SERVICE MANUAL

17K1E 17K2E

GENERAL INFORMATION

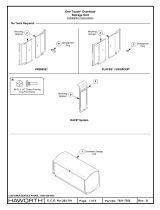

RECEIV ER MODEL, BREAKDOWN CHART

M odel

Type of R eceiver

17K1E

Console,

re d -brn m ahogany

17K1BE C onsole,

lim ed oak

17K2E C onsole,

red -b rn m ahogany

17K2BE

C onsole,

lim ed oak

C -

CHASSIS - T elevision ch assis TS-172 is built around a 17"

rectangular picture tube. The picture, sound,

and scanning circu its, together with a conven

tional transform er type "B " supply, are con

tained on a single ch assis.

TUNING RANGE - Channels 2 through 13

11, 12 & 13IF FREQ - Channels 2, 3, 4, 5, 6,

Sound: 21.9 me

P ictu re: 26 .4 me

Channels 7, 8, 9 & 10

Sound: 27.3 me

P ictu re: 22. 8 me

ANTENNA - T A -6 "B ilt-In -T en na". P rovision s for connec

tion of an external antenna.

ANTENNA IMPEDANCE - 300 ohm s

CHASSIS

TS-172

MODELS

I7K1E

17K1BE

I7K2E

17K2BE

POW ER SU PPLY - 117 volts, 60 cy cle AC curren t only

POW ER CONSUMPTION - 205 watts

AUDIO OUTPUT - 4 watts

CHASSIS TU BE CO M PLEM ENT -

Ref.

No.

Tube

Function

V -l

i

6CB6

RF A m p lifier

V -2 12AT7

M ix e r-O scilla tor

V -3

6AU 6/6AG 5

1st IF A m plifier

V -4

6AU 6/6AG 5 2nd IF Am p lifier

V -5

6 AG 5

3rd IF A m plifier .

V -6

6AL5 or

1N60 xtal

Video D etector

V - 7

6AH6 or

6C B6/6B C5 Video Am plifier

V -8

6AU 6/6A G 5

Audio D rive r-L im ite r

V -9

6AL5

Ratio D etector

V -10

6J5/G T

Audio A m plifier

V -ll

6V 6/G T

Audio Output

V -l 2

6SN7GT 1st & 2nd C lippers

V -l 3

12AU7 or

6SN7GT

V ertica l Sw eep Generator

V - 14

6W6GT or

6 AS 5

V ertica l Sweep Output

V - 1 5

6AL5 or

6H6

Phase D etector

V -16

6SN7GT

H orizontal O scilla tor

V - 1 7

6BQ6GT

H orizontal Output & High

Voltage G en erator

V -18

6W4GT

Dam ping Diode

V-19

1B3GT

High Voltage R ectifier

V -20

17BP4 or

17AP4

Pictu re Tube: rectan gular

V-21 5U4G

Low Voltage R ectifier

HIGH VOLTAGE WARNING

Operation of this re ce iv er, outside its cabinet or with

cov e rs rem oved, involves a sh ock hazard from the pow ef

su pplies. No w ork should be attempted on this re ceive r by

anyone not thoroughly fa m iliar with the precautions n e c e s

sary when working on high voltage equipm ent.

CATHODE RAY PICTURE TUBE HANDLING PRECAUTIONS

Extrem e care m ust be used in handling the picture tube*

The tube is highly evacuated and, due to its large size, is

subjected to a con sid erable atm osph eric p re ssu re. The

handler should wear safety goggles and gloves for p ro te c

tion. Avoid nicking or scratch ing the glass by rough contact

with other ob jects.

4545 AUGUSTA BOULEVARD

B efore rem oving glass tubes, disch arge the capacity

form ed by the inner and outer aquadag coatings on the tube

by shorting the anode contact on the side of the tube to the

outer surface with a w ell insulated piece of w ire.

CHICAGO 51, ILLINOIS

PART NO. 54P70217 4

Price 15 Cents

PRINTED IN U. S. A.

Scanned by mbear2k - Jan 2012

INSTALLATION AND OPERATING INSTRUCTIONS

RECE IVER LOCATIONS

The re ce iv er m ay be placed anywhere in the room , but

for greatest satisfaction it should be located.

1. Away from any bright light that m ay fa ll directly on the

screen or be reflected from it; this includes windows and

lam ps. Som e illum ination in the room , off to one side, is

d esirable, how ever, to prevent eye-stra in .

2. T o provide com fortable view ing and ease of operation .

3. At least on e-inch away from a wall to allow for cabinet

ventilation. This is very im portant.

ANTENNAS

The ch oice of television antenna depends entirely on the

location of the re ce iv e r with resp ect to all television station

transm itting antennas in the area. M aximum pick-up is ob

tained when the receivin g antenna is d irectly in line of sight

with the transm itting antenna.

"B ilt-In -T en n a". All re ceiv ers using theT S-172 series

television ch assis are equipped with the M otorola "B ilt-In -

Tenn a", m ounted inside the cabinet, for use in good signal

areas.

to receive stations on channels of w idely separated frequ en

cie s.

Location of the antenna should be decided from the stand

point of m aximum signal pick-u p . In gen era l, the antenna

should be broadside to the transm itting antenna and should

be as high as possible. If a r e fle ctor is used, the antenna

should be oriented so that the d river elem ent is closest to

the station and the reflector farthest away.

Locating the antenna and lead -in as far away as possible

from highw ays, h ospitals, d octors' o ffice s, ele ctrica l m a

chinery, etc. , w ill help to reduce noise pick-u p from such

sou rces. A lso, it is desirable to keep the antenna at least

six feet away from other antennas, m etal ro o fs, gutters, or

other m etal objects to prevent unwanted reflection s and

shielding.

Lead-In. Since the TS-172 ch assis is designed for 300

ohm input, the standard 300 ohm twin lead line should be

used for connecting the outside antenna to the re ce iv er.

Tw isting the line one com plete turn per foot of running length

helps to reduce noise pick -up on the line. The lea d-in

should be supported on stan d-off insu lators and kept tight

enough to prevent m ech anical dam age through swaying.

Avoid running the lea d -in clo se to m etal gutters, iron

standpipes, etc.

When this antenna is used, the follow ing precautions

should be observed for best reception :

1. In order to get m axim um perform ance and sa tisfa ctory

pictures from the "B ilt-In -T en na ", am ple signals from the

television station must be present at the loca tion of the r e

ce iv e rs. N orm ally, the strength of the signals w ill vary

throughout the room in which the receiv er is located. F or

this reason, better pictures w ill be obtained if the re ceiv er

is tried in all possible location s in the viewing room and is

then placed where the clea rest pictures are re ceiv ed from

all stations. A void large m etallic objects, such as radia

tors, m etal panels, etc.

2. L am ps, vases and m etallic ob jects, when placed on top

of the rece iv er, m ay affect the efficien cy of the "B ilt-In -

T enna".

Indoor Antenna. If additional pick -up is n ecessa ry, an

indoor antenna, placed on or near the re ce iv e r, m ay be

used. The antenna should be rotated and the arm s should

be adjusted for the best signal, with no ghosts or r e fle c

tions. N orm ally, the arm s should be extended on the low

channels (2 -6 ) and telescoped on the high channels (7-13).

Outdoor Antenna. The M otorola "B ilt-In -T en na " or the

indoor type antenna w ill give sa tisfactory reception in strong

signal areas; but, if the rece iv er is located in a fringe or

weak signal area, an outdoor antenna is recom m en ded.

In areas free of obstructions and reflection s, within re a

sonable proxim ity to television tran sm itters, a dipole and

re flecto r will prove sa tisfa ctory. Since such an antenna has

a rela tively sm all band cov era ge, a sp ecial antenna covering

all twelve television channels should be used if it is desired

In very strong signal area s, or w here sev ere local in

terferen ce is encountered, 300 ohm shielded twin lead is

recom m ended. The shield braid should be grounded.

An approved lightning arrestor should be used.

RECE IVER ANTENNA CONNECTION

The antenna lead -in to the television re ceive r is con

nected to the two screw s of the term inal strip on the rear

of the cabinet. D isconnect the "B ilt-In -T en n a " leads from

the term inal strip before attaching an external antenna lead -

in. Som etim es, rev ersin g the lead -in connections at the r e

ceiv er may im prove picture quality and o v erall perform an ce.

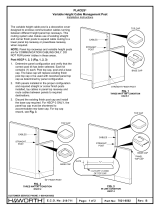

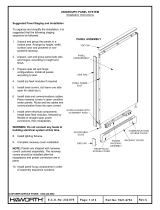

OPERATING CONTROLS

There are two dual con trols, consisting of a sm all and

a large knob each, on the front panel of the r e ce iv e r. See

Figure 1 for front panel control functions.

FIGURE I. OPERATING CONTROLS

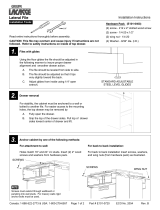

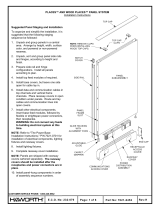

SERVICE ADJUSTMENTS

The receiv er is com pletely adjusted at the factory, so

norm ally none other than the front panel con trol operating

instructions need be follow ed inputting the re ceive r in op er

ation. H ow ever, to provide for any m isadjustm ent of the

service con trols, due to handling, the follow ing instructions

are in ord er. See Figure 2 for location of the s e rv ice ad

justm ent con trols.

