Page is loading ...

8144A001R4-2/07

DNAGNITAREPO,NOITALLATSNI

ROFSNOITCURTSNIECIVRES

HB

™

VBDNA

™

SRETAEHTINU

RETAWTOHROMAETSROF

gnikeesnehW.rotcartnocgnitaehruoyllac,retaehotsriaperroecivresroF

gnitaRnonwohssarebmuNlaireSdnarebmuNledoMedivorp,retaehnonoitamrofni

.retaehehtfopotnodetacollebaL

rebmuNledoMrebmuNlaireSetaDnoitallatsnI

rot

cartnoCgnitaeH rebmuNenohP

sserddA

2

I. PRECAUTIONS - IMPORTANT INFORMATION .................................................3

II. GENERAL INFORMATION

A. Installation Limitations ..............................................................................................4

B. Inspection on Arrival .................................................................................................4

III. INSTALLATION

A. Special Precautions ....................................................................................................4

B. Unit Suspension ........................................................................................................4

C. Unit Heater Mounting Height ....................................................................................5

D. Piping Installation ......................................................................................................5

E. Wiring Instructions .....................................................................................................5

IV. OPERATION

A. Prior to Operation ......................................................................................................8

B. Initial Start-up ............................................................................................................8

V. MAINTENANCE

A. Regular Inspection .....................................................................................................9

B. Motors ........................................................................................................................9

C. Casings .......................................................................................................................9

D. Coils ...........................................................................................................................9

VI. APPLICATION GUIDELINES

A. General Guidelines ..................................................................................................10

B. Steam Performance Data .........................................................................................11

C. Selection Procedure - Steam Application ................................................................12

D. Steam Calculation Formulas ....................................................................................13

E. Steam Correction Factors .........................................................................................14

F. Hot Water Performance Data ....................................................................................17

G. Selection Procedure - Hot Water Application ..........................................................18

H. Hot Water Calculation Formulas .............................................................................19

I. Hot Water Correction Factors ...................................................................................20

VII. OPTIONS, ACCESSORIES AND CONTROL SEQUENCES

A. Field Installed Options for Horizontal and Vertical Models ....................................21

B. Control Sequences ...................................................................................................21

C. Field Installed Options for Horizontal Models Only ...............................................21

D. Field Installed Options for Vertical Models Only ...................................................22

VIII. DIMENSIONAL DATA

A. BH Dimensional Data ..............................................................................................25

B. BV Dimensional Data ..............................................................................................26

IX. MOTOR DATA ...........................................................................................................27

WARRANTY ................................................................................................Back Cover

TABLE OF CONTENTS

3

I. IMPORTANT INFORMATION - READ CAREFULLY BEFORE INSTALLATION

The following terms are used throughout this manual to bring attention to the presence of hazards of various risk levels, or to

important information concerning product life.

ECITON

.launamsihtfokcabehtnodetnirpsihcihwfoypoca,ytnarrawdetimilasahrotaidarsihT

dnadeniatniam,dellatsnineebsahrotaidarehtfiylnodilavsirotaidarsihtrofytnarrawehT

.snoitcurtsniesehthtiwecnadroccanidetarepo

GNINRAW

ytreporpesuacnacecnanetniamroecivres,noitaretla,tnemtsujda,noitallatsnireporpmI

reporpehtnisnoitcurtsnillawollofoteruliaF.efilfossolroyrujnilanosrep,egamad

lladnatsrednudnadaeR.egamadytreporproyrujnilanosrepesuacnacredro

sihtgnicivresrogniniatniam,gnitarepo,pu-gnitrats,gnillatsnierofeb,snoitcurtsni

rofreta

ehraendetsopdnanoitidnocelbigelnierutaretildnalaunamsihtpeeK.retaeh

.naicinhcetecivresdnarenwoybecnerefer

,decneirepxenaybylnodemrofrepebtsumecivresdna,ecnanetniam,noitallatsnI

.ycnegaecivresrorellatsnielb

aegdelwonkdnadelliks

tohhcuotnikserabteltonod,snrubdiovaoT.TOHsi,noitareponinehw,retaehsihT

.secafrus

.n

erdlihcraenesuninoituacemertxeesU

.gnitareposiretaehehtrevenehwnoituacemertxeesU

dezirohtuanaotretaehnr

uteR.snoicnuflamretaehehtretfaretaehynaetarepotonoD

.riaperronoitanimaxerofytilicafecivres

.sroodtuoesu

tonoD

dednemmocertonsiesurehtoynA.launamsihtnidebircsedsaylnoretaehsihtesU

.rerutcafunamehtyb

ECITON

nosnoitcurtsnilaicepssetacidnI

ecnanetniamro,noitarepo,noitallatsni

otdetalertontubtnatropmierahcihw

.sdrazahyrujnilanosrep

GNINRAW

suodrazahyllaitnetopasetacidnI

dluoc,dediovatonfi,hcihwnoitautis

royrujnisuoires,htaednitluser

.egamadytreporplaitnatsbus

4

A.

SPECIAL PRECAUTIONS

1. Disconnect power supply before making wiring

connections to prevent electrical shock and

equipment damage. All units must be wired strictly

in accordance with wiring diagram furnished with

unit.

2. Units should not be installed in atmospheres where

corrosive fumes or sprays are present.

3. Units must not be installed in potentially explosive

or fl ammable atmospheres.

4. Be sure no obstructions block air intake or air

discharge of unit heater.

5. Do not install unit above recommended maximum

mounting heights (see Table 1) or below the

minimum height of eight feet.

II. GENERAL INFORMATION

A. INSTALLATION LIMITATIONS

Installation and service instructions in this manual are

applicable to the steam/hot water unit heaters which

should be installed in their proper applications for their

most effective function as overhead heating units. The

copper coils are warranted for operation at steam or

hot water pressures up to 150 psig, and/or temperatures

up to 375°F. Canadian Standards Association (CSA)

requirements state that explosion-proof units may not

be used with a fl uid temperature in excess of 329°F and

still maintain their explosion-proof rating, for national

electric code ignition temperature rating T3B for grain

dust.

