Page is loading ...

Patent Pending

August 23, 2017

HK1015

Makers of Huck

®

, Marson

®

, Recoil

®

Brand Fasteners, Tools & Accessories

Declaration of Conformity

2

Safety Instructions

3

Principle of Operation

4

Tool Specications

4

Preparation for Use

5

Maintenance

5

Operating Instructions

6

Disassembly Procedure

6-7

Assembly Procedure

8

Fill and Bleed Procedure

9

Components Drawings

10-11

Troubleshooting

14

Accessories

14

Instruction Manual

256

Pneudraulic Installation Tool

256 Pneudraulic Installation Tool (HK1015)

2

256 Pneudraulic Installation Tool (HK1015)

3

I. GENERAL SAFETY RULES:

1.Ahalfhourlonghands-ontrainingsessionwithqualiedpersonnelis

recommendedbeforeusingHuckequipment.

2.Huckequipmentmustbemaintainedinasafeworkingconditionatall

times.Toolsandhosesshouldbeinspectedatthebeginningofeach

shift/dayfordamageorwear.Anyrepairshouldbedonebyaqualied

repairmantrainedonHuckprocedures.

3.Formultiplehazards,readandunderstandthesafetyinstructionsbefore

installing,operating,repairing,maintaining,changingaccessorieson,

orworkingneartheassemblypowertool.Failuretodosocanresultin

serious bodily injury.

4.Onlyqualiedandtrainedoperatorsshouldinstall,adjustorusethe

assemblypowertool.

5.Donotmodifythisassemblypowertool.Thiscanreduceeffectivenessof

safetymeasuresandincreaseoperatorrisk.

6.Donotdiscardsafetyinstructions;givethemtotheoperator.

7.Donotuseassemblypowertoolifithasbeendamaged.

8.Toolsshallbeinspectedperiodicallytoverifyallratingsandmarkings

required,andlistedinthemanual,arelegiblymarkedonthetool.The

employer/operatorshallcontactthemanufacturertoobtainreplacement

markinglabelswhennecessary.Refertoassemblydrawingandpartslist

forreplacement.

9. Tool is only to be used as stated in this manual. Any other use is

prohibited.

10.ReadMSDSSpecicationsbeforeservicingthetool.MSDS

specicationsareavailablefromtheproductmanufactureroryourHuck

representative.

11.OnlygenuineHuckpartsshallbeusedforreplacementsorspares.Use

ofanyotherpartscanresultintoolingdamageorpersonalinjury.

12.Neverremoveanysafetyguardsorpintaildeectors.

13.Neverinstallafastenerinfreeair.Personalinjuryfromfastenerejecting

may occur.

14.Whereapplicable,alwaysclearspentpintailoutofnoseassembly

before installing the next fastener.

15.Checkclearancebetweentriggerandworkpiecetoensurethereisno

pinchpointwhentoolisactivated.Remotetriggersareavailablefor

hydraulictoolingifpinchpointisunavoidable.

16.Donotabusetoolbydroppingorusingitasahammer.Neveruse

hydraulicorairlinesasahandleortobendorprythetool.Reasonable

careofinstallationtoolsbyoperatorsisanimportantfactorin

maintainingtoolefciency,eliminatingdowntime,andpreventingan

accidentwhichmaycauseseverepersonalinjury.

17.Neverplacehandsbetweennoseassemblyandworkpiece.Keephands

clear from front of tool.

18.Toolswithejectorrodsshouldneverbecycledwithoutnoseassembly

installed.

19.Whentwopiecelockboltsarebeingusedalwaysmakesurethecollar

orientationiscorrect.Seefastenerdatasheetforcorrectpositioning.

II. PROJECTILE HAZARDS:

1.Riskofwhippingcompressedairhoseiftoolispneudraulicorpneumatic.

2.Disconnecttheassemblypowertoolfromenergysourcewhenchanging

inserted tools or accessories.

3.Beawarethatfailureoftheworkpiece,accessories,ortheinsertedtool

itselfcangeneratehighvelocityprojectiles.

4.Alwayswearimpactresistanteyeprotectionduringtooloperation.The

gradeofprotectionrequiredshouldbeassessedforeachuse.

5. The risk of others should also be assessed at this time.

6.Ensurethattheworkpieceissecurelyxed.

7.Checkthatthemeansofprotectionfromejectionoffastenerorpintailis

inplaceandoperative.

8.Thereispossibilityofforcibleejectionofpintailsorspentmandrelsfrom

front of tool.

