Quadrafire DISCOVERY-I Installation guide

- Category

- Stoves

- Type

- Installation guide

This manual is also suitable for

Quadrafire DISCOVERY-I has an automatic combustion control (ACC) system that optimizes fuel burn, resulting in improved heating efficiency and reduced emissions. It is designed for use with solid wood fuel, generates heat output ranging from 12,000 to 44,000 BTU/hour, and has a large firebox with a 1.4 cubic feet capacity. The appliance is safety-oriented, with features such as a cool-touch glass door handle, warning labels, and a sturdy construction. It also offers customizable options, including decorative panels, and a blower for enhanced heat circulation.

Quadrafire DISCOVERY-I has an automatic combustion control (ACC) system that optimizes fuel burn, resulting in improved heating efficiency and reduced emissions. It is designed for use with solid wood fuel, generates heat output ranging from 12,000 to 44,000 BTU/hour, and has a large firebox with a 1.4 cubic feet capacity. The appliance is safety-oriented, with features such as a cool-touch glass door handle, warning labels, and a sturdy construction. It also offers customizable options, including decorative panels, and a blower for enhanced heat circulation.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

Quadrafire DISCOVERY-I Installation guide

- Category

- Stoves

- Type

- Installation guide

- This manual is also suitable for

Quadrafire DISCOVERY-I has an automatic combustion control (ACC) system that optimizes fuel burn, resulting in improved heating efficiency and reduced emissions. It is designed for use with solid wood fuel, generates heat output ranging from 12,000 to 44,000 BTU/hour, and has a large firebox with a 1.4 cubic feet capacity. The appliance is safety-oriented, with features such as a cool-touch glass door handle, warning labels, and a sturdy construction. It also offers customizable options, including decorative panels, and a blower for enhanced heat circulation.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Quadrafire 2100 Millennium Wood Stove Installation guide

Quadrafire 2100 Millennium Wood Stove Installation guide

-

Quadrafire Discovery I Wood Stove User manual

Quadrafire Discovery I Wood Stove User manual

-

Quadra-Fire EXPLRMED-PMH Installation guide

-

Quadrafire 2100 Millennium Wood Stove User manual

Quadrafire 2100 Millennium Wood Stove User manual

-

Quadrafire Discovery III Wood Stove Installation guide

Quadrafire Discovery III Wood Stove Installation guide

-

Quadrafire Discovery III Wood Stove User manual

Quadrafire Discovery III Wood Stove User manual

-

Quadrafire 3100 Millennium ACC Install Manual

Quadrafire 3100 Millennium ACC Install Manual

-

Quadrafire Discovery II Wood Stove Installation guide

-

Quadra-Fire 4300 Millennium Wood Stove Installation guide

-

Quadrafire 1200-I Pellet Insert Install Manual

Quadrafire 1200-I Pellet Insert Install Manual

Other documents

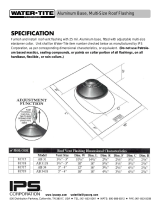

-

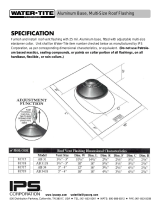

Water-Tite 81715 Operating instructions

Water-Tite 81715 Operating instructions

-

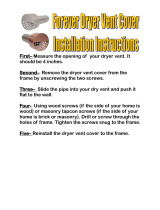

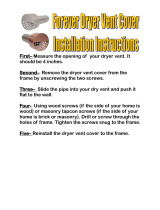

The Forever Cap FDVC4 Installation guide

The Forever Cap FDVC4 Installation guide

-

Design House 519579 Installation guide

-

Quadra-Fire 4300 Series Operating instructions

-

Quadra-Fire 4300 Series Operating instructions

-

Quadra-Fire 3100 Series Operating instructions

-

Quadra-Fire 3100 Series User manual

-

US Stove HS40DLTTT1 Installation guide

-

HY-C CBC1017 Installation guide

-

Quadra-Fire Discovery I Wood Stove Installation guide