B. INSPECTION ON ARRIVAL

1. Inspect unit upon arrival. In case of damage, report

immediately to transportation company and your

local Burnham Hydronics Representative.

2. Check rating plate on unit and motor to verify that

power input and motor specifi cation meet available

electric power at point of installation.

3. Inspect unit received for conformance with

description of product ordered (including

specifi cations where applicable).

III. INSTALLATION

GNINRAW

DRAUGNAFTELTUOEVOMERTONOD

.STINUVBLEDOMMORF

Figure 1: Horizontal Air Delivery

B. UNIT SUSPENSION

Horizontal Delivery Units, Model BH Series

All horizontal delivery units have two tapped holes

(3/8”-16) in the top for unit suspension. Piping

support hangers or clamps are recommended and

should be placed as close to the unit heater as

possible. For other models, independent suspension

can be made with threaded rods, pipes, or ceiling

hanger brackets.

5

Vertical Delivery Units, Model BV Series

Models BV-42 through BV-161 have 4 tapped holes

(1/2”-13) on the top surface for unit suspension.

Suspension can be made with threaded rods, pipes,

or ceiling hanger brackets. Models BV-193 through

BV-610 have angle-iron frame mounting brackets for

heavy-duty installation with applicable hardware.

C. UNIT HEATER MOUNTING HEIGHT

Do not install unit above recommended maximum

mounting heights or below the minimum height of eight

feet. The height at which unit heaters are installed is

critical. Maximum mounting heights for all units are

listed in Table 1. Maximum mounting heights for Model

BV is given for units with or without air diffusion

Figure 2: Vertical Air Delivery

No Defl ector

Two-Way Louver

4-Cone Anemostat

Truncone

accessories. Locate horizontal delivery unit heaters so

air streams of individual units wipe the exposed walls

of the building with either parallel or angular fl ow

without blowing directly against the walls. Heaters

should be spaced so the air stream from one supports

the air stream from another heater. Locate vertical

delivery unit heaters in the center area of the space to

be heated, using horizontal delivery unit heaters along

the walls where heat loss is usually greatest.

D. PIPING INSTALLATION

Horizontal and Vertical Unit Heaters

Note: Only make piping connections using two (2)

pipe wrenches. One wrench is used as a “back-up”

while the other wrench is used for applying force

necessary to tighten the fi tting.

The illustrations, on page 6, suggest four (4) different

piping confi gurations. Refer to the ASHRAE Guide &

Specialty Manufacturer for selection of fi lter, piping

traps and other specialty sizing. Piping is typical for

unit heaters.

E. WIRING INSTRUCTIONS

1. Disconnect power supply before making wiring

connections to prevent electrical shock and

equipment damage. All units must be wired strictly

in accordance with wiring diagram (Figure 3).

2. All wiring must be done in accordance with the

National Electric Code and applicable local codes.

In Canada, wiring must conform to the Canadian

Electric Code. It is recommended that all wiring be

adequately grounded.

3. Electric wiring must be sized to carry the full load

amp draw of the motor, starter, and any controls that

are used with the unit heater. Overcurrent protectors

should be sized based on motor current rating shown

on the unit serial plate, and applicable national

electric code procedures.

4. All units should be installed with an electrical

junction box. Junction boxes are either integral to

the motor or to be attached to the unit casing. Units

with explosion-proof motors have an explosion-

proof junction box attached to the motor. Any

damage to or failure of Burnham Hydronics heater

units caused by incorrect wiring of the units is not

covered by Burnham Hydronics standard warranty.

6

Figure 3: 115V / 60Hz / 1PH Wiring Schematic

7

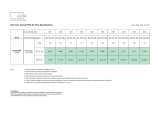

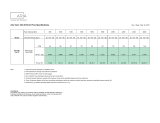

epyTlatnoziroH epyTlacitreV

ledoM

rebmuN

.tF-thgieH

ledoM

rebmuN

rotcelfeDoN teJ-enoC enocnurT

yaW-enO

srevuoL

yaW-owT

srevuoL

enoC-3

tatsomenA

enoC-4

tatsomenA

.tF-thgieH .tF-thgieH .tF-thgieH .tF-thgieH .tF-thgieH .tF-thgieH .tF-thgieH

H S H S H S H S H S H S H S H S

81-HB971 24-VB117151118913111822822882

42-HB981 95-VB3102813195261410182982853

33-HB0102 87-VB412291411162715111031103803

74-HB2152 59-VB614212611162715111031103803

36-HB4192 931-VB817242813123128131633163954

68-HB5113 161-VB1213821241533202410441040105

801-HB5123 391-VB3243133261935222514461442155

121-HB6133 212-VB5273335261935222514461442155

561-HB7143 742-VB6293436271640362812571253156

391-HB8173 972-VB0354730381355303120681063157

852-HB9104 333-VB0354730371355303120671063157

092-HB0244 583-VB0354630371355303120671063157

043-HB0264 005-VB7365447391562473624791473139

016-VB63453463913614145227------------

noitidnocdradnatstagnitareposretaehroferaseulaV.enalplacitrevehtmorf°03neposr

evuollatnozirohhtiW:SETON

.)riagniretneF°06dnamaetS.isp2(

.noitisopdenepo-yllufriehtnisrotcelfedhtiweratejenocdnasrevuolyaw-owtrofsthgiehdetsiL

Table 1: Recommended Maximum Mounting Height

Unit Heater Connection for High Pressure Steam

Unit Heater Connection for Low Pressure Steam - Open Grav-

ity or Vacuum Return System

Horizontal Unit Heater Connected to

Overhead Hot Water Mains

Vertical Unit Heater Connected to

Overhead Hot Water Mains

Figure 4: Hot Water System Piping

Figure 5: Steam System Piping

8

IV. OPERATION

A. PRIOR TO OPERATION

1. Check all electrical connections to assure they are

secure.

2. Check rigidity of unit mounting. Tighten all

fasteners, if necessary.

3. Inspect piping, strainers, traps, fi ttings, etc.

B. INITIAL START-UP

1. Set thermostat to lowest position.

2. Turn on power supply to unit.

3. Open return gate valve, and then open supply gate

valve to unit.

4. Raise thermostat setting to desired position.

5. Adjust louvers (if provided) for desired heat

distribution.