III. OPERATING HAZARDS:

1.Useoftoolcanexposetheoperator’shandstohazardsincluding:

crushing,impacts,cuts,abrasionsandheat.Wearsuitableglovesto

protecthands.

2.Operatorsandmaintenancepersonnelshallbephysicallyabletohandle

thebulk,weightandpowerofthetool.

3. Hold the tool correctly and be ready to counteract normal or sudden

movementswithbothhandsavailable.

4.Maintainabalancedbodypositionandsecurefooting.

5.Releasetriggerorstopstartdeviceincaseofinterruptionofenergy

supply.

6.Useonlyuidsandlubricantsrecommendedbythemanufacturer.

7.Avoidunsuitablepostures,asitislikelyforthesenottoallow

counteractingofnormalorunexpectedtoolmovement.

8.Iftheassemblypowertoolisxedtoasuspensiondevice,makesurethat

xationissecure.

9.Bewareoftheriskofcrushingorpinchingifnoseequipmentisnottted.

IV. REPETITIVE MOTION HAZARDS:

1.Whenusingassemblypowertool,theoperatorcanexperience

discomfortinthehands,arms,shoulders,neckorotherpartsofthebody.

2.Whenusingtool,theoperatorshouldadoptacomfortableposture

whilemaintainingasecurefootingandavoidawkwardoroffbalanced

postures.

3.Theoperatorshouldchangepostureduringextendedtaskstohelpavoid

discomfort and fatigue.

4.Iftheoperatorexperiencessymptomssuchaspersistentorrecurring

discomfort,pain,throbbing,aching,tingling,numbness,burning

sensationsorstiffness,thesewarningsshouldnotbeignored.The

operatorshouldtelltheemployerandconsultaqualiedhealth

professional.

V. ACCESSORIES HAZARDS:

1.Disconnecttoolfromenergysupplybeforechanginginsertedtoolor

accessory.

2.Useonlysizesandtypesofaccessoriesandconsumablesthatare

recommended.Donotuseothertypesorsizesofaccessoriesor

consumables.

VI. WORKPLACE HAZARDS:

1.Beawareofslipperysurfacescausedbyuseofthetoolandoftrip

hazardscausedbytheairlineorhydraulichose.

2.Proceedwithcautionwhileinunfamiliarsurroundings;therecouldbe

hiddenhazardssuchaselectricityorotherutilitylines.

3.Theassemblypowertoolisnotintendedforuseinpotentiallyexplosive

environments.

4.Toolisnotinsulatedagainstcontactwithelectricalpower.

5.Ensuretherearenoelectricalcables,gaspipes,etc.,whichcancausea

hazardifdamagedbyuseofthetool.

VII. NOISE HAZARDS:

1.Exposuretohighnoiselevelscancausepermanent,disablinghearing

lossandotherproblemssuchastinnitus,thereforeriskassessmentand

theimplementationofpropercontrolsisessential.

2.Appropriatecontrolstoreducetheriskmayincludeactionssuchas

dampingmaterialstopreventworkpiecefrom‘ringing’.

3.Usehearingprotectioninaccordancewithemployer’sinstructionsandas

requiredbyoccupationalhealthandsafetyregulations.

4.Operateandmaintaintoolasrecommendedintheinstructionhandbook

topreventanunnecessaryincreaseinthenoiselevel.

5.Select,maintainandreplacetheconsumable/insertedtoolas

recommendedtopreventanunnecessaryincreaseinnoise.

6.Ifthepowertoolhasasilencer,alwaysensurethatitisinplaceandin

goodworkingorderwhenthetoolisbeingoperated.

VIII. VIBRATION HAZARDS:

1.Exposuretovibrationcancausedisablingdamagetothenervesand

bloodsupplytothehandsandarms.

2.Wearwarmclothingwhenworkingincoldconditionsandkeephands

warm and dry.

3.Ifnumbness,tingling,painorwhiteningoftheskininthengersor

hands,stopusingthetool,tellyouremployerandconsultaphysician.

4.Supporttheweightofthetoolinastand,tensionerorbalancerinorder

tohavealightergriponthetool.

IX. PNEUMATIC / PNEUDRAULIC TOOL SAFETY INSTRUCTIONS:

1.Airunderpressurecancausesevereinjury.

2.Alwaysshutoffairsupply,drainhoseofairpressureanddisconnecttool

fromairsupplywhennotinuse,beforechangingaccessoriesorwhen

makingrepairs.

3.Neverdirectairatyourselforanyoneelse.