2

Scanned by mbear2k - Jan 2012

FIGURE 2. SERVICE ADJUSTMENT CONTROLS

FOCUS CONTROL

The FOCUS con trol should be adjusted until the fine h or

izontal line stru ctu re of the raster is clea rly visible over

the picture area. The con trol should be turned through the

co rr e ct point several tim es so that optimum focu s is o b

tained.

CENTERING

By m eans of a lever extending from the focu s c o il, thru

the rear screen , the focu s co il can be shifted to center the

pictu re in its m ask.

VE R TIC AL SIZE AND VE R TIC A L LINEARITY

Adjust the VE R TIC AL SIZE control until the picture fills

the m ask vertica lly . A djust the V ERTICAL LINEARITY

con trol for best overall v ertica l linearity. Adjustm ent of

the VERTICAL SIZE con trol will requ ire a readjustm ent of

the VERTIC A L LIN EARITY con troland p o ss ib ly of the V ER

TICAL HOLD control. Center picture with the centering

lever on the focus coil.

HORIZONTAL SIZE

Adjust the HORIZONTAL SIZE lev er until the picture

fills the m ask h orizon tally. C enter picture with the cen

tering lev e r.

HORIZON TAL OSCILLATOR ADJUSTMENT

The H ORIZONTAL HOLD con trol should have a sync

range of approxim ately 180 d egrees. If the control is too

critica l, adjust as follow s:

1. Short out HORIZON TAL OSCILLATO R co il L -2 3. This

m aybe done with the ch assis in the cabinet by shorting pins

3 & 8 of the test sock et on ch assis rear.

2. With the centering le v er, m ove the picture to the left so

that the right edge of the raster can be seen. Adjust the

HORIZONTAL HOLD control to about the m iddle of its range

andnote the width of the blanking pulse. (The blanking pulse

appears as a gray bar at the right edge of the pictu re).

3. R em ove short from HORIZON TAL O SCILLA TO R co il.

4. Adjust HORIZO N TAL OSCILLATOR co il until the sam e

amount of blanking pulse can be seen as was noted in step 2.

VER TIC A L HOLD ADJUSTM ENT

Adjust the V ERTIC A L HOLD con trol for the center of

the v ertica l sync lock -in range.

BRIGHTNESS

Adjust the BRIGHTNESS con trol, in com bination with

the CONTRAST con trol for the m ost pleasing pictu re. K eep

the brilliance slightly below m axim um , how ever, in ord er

to protect the flu orescen t screen of the picture tube and to

prevent poor picture detail.

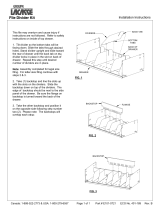

ADJUSTM ENT OF ION T RA P

Under conditions of rough shipm ent, it is possib le for

the ion trap to becom e m isaligned. To prevent serious dam

age to the picture tube, the follow ing m ethod of adjustm ent

should be used. See F igu re 3.

The m agnet should be placed on the neck of the tube in

the direction indicated by the m arking on the magnet (usu

ally an arrow which points tow ard the picture tube screen)

so that the stron ger magnet of the double m agnet type or the

only magnet in the single m agnet type is positioned over the

internal pole p ieces which are mounted on the gun structu re.

Adjust the BRIGHTNESS control for low intensity and m ove

the m agnet a short distance forw ard and backward at the

sam e tim e rotating it to obtain the brightest raster. If, in

obtaining the brightest raster, the ion trap magnet has to be

m oved m ore than 1/4 " from the gun pole p ieces the m agnet

is probably weak and a new m agnet should be tried. N ever

co rrec t for a shadowed ra ster with the ion trap magnet if

3

Scanned by mbear2k - Jan 2012

FIGURE 3. PICTURE TUBE ADJUSTMENT LOCATIONS

such co rrection results in d ecrea sed brightness. The ion

trap magnet must always be adjusted for m aximum brigh t

ness and if shadows occu r at this setting they should be

elim inated by adjusting the focus and deflection co ils as ex

plained under "F ocu s C oil and D eflection Yoke A djustm ent1'.

CAUTION: Keep BRIGHTNESS con trol at low intensity

until ion trap is p rop erly set.

A m irror placed in front of the receiv er w ill aid in m ak

ing this adjustm ent.

DEFLECTION YOKE ADJUSTMENT

If the deflection yoke sh ifts, the picture w ill be tilted.

To c orr e ct, loosen the thum bscrew on top of the deflection

yoke and rotate yoke until the picture is straight. B efore

tightening the thum bscrew , m ake certain that the d eflection

yoke is as far forw ard as possib le.

If the yoke support and the picture tube have shifted in

transit, or if fo r any reason these parts have been rem oved

and replaced, it is best to do a com plete job of reposition

ing. See Figure 3. The starting point is the position of the

picture tube. It should be adjusted so that the distance from

the center of the tube face to the front edge of the ch assis is

1-1/16". The clam p on the front of the tube should then be

tightened. The picture tube rear support bracket position

ing adjustm ent screw s should be loose enough to perm it

sliding the brack et forw ard until the rubber cushion fits

snugly up against the flare of the tube. L oosen the yoke ad

justm ent thum bscrew and push the yoke up against the flare

of the tube. CAUTION: Do not use force in sliding the

brack et up. If to much force is used, a strain w ill be

placed on the neck of the tube when the support bracket

positioning adjustment screw s are tightened. A lso the yoke

m ay be force d out of position. The opening in the yoke

should be con cen tric with the neck of the tube.

FOCUS COIL

The focu s co il should be positioned so that it is spaced

l / 4 " from the d eflection yoke when parallel with the yoke.

The opening in the focu s c o il should be con centric with the

neck of the tube. The spacing should be adjusted before the

front of the picture tube is clam ped down because it is n ece s

sa ry to rem ove the tube to change the position of the focus

co il. Its position is changed by ch oice of location of the co il

mounting studs in the scallop ed holes on the top and bottom

of the co il m ounting bracket. The opening in the focus co il

can be made con cen tric with the neck of the tube by lo osen

ing the nuts on the studs which support the focus co il b r a ck

et and turning the studs with a screw driver in the slots p ro

vided. The studs are eccen tric and m ove the coil both v e r

tically and horizontally. They should be used only to center

the neck of the tube in the opening of the co il.

TEST SOCKET

A test socket is provided on the rear of the ch assis

which allow s adjustm ent of the h orizontal oscillato r and

checking of sen sitivity without rem oving ch a ssis from ca b i

net. See F igu re 2 for socket conn ection s.

ALIGNMENT

g e n e r a l

The ch assis should be mounted on angle iron brackets

(M otorola Part Num ber 7X700210) so that all conn ections

and adjustm ents m ay be made easily.

Since the power cord circu it is broken by the interlock

when the cabinet back is rem oved, it w ill be n e cessa ry to

obtain an extra pow er cord with the fem ale interlock r e ce p

tacle in order to make a pow er con n ection to the receiv er.

O rder M otorola P art No. 30B470756.

4

Scanned by mbear2k - Jan 2012

A com plete re ceiv er alignm ent can be m ost conveniently

perform ed in the follow ing ord er:

1. Audio T ake-O ff & Ratio D etector

2. 4. 5 Me Trap

3. IF C oils & M ixer T ra n sform er

ORDER OF ALIGNMENT

3. F rom either side of capacitor C -52 , connect an e le c

tronic voltm eter to ch assis decoupled thru 10K ohm s.

4. Set the contrast control for m aximum gain (fully clo ck

w ise).

5. Peak L -20 for m aximum reading on m eter.

6. Peak T -3 prim ary (top co re ) for m aximum reading on

m eter.

4. O sc & RF Sections

7. M ove the m eter and decoupling re s isto r from C-52 to

junction of R-41 and lead to volum e control.

AUDIO TA K E -O FF & RATIO DETECTOR ALIGNMENT

Equipment Required:

AM Signal G enerator: A ccu ra tely calibrated at 4. 5 me

(Optional) Adjustable output

DC M eter: Low range electron ic voltm eter

R efer to F igure 4 for location of adjustm ents.

1. If possible it is d esirable to align the audio section from

an actual station signal, since the 4. 5 me alignm ent fr e

quency will be exact. The fine tuning trim m er should be

turned of the station slightly, to prevent overloading the

ratio detector.

2. If a signal generator is used, tune it accu rately to 4. 5

me and adjust the output to approxim ately 10,000 m icr o

volts. Connect the high side of the signal generator through

a 1000 m m f ca p acitor to the grid (pin 1) of the video am p li

fier tube V -7 , and the low side to ch a ssis. The follow ing

applies whether the. station signal or signal generator is

used.

8. Adjust T -3 secondary (bottom core ) for zero resp on se

on the low est scale of the m eter. This corresp on ds to the

cr o ss -o v e r point on the FM detector cu rve. If desired , the

sym m etry of the curve m ay be checked by tuning the g e n er

ator ± 2 5 kc fro m 4. 5 m e and noting the voltage produced,

rev ersin g the m eter conn ections as n ecessa ry. F or proper

balance of the ratio d etector system , the voltage in each d i

rection should be approxim ately equal. If not, ch eck the

tuning of L -20 and the prim ary & secondary of T -3 , the

ratio d etector. If nece ssa ry, replace the ratio detector tube

V -9 (6AL 5). The generator m ay be calibrated by tuning the

secondary of T -3 to zero on a station signal and tuning the

generator to the sam e zero resp on se, noting whether it in

dicates 4. 5 m e.