6. To insure proper sequence of operation, cycle unit

on and off a few times by raising and lowering

thermostat setting.

7. Check for proper rotation of fan. All fans must rotate

in a counterclockwise direction when viewed from

the back (BH) of the unit heater.

9

A.

INSPECT REGULARLY

Under average conditions, it is recommended that

unit heaters be inspected before every heating season

— more often in locations where air is contaminated

with corrosive fumes, dust, soot or oil spray. Check

for dirty, clogged coils, excessive vibration and loose

connections. Inspect piping, strainers, traps, fi ttings, etc.

B. MOTORS

1. Cleaning

Remove grease and dirt on motor during each

inspection or lubrication. Open frame motors should

be blown clean every heating season, or whenever

coils are cleaned, whichever is sooner.

2. Lubrication

Lubricate motor according to manufacturer’s

instructions located on the motor. When no motor

oiling instructions are on the motor, oil the motor

every two thousand hours of operation with SAE20

motor oil for units in normal applications. Adjust

oiling according to usage and atmosphere. Some

motors do not have oil fi ttings. These motors are

lubricated for long life and do not require further

lubrication.

3. Overload Protection

A change in line voltage higher or lower than motor

nameplate rating may cause overheating and serious

motor damage. Check plant voltage conditions.

A separate manual starter with thermal overload

protection device is recommended for those units

that do not have motors with built in overload

protection.

C. CASINGS

1. Cleaning

Periodic cleaning of casings is recommended to

remove dirt, grease and corrosive substances that

may injure fi nish. Rusted or corroded spots should

be cleaned and repainted.

2. General Inspection

Tighten fan guard and motor bracket. Check fan for

proper clearance, free rotation and fi rm connection

to shaft. When servicing is complete, tag unit to

indicate date of inspection, lubrication and cleaning.

GNINRAW

launamsihtniderevoctnempiuqeehT

dnadeniatniam,dellatsniebdluohs

.naicinhcetdeifilauqaybdecivres

V. MAINTENANCE

ECITON

deifilauqlacolruoytcatnocecivresroF

rorotcartnocecivresdnanoitallatsni

.ynapmocytilituetairporppa

D. COILS

1. Cleaning

Clean coil at least once a year, more often under

unfavorable conditions. Unless coil is kept

reasonably free of dirt, lint and grease, its original

heating capacity will be reduced — possibly to a

serious degree, and motor damage may result.

Two commonly used cleaning methods are:

a. Loosen dirt by brushing fi ns on side where air

enters coil and then turn on fan to blow dirt from

unit.

b. Use high-pressure air hose to loosen dirt by

blowing from side where air leaves coil (side

adjacent to louvers on blow-through units (BH);

side adjacent to fan on draw-through units (BV)).

For thorough cleaning of coil, remove motor and

fan and spray a mild alkaline cleaning solution

over the coil. After a few minutes, follow by a

hot water rinse. (A steam gun can be used for

spraying cleaning solution and hot water.) Coils

subjected to corrosive fumes should be checked

and cleaned frequently.

2. Internal Corrosion Safeguards

Provide controlled water treatment -- don’t use

excess of boiler compounds. Contact your boiler

compound supplier for proper usage or the services

of a water treatment laboratory. Periodic internal

fl ushing of the coils is recommended in areas where

water supply is suspected of causing scale. Use an

alkaline-chelant solution and introduce it at the main

pump of the hydronic system. Flush thoroughly.

GNINRAW

sahcussdicalarenimrocinagronignisU

hguohtneve,dica)cirolhcordyh(citairum

,egamaderevesotdaelyam,detibihni

.egakaeldnanoisorrocgnidulcni

De-aerate boiler feed-water (particularly if large

amount of new water is used). Insure rapid continuous

and adequate condensate drainage by properly sized

and installed traps and piping. Check traps for sticking.

Clean strainers ahead of traps. (When traps don’t work,

condensate accumulates in unit heater coil; water

hammer results.) Adequately vent each unit. Use low-

pressure steam when possible.

10

VI. APPLICATION GUIDELINES

A. GENERAL GUIDELINES

1. The fi rst step in the design of a job is typically to

determine the heat loss. Refer to ASHRAE and

others for publications on the basic methodology

used in calculating the building or area’s heat loss.

Special attention should be paid to the building type

(architecturally) and application placement (area

use) in this procedure.

2. The second step is to decide the necessary

engineering data for design conditions such as CFM,

fi nal air temperature, quantity and location of units,

based on the specifi c Burnham Hydronics Unit

Heater model selected.

3. Burnham Hydronics steam/hot water unit heaters’

versatility offers a wide selection of outputs and

airfl ow allowing almost unlimited fl exibility in job

design.

4. Keep the following guidelines in mind when

designing any job using steam/hot water unit

heaters:

• Always direct airfl ow to regions of greatest heat

loss.

• Use louvers for adjustment of throw length and

complete directional control of airfl ow.

• Mount units at the lowest practical and allowable

level.

• Select lower CFM models for lower installation

heights and heavily occupied areas. Select higher

CFM models for areas where higher installation is

required.

• More, smaller units will provide better heat

distribution than fewer larger units.

• Watch fi nal air temperatures on units mounted at

lower levels or in heavily occupied areas to ensure

that air is warm enough to avoid drafts being felt.

• Sound classifi cations: Burnham Hydronics Unit

Heaters provide exceptional heat output while

Typical BH Unit Arrangement

considering the nuisance of a loud unit. All units

were designed to minimize sound created by airfl ow

and motor operation by careful component selection

and inlet geometry. Sound Classifi cation Table 2

shows typical rooms and their corresponding sound

class rating.

GNIDLIUBROMOORFOEPYT GNITARSSALCDNUOS

smoortseR,sreyoF,slatipsoH,seirarbiL,seciffO,sloohcS I

seitilicaFgniniDlaicremmoC,sesuohbulC,serotStnemtrapeD,smoorwohS II

sraB,smuisanmyG,serotSesuoheraW,seibboLegraL III

saerAnommoCmuidatS,spohSenihcaM,saerAgnippihS,seirotcaFllamS IIV-II

spohSnoitacirbaF,seirotcaFegraL IIV

Table 2: Sound Class Ratings*

*When placed in the paired room, the unit’s noise should be relatively comparable to the ambient sound level.

