM802KRT-E

Model Indoor unit 2 RAV- SM802KRT-E

Outdoor unit RAV- SM1603AT(Z)(ZG)-E

Cooling capacity (kW) 14.0

Heating capacity (kW) 16.0

Indoor unit

Power supply 1 phase 230V (220 – 240V) 50Hz

Running current (A) 24.40 – 22.37

Power consumption (kW) 5.10

Cooling Power factor (%) 95

EER 2.75

Electrical

Energy efficiency class ∗ —

characteristics

Running current (A) 23.83 – 21.84

Power consumption (kW) 4.98

Heating Power factor (%) 95

COP 3.21

Energy efficiency class ∗ —

Fan Cross flow fan

Fan unit Standard air flow H/M/L (m³/min.) 18.5 / 14.6 / 12.2

Motor (W) 30

Sound pressure level H/M/L (dB•A) 45 / 41 / 36

Sound power level H/M/L (dB•A) 60 / 56 / 51

Outdoor unit

Power supply 1 phase 230V (220 – 240V) 50Hz

Standard length (m) 7.5

Refrigerant

Min. length (m) 5

Max. total length (m) 50

pipe

Height

Outdoor lower (m) 30

difference

Outdoor higher (m) 30

Fan Propeller fan

Fan unit Standard air flow volume (m³/min.) 103

Motor (W) 100 + 100

Gas side

Main (mm) 15.9

Connecting

Sub (mm) 15.9

pipe

Liquid side

Main (mm) 9.5

Sub (mm) 9.5

Sound pressure level Cooling/Heating (dB•A) 51 / 53

Sound power level Cooling/Heating (dB•A) 68 / 70

∗ : IEC standard

– 18 –

<Triple type>

Indoor unit 1 RAV- SM562KRT-E

Model

Indoor unit 2 RAV- SM562KRT-E

Indoor unit 3 RAV- SM562KRT-E

Outdoor unit RAV- SM1603AT(Z)(ZG)-E

Cooling capacity (kW) 14.0

Heating capacity (kW) 16.0

Indoor unit

Power supply 1 phase 230V (220 – 240V) 50Hz

Running current (A) 24.40 – 22.37

Power consumption (kW) 5.10

Cooling Power factor (%) 95

EER 2.75

Electrical

Energy efficiency class ∗ —

characteristics

Running current (A) 23.83 – 21.84

Power consumption (kW) 4.98

Heating Power factor (%) 95

COP 3.21

Energy efficiency class ∗ —

Fan Cross flow fan

Fan unit Standard air flow H/M/L (m³/min.) 14.0 / 12.5 / 10.7

Motor (W) 30

Sound pressure level H/M/L (dB•A) 39 / 36 / 33

Sound power level H/M/L (dB•A) 54 / 51 / 48

Outdoor unit

Power supply 1 phase 230V (220 – 240V) 50Hz

Standard length (m) 7.5

Refrigerant

Min. length (m) 5

Max. total length (m) 50

pipe

Height

Outdoor lower (m) 30

difference

Outdoor higher (m) 30

Fan Propeller fan

Fan unit Standard air flow volume (m³/min.) 103

Motor (W) 100 + 100

Gas side

Main (mm) 15.9

Connecting

Sub (mm) 12.7

pipe

Liquid side

Main (mm) 9.5

Sub (mm) 6.4

Sound pressure level Cooling/Heating (dB•A) 51 / 53

Sound power level Cooling/Heating (dB•A) 68 / 70

∗ : IEC standard

– 19 –

1-1-6. Compact 4-way Cassette (600 × 600) Type

<Triple type>

Indoor unit 1 RAV- SM562MUT-E

Model

Indoor unit 2 RAV- SM562MUT-E

Indoor unit 3 RAV- SM562MUT-E

Outdoor unit RAV- SM1603AT(Z)(ZG)-E

Cooling capacity (kW) 14.0

Heating capacity (kW) 16.0

Indoor unit

Power supply 1 phase 230V (220 – 240V) 50Hz

Running current (A) 23.88 – 21.89

Power consumption (kW) 4.99

Cooling Power factor (%) 95

EER 2.81

Electrical

Energy efficiency class ∗ —

characteristics

Running current (A) 22.44 – 20.57

Power consumption (kW) 4.69

Heating Power factor (%) 95

COP 3.41

Energy efficiency class ∗ —

Fan Turbo fan

Fan unit Standard air flow H/M/L (m³/min.) 13.3 / 11.2 / 9.1

Motor (W) 60

Sound pressure level H/M/L (dB•A) 43 / 39 / 34

Sound power level H/M/L (dB•A) 58 / 54 / 49

Outdoor unit

Power supply 1 phase 230V (220 – 240V) 50Hz

Standard length (m) 7.5

Refrigerant

Min. length (m) 5

Max. total length (m) 50

pipe

Height

Outdoor lower (m) 30

difference

Outdoor higher (m) 30

Fan Propeller fan

Fan unit Standard air flow volume (m³/min.) 103

Motor (W) 100 + 100