NOTE: As the adjustm ents are brought to reson a n ce, it is

advisable to reduce the signal generator output to prevent

overloading.

With a 10,000 m icrovolt signal fed into the grid of the

video am plifier tube, and the contrast control turned fully

clock w ise, the voltage read from one side of capacitor C -52

to chassis should be greater than 5. 0V.

NO. TYPE

FUNCTION

V-l

6C86

R-F AMP.

V-2

I2AT7

MIXER-OSC.

V-3

6AU6/6AG5

1 ST. IF AMP.

V-4

6AU6/6AG5

2 ND. IF AMP,

V 5

6AG5

3 RD. IF AMP

V 6

6AL5 VIDEO DET.

V-7

6AH6/6CB6

VIDEO AMP.

V-8

6AU6/6AG5

AUDIO DRIVER LIMITER

V-9

6AL5

RATIO DET.

V-IO 6J5GT

AUDIO AMP.

V-ll

6V6GT

AUDIO OUTPUT

V-12 6SN7GT

1 ST. a 2ND. CLIPPER

V-13 I2AU7/6SN7GT

VERT SWEEP GEN.

V-l 4 6W6GT/6AS5

VERT. SWEEP OUTPUT

V-15

6AL5/6H6

PHASE DET.

V-16 6SN7GT

HORIZ. OSC.

V-17 6B06GT

HORiZ. OUTPUT a H.V. GEN.

V-18

6W4GT

DAMPING DIODE

V-19 IB3GT H.V. RECT.

V-2!

5U4G

L.V. RECT.

*1N60 CRYSTAL USED IN PLACE OF V-6 IN SOME SETS.

-FINE TUNING

-CHANNEL SELECTOR

POWER SWITCH a

VOLUME

^ ANTENNA

INPUT

©

C-6

R'F

TRIMMER

©

MIXER l-F

C&(PRI - TOP)

v>l2 (SEC-BOT)

sosc

TOP VIEW

OF CHASSIS

©

-L-I5

L -l l (TOP) L-I2 (BOT.)

(TOP) L-I4 (BOT)

Cgp2ND. I-F LOW TRAP

©

RATIO

0ET ( O )

(PRI. T 0 P )V V

fSFr. arm

• V -|9|

l I

r1-------

L-'8 jx, L-20

4.5 MCHjP S!P s ound t a k e - o ff

TRAP

“ S ? - ! f v -16

^is)

T-8

GET NO 69C70I993-0

FIGURE 4. TUBE AND ALIGNMENT ADJUSTMENT LOCATIONS

Scanned by mbear2k - Jan 2012

1. Connect the high side of the signal gen erator thru a 1000

m mf cap acitor to the grid (pin 1) of the video am plifier tube

V -7, and the low side to ch a ssis.

2. Connect the voltm eter and germ anium crysta l re ctifier,

as shown in Figure 5, between the cathode of the picture

tube (yellow lead) and ch a ssis. Use the low est voltage scale

on the m eter.

4. 5 MC TRAP ALIGNMENT

to ch assis. Set the center frequ ency of the sw eep to about

24. 6 me and adjust initially for a sw eep deviation of ap

proxim ately 12 m e. H ow ever, a sw eep of from 8 to 10 me

may be found better for o v era ll alignm ent.

4. Using R -26 (100K) as a decoupling re sisto r, connect the

scope to pin 4 of test socket and ch assis. If a stronger out

put is required, connect the scope between the picture tube

cathode and ch assis. The cu rve seen at this position w ill be

the rev erse of the polarity shown in Figu re 6.

3. With the signal generator accurately set at 4. 5 me and

m aximum output, adjust trap L.-18 for m inimum reading on

the m eter.

IF AM PLIF IE R ALIGNMENT

5. Set the contrast con trol at m inimum .

NOTE: If a distorted or unstable picture is seen on the o s

cillo scop e during alignm ent, it may be n ece ssa ry to stop the

oscilla to r by discon n ecting re sisto r R -9 (1500) from the

plate (pin 6) of the oscilla to r tube V -2B (12A T7), or by sub

stituting another tube with pin 6 rem oved.

Equipment R equired:

CAUTION:

IF Sweep G enerator m eeting the follow in g requirem ents:

18 to 30 m e, approxim ately 12 m e sw eep width. Output

constant and adjustable to at least . 1 volt m aximum

with accu rately calibrated, adjustable m arkers.

Cathode Ray O scillosco p e: preferably one with a c a li

brated input attenuator.

NOTE: If there is no bu ilt-in m arker in the sw eep gen era

tor, loo se ly couple the output of an accurately calibrated

AM signal generator to the IF strip. At all tim es, keep the

m arker output low enough to prevent the m arker from d is

torting the response cu rve.

A. Do not reduce the os c illosco p e gain and in crea se signal

input so that the top of the curve is flattened, due to lim it

ing in the video or scope a m p lifiers.

B. The d ress of plate & grid com ponents in the IF a ffects

tuning. Do not m ove in d iscrim in a tely.

C. On the IF coils and on the traps, the resonance point

w ill be found at two settings of the slug. The c or r e c t setting

is the one which is found with the greater part of the adjust

ing screw out of the co il.

NOTE: The 1st & 2nd IF traps are tuned from bottom of

ch assis while IF co re s are adjusted from the top.

If a wide band scope is used, the m arker w ill be m ore

distinct if a capacitor of 100 to 1000 m m f is placed a cross

the scop e input. Use the sm allest size p ossible, since too

large a value w ill affect the shape of the curve.

1. R em ove the high voltage generator tube V-17 (6BQ6GT)

from its socket to elim inate horizontal pick-up in the o s c il

loscop e. Replace 6BQ6 with 2500 ohm 25 watt resisto r con

nected from B plus side of fuse to ch assis.

2. By m eans of an external battery, apply a negative 3. 0

volt bias from the bottom of the 1st IF tube grid co il dam p

ing re sisto r, R-13, to ch assis.

3. Using leads as short as p ossib le , connect the hot side of

the sw eep generator to the grid (pin 1) of the 1st IF tube V -3

through a 5000 m m f cap acitor (do not use the loose or

"sp rayin g" m ethod of coupling). The low side is connected

6. Tune the low frequ ency trap L-14 located on the 2nd IF

coil for m axim um attenuation on the curve at 21.9 m e,

DIAG. NO 63A791272-0

DC PROBE 220K

H I

I00MMF

it 22UK

3—a v v w —< >—9 i ——►

1 N 34

220K

B - B -

FIGURE 5. ELECTRONIC VOLTMETER CONNECTIONS

21.9

27.3

21.9

27.3

FIGURE 6. IF RESPONSE CURVE

FIGURE 7. OVERALL RESPONSE CURVE FROM MIXER

6

Scanned by mbear2k - Jan 2012

7. Tune the high frequen cy trap L-12 located on the 1st IF

co il for m aximum attenuation on the curve at 27. 3 m e.

8. Adjust the 1st IF co il, L - ll , to place a 26 .6 m e m arker

on the high side of the response curve 60% down from m ax

im um respon se. See Figure 6.

9. Adjust the 2nd IF coil, L -15, to place a 22. 7 me m arker

on the low side of the respon se curve 6 0 down from m axi

mum respon se.

10. Adjust the 3rd IF plate transform er T -2 to provide a

flat top or sym m etrica l response curve.

11. R eset the traps (steps 6 and 7) and again check the IF

for prop er resp on se.

NOTE: It is suggested that the bias be rem oved for accurate

setting of the traps.

12. With bias applied, connect the sw eep between the grid

(pin 2) of the m ixer tube V -2A (12AT7) and chassis.

13. D isconnect the trim m er, C -14, in LC circu it in the

grid of the m ixer tube, or short the trim m er thru a 10,000

m m f cera m ic disc type to chassis.

14. B ring both co re s of the m ixer tra n sform er, T -l, s i

m ultaneously from the outside tow ards the center. The

half-w ay m arkers should be 26.4 me and 22 .9 m e.

NOTE: In aligning the three IF co ils, each coil is adjusted

individually, but when adjusting the p rim ary and secondary

of the m ixer tran sform er, the adjustm ents should be made

sim ultaneously. The important point to keep in mind is to

obtain a flat response curve with as m uch gain as possible.

The sides of the curve should be straight and as steep as

possible. Simultaneous adjusting of the prim a ry and s e c

ondary is the easiest way to obtain this result. The tran s

form er by itself is, in effect, tuned for the sam e pass band

as the three staggered circu its. See F igure 7. The only

difference in the ov erall w aveform should be that the sides

of the overall wave are steeper. Constant use of the 50%

m arkers (22. 9 me and 26. 4 me) should be resorted to,

since it is absolutely n ecessa ry to obtain the prop er curve.

A slight dip (not exceeding 10%) is p erm issib le in the m ixer

transform er response cu rve.

BANDWIDTH

The bandwidth may be determ ined by connecting an AM

generator to the m ixer grid. With the generator frequency

at 24. 6 m e, adjust the output for 1 volt reading on a VTVM

connected to pin 4 of test socket and ch a ssis. Double the

output of the generator. Now by tuning either side of 24. 6

me and noting the frequ encies at which the VTVM again

reads 1 volt, the 6 db bandwidth points are indicated. These

points should be 22.9 m e and 26. 4 m e. By watching the

m eter while tuning slow ly thru the band any serious peaks

or holes in the respon se can also be detected.