11

Table 3: Steam Performance Data -- High Motor Speed

Performance Data at Standard Conditions of 2 lb. Steam and 60°F Entering Air

Table 4: Steam Performance Data -- Reduced Motor Speed

Performance Data at Standard Conditions of 2 lb. Steam and 60°F Entering Air

B. STEAM PERFORMANCE DATA

ledoM

epyT

ledoM

rebmuN

.rH/UTB

.tF.qS

RDE

ATADRIA

dnuoS

**ssalC

.xaM

gnitnuoM

*)tf(thgieH

taeH

tadaerpS

*thgieH.xaM

mfC

teltuO

yticoleV

)mpF(

riAlaniF

.pmeT

)F°(

etasnednoC

rh/bl

81-HB000,8157II9 7100401520181

42-HB000,42001II9 8105408590152

33-HB000,33831II010203601590153

74-HB000,74691III215203700602194

36-HB000,36362III4192021150621166

68-HB000,68853III5113043103791198

801-HB000,801054III51230551526521111

121-HB000,121405III61335771517321621

561-HB000,561886VI71430052057121071

391-HB000,391408VI81730092078221002

852-HB000,8525701V 91040093029121762

092-HB000,0928021V 024400340101221003

043-HB000,0437141V 02640315569121253

24-VB000,24571II11

51

71

11

05997730134

95-VB000,95642II31

81

02

31

051134911116

87-VB000,87523II41

91

22

41

055129901118

59-VB000,59693II61

12

42

61

5771631131199

931-VB000,931975III81

42

72

81

00524821611441

161-VB000,161176III12

82

13

12

00920941511761

391-VB000,391408VI32

13

43

32

00933461901002

212-VB000,212388VI52

33

73

52

00342181901912

742-VB000,7429201VI62

43

93

62

03155081701652

972-VB000,9723611V03

73

54

03

00850402701882

333-VB000,3338831V03

73

54

03

00668691011543

583-VB000,5834061IV03

63

54

03

06870391601893

005-VB000,0053802IV73

44

65

73

097010942301815

016-VB000,0162452IV63

34

45

63

053215432601136

YREVILEDRIALACITREV YREVILEDRIALATNOZIROH

ledoM

epyT

ledoM

rebmuN

.rH/UTB

.tF.qS

RDE

ATADRIA

dnuoS

**ssalC

.xaM

gnitnuoM

*)tf(thgieH

taeH

tadaerpS

*thgieH.xaM mfC

teltuO

yticoleV

)mpF(

riAlaniF

.pmeT

)F°(

etasnednoC

rh/bl

81-HB008,4126I 9 2101359340151

42-HB007,9128I 9 3105355421112

33-HB001,72311I 014109459311192

74-HB005,83161II218156556432104

36-HB007,15612II411207807451145

68-HB005,07492II5122040107532137

801-HB006,88963II5132042100562119

121-HB002,99314II61325141075521301

561-HB003,531465III71420991006321931

391-HB003,851956III81620132596321461

* denepoyllufsedalb,rotcelfedtejenochtiwdeppiuqesepytlacitrev,enalplacitrevmorf°03neposrevuollatnozirohhtiwstinU

.dlobninwohsera

yrosseccateltuolanoitiddarof12egapeesesaelP.srotcelfedtuohtiwstinurofsiataddaerps/thgiehgnitnuomdedlob-noN

.atadecnamrofrep

.snoitinifeDssalCdnuoSrof7egapeeS**

YREVILEDRIALATNOZIROH

12

C.

SELECTION PROCEDURE - STEAM APPLICATION

Example 1:

GIVEN DESIGN CONDITIONS:

Unit Heater Model: BH-63

Steam Pressure: 10 lb

Entering Air Temperature: 70°F

APPLICATION PROCEDURE:

:yticapaC.1

utB

A

utB=

S

rotcaFyticapaCgnitaeHx

=60.1x000,36= rh/utB087,66

si36-HBnafoyticapacdradnatsehT

000,36 .3elbaTmorfrh/utB

rotcafnoisrevnocyticapacgnitaehmaetS

siecnatsmucr

icnevigrof 60.1 .5elbaTmorf

:etasnednoC.2

utB=etaRetasnednoC

A

maetSfotaeHtnetaL/

5.259/087,66= rh/.bl11.07=

.bl01tamaetsfotaehtnetalehT

si 5.259 .8elbaTmorf,.bl/utB

riAlaniF.3

:erutarepmeT

RTA

A

TAF(=

S

TAE-

S

rotcaFesiR.pmeTriAx)

=701x)F°06-F°21(= F°46.55

TAF

A

TAE=

A

RTA+

A

°46.55+F°07= F

F°46.521=

ta36-HBnafoerutarepmetrialanifehT

.dts sisnoitidnoc F°211 .3elbaTmorf

rofrotcafnoisrevnocesirerutarepmetri

A

siecnatsmucricnevig 70.1 .6elbaTmorf

.4gnitnuoM.xaM

:thgieH

HMM

A

HMM=

S

rotcaFnoitcerroCx

=49.0xteef41= eef61.31 t

noitidnoc.dtstathgiehgnitnuom.xamehT

si 41 .3elbaTmorf,teef

sirotcafnoitcerrocthgiehgnitnuomehT

49.0 .7elba

Tmorf

Example 2:

GIVEN DESIGN CONDITIONS:

Vertical Air Delivery requested

Heating Load: 100,000 Btu/hr

Entering Air Temperature: 50°F

Steam Pressure: 2 lb

APPLICATION PROCEDURE:

:noitceleStinU.1

utB

S

utB=

A

rotcaFyticapaCgnitaeH/

=70.1/000,001= rh/utB854,39

tceleS.)snoitidnocdradnatsta( .59-VB

ehtteemlliwledom59-VBna,3elbaTmorF

foyticapacdetarstihtiwstnemeriuqergnitaeh

000,59 .snoitidnocdradnatst

arh/utB

gnitaeHlautcA.2

:yticapaC

snoitidnoclautcata59-VBnafoyticapacehT

utBeblliw

A

utB=

S

rotcaFyticapaCgnitaeHx

=70.1x000,59= rh/utB056,101 .

rofrotcafnoisrevnocyticapacgnitaehmaetS

siecnatsmucricnevig 70.1 .5elbaTmorf

13

D.