4.Whippinghosescancausesevereinjury,alwayscheckfordamagedor

loosehosesandttings.

5. Cold air should be directed away from hands.

6.Wheneveruniversaltwistcouplings(clawcouplings)areused,lockpins

shallbeinstalledandwhip-checksafetycablesshallbeusedtosafeguard

againstpossiblehosetohoseorhosetotoolconnectionfailure.

7.Donotexceedmaximumairpressurestatedontool.

8.Nevercarryanairtoolbythehose.

Safety Instructions

GLOSSARYOFTERMSANDSYMBOLS:

- Productcomplieswithrequirementssetforthby

therelevantEuropeandirectives.

- Readmanualpriortousingthisequipment.

- Eyeprotectionisrequiredwhileusingthis

equipment.

- Hearingprotectionisrequiredwhileusingthis

equipment.

Notes:areremindersofrequiredprocedures.

Bold, Italic type, and underline:emphasizeaspecic

instruction.

WARNINGS: Must be understood to avoid

severe personal injury.

CAUTIONS: Show conditions that will damage

equipment or structure.

256 Pneudraulic Installation Tool (HK1015)

4

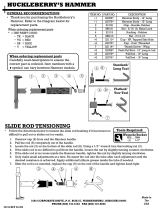

1

2

12

10

11

5

6

3

4

9

7

Spring

8

Pressurized Air

Exhaust Air

Pressurized Hydraulic Fluid

Non-pressurizedHydraulicFluid

AirPiston

movesup

Exhaust Air

PullPiston

movesback

Hydraulic

PistonRod

movesup

ThrottleValve

movesdownto

(PULLposition)

Trigger

Depressed

Hydraulic

PistonRod

movesdown

ThrottleValve

movesupto

RETURNposition

Trigger

Released

PullPistonreturns

tohomeposition

Exhaust Air

WhentheTriggerisdepressed(1),the

ThrottleValvemovestothedownposition

(2),andpressurizedairisdirectedtothe

bottomoftheAirPiston,causingittomove

upward(3).TheairabovethePistonis

exhausted and directed through the center

oftheThrottleValveandoutthebottom

ofthetool(4).TheAirPistonhasaRod

andaHydraulicPistonattached.Whenthe

AirPistonrodmovesupward,acolumnof

pressurizedhydraulicuidisforcedup(5)

intothetoolhead,whichmovesthePull

Pistonback(6).Theattachednoseassembly

moveswiththePullPistontostartfastener

installation. When fastener installation is

completed,theTriggerisreleased(7).Air

pressure,withtheassistanceofaSpring(8),

causestheThrottleValvetoreturntoitsup

position(9).Pressurizedairisre-directedto

thetopoftheAirPiston,causingit,along

withtheHydraulicPistonRod,tomove

downward(10).TheairfrombelowtheAir

Pistonisexhaustedthroughthebottom

ofthetool(11).Asthisoccurs,hydraulic

pressureisreversedandthePullPistonis

returnedforward(12).Areturnpressure

reliefvalveprotectsthetoolagainstpressure

spikes.Thereservoirreplenishesthehydraulic

system as needed.

Principle of Operation

POWER SOURCE:

110psiMAXshopair

HOSE KITS:

UseonlygenuineHUCKHoseKits

rated@10,000psiworking

pressure.

HYDRAULIC FLUID:

HydraulicuidshallmeetDEXRON®

III,DEXRONVI,MERCON,AllisonC-4

orequivalentATFspecications.

Fireresistantuidmaybeusedif

itisanesterbaseduidsuchas

QuintolubricHFDorequivalent.

WaterbaseduidshallNOTbeused

asseriousdamagetoequipmentwill

occur.

WEIGHT: 11.1 lbs (5.03 kg)

MAX OPERATING TEMP:

125°F (51.7°C)

SPEED/CYCLES: 30perminute

MAX FLOW RATE:

22.4 scfm (634 l/m)

MIN PULL CAPACITY:

9986 lbs (44.42 kN) @ 90psi

MAX INLET PRESSURE:

110psi(6.2 bar)

MIN STROKE:

.875 inches (2.22 cm)

.750 inches (1.91 cm) when used with

Stroke Limiter 118362-1

Where the following trade names are used

in this manual, please note:

DEXRON is a registered trademark of General

Motors Corporation.

Loctite is a registered trademark of Henkel

Corporation, U.S.A.

LUBRIPLATE is a registered trademark of Fiske

Brothers Rening Co.

MERCON is a registered trademark of Ford

Motor Corp.