REGENERATION CHECK

After the above IF and m ixer transform er alignm ent has

been m ade, a check for regeneration in the IF am plifier

strip should be m ade. This is done by rem oving the battery

bias and observin g the output response curve on the o sc illo

scop e, as taken between the picture tube cathode and ch a s

sis. The bandwidth m ay change with the bias rem oved but

should not change m ore than 0. 2 m e. Set the contrast co n

trol to m aximum gain. D ecrease the input until the output

signal show s a m arked de crea se. Any regen eration present

w ill be indicated by sharp peaks on the o v erall resp onse

curve. The oscillator should be stopped, as d escrib ed

above, during this procedu re.

CAUTION: Do not inject too m uch m arker signal.

MIXER LC ADJUSTMENT

Reconnect bias rem oved for regeneration check. R e

place trim m er C-14 in LC circu it of m ixer grid or rem ove

10, 000 m m f cera m ic between trim m er and ch a ssis. Adjust

the trim m er so it is tuned to the center of the m ixer r e

sponse curve. This is indicated by observing the effect of

the LC circu it on the m ixer response. In creasing the c a

pacity of the trim m er and bringing the LC circu it from

above the IF range into the IF range, it w ill be noted that

the m ixer curve w ill pull down on the high side, straighten

out as the LC circu it approaches the m iddle of the range,

and pull down on the low side as the LC circu it approaches

the low end of IF range. The proper tuning point is that

point at which the m ixer curve straightens out. In effect,

the LC circu it is sim ilar to a ja ck co il when it is within the

IF range.

CAUTION: Tuning the LC circu it v e ry low wil cause

oscilla tion.

IF SENSITIVITY MEASUREMENTS

IF Stages Only

1. Rem ove the battery bias fro m 1st IF tube grid.

2. C onnect an AM signal generator, set at 24. 6 m e, thru

a blocking cap acitor of 5000 m m f, between ch a ssis and the

gr.d (pin 1) of the 1st IF tube V -3.

3. Connect an electro n ic voltm eter a cross the video d etec

tor load re sisto r R -28 (5600). Both leads fro m the m eter

should be decou pled with 100K ohm resisto rs.

4. 5iet the contrast control for m aximum sensitivity.

5. Stop the oscillato r tube by discon necting resisto r R -9

(1500) from the plate (pin 6) of tubeV -2 B (12AT7) or by su b

stituting another tube with pin 6 rem oved.

6. The signal requ ired to produce 1 volt (negative) above

contact potential on the m eter should be less than 700 m ic r o

volts.

M ixer & IF Stages

The prelim inary preparations are the sam e as for ch eck

ing the sensitivity of the IF stages except:

1. Connect the AM signal generator, set at 24. 6 m e, thru

a 5000 m m f capacitor, between ch a ssis and the grid (pin 2)

ri the m ixer tube V -2A (12AT7).

2. The signal required to produce 1 volt (negative) above

contact potential on the m eter should be less than 125 m ic ro

volts.

OSCILLATO R, ANTENNA AND RF ALIGNMENT

NOTE: The IF must be aligned before the RF section can

be p rop erly phased.

Equipment Required:

Sweep G en erator: Frequen cy range 40-220 m e; 10 me sw eep

7

Scanned by mbear2k - Jan 2012

width

Output constant and adjustable

Adjustable m arkers (m ark ers should be

calibrated occasio n ally by checking

against an accurate signal generator)

O scilloscop e : P referably one with a calibrated input atten

uator.

Signal G enerator: F requen cy Range 40 to 220 me

A ccu rately calibrated

AM m odulated, 400 cycle

FREQUENCY CHART

Chan

F requency

Picture

Sound

O scillator

2

54-60

55. 25 59. 75

81.65

3

60-66

61. 25

65. 75

87.65

4 66-72

67. 25

71. 75

93. 65

5

76-82

77. 25

81. 75

103.65

6

82-88

83. 25

87. 75

109.65

7

174-180 175. 25 179.75

152.45

8

180-186

181.25

185. 75

158.45

9

186-192

187. 25

191.75

164.45

10

192-198

193.25

197. 75

170.45

11

198-204

199.25

203.75 225.65

12

204-210 205. 25 209.75

231.65

13

210-216

211.25

215. 75

237. 65

ANTENNA & RF ALIGNMENT PROCEDURE

1. R em ove high voltage generator tubeV -17 (6BQ 6GT) from

its socket and substitute a 2500 ohm 25 watt resistor co n

nected from the B plus side of the fuse to ch a ssis. Stop the

oscilla tor by disconnecting R -9 (1500) from plate (pin 6) of

V -2B (12AT7).

2. Connect the sw eep generator across the antenna term i

nals on the ch assis with the antenna le a d -in rem oved. The

line fro m the sw eep generator should be as short as p o s si

ble.

3. Connect the oscillo scop e through a decoupling resisto r

of 150,000 ohm s, between the cathode (pin 3) of the m ixer

tube V -2 (12AT7) and chassis.

4. Short out the AGC circu it with a clip lead from the AGC

bus to ch assis.

5. R efer to F igure 4 for the RF trim m er location and to

Figu re 8 for the locations of the antenna and RF co ils. The

frequency chart listed previou sly gives the channel and

alignm ent frequ en cies.

6. The antenna coils are tuned to the video ca rrie r fr e

quency and the RF co ils are tuned to the sound ca rrie r s.

Figu re 9 shows the shape of the curve which should appear

on the scope for channels 2-6 and Figure 10 the curves for

channels 7-10 and 11-13.

7. Turn the station selector switch to channel 10. Set the

center frequ en cy of the sweep generator to the cen ter fr e

quency of channel 10 (195 m e).

8. A djust cera m ic trim m er, C -6 , so that picture and sound

m arkers are as in Figure 11.

9. Check channels 7 to 13 for prop er response and, if n ec e s

sary, tune the co ilL -6 . These co ils may be tuned by spread -

ingthem to decrea se inductance or com p ressing them to in

crea se their inductance. See Figure 8 for location of coils .

This w ill have m ore e ffect on channels 10 to 13 than'7 to 9.

If L -6 is adjusted, it m ay be n ece ssa ry to readjust RF trim

m er C -6 and rech eck the high channels.

10. M ove bandswitch to channel 6.

11. With center frequen cy of sw eep generator at the center

frequ ency of channel 6 (85 m e) introduce m arkers c o rr e s

ponding to sound and picture c a rriers and com pare with

curve of Figure 9.

NOTE: A convenient m ethod of determ ining whether a co il

is tuned co rrec tly is to insert a brass or iron slug into the

co il. B rass d ecre a se s and iron increases the inductance.

12. After channel 6 has been aligned, p rog ress downward

through channel 2.

CAUTION: Make certain the station selector sw itch is

on the c o rr e ct channel before checking band pass.

OSCILLATOR ADJUSTM ENT

1. Put oscilla tor back in circu it.

2. R em ove the short from the AGC circu it and apply a -3

volt battery bias to the AGC bus.

3. Move the scop e to the test socket on the ch assis rear

with the high side connected to pin 4 and the low side to

ch a ssis.

4. Set the con trast con trol at m inim um (cou n terclock w ise).

5. R em ove the fine tuning knob and turn shaft until the slot

is in a horizontal position. This rep resen ts the m id -cap acity

position.

6. Turn station selector sw itch to channel 12.

7. Set the sw eep generator on channel 12 with a center fr e

quency of 207 m e and at least a 12 me sw eep. K eep the out

put low enough to show no evidence of lim iting in the overall

response cu rve.

NOTE: B efore aligning the oscilla tor section , make certain

that L -8 (3. 3 m icroh e n ries) in the m ixer grid is d ressed

away from C-16 (2 m m f) tied to the sam e grid.

8. Introduce a m arker corresp ond in g to the sound ca rrier

of channel 12 (209. 75 m e).

9. Adjust C-12 o scilla tor cera m ic trim m er so that the

sound m arker fa lls into the 21.9 me trap dip in the response

cu rve.

10. Turn generator and station se lector to channel 9 with

the fine tuning shaft slot still in the h orizontal position.

11. Spread or co m p ress the 3 -turn coil located in the ce n

ter of the o scilla tor plate (L -4M , Figu re 8) so that the sound

m ark er for channel 9 falls into the 27. 3 m e trap dip in the

response cu rve. As the oscilla tor is tunedbelow the ca rrie r

on channels 7, 8, 9, 10, the 27. 3 me trap w ill be in the sam e

position as the 21. 9 m e trap in step 9.

12. Repeat steps 6, 7, 8 & 9.

13. Turn generator and station se lector to channel 13.

14. Turn fine tuning trim m er so that the sound m arker for

channel 13 falls into the 21. 9 me trap dip of respon se cu rve.

The slot in the fine tuning shaft should not have m oved m ore

than 30 degrees from the horizon tal position to accom p lish

Scanned by mbear2k - Jan 2012

this (each number on the station selector knob represen ts

30 d e gr e e s .)

15. If m ore than a 30 degree change in fine tuning trim m er

was needed in step 14, adjust channel 13 oscillator c o il

(L -7 ) by spreading or com p ressing until the 30 degree r e

quirem ent is m et.

NOTE: Each adjustment of channel 13 oscillator coil will

necessitate a re-ch eck in g of the oscilla tor trim m er C-12

on channel 12 as per steps 6, 7, 8 & 9.