STEAM CALCULATION FORMULAS

1. Refer to Table 5:

a. To determine the heating capacity (Btu/hr) of a

unit heater at a steam pressure and/or entering

air temperature other than standard conditions of

2 lb. Steam and 60°F entering air temperature.

b. To fi nd actual unit heater capacity when

operating at non-standard (actual) conditions:

Btu

A

= Btu

S

x Heating Capacity Factor

c. To select a heater capacity based on standard

conditions to meet a heating capacity at non-

standard (actual) conditions:

Btu

S

= Btu

A

/ Heating Capacity Factor

2. Refer to Table 6:

a. To determine the air temperature rise of a unit

heater at a steam pressure and/or entering air

temperature other than standard conditions of

2 lb. Steam, 60°F entering air temperature.

b. To fi nd actual air temperature rise of unit

heater when operating at non-standard (actual)

conditions:

ATR

A

= (FAT

S

- EAT

S

) x Air Temperature Rise

Factor

c. To fi nd actual fi nal air temperature of unit

heater when operating at non-standard (actual)

conditions:

FAT

A

= EAT

A

+ ATR

A

3. Refer to Table 7:

To determine how non-standard steam pressures

(other than 2 lb.) affect mounting height.

Max. Mounting Height

A

= Max. Mounting

Height

S

x Correction Factor

4. Refer to Table 8:

To determine the rate of condensate production at

steam pressures other than 2 lb.

Condensate Rate = Btu

A

/ Latent Heat of Steam

5. Terminology:

a. ATR

A

= Air temperature rise at non-standard

(actual) conditions

b. Btu

A

= Capacity at actual operating conditions

c. Btu

S

= Capacity at standard conditions (2 lb.

Steam, 60°F entering air temperature) from

Tables 3 and 4.

d. EAT

A

= Entering air temperature at non-standard

actual) conditions

e. EAT

S

= Entering air temperature at standard

conditions (60°F)

f. FAT

A

= Final air temperature at non-standard

(actual) conditions

g. FAT

S

= Final air temperature at standard

conditions from Tables 3 and 4.

h. Max. Mounting Height

A

= Maximum mounting

height at actual conditions

i. Max. Mounting Height

S

= Maximum mounting

height at standard conditions

14

E.