Gas side

Main (mm) 15.9

Connecting

Sub (mm) 12.7

pipe

Liquid side

Main (mm) 9.5

Sub (mm) 6.4

Sound pressure level Cooling/Heating (dB•A) 51 / 53

Sound power level Cooling/Heating (dB•A) 68 / 70

∗ : IEC standard

– 20 –

1-1-7. Slim Duct Type

<Triple type>

Indoor unit 1 RAV- SM564SDT-E

Model

Indoor unit 2 RAV- SM564SDT-E

Indoor unit 3 RAV- SM564SDT-E

Outdoor unit RAV- SM1603AT(Z)(ZG)-E

Cooling capacity (kW) 14.0

Heating capacity (kW) 16.0

Indoor unit

Power supply 1 phase 230V (220 – 240V) 50Hz

Running current (A) 23.88 – 21.89

Power consumption (kW) 4.99

Cooling Power factor (%) 95

EER 2.81

Electrical

Energy efficiency class ∗ —

characteristics

Running current (A) 22.44 – 20.57

Power consumption (kW) 4.69

Heating Power factor (%) 95

COP 3.41

Energy efficiency class ∗ —

Fan Centrifugal fan

Standard air flow H/M/L (m³/min.) 13.0 / 11.3 / 9.7

Fan unit Motor (W) 60

External

Standard (at shipment) (Pa) 10

static pressure

Set up for tap exchange (Pa) 10 / 20 / 35 / 50

Sound

Under air inlet H/M/L (dB•A) 45 / 40 / 36

pressure level

Back air inlet H/M/L (dB•A) 33 / 31 / 28

Sound

Under air inlet H/M/L (dB•A) 60 / 55 / 51

power level

Back air inlet H/M/L (dB•A) 48 / 46 / 43

Outdoor unit

Power supply 1 phase 230V (220 – 240V) 50Hz

Standard length (m) 7.5

Refrigerant

Min. length (m) 5

Max. total length (m) 50

pipe

Height

Outdoor lower (m) 30

difference

Outdoor higher (m) 30

Fan Propeller fan

Fan unit Standard air flow volume (m³/min.) 103

Motor (W) 100 + 100

Gas side

Main (mm) 15.9

Connecting

Sub (mm) 12.7

pipe

Liquid side

Main (mm) 9.5

Sub (mm) 6.4

Sound pressure level Cooling/Heating (dB•A) 51 / 53

Sound power level Cooling/Heating (dB•A) 68 / 70

∗ : IEC standard

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

-

113

113

-

114

114

-

115

115

-

116

116

-

117

117

-

118

118

-

119

119

-

120

120

-

121

121

-

122

122

-

123

123

-

124

124

-

125

125

-

126

126

-

127

127

-

128

128

-

129

129

-

130

130

-

131

131

-

132

132

-

133

133

-

134

134

-

135

135

-

136

136

-

137

137

-

138

138

-

139

139

-

140

140

-

141

141

-

142

142

-

143

143

-

144

144

-

145

145

-

146

146

-

147

147

-

148

148

-

149

149

-

150

150

-

151

151

-

152

152

-

153

153

-

154

154

-

155

155

-

156

156

-

157

157

Toshiba RAV-SM1603ATZ-E User manual

- Category

- Split-system air conditioners

- Type

- User manual

- This manual is also suitable for

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Toshiba RAV-SP454AT-E Owner's manual

-

Toshiba RAV-SM404SDT-E User manual

-

Toshiba RAV-SM1403UT-E User manual

-

Toshiba RAV-SM802AT-E User manual

-

Toshiba RBC-AMT32E Owner's manual

-

Toshiba RBC-AS41E Owner's manual

-

Toshiba RAV-SM1403AT-E1 User manual

-

Toshiba RAV-SM806KRT-TR User manual

-

Toshiba RAV-SM561AT-E User manual

-

Toshiba RAV-SM2802DT-E User manual

Other documents

-

Fujitsu UTY-RNBLU Installation guide

-

Sanyo DHX4852 Installation Instructions Manual

-

Sanyo 85464359981002 User manual

-

Balcar R410A User manual

Balcar R410A User manual

-

Fujitsu UTB-YCA Operating instructions

-

Hitachi RAS-11HNBRMQ1 Installation & Maintenance Manual

-

Chariot Carriers Merci Installation guide

-

Hitachi RAM-280FSPH Inverter Driven Multi-Split System Air Conditioner User manual

-

Bio Green Thermo 2 Installation and Operating Instruction

Bio Green Thermo 2 Installation and Operating Instruction

-

Hitachi RAS-10FSNMQ Installation & Maintenance Manual