16. Check channels 12, 11, 10, 9, 8, and 7 by noting whether

the fine tuning trim m er can drop the sound m arker for each

channel in the trap dip by a 30 degree rotation. If one of the

channels does not m eet the 30 degree requirem ent, a co m

prom ise m ust be made by resetting channel 9 or 12, w hich

ever is clo ser to the channel in question.

Exam ples:

1. If channel 11 does not m eet the 30 degree re q u ire

m ent, return station selector and generator to chan

nel 12 and tune cera m ic trim m er C-12 toward chan

nel 11 (trim m er frequ encies low ered by tightening

screw ). This w ill tend to m ove channel 12 sound

m ark er out of the trap dip, but this can be com pen

sated for by the fine tuning trim m er. Do not adjust

trim m er any m ore then is necessa ry to get the chan

nel in question back within the 30 d egree req u ire

ment.

2. If channel 10 does not m eet the 30 degree re q uire

ment, m ove station selector and generator to chan

nel 9 and tune the 3-turn co il (L -4 M , F igu re 8)

toward channel 10 (c o il freq raised by spreading

turns). This w ill also tend to m ove channel 9 sound

m arker out of the trap dip, but this can be com pen

sated for by the fine tuning trim m er. A gain, do not

adjust the coil any m ore than is n ecessa ry to bring

the channel in question back within the 30 d egree r e

qu irem ent.

17. Tilrn sw eep generator and station s e lector switch to

channel 6.

18. Adjust channel 6 o scilla tor coil (L .-4E, Figure 8) so

that the sound m arker for channel 6 falls into the 21.9 me

trap dip with the fine tuning trim m er at m id-cap a city (shaft

slot in horizontal position ). Always spread or com press

channel 6 o scilla tor co il in units of 3 turns. C om pressing

turns w ill m ove cu rve toward sound m ark er, w hile spread

ing w ill m ove cu rve tow ard video m ark er.

IM PORTA N T: Since the co ils are in s e r ie s, the proper

alignm ent of channel 6 w ill sim p lify the phasing of the chan

nels to follow .

19. Adjust channels 5 and 4 so that the sound m arker for

each channel falls into the 21.9 m e trap dip in the curve with

the fine tuning trim m er set no m ore than 15 degrees from

m id-cap a city.

20. Channels 3 and 2 should be adjusted so that the sound

m arker fa lls into the 21. 9 m e trap dip with the fine tuning

trim m er within 15 degrees of m axim um capacity.

CHANNELS 2 TO 6

S

----

SOLID LINE INDICATES OPTIMUM

RESPONSE.

— DOTTED LINES INDICATES

PERMISSIBLE VARIATION.

FIGURE 9. RF RESPONSE CURVES CHANNELS 2-6

CHANNELS 7 TO 13

FIGURE 8.

ANTENNA, RF AND OSCILLATOR COIL LOCATIONS FIGURE 10. RF RESPONSE CURVES CHANNELS 7-13

L-5B

CHANNEL 5

CHANNEL 7

L-2

L-5A

CHANNEL 4

CHANNEL 3

CHANNEL 2

ANT. SECT.

-2A

L-2B REAR VIEW OF

L-2C OSC. SECTION

L-4C L-4M

9

Scanned by mbear2k - Jan 2012

OVER A LL RECE IVER SENSITIVITY MEASUREMENT

An overall m easurem ent of sensitivity is m ade as fo l

low s:

1. Connect an AM signal generator to the input term inals

of the re ceiv e r ch assis after rem oving the short 300 ohm

lead which conn ects to the antenna input strip on the back of

the cabinet. To m atch the generator to the re ceive r input,

a resistive m atching network should be used. In the case of

a generator with a 50 ohm output im pedance, for exam ple,

place a 100 ohm re sistor in series with the output term inal

of the generator and a 150 ohm re sisto r in series with the

ground term inal.

2. F rom cathode of picture tube to ch assis connect a ca li

brated oscillo s co p e.

NOTE: T o calibrate scop e, conn ect it a cro ss 6.3 volt fila

ment supply. The p eak -to-peak amplitude on the screen w ill

then be approxim ately 18V (6. 3x2. 8).

3. Set contrast control for m aximum sen sitivity.

4. Tune signal generator to the video ca rrie r frequ ency of

the channel being checked. G enerator signal should be 30%

m odulated at 400 cy cles. The signal from the generator to

produce 20 volts p eak-to-pea k at picture tube cathode should

be less than 25 m icrov olts on channels 2 to 6 and less than

75 m icrov olts on channels 7 to 13.

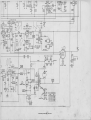

CIRCUIT DESCRIPTION

The circu it description appearing in the TS-89 serv ice

manual applies to the T S-172 ch assis with the follow ing ex

ceptions:

1. C -17 , the RF to m ixer coupling condenser, is 6 m m f in

stead of 8 m m f.

2. In som e sets, V -6 (6A L 5) the video d etector, is replaced

by a 1N60 germ anium crystal.

3. C apacitor C-41 and resisto r R -32, a part of the cathode

com pensating netw ork on the T S -89, between the ground end

of the con trast con trol and the low est tap^have been rem oved.

L -17 is changed to a red -g reen dot coil.

4. In som e sets, a 6CB6 tube is substituted for the 6AH6 in

the video am plifier stage (V -7 ). The screen re sisto r, R -35

changes from 33K to 22K with this substitution. Another

substitution for the 6AH6 is a 6BC5. The screen resisto r

R -35 is changed to 22K with this substitution also.

5. An additional RC netw ork, consisting of R-100 (470K)

and C -92 (100 m mf) has been added in the clipp er input c ir

cuit. This network, w hich has a short tim e constant, helps

to m inim ize the effect of noise pulses at the clipper grid.

I

6. In som e sets, a 6SN7 tube is substituted for the 12AU7

vertica l sw eep generator (V-13). The second m ultivibrator

grid re sisto r, R -63 , changes from 330K to. 100K with this

substitution.

7. In som e sets a 6AS5 tube is substituted for the 6W6 v e r

tical output tube. No com ponent changes are required with

this substitution.

8. In som e sets a 6H6 tube is substituted for the 6AL5 h or

izontal phase detector V-15. No com ponent changes are r e

quired with this substitution.

9. The damping re sistor a cro ss oscilla tor coil L -4E was

changed from 2200 ohm s to 3900 ohm s to stabilize the o s c il

lator on the low channels.

10. In som e sets, 6AG5 tubes are substituted for 6AU6

tubes in the first and second IF am plifier stages. L -ll, the

first IF coil, L-12, the low frequ en cy trap, L-15, the s e c

ond IF co il, and L-14, the high frequency trap, are changed

in value with this substitution. See parts list. R-13, the

dam ping resistor a cross T -l, changes from 6800 ohm s to

4700 ohm s. R-14, the first IF stage cathode re sisto r, is

bypassed with a 1500 m mf capacitor and R-14 and R-19, the

second IF stage cathode re s isto r, change from 47 to 56

ohm s with this substitution.

11. In som e sets, a 6AG5 is substituted for the 6AU6 in the

audio d riv er-lim ite r stage. This is an exact replacem en t

and requires no circu it or com ponent chan ges; how ever,

substitution of one for the other in the field requ ires r e

touching the alignm ent of the p rim a ry of the d iscrim inator

tra n sform er for best perform a n ce.

12. R-15, R -20 , C -2 4 , and C -29 are rem oved. R-14 and

R-19, the cathode resisto rs for V -3 and V -4 , are grounded

directly. The su pp ressors are also grounded.

13. The video am plifier B plus supply was changed from

the 240 volt bus to the 265 volt bus and the audio am plifier

B plus supply was changed from the 265 volt bus to the 310

volt bus. The bootstrap cap acitor C -83 , which was conn ect

ed to the 240 volt bus is now connected to the 310 volt bus.

14. In later sets, the horizontal output tube screen re sisto r

R -94 , is returned to the load side of the fuse F -l .

15. It has been found that certain pow er tra n sform ers

raise the "B " voltage 35 to 45 volts too high. In ord er to

afford a m easu re of p rotection for the 6BQ6 and 6W4 in

these instan ces, a resisto r R-104 has been placed in serie s

with the speaker field.

This condition arises only with certain issue "O ", "A ",

or "B " tra nsform ers (issue designation follow s the part

num ber stam ped on tra n sform ers). In issue "C " tra n sform

ers, which are currently being produced, this d ifficulty has

been rem edied and the re sistor is no longer n ecessa ry .

In future replacem ents of tra nsform ers, a ch eck should

be m ade of "B " voltage. If it is found to be low after the

new tra nsform er has been installed, rem ove the re s istor

mentioned above. If "B " voltage is found to be higher than

norm al, insert co rr e ct R-104 resistor in se ries with speak

er field, as shown in schem atic diagram . C orre ct part

num bers for these resisto rs w ill be found in R E PL A C E

MENT PARTS LIST.

The tube substitutions w ere necessa ry because of the

critica l shortage in som e tube types. These substitutions

do not affect the operation or circu it theory.

)

10

Scanned by mbear2k - Jan 2012

REPLACEMENT PARTS LIST

NOTE: When ordering parts, specify m odel number of set in addition to part number and description of part.

Ref. Part List

No. Number Description Price

CHASSIS PARTS - ELECTRICAL

Capacitors

C-l

_

See Tuning Unit Parts List..

-

C-2 21K77375

Ceramic

tubular: 220 mmf 500V .20

C-3

21A470789 Ceramic

disc: 5000 mmf 450V .30

C-4 21K77375

Ceramic

tubular: 220 mmf 500V .20

C-5

21K470322

Molded: 20 mmf 500V

......

