2

Table of Contents

WARRANTY ............................................................................................................................................................................. 3

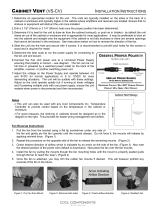

INSTALLATION ........................................................................................................................................................................ 4

Mechanical ........................................................................................................................................................................ 4

Service Clearance ..................................................................................................................................................... 4

Common Electric Heater Calculations ....................................................................................................................... 4

Applied vs Rated KW Factors .................................................................................................................................... 4

Curb and Ductwork ............................................................................................................................................................ 6

Roof Mount Installation .............................................................................................................................................. 7

Installation with Exhaust Fan ..................................................................................................................................... 7

Duct Mount Installation .............................................................................................................................................. 8

Indoor (Inline) Installation .......................................................................................................................................... 8

Heat Module Add-On Installation ............................................................................................................................... 9

ELECTRICAL .......................................................................................................................................................................... 10

Fan to Building Wiring Connection .................................................................................................................................. 12

Remote Control Panel ..................................................................................................................................................... 12

Electric Cabinet Heater ............................................................................................................................................ 13

AC Interlock ............................................................................................................................................................. 13

Motorized Intake Damper ........................................................................................................................................ 13

Permanent Split Capacitor (PSC) Motor Speed Control ................................................................................................. 13

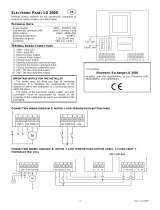

Electronically Commutated Motor (ECM) Speed Control ................................................................................................ 14

External PWM Signal ............................................................................................................................................... 14

Unit Mount Controller ...................................................................................................................................................... 14

Motor Speed Controller (MSC) Installation ...................................................................................................................... 15

MSC Controls Overview .................................................................................................................................................. 16

MSC Menu ............................................................................................................................................................... 16

Input Threshold ........................................................................................................................................................ 18

MSC Menu Tree ...................................................................................................................................................... 19

Heater Controller ..................................................................................................................................................... 20

Variable Frequency Drive (VFD) ..................................................................................................................................... 21

Variable Frequency Drive (VFD) Installation ........................................................................................................... 22

Input AC Power ........................................................................................................................................................ 22

VFD Output Power ................................................................................................................................................... 22

VFD Programming ................................................................................................................................................... 23

ACTECH SMV VFD ................................................................................................................................................. 24

START-UP OPERATION ........................................................................................................................................................ 25

Start-up Procedure .......................................................................................................................................................... 25

Pulley Adjustment ............................................................................................................................................................ 26

Pulley Alignment/Proper Belt Tension ............................................................................................................................. 27

Pulley Combination Chart ................................................................................................................................................ 28

Sequence of Operation ................................................................................................................................................... 29

Main Circuit .............................................................................................................................................................. 29

Optional Remote Panel Circuit ................................................................................................................................ 30

Silicon Controlled Rectifier (SCR) Electrical Control ....................................................................................................... 31

Modulating Coil Thermostat Settings .............................................................................................................................. 31

Thermostat with Dip Switch Settings ....................................................................................................................... 31

Thermostat without Dip Switch Settings .................................................................................................................. 31

SCR Electrical Circuit Check ........................................................................................................................................... 32

Components .................................................................................................................................................................... 33

Remote Panel Option .............................................................................................................................................. 34

Troubleshooting ............................................................................................................................................................... 35

MSC Troubleshooting .............................................................................................................................................. 37

MAINTENANCE ...................................................................................................................................................................... 38

General Maintenance ...................................................................................................................................................... 38

2 Weeks After Start-up .................................................................................................................................................... 38

Every 3 Months ............................................................................................................................................................... 38

Yearly .............................................................................................................................................................................. 38

Unit Filters ....................................................................................................................................................................... 39

Start-Up and Maintenance Documentation ..................................................................................................................... 40