STEAM CORRECTION FACTORS

Table 5: Steam Heating Capacity Conversion Factors

tinU

retaeH

sepyT

gniretnE

.pmeTriA

)F°(

)GISP(ERUSSERPMAETS

0 2 5 01 51 02 03 04 05 06 07 57 08 09 001 521 051

01-45.195.146.137.108.168.179.160.231.202.262.282.213.263.214.215.206.2

054.105.155.146.117.177.178.169.140.290.261.281.212.262.213.214.205.2

0173.114.164.155.116.186.187.168.149.100.260.290.211.261.202.213.204.2

0272.123.173.164.135.185.186.177.158.109.169.199.120.260.211.212.203.2

0391.142.192.183.144.105.106.186.167.118.178.109.139.179.120.211.202.2

0411.161.112.192.143.124.115.106.176.137.187.118.148.188.139.120.211.2

0530.180.131.112.182.133.134.115.185.146.107.127.157.197.148.139.120.2

0669.000.150.131.191.152.153.134.105.165.116.146.166.117.157.148.139.1

0788.039.079.060.121.171.172.153.124.174.135.155.185.126.166.167.148.1

0818.058.009.089.040.101.191.172.143.193.154.174.105.145.185.186.167.1

0947.087.038.019.079.020.121.191.162.113.173.104.124.164.105.195.176.1

00176.017.067.048.009.059.040.121.191.142.192.123.143.183.124.115.195.1

01-94.125.185.146.107.157.138.109.169.120.270.201.211.251.291.272.243.2

014.154.105.175.126.176.157.128.178.149.199.120.240.280.211.291.262.2

0133.173.124.194.155.106.186.157.118.178.129.149.169.100.230.211.281.2

0252.192.143.114.174.125.116.186.147.197.148.168.188.129.159.199.101.2

0381.122.172.143.104.154.135.116.176.127.167.197.108.148.188.119.130.2

0411.151.102.172.123.173.164.135.195.146.196.117.137.177.108.188.159.1

0530.170.121.191.152.103.193.164.125.175.126.146.166.196.137.118.188.1

0669.000.150.121.181.132.123.193.154.105.155.175.195.126.166.147.118.1

0709.039.089.050.111.161.152.123.183.134.174.194.115.155.195.176.147.1

0838.068.019.089.040.190.181.152.113.163.104.124.144.184.125.106.176.1

0967.008.058.019.079.020.111.181.142.192.133.163.183.114.154.135.106.1

001

96.037.087.058.009.069.040.111.171.122.172.192.113.143.183.164.135.1

YREVILEDLACITREVYREVILEDLATNOZIROH

15

Table 6: Air Temperature Rise Conversion Factors

)GISP(erusserPmaetS

2501510203040506070809001521051571

rotcaFnoitcerroC

00.179.049.029.098.068.048.028.008.097.077.067.057.047.027.017.0

Table 7: Steam Unit Heater Mounting Height Correction Factors

tinU

retaeH

sepyT

gniretnE

.pmeTriA

)F°(

)GISP(ERUSSERPMAETS

0 2 5 01 51 02 03 04 05 06 07 57 08 09 001 521 051

01-33.183.134.105.165.116.107.187.148.119.159.179.100.240.280.271.252.2

082.133.183.154.115.165.156.137.197.168.119.139.159.100.240.231.212.2

0142.172.133.104.164.125.106.186.147.118.168.198.119.159.199.190.271.2

0271.122.172.153.124.164.155.126.196.157.118.148.168.109.159.140.221.2

03

21.171.112.192.163.114.115.185.156.117.167.197.128.168.198.199.170.2

0470.111.161.142.101.163.164.145.106.166.117.147.167.118.158.149.130.2

0510.160.111.191.142.103.104.184.155.116.166.196.127.157.197.198.189.1

0669.000.150.131.191.152.153.134.105.165.116.146.166.107.157.148.139.1

0709.049.000.170.141.191.192.183.154.105.165.185.116.156.196.197.178.1

0848.088.039.020.180.141.142.123.193.154.115.135.165.106.146.147.138.1

0987.038.088.059.020.180.181.162.133.104.154.174.194.145.195.186.177.1

00127.067.028.009.079.020.121.112.182.133.193.124.144.194.135.136.117.1

01-63.114.164.145.116.176.177.158.129.199.150.280.201.251.291.292.293.2

013.153.104.184.155.116.117.197.168.139.199.120.240.290.241.242.233.2

0152.192.153.134.194.155.156.147.118.188.149.169.199.140.280.281.272.2

0291.142.192.173.144.105.106.186.157.128.188.119.139.100.220.221.222.2

0331.181.132.113.183.144.145.126.196.167.128.158.178.129.179.170.261.2

0480.121.171.152.123.183.184.165.146.107.167.197.118.168.119.110.201.2

0520.160.121.102.162.123.124.115.185.156.107.137.157.108.158.159.140.2

0669.000.160.141.102.162.163.154.125.185.156.176.107.147.197.198.199.1

0709.049.000.180.141.102.103.193.164.135.195.126.146.196.137.138.139.1

0848.088.049.020.190.151.152.133.104.174.135.165.185.136.176.177.178.1

0987.028.088.069.020.180.181.172.143.114.174.105.125.175.116.117.118.1

001

27.067.028.098.079.020.121.112.182.153.114.134.164.115.155.156.157.1

YREVILEDLACITREVYREVILEDLATNOZIROH

16

Table 8: Properties of Steam

eguaG

erusserP

)GISP(

pmeT

)F°(

taeHtnetaL

).bl/utB(

eguaG

erusserP

)GISP(

pmeT

)F°(

taeHtnetaL

).bl/utB(

eguaG

erusserP

)GISP(

pmeT

)F°(

taeHtnetaL

).bl/utB(

eguaG

erusserP

)GISP(

pmeT

)F°(

taeHtnetaL

).bl/utB(

00.2123.079

43

4.9727.429 070.6133.798 9016.3434.578

25.8122.669 639.1829.229 277.7130.698 2114.5439.378

44.4224.269 833.4821.129 473.9138.498 5112.7435.278

52.7226.069 047.6823.919 679.0235.398 8119.8430.178

68.9228.859 240.9826.719 874.2233.298 1217.0536.968

88.4326.559 443.1929.519 089.3231.198 4214.2532.868

014.9325.259 645.3923.419 284.5239.988 5219.2538.768

217.3426.949 846.5927.219 489.6238.888 7210.4539.668

418.7428.649 057.7922.119 684.8236.788 0317.5535.568

616.1522.449 257.9927.909 888.9235.688 3313.7531.468

813.5527.149 457.1032.809 092.1334.588 6319.8539.268

028.8523.939 656.3037.609 295.2333.488 9314.0635.168

221.2629.639 855.5033.509 499.3332.388 2410.2633.068

423.5627.439 063.7039.309 692.5331.288 5415.3630.958

623.8625.239 261.9035.209 896.6331.188 0519.5639.658

823.1725.039 469.0132.109 0019.7330.088 5714.7738.648

031.4725.829 666.2139.998 3018.9335.878 0029.7832.738

238.6726.629 864.4136.898 6017.1439.678 5223.7935.828

17

Table 10: Hot Water Performance Data -- Reduced Motor Speed

Table 9: Hot Water Performance Data -- High Motor Speed

F. HOT WATER PERFORMANCE DATA (at Standard Conditiions of 200°F Entering Water, 60°F Entering Air and

20°F Water Temperature Drop)