.25

C-6 1X701662

Trimmer,, ceramic: .5-3 mmf;

complete with screw & mtg

nut . . . .

.................

.20

Ref. Part List

No. Number Description Price

C-62 8R9851 Paper: .02 mf 20 0 V ..........20

C-63 8R9870 Paper: .01 mf 6 0 0 V ..........25

C-64 8R9866 Paper: .001 mf 6 0 0 V .........20

C-65 21R6590 Mica: 500 mmf 5 0 0V ..........25

C-66 8R9873 Paper: .05 mf 6 0 0 V ..........25

C-67 8R9875 Paper: .15 mf 60 0 V ..........35

C-68A,B

C & D 23B700160 Electrolytic: 4-section; 80

mf/400V, 40 mf/300V, 20 mf/

300V, 10 mf/300V.......... 3.05

C-69A,B

C-7

C-8

C-9

C-10

C-ll

C-12

C-13

C-14

C-15

C-16

C-17

C-18

C-19

C-20

C-21

C-22

C-23

C-24

C-25

21A470790

21A470790

21K482726

1X701662

1X792784

21K478280

21K470324

21A470789

21K77375

21K478280

21A470789

21A470789

21A470790

21A470790

21A470789

Ceramic disc: 1500 mmf 500V

Ceramic disc: 1500 mmf 500V

Ceramic disc: 10,000 mmf 450V

See Tuning Unit Parts List..

Fine Tuning Trimmer (part of

station selector switch)...

Trimmer, ceramic: .5-3 mmf;

complete with screw & mtg

nut

......................

See Tuning Unit Parts List..

Trimmer, ceramic: 3-13 mmf;

complete with screw & mtg

nut

.....................

See Tuning Unit Parts List..

Molded: 2 mmf (temp comp)..

Molded: 6 mmf 500V

.......

Ceramic disc: 5000 mmf 450V

Ceramic tubular: 220 mmf

500V

....................

Molded: 2 mmf

Ceramic disc:

Ceramic disc:

Ceramic disc:

Ceramic disc:

Ceramic disc:

500V ...

5000 mmf

5000 mmf

1500 mmf

1500 mmf

450V

450V

500V

500V

5000 mmf 450V.

.30

.30

.30

.20

.45

.25

.25

.30

.20

.25

.30

.30

.30

.30

.30

C & D 23B700159

C-70

C-71

C-72

C-73

C-74

C-75

C-76

C-77

C-78

C-79

C-80

C-81

C-82

C-83

C-84

C-85

C-86A ,B

& C

Electrolytic: 4 section; 80

mf/400V, 40 mf/400V, 100 mf/

50V, 20 mf/25V ........... 3.10

8R9869 Paper: .005 mf 600V

......

.20

8R9866 Paper: .001 mf 600V

.....

.20

8R9866 Paper: *.001 mf 600V

......

.20

8R9866 Paper: .001 mf 600V

......

.20

8R9870

Paper: .01 mf 600V

........ .25

8R9869 Paper: .005 mf 600V

......

.20

21K400037 Ceramic tubular: 270 mmf 500V .25

21R2741

Mica: 680 mmf 500V

....... .35

8R9869 Paper: .005 mf 600V

......

.20

8R9854 Paper: .1 mf 200V

.......

.25

8R9874

Paper: .1 mf 600V

....... .35

8R490263

Molded paper: .1 mf 600V...

.35

21K700883

Ceramic tubular: 180 mmf

3000V

...................

.50

8R9874

Paper: .1 mf 600V

........

.35

21K790574

Ceramic tubular: 60 mmf 1500V

(in deflection yoke)

.....

.35

8R9874

Paper: .1 mf 600V

........ .35

i

23B700613

Electrolytic: 3-section; 80 mf/

400V, 20 mf/300V, 10 mf/300V 2.55

C-26

21A470789 Ceramic disc: 5000 mmf 450V

.30

& C 23B700614

C-27

21K77375

Ceramic

tubular: 220 mmf 500V .20

C-28 21K470329 Molded:

comp)

30 mmf 500V (temp

.30

C-88

A & B

23B700615

C-30 21A470789 Ceramic disc: 5000 mmf 450V .30

C-89

8R9810

C-31

21K77375

Ceramic

tubular: 220 mmf 500V .20

C-91

8R9854

C-32

21A470789 Ceramic disc: 5000 mmf 450V.

.30

C-92 21R6574

C-33 21A470789 Ceramic disc: 5000 mmf 450V. .30

C-93 21K482726

C-34 21A470789

Ceramic disc: 5000 mmf 450V .30

C-94

21K482726

C-35

21A470789 Ceramic disc: 5000 mmf 450V .30

C-95 21K780599

C-36

21K470329 Molded:

comp)

30 mmf 500V (temp

.30

C-96 21K780599

C-37

21K470324 Molded: 6 mmf 500V .......

.25

Capacitor-Resistc

C-38 8R9854 Paper:

.1 mf 200V .......

.25

C-42 21K470329 Molded: 30 mmf 500V ...... .30 CR-1 21B702478

C-43

21A478274 Molded: 2.2 mmf 500V

....

.25

C-44 21K790683

Molded: 60 mmf 500V

.....

.25

C-45

21A470789 Ceramic disc: 5000 mmf 450V.

.30 CR-2

21B702479

C-46 21A470789

Ceramic disc: 5000 mmf 450V.

.30

C-47

21K790439

Silver mica: 15 mmf (part of

T-3 base)

...............

.20 CR-3

21B702636

C-48 8R9866 Paper: .001 mf 600V

.....

.20

C-49

21A790131

Ceramic

tubular: 150 mmf 500V .35

C-50 21R6590 Mica: !

500 mmf 500V

...... .25

C-51 21R6590 Mica: J500 mmf 500V ......

.25

C-52 23A90205 Electrolytic: 10 mf 50V....

.45

Crystal

C-53 21K482726 Ceramic

disc: 10,000 mmf 450V .30

E-l

48B702302

C-54

8R9869

Paper: .005 mf 600V

.....

.20

C-55 21R6650

Mica: 68 mmf 500V

.......

.20

C-56 8R9869

Paper:

.005 mf 600V

.....

.20

Fuse

C-57

21K470322

Molded:

20 mmf 500V

.......

.25

F-l

65K702901

C-58 8R9873 Paper: .05 mf 600V ......

.25

C-59 8R9869 Paper: .005 mf 600V......

.20 Coils

C-60 8R9869 Paper:

.005 mf 600V

.....

.20 L-l

24A790033

C-61 8R9870 Paper: .01 mf 600V

.....

.25

Electrolytic: 3-section; 60 mf/

400V, 40 mf/300V, 20 mf/25V. 2.45

Electrolytic: 2-section; 35 mf/

400V, 100 mf/50V

.........

.

1.50

Paper: .25 mf 100V

......

.

.25

Paper: .1 mf 2 0 0 V

...........

35

Mica: 100 mmf 500V

.......

.15

Ceramic disc: 10,000 mmf 450V .30

Ceramic disc: 10,000 mmf 450V .30

Ceramic tubular: 1000 mmf 500V .25

Ceramic tubular: 1000 mmf 500V .25

coupling(optional to C-54,

R-46 & R-47)

......

.

..........

70

Capacitor-Resistor: video

compensating (optional to

C-39, C-40, R-32 & R-33).. . .70

Capacitor-Resistor: vertical

integrating (optional to

C-59, C-60, C-61, R-58, R-59,

& R-60)

.....................

80

(optional to 6AL5 video

detector)

................

1.35

leads

Coil

.25

.50

11

Scanned by mbear2k - Jan 2012

Ref. Part

List Ref.

Part

List

No.

Number Description

Price

No. Number

Description

Price

L-2

_

See Tuning Unit Parts List..

_

R-7

_

See Tuning Unit Parts List..

-

L-3

-

See Tuning Unit Parts List..

-

R-8 6R6320

10,000 10% 1/2W

___

...

doz

1.20

L-4

-

See Tuning Unit Parts List..

-

R-9

6R6038

1500 10% 1/2W

.......

,doz 1.20

L-5

-

See Tuning Unit Parts List..

-

R-10

6R6117

5600 10% 1/2W

.......

,doz 1.20

L-6

24K792825

RF coil: channel 13

.......

.25

R-ll

6R6393

1200 10% 1/2W

.......

.doz 1.20

L-7

-

See Tuning Unit Parts List..

-

R-12 6R6080

4700 10% 1/2W

.......

.doz

1.20

L-8

24K792577

RF choke: 3.3 microhenries..

.20

R-13

6R6428

6800 10% 1/2W (for 6AU6)dz

1.20

L-9

24K780128 RF choke: 2.2 microhenries.. .20 or

6R6080

4700 10% 1/2W (for

L-10

24K790035

RF choke: 5.6 microhenries..

.30

6AG5)

...............

.

.doz 1.20

L-ll

24B701343

1st IF: complete with LC

R-14

6R5550

47 10% 1/2W (for 6AU6),

.doz 1.20

trap, cores, & mtg nuts

or

6R5614 56 10% 1/2W (for 6AG5).

.doz 1.20

(for 6AU6)

..............

.90

R-16 6R6069

2200 10% 1/2W

.......

.

.doz

1.20

or

24K702495 1st IF: complete with LC R-17

6R6394

12,000 10% 1/2W

.....