Never-Seez is a registered trademark of Bostik,

Inc.

Quintolubric is a registered trademark of

Quaker Chemical Corp.

Slic-tite is a registered trademark of LA-CO

Industries, Inc.

Spirolox is a registered trademark of Smalley

Steel Ring Company

Teon is a registered trademark of E. I. du

Pont de Nemours and Company.

Threadmate is a registered trademark of

Parker Intangibles LLC.

TRUARC is a trademark of TRUARC Co. LLC.

Vibra-Tite is a registered trademark of ND

Industries, Inc. USA.

.96

(2.4)

15.05

(38.2)

6.17

(15.7)

3.98

(10.1)

8.78

(22.3)

6.12

(15.5)

Ø

1.92

(4.9)

Ø

4

°

HUCK

Specications

256 Pneudraulic Installation Tool (HK1015)

5

Preparation for Use

NOTE: WARNING Sticker and HUCK Trademark Sticker

must be in place and readable at all times.

GENERAL

1.Theefciencyandlifeofanytooldependsupon

propermaintenance.Regularinspectionand

correctionofminorproblemswillkeeptool

operatingefcientlyandpreventdowntime.The

toolshouldbeservicedbypersonnelwhoare

thoroughlyfamiliarwithhowitoperates.

2. Aclean,well-lightedareashouldbeavailablefor

servicingthetool.Specialcaremustbetaken

topreventcontaminationofpneumaticand

hydraulic systems.

3.Properhandtools,bothstandardandspecial,

mustbeavailable.

4.Allpartsmustbehandledcarefullyandexamined

fordamageorwear.AlwaysreplaceSeals,when

toolisdisassembledforanyreason.Components

should be disassembled and assembled in a

straightlinewithoutbending,cocking,orundue

force.Disassemblyandassemblyprocedures

outlined in this manual should be followed.

5.ServicePartsKit256KITincludesconsumable

partsandshouldbeavailableatalltimes.Other

components,asexperiencedictates,shouldalso

beavailable.

DAILY

1. If a Filter-Regulator-Lubricator unit is not being

used,uncoupleairdisconnectsandputafew

dropsofAutomaticTransmissionFluidorlight

oil into the air inlet of the tool. If the tool is in

continuoususe,putafewdropsofoilinevery

two to three hours.

2. Bleed the air line to clear it of accumulated dirt or

water before connecting air hose to the tool.

3.Checkallhosesandcouplingsfordamageorair

leaks,tightenorreplaceifnecessary.

4.Checkthetoolfordamageorair/hydraulicleaks,

tightenorreplaceifnecessary.

5. Check the nose assembly for tightness or

damage,tightenorreplaceifnecessary.

6.Checkoillevelintoolreservoir,replenishif

necessary.

WEEKLY

1. Disassemble and clean nose assemblies and

reassemble.

2.Checkthetoolandallconnectingpartsfor

damageoroil/airleaks,tightenorreplaceif

necessary.

TheModel256InstallationToolisshippedwithaplastic

plugintheairinletconnector.Theconnectorhas1/4-18

femalepipethreadstoaccepttheairhosetting.Quick

disconnectttingsand1/4”insidediameterairhoseare

recommended.Anairsupplyof90-100psicapableof22.4

CFMmustbeavailable.Airsupplyshouldbeequipped

withalter-regulator-lubricatorunit.

1. Removeplasticshippingplugfromairinletconnector

andputinafewdropsofAutomaticTransmission

Fluid,DEXRONIII,orequivalent.

2. ApplyTEFLONinstickformtothreadsofAirHose,and

screw hose into the tool.

3. Setairpressureonregulatorto90-100psi.

4. Screwairtting(notsuppliedwithtool)intoAirHose

andconnecttoairsource.Quickdisconnectttinginto

AirInletConnector,orscrewquickdisconnecttting

intoAirInletConnector,thenattachoptionalAirHose

suppliedwithtool.

5. Cycletoolafewtimesbydepressingandreleasing

trigger.

6. Disconnect air hose from tool.

7. Removeretainingnutandstop.

8. Selectpropernoseassemblyforfastenertobe

installed.

9. Screwcolletassembly,includinglockcollarandshim,if

applicable,ontospindleholdingHydraulicPullPiston

of tool with 3/8 hex key. Wrench tight.

10.Slidenoseassemblyanvilovercolletassemblyandinto

counterbore.

11.Slidetool’sStopandRetainingNutovernoseassembly

anvilandscrewNutontotoolhead.

12.Connectairhosetotoolandinstallfastener(s)ina

testplateofproperthicknesswithpropersizeholes.