ledoM

epyT

ledoM

rebmuN .rH/UTB

ATADRETAW ATADRIA

MPG

erusserP

porD

fo.tf(

)retaw

xaM/niM

MPG

dnuoS

**ssalC

.xaM

gnitnuoM

*).tf(thgieH

taeH

tadaerpS

*thgieH.xaM mfC

teltuO

yticoleV

)mpF(

riAlaniF

.pmeT

)F°(

81-HB000,313.194.00.5/3.0II9 8100400509

42-HB003,717.138.00.5/3.0II010205407569

33-HB005,425.221.00.01/4.0II112203659469

74-HB008,334.312.00.01/4.0III3162037085301

36-HB005,647.474.00.51/5.0III5103021109589

68-HB009,162.697.00.51/5.0III61130431017301

801-HB000,181.858.00.02/5.0III61330551506801

121-HB000,090.940.10.02/7.0III71635771096701

561-HB000,3313.3184.20.03/0.2VI81830052537901

391-HB000,6516.5153.30.03/0.2VI91040092058011

852-HB000,8918.9145.30.04/5.2V02240093598701

092-HB000,4224.2254.40.04/5.2V12640034099801

043-HB000,3723.7

242.30.05/5.2V22050315549901

24-VB005,031.390.00.01/5.0II11

51

71

11

05967719

95-VB003,445.481.00.51/8.0II41

91

12

51

051104979

87-VB005,850.634.00.02/0.1II51

12

32

61

055109969

59-VB000,172.716.00.52/3.1II71

32

52

71

5771231199

931-VB000,1113.1148.00.03/0.1III81

52

82

91

00521821301

161-VB008,8211.3111.10.04/3.1III22

03

33

12

00928841301

391-VB007,2415.4118.00.05/5.1VI42

33

63

42

0093046159

212-VB000,9511.6189.00.06/0.2VI52

53

73

52

0034908169

742-VB000,7919.9156.10.06/0.2VI72

63

04

72

0315308179

972-VB000,0222.2210.20.57/3.2V13

93

74

13

0085730279

333-VB000,5627.6272.10.57/8.2V03

83

64

03

0066669199

583-VB000,8031.1386.10.57/3.3IV33

04

94

33

0687829179

005-VB000,3049.0423.20.001/0.3IV04

84

06

04

09701784249

016-VB000,9543.6424.20.001/0.6IV93

74

85

04

05321343279

YREVILEDRIALACITREV YREVILEDRIALATNOZIROH

ledoM

epyT

ledoM

rebmuN

.rH/UTB

ATADRETAW ATADRIA

MPG

erusserP

porD

fo.tf(

)retaw

dnuoS

**ssalC

.xaM

gnitnuoM

*).tf(thgieH

taeH

tadaerpS

*thgieH.xaM mfC

teltuO

yticoleV

)mpF(

riAlaniF

.pmeT

)F°(

81-HB066,013.194.0I9 3101309329

42-HB681,417.138.1I 014105305489

33-HB090,025.221.0I 116109409389

74-HB617,724.312.0II3181565554501

36-HB031,837.474.0II5112078064101

68-HB857,052.697.0II61220401055501

801-HB024,661.858.0II61320421584011

121-HB008,370.940.1II71625141555801

561-HB060,9013.3184.2III81720991095111

391-HB029,7216.5153.3III91820132086111

* denepoyllufsedalb,rotcelfedtejenochtiwdeppiuqesepytlacitrev,enalplacitrevmorf°03neposrevuollatnozirohhtiwstinU

.dlobninwohsera

yrosseccateltuolanoitiddarof12egapeesesaelP.srotcelfedtuohtiwstinurofsiataddaerps/thgiehgnitnuomdedlob-noN

.atadecnamrofrep

.snoitinifeDssalCdnuoSrof7egapeeS**

YREVILEDRIALATNOZIROH

18

G.

SELECTION PROCEDURE - HOT WATER APPLICATION

:yticapaC.1

utB

A

utB=

S

rotcaFyticapaCgnitaeHx

=272.1x003,44= rh/utB053,65

si95-VBnafoyticapacdradnatsehT

003,44 .9elbaTmorfrh/utB

rotcafnoisrevnocyticapacgnitaehmaetS

siecnatsmucricnevigrof 272.1 .11elbaTmorf

:etaRwolFretaW.2

dradnatssaemaS

anopudesabsi95-VBnoyticapacdradnatsehT

foetarwolfretaw 5.4 .9elbaTmorf,MPG

riAlaniF.3

:erutarepmeT

TAF

A

TAE=

A

TAE+064([+

A

/)

mfCx675(

S

utB/)

A

])1-

TAF

A

/)07+064([+F°07=

=])1-053,65/)0511x675( F°911

si95-VBnafowolfriadradnatsehT 0511 ,MFC

.9elbaTmorf

.4gnitnuoM.xaM

:thgieH

DTW

A

utB=

A

/053,65=)AGx084(/

=)5.4x084( F°90.62

anopudesabsi95-VBnoyticapacdradnatsehT

foetarwolfretaw 5.4 .9elbaTmorf,MPG

gnitnuoM.xaM.5

:thgieH

HMM

A

HMM=

S

rotcaFnoitcerroCx

=68.0xteef41= teef0.21

noitidnocdradnatstathgiehgnitnuom.xamehT

si 41 .9elbaTmorf,teef

sirotcafnoitcerrocthgiehgnitnuomehT

68.0 .41elbaTmorf

Example 1:

GIVEN DESIGN CONDITIONS:

Unit Heater Model: BV-59, Entering Water Temperature: 250°F, Entering Air Temperature: 70°F

APPLICATION PROCEDURE:

Example 2:

GIVEN DESIGN CONDITIONS:

Horizontal Air Delivery requested, Heating Load: 120,000 Btu/hr, Entering Air Temp.: 50°F, Entering Water Temp.:

180°F

:noitceleStinU.1

utB

S

utB=

A

rotcaFyticapaCgnitaeHx

=049.0/000,021= rh/utB066,721

tceleS.)snoitidnocdradnatsta( .561-HB

rofrotcafnoisrevnocyticapacgnitaehretaWtoH

siecnatsmucricnevig 049.0 .11elbaTmorf

gnitaeHlautcA.2

:yticapaC

lautcata561-HBnafoyticapacehT

utBeblliwsnoitidnoc

A

utB=

X

gnitaeHx

=049.0x000,331=rotcaFyticapaC

rh/utB020,521

rofrotcafnoisrevnocyticapacgnitaehretaWtoH

siecnatsmucricnevig 049.0 .11elbaTmorf

riAlaniF.3

:erutarepmeT

TAF

A

TAE=

A

TAE+064([+

A

utB(x)

A

/)

mfCx675(

S

x05+064([x05=])

=])0052x675(/)020,521( F°49

siecnatsmucricnevigrofmfC 0052 morf

.9elbaT

.4erutarepmeTretaW

:porD

DTW

A

utB=

A

MPGx084(/

A

)

=)3.31x084(/020,521= °5.91 F

MPG

A

siecnatsmucricnevigrof 3.31 morf

.9elbaT

gnitnuoM.xaM.5

:thgieH

HMM

A

HMM=

S

tcerroCx rotcaFnoi

=80.1x81= teef4.91

sirotcafnoitcerrocthgiehgnitnuomehT 80.1

.41elbaTmorf

APPLICATION PROCEDURE:

19

H.

HOT WATER CALCULATION FORMULAS

1. Refer to Table 11:

a. To determine the heating capacity (Btu/hr) of a

unit heater at a water temperature and/or entering

air temperature other than standard conditions of

200°F entering water temperature, 60°F entering

air temperature.

b. To fi nd actual unit heater capacity when

operating at non-standard (actual) conditions:

Btu

A

= Btu

S

x Heating Capacity Factor

c. To select a heater capacity based on standard

conditions to meet a heating capacity at non-

standard (actual) conditions:

Btu

S

= Btu

A

/ Heating Capacity Factor

2. Refer to Table 12:

a. To determine how water temperature drop affects

heat capacity in Btu, water fl ow rate is in GPM

and pressure drop in feet of water. These factors

should be applied to the values at actual entering

water and air temperature conditions.

b. To fi nd actual unit heater capacity or fl ow rate

or pressure drop when operating at non-standard

(actual) conditions:

Btu

A

= Btu

S

x Btu Correction Factor

GPM

A

= GPM

S

x GPM Correction Factor

WPD

A

= WPD

S

x WPD Correction Factor

c. To select a heater capacity based on standard

conditions to meet a heating capacity at non-

standard (actual) conditions:

Btu

S

= Btu

A

/ Btu Correction Factor

d. Other useful formulas:

FAT

A

= EAT

A

+ [(460 + EAT

A

) x (Btu

A

) / (576 x

Cfm

S

)] For BH units only

FAT

A

= EAT

A

+ [(460 + EAT

A

) / (576 x Cfm

S

/

Btu

A

)-1)] For BV Units only

3. Refer to Table 13:

a. To determine how glycol solutions affect heater

capacity. These factors should be applied to the

heater capacity at actual entering water and air

temperature conditions.

b. To fi nd actual unit heater capacity when operated

with glycol solution:

Btu

AG

= Btu

S

(or Btu

A

) x Glycol Correction

Factor

c. To select a heater capacity based on standard

conditions to meet a heating capacity with glycol

solution:

Btu

S

(or Btu

A

) = Btu

AG

/ Glycol Correction

Factor

4. Refer to Table 14:

To determine how water temperatures other than

200°F affect mounting height of unit.

Max. Mounting Height

A

= Max. Mounting

Height

S

x Correction Factor

5. Terminology:

a. Btu

A

= Capacity at non-standard (actual)

conditions

b. Btu

AG

= Capacity with Glycol solution

c. Btu

S

= Capacity at standard conditions (200°F

entering air temperature, 60°F entering air

temperature) from Tables 9 and 10

d. Cfm

S

= Unit airfl ow as found in Tables 9 and 10

e. EAT

A

= Entering air temperature at actual

conditions

f. FAT

A

= Final air temperature at actual conditions

g. GPM

A

= Water fl ow rate at actual conditions in

GPM

h. GPM

S

= Flow rate at standard conditions (200°F

entering water temperature, 60°F entering air

temperature) from Tables 9 and 10

i. Max. Mounting Height

A

= Maximum mounting

height at actual conditions

j. Max. Mounting Height

S

= Maximum mounting

height at standard conditions

k. WPD

A

= Water pressure drop at non-standard

(actual) conditions

l. WPD

S

= Water pressure drop at standard

conditions (200°F entering water temperature,

60°F entering air temperature) from Tables 9 and

10

20

riAgniretnE

)F°(.pmeT

)F°(ERUTAREPMETRIAGNIRETNE

0 01 02 03 04 05 06 07 08 09 001

001

967.0386.0995.0815.0934.0163.0682.0212.0041.0960.0000.0

011

648.0957.0476.0295.0215.0434.0753.0382.0012.0831.0860.0

021

329.0538.0947.0666.0585.0605.0924.0353.0972.0702.0731.0

031

000.1119.0428.0047.0856.0875.0005.0424.0943.0672.0502.0

041

770.1789.0998.0418.0137.0156.0175.0494.0914.0543.0372.0

051

451.1360.1479.0888.0508.0327.0346.0565.0984.0414.0243.0

061

132.1931.1940.1269.0878.0597.0417.0636.0955.0384.0014.0

071

803.1512.1421.1630.1059.0768.0687.0607.0926.0255.0874.0

081

583.1192.1991.1011.1420.1049.0758.0777.0996.0126.0745.0

091

294.1763.1472.1481.1790.1210.1929.0848.0867.0096.0516.0

002

935.1344.1943.1852.1071.1480.1000.1819.0838.0957.0486.0

012

516.1915.1424.1233.1342.1751.1170.1989.0809.0828.0257.0

022

269.1495.1994.1604.1213.1922.1341.1060.1879.0798.0028.0

032

967.1076.1375.1084.1093.1103.1142.1031.1840.1669.0988.0

042

648.1647.1946.1455.1364.1373.1682.1102.1811.1530.1759.0

052

329.1228.1327.1826.1635.1644.1753.1272.1881.1401.1520.1

062

000.2898.1897.1207.1906.1815.1924.1243.1752.1371.1490.1

072

770.2479.1378.1677.1286.1095.1005.1314.1723.1242.1261.1

082

451.2050.2849.1058.1557.1366.1175.1384.1793.1113.1032.1

092

132.2621.2320.2429.1928.1437.1346.1455.1764.1083.1003.1

003

803.2202.2890.2899.1209.1708.1417.1526.1735.1944.1763.1

I. HOT WATER CORRECTION FACTORS

Table 11: Hot Water Heating Capacity Conversion Factors

Table 12: Correction Factors for Varying Water Temperature Drop*

Table 13: Ethylene Glycol Correction Factors**

Table 14: Hot Water Unit Heater Mounting Height Correction Factors***

)F°(,porDerutarepmeTretaW

5 01 51 02 52 03 53 04 54 05 55 06

rotcaFnoitcerroCutB

32.131.160.100.159.009.068.028.087.027.096.076.0

rotcaFnoitcerroCMPG

46.412.204.100.167.016.005.024.063.003.062.032.0

rotcaFnoitcerroCDPW

42.7123.458.100.116.014.003.022.081.041.021.011.0

.snoitidnocerutarepmetriaF°06dnaretawgniretneF°002dradnatsrofylnodilavsrotcafnoitcerrocporderutarepmetretaW*

)F°(erutarepmeTnoituloS

%NOITULOSLOCYLGENELYHTE

%02 %03 %04 %05 %06 %07 %08

001

99.069.039.098.058.018.067.0

051

99.069.049.009.078.038.087.0

002

99.079.049.029.088.058.018.0

052

89.069.049.029.098.068.028.0

.59.0ybrotcafnoitcerroclocylGenelyhtEylpitlum,rotcafnoitcerrocnoituloslocylGenelyporProF**

F°,ERUTAREPMETRETAWGNIRETNE

041 051 061 071 081 091 002 012 022 032 042 052 062 072 082 092 003

noitcerroC

rotcaF

33.152.191.131.180.140.100.179.049.019.098.068.048.028.008.087.077.0

.F°07otF°05morfgnignarerutarepmetriagniretnehtiwesuroferasrotcaF***

/