.doz 1.20

trap, cores, & mtg nuts

R-18 6R6229

1000 10% 1/2W

.......

.doz

1.20

(for 6AG5)

..............

.90 R-19 6R5550

47 10% 1/2W (for 6AU6).

.doz

1.20

L-12

-

27.3 me trap (part of L-ll).

-

or

6R5614

56 10% 1/2W (for 6AG5).

,doz 1.20

L-13

24K790035

RF choke: 5.6 microhenries..

.30

R-21 6R6069

2200 10% 1/2W

.......

,doz 1.20

L-14

-

21.9 me trap (part of L-15).

-

R-22 6R6428 6800 10% 1/2W

.......

,doz 1.20

L-15

24K701344

2nd IF: complete with LC

R-23 6R2035

82 10% 1/2W

.........

doz

1.20

trap, cores, & mtg nuts

R-24

6R6038 1500 10% 1/2W

.......

.doz

1.20

(for 6AU6)

..............

.90 R-25

6R6031

100,000 10% 1/2W

....

.doz

1.20

or 24K702496

2nd IF: complete with LC R-26

6R6031

100,000 10% 1/2W

....

.doz

1.20

trap, cores, & mtg nuts R-27

6R3966 1.5 meg 20% 1/2W

....

.doz 1.20

(for 6AG5)

..............

.90 R-28 6R6117 5600 10% 1/2W

.......

.doz 1.20

L-16

24K792771

RF choke: yellow dot

......

.35

R-29 6R6004

1 meg 20% 1/2W

......

,doz

1.20

L-17

24K792772 RF choke: red-grn dot

......

.35

R-30

6R5550

47 10% 1/2W

.........

.doz 1.20

L-18

24B792735

4.5 me trap: less core & mtg

R-31A

nut

.....................

.50

& B 18A792009

Contrast & Volume control:

or

1X792736

4.5 me trap: complete with

dual; 2000 tapped & 1 meg

core & mtg nut

..........

.75

respectively; includes

L-19

24K701652

Compensating coil: black dot

.50.

power switch .........

.

1.75

L-20 24A470159

Sound take-off: less core & R-35 6R6400

33,000 10% 1W (for 6AH6)...

.20

mtg nut

.................

.35 or 6R6341

22,000 10% 1W (for 6CB6)..

.20

or

1X790341

Sound take-off: complete with

.R-36

- 12,000 (not replaceable;

core & mtg nut

..........

.80

part of L-19)

........

-

L-21

24K701651

Compensating coil: green dot

R-37

6R5671

4700 10% 2W

.........

.25

(wound on R-99)

.........

.50 R-3 8

6R3933

220 20% 1/2W

........

.doz

1.20

L-22

24B700548 Focus coil . . . ,

...........

10.20

R-39

6R2004 8200 10% 1/2W

.......

.doz

1.20

L-23

24K790059

Horizontal oscillator: less R-40

6R5660

180 10% 1/2W

........

.doz

1.20

core & clip

.............

.95

R-41

6R6012

33,000 20% 1/2W

.....

.

.doz 1.20

or

24B790055

Horizontal oscillator: com R-42

6R6428 6800 10% 1/2W

.......

.doz 1.20

plete with core & clip .... 1.45 R-43

6R6428

6800 10% 1/2W .......

.doz

1.20

L-24

24K700776

R-44 6R2122

4.7 meg 20% 1/2W

....

.doz 1.20

or

24K700778

R-45

6R6414

270,000 10% 1/2W

....

.doz

1.20

or

24K700694

R-46

6R6032

470,000 20% 1/2W

....

.doz 1.20

or

24K700714

R-47

6R6032

470,000 20% 1/2W

....

.doz

1.20

or

24K700774

Deflection yoke: complete...

11.00

R-48

6R6022

330 10% 1/2W ........

.doz 1.20

L-25

24K790145

RF choke: 0.47 microhenries.

.20

R-49

6R476004

1000 20% 2W .........

.25

L-26

24K790145

RF choke: 0.47 microhenries.

.20

R-50

6R6320

10,000 10% 1/2W

.....

.doz 1.20

L-27

24K700089

Horizontal size: less core &

R-51

6R3927

2.2 meg 20% 1/2W

....

.doz

1.20

.55

R-52

6R6004

1 meg 20% 1/2W

......

.doz

1.20

or

24B700088

Horizontal size: complete

R-53

6R6397

22,000 10% 1/2W ....

doz

1.20

with core, clip, & mtg nut.

1.35

R-54

6R2096

330,000 10% 1/2*

....

.doz

1.20

R-55

6R6428

6800 10% 1/2W .......

.doz 1.20

Speakers

R-56

6R5581

3300 10% 1/2W

.......

.doz

1.20

LS-1

50K700850

Speaker: 8” electro; 100 ohm

R-57

6R5581 3300 10% 1/2W .......

1.20

field (hot); 3.2 ohm voice

■*

R-58

6R6031

100,000 10% 1/2W

---

-

.doz

1.20

coil (17K1E, 17K2E)

.......

6.30*

R-59

6R603I

100,000 10% 1/2W

....

.doz

1.20

exch

4.75

R-60

6R6397

22,000 10% 1/2W

.....

.doz

1.20

50C701846

Speaker: 8” electro; 100 ohm

R-61

6R6031

100,000 10% 1/2W

....

.doz

1.20

field (hot); 3.2 ohm voice

R-62

6R5577

2700 10% 1/2W

.......

.doz

1.20

coil (17K1E)

.....

.

......

6 .30*

R-63

6R2096

330,000 10% 1/2W (for

exch

4.75

or

6R6031

100,000 10% 1/2W (for

.doz

1.20

Resistors

.doz

1.20

Note: All resistors are insulated carbon

R-64 18A90147

Vertical Hold Control: 1

meg .80

type

unless otherwise specified.

R-65

6R6428

6800 10% 1/2W

.......

1.20

R-66 6R5577

2700 10% 1/2W .......

1.20

R-l

6R6397

22,000 10% 1/2W ......doz

1.20

R-67

6R6032

470,000 20% 1/2W

.....

.doz 1.20

R-2

6R6056

47,000 10% 1/2W

......doz

1.20

R-68

18A702403

Vertical Size Control: 5

meg

.80

R-3

6R5614

56 10% 1/2W

.........

doz

1.20

R-69

6R2118

3.3 meg 20% 1/2W

....

.doz 1.20

R-4

6R2036

33 10% 1/2W .

........doz

1.20

R-70

6R3949

470 20% 1/2W ........

.doz

1.20

R-5

6R6229

1000 10% 1/2W ........doz

1.20

R-71

18A702407

Vertical Linearity Control:

1.50

R-6

6R5659

3900 10% 1/2W ........doz

1.20

♦Plus Federal Excise *ax At Current Rate

12

Scanned by mbear2k - Jan 2012

Ref.

Part

List

No.

Number

Description

Price

R-72

6R6291

560 10% 1/2W (in deflection

yoke)

............

....doz 1.20

R-73

6R6291

560 10% 1/2W (in deflection

yoke)

............

....doz 1.20

R-74

6R6056

47,000 20% 1/2W

---

....doz 1.20

R-75

18A702401

Brightness control: 1

meg. . .

.80

R-76

6R6004

1 meg 20% 1/2W

---

....doz

1.20

R-77

17K700782

Wire wound: 375 10%

10W

___

.35

R-78

18A702404

Focus control: 1000 .

1.55

R-79

17K792705

Wire wound: 2000 10%

10W. ,

.35

R-80 6R6477

15,000 10% 1/2W ...

1.20

R-81

6R6031

100,000 10% 1/2W ..

1.20

R-82

6R6031

100,000 10% 1/2W ..

1.20

R-83

6R2122

4.7 meg 20% 1/2W ..

1.20

R-84

6R2122

4.7 m?g 20% 1/2W . .

1.20

R-85

6R6428

6800 10% 1/2W

....

1.20

R-86

6R6229

1000 10% 1/2W

....

1.20

R-87

6R3949 470 20% 1/2W

.....

1.20

R-88 6R5631

120,000 10% 1/2W ..

....doz

1.20

R-89

18A791574

Horizontal Hold: 100,

000

___

.80

R-90

6R6074

68,000 10% 1/2W ...

1.20

R-91

6R6038

1500 10% 1/2W

....

1.20

R-92

6R6032

470,000 20% 1/2W ..

1.20

R-93

6R5583

47 10% 1W

.......

.20

R-94

6R5690

6800 10% 2W

......

.25

R-95 6R5721

150,000 10% 1W

---

.20

R-96

6R5721

150,000 10% 1W

___

.........

.20

R-97

6R5577

2700 10% 1/2W (in deflec

tion yoke)

........

....doz 1.20

R-98

6R6328

100,000 10% 1W (in deflec

tion yoke) ........

.........

.20

R-99

-

2700 (not replaceable

of L-21) ..........

; part

_

R-100

6R6032

470,000 20% 1/2W ..

1.20

R-101

6R6018 100 20% 1/2W

......

1.20

R-102 6R5551

120 10% 1/2W

.....

1.20

R-103

6R5551

120 10% 1/2W

.....

....doz

1.20

R-104 17K702449

Wire wound: 150 10%

15W

(for 25C701025 & 25C700161

trans)

...........

.50

or

17X700423

Wire wound: 75 10%

25C700169 trans)

___

10W (for

.25

Tr ansforrears

T-l

24K792578

Mixer IF: less cores & mtg

nuts

....................

.45

or 1X792591 Mixer IF: complete with cores

& mtg nuts

..............

.85

T-2

2*B792585

3rd IF: less core, mtg nut, &

colored leads

...........

.65

or

1X792592

3rd IF: complete with core,

mtg nut, C-35, & colored

leads

...................

1.10

T-3 24B790125

Ratio Detector: complete less

shield can

..............

2.00

T-4

25B790686 Audio Output

.............

1.40

T-5

25K701619

Vertical Output

..........

3.25

T-6

24K792753

High Voltage Transformer ....

7.25

T-7 35B790140 Filament Transformer:

isolating (for V-18)

......

3.05

T-8

25C700161

or 25C700169

or 25C701025

or

25K700882 Power Transformer .........

16.65

Tubes

V-l

6CB6

RF Amplifier

.............

-

V-2 12AT7

Mixer-Oscillator

.........

-

V-3

6AU6

or

6AG5

1st IF Amplifier

.........

-

V-4

6AU6

or

6AG5

2nd IF Amplifier

.........

-

V-5

6AG5

3rd IF Amplifier

.........

-

V-6

6AL5

or

1N60

Video Detector

...........

-

V-7

6AH6

or 6CB6

Video Amplifier

.....

.

-

Ref.

Part

List

No. Number

Description

Price

V-8 6AU6

or 6AG5 Audio Driver-Limiter

......

-

V-9

6AL5 Ratio Detector ............

-

V-10

6J5/GT Audio Amplifier

..........

-

V-ll 6V6/GT Audio Output

.............

-

V-12

6SN7GT 1st & 2nd Clipper .........

-

V-13

12AU7

or 6SN7GT Vertical Sweep Generator ...

-

V-14 6W6

or 6AS5 Vertical Sweep Output

.....

-

V-15 6AL5

or

6H6 Phase Detector

...........

-

V-16

6SN7GT

Horizontal Oscillator

.....

-

V-17 6BQ6GT

Horizontal Output & High

Voltage Generator ........ -

V-18

6W4GT Damping Diode

............

-

V-19 1B3GT High Voltage Rectifier

....

-

V-20 17BP4

or 17AP4 Picture Tube: 17” rectangular

-

V-21 5U4G Low Voltage Rectifier

.....

-

TUNER

Model TT-13 Tuning Unit

1X700100 TT-13 Tuning Unit: includes

station selector switch,

fine tuning trimmer, and

the following components:.. 10.85

C-l 21K478234 Capacitor, molded: 8 mmf

500V

...................

. .25

C-10 21K482726 Capacitor, ceramic disc:

10.000 mmf 4 5 0V

............

30

C-13* 21K482726 Capacitor, ceramic disc:

10.000 mmf 45 0 V

............

30

C--15 21K400173 Capacitor, molded: 10 mmf

500V (temp comp)

........

.

.30

L~2 24C792764 Coil, antenna: channels 2

thru 6; includes L-2A thru

L-2E (L-2F thru L-2L are

part of switch)

.............

25

L-3 24K790536 Coil, RF: channels 2 thru 6;

includes L-3A thru L-3E

(L-3F thru L-3L are part

of switch)

..................

20

L-4 24C700114 Coil, oscillator: channels 2

thru 6; includes L-4A thru

L-4E (L-4F thru L-4L are

part of switch)

.............

05

L-4M 24K700115 Coil, oscillator; channel 10 .10

L-5 24K792765 Coil, antenna primary: low

frequency; includes L-5A,

L-5B , & L - 5 C

................

15

L-7 24K700116 Coil, oscillator: channel 13 .10

R-7 6R5659 Resistor: 3900 10% l/2W.doz 1.20

42K790136 Clip, spring (on collar)

.......

10

43K700725 Collar, spring (on rear end

of fine tuning shaft).........10

47K700726 Shaft, fine tuning

........ .50

Part List

Number Description Price

CHASSIS PARTS - MECHANICAL

7K700153 Bracket, coil mtg (L-27)

............

05

7B700194 Bracket, focus coil housing (around

focus coil)

........................

60

7A700196 Bracket, focus coil mtg (across top

of focus coil)

.....................

25

7A791965 Bracket, interlock safety

...........

05

7K700661 Bracket, picture tube rear support:

with grounding spring & 2nd anode

lead insulator

.....

............

2.00

7A792568 Bracket, yoke adjustment (across top

of yoke)

...........................

30

13

Scanned by mbear2k - Jan 2012

Part

Number

35K700532

35A700603

38K7927.73

42K471342

42A701441

42A700147

42B70721

42A76244

42A801062

42K791405

39K17396

46A478242

46K791756

46A470310

46K480256

46A70023

46A470302

46K471143

46A700090

35K792757

5K792031

5A790684

14K791892

14K87179

14A791787

4S7655

4S7688

4S9751

4S2635

2A470049

27K791404

2S7022

257004

257005

2S7003

2S7051

2S7050

2A790191

2B70703

35K702281

35K702282

35K702279

64A702001

64K791818

Description

Bumper, rubber (circular bumper in

rear support bracket)

..............

15

Bumper, rubber (used with RCA yokes

only)

..............................05

Button, plug (covers V-6 socket hole

when 1N60 used)

.............

doz .40

Cap, plate (V-19) .........

......

.05

Cap, plate: with lead (V-17)....... .25

Clamp, lead retainer (dresses V-19

filament leads)

.............

doz .15

Clip, coil mounting (T-3 second

ary)

........................

doz .25

Clip, coil retainer (L-23)

....

doz .25

Clip, hairpin (L-27) ..........doz .50

Connector, 2nd anode

................

50

Contact, pin terminal (on speaker

leads)

.

....................

per/c .50

Core, brass, & screw (T-2)

......

: .15

Core, brass, & screw (L-ll & L-15). .05

Core, iron, & screw (T-l primary,

L-18, & L-20)

.......

.

..............

15

Core, iron, & screw (T-l secondary

& L-12)

............................ 15

Core, iron, & screw (T-3 primary &

L-14) ..............................15

Core, iron, & screw (T-3 secondary) .20

Core, iron, & screw (L-23)

..........

15

Core, iron, & slide adjustment

(L-27)

..............

..............

45

Cushion, focus coil (between coil &

tube) ..............................20

Grommet, insulating: 9/32” hole.doz .30

Grommet, tube socket ..........doz .35

Insulator, coil (in T-2 can)....doz .35

Insulator, coil (in T-3 shield

can)

.............

......

.

.doz .25

Insulator, 2nd anode lead: armite

(on picture tube rear support brkt) .05

Lockwasher, int: 3/8"; cad pi

(front controls mtg)........per/c .50

Lockwasher, int-ext: 1/4”; cad pi

(7B700194 brkt mtg)

.........

doz .15

Lockwasher, int-ext: #8; cad pi

(T-8 mtg)

.................

per/c .50

Lockwasher, int: thin; 1/2” cad pi

(7B700194 bracket mtg)........doz .15

Nut, coil & core mtg (T-l, T-2,

L-ll, L-12, L-14, L-15, L-18 &

L-20)

.......................

doz .50

Nut, coil & core mtg (L-27)

....

doz .50

Nut, hex: 1/4-20 x 7/16; cad pi

(7B700194 bracket mtg)

....

....doz .15

Nut, hex: 3/8-32 x 9/16; cad pi

(front controls mtg)

. . .

......

doz .20

Nut, hex: 6-32 x 1/4; cad

pi (for

3S490459 screw)

....

....

per/c

.50

Nut, hex: 8-32 x 5/16

stl ; cad pi

(T-8 mtg)

.....

.50

Nut, hex: palnut ; 3/8-

-32 :

x 9/16;

cad pi (rear controls mtg)

....

doz

Nut, hex: palnut; 6-32 (T-2 shield

mtg)

...............

*

.....

per/c

Nut, special: cad pi (ceramic

trimmer mtg)

................

doz

Nut, special: palnut (T-3 primary

coil mtg)

...................

doz

Pad, cushion (around top of picture

tube)

............

. . . .

.........

Pad, cushion (long pad at bottom of

picture tube) .........

.

........

Pad, cushion (small pads on picture

tube mtg strap)

..........

.

. .doz

Plate, adaptor (to adapt V-14 socket

hole to miniature socket) .......

Plate, chassis cover (removable

plate on chassis side)

.........

64A90034 Plate, electrolytic mtg (for two

electrolytics)

.....................

05

64A700690 Plate, electrolytic mtg (for three

electrolytics)

..............

doz .35

64K700748 Plate, socket cover (covers unused

hole when two electrolytics used

.

.................

...........

doz .30

64A700745 Plate, transformer cover (for

25C700161 & 25K700882 transformers

only)

..........................

.10

1X700523 Plate, tube mtg: with socket & mtg

bracket (V-19)

.................

.35

28K471323 Plug, line cord: 2-pin

..........

. .20

9A22367 Receptacle: 5-prong (spkr recep

tacle) . ..

.................

.

........

15

5S8497 Rivet: .088 x 1/8 stl; pol nkl

(V-l, V-2 & V-5 socket mtg)..per/c .50

5S7771 Rivet: .088 x 3/16 stl; pol nkl

(mounts V-14 socket when 6AS5

used)

.....................

per/c .50

5S2815 Rivet: .088 x 7/32 stl; pol nkl

(9A485495, 9K780442, 9K484167

socket mtg)

...............

per/c .50