Inspectfastener(s).

NOTE: Threadmate® should be used on collet threads

for nose assemblies without lock collars. All other

noses should be staked.

Caution:DonotuseTEFLONtapeonthreads.Use

onlyinstickform:HuckP/N503237.

WARNING: Inspect tool for damage or wear

before each use. Do not operate if damaged or

worn, as severe personal injury may occur.

Maintenance

256 Pneudraulic Installation Tool (HK1015)

6

Operating Instructions

LOCKBOLT® FASTENER INSTALLATION:

Placepininworkholeandplacecollaroverpin.See

WARNING.(IfCollarhasonlyonetaperedend,thatend

mustbefacingtowardtool,notnexttoworkpiece.)Hold

pinandpushnoseassemblyontopinprotrudingthrough

collaruntilnoseassemblyanviltouchescollar.Press

triggerandholdpresseduntilcollarisswagedandpintail

breaks. Release trigger and tool will go into return stroke.

The tool and nose assembly are ready for the next fastener

installation cycle.

BLIND FASTENER INSTALLATION:

Removeexcessgapfrombetweenthesheetstopermit

correct fastener installation. Tool and nose assembly must

beheldagainstworkpiece,andatarightangletoit.Press

triggerandholditpresseduntilfastenerisinstalledand

pintailbreaks.Releasetriggerandtoolwillgointoits

return stroke. The tool and nose assembly are ready for

next fastener installation cycle.

Failure to understand WARNINGS may cause serious personal injury. Failure to understand CAUTIONS may

cause damage to structure and Tool. For additional Safety Information, see page 4.

NOTE:Disassembleonlythosecomponentsnecessaryto

replacedamagedO-rings,Quadrings,Back-uprings,and

wornordamagedcomponents.Alwaysusesoft-jawvice

toavoiddamagetotool.

1.Disconnectairhosefromtoolandremovenose

assembly.

3.(Figure1)InsertFillToolthroughreservoirhousing

andscrewintoReservoirPlunger,lockingitintheout

position.

4.Unscrew4CapScrewswith5/32hexkey.Carefully

liftToolHeadstraightupfromHandle,andremove

PullandReturnGlandAssemblies.Removesealsfrom

glands.

5.UnscrewReliefValvePlugfromfrontofhead.Remove

ReliefValveSpring,Guide,Sleeve,andBall.Usinga

smallmagnetishelpful.

6.UnscrewReservoirFillPlug.Holdoverwasteoil

containerandreleaselltoolslowly.

7.UnscrewReservoirHousingfromhead.Remove2

Springs.SlideReservoirPlungerfromhead.Remove

spacerandQuadRing.Apickmaybeusedtoremove

the Quad Ring.

WARNING: Be sure air hose is disconnected

from tool before cleaning or performing

maintenance. Severe personal injury may occur

if air hose is not disconnected.

Reservoir

FillPlug

Reservoir

Plunger

Quad

Ring

Spacer

112465

Fill Tool

Assembly

Fill Tool in the

Lock-out position

Plug“A”

Screw“B”

4CapScrews

spring

Tool Head

Pintail

Deflector

HUCK

Check Va lve

Components

Reservoir

Housing

RETURNGland

Assembly

PULLGlandAssembly

Relief

Valve

Plug

Relief Valve Components

guide

ball

sleeve

2Springs

spring

guide

ball

plug

Cylinder

Cap

See also Fig. 10

(Plug“C”)

Figure 1

CAUTION: Do not scratch piston rod or cylinder

during removal. Use a plastic or wooden drift

to avoid damaging handle bore.

Disassembly Procedure

WARNING: Do not pull a fastener without a

collar. The fastener will eject with velocity

and force when the pintail breaks off. This

may cause serious injury.

WARNING: Do not pull a fastener without a

collar. The fastener will eject with velocity

and force when the pintail breaks off. This

may cause serious injury.

CAUTION: Remove excess gap from between

the sheets. This permits enough pintail to

emerge from collar for ALL jaw teeth to

engage with pintail. If ALL teeth do not engage

properly, jaws will be stripped/damaged.

CAUTION: To avoid structural and Tool

damage, be sure enough clearance is allowed

for nose assembly at full stroke. Do not abuse

the tool by dropping it, using it as a hammer

or otherwise causing unnecessary wear and

tear. Reasonable care of installation tools by

operators is an Important factor in maintaining

tool efciency and reducing downtime.

256 Pneudraulic Installation Tool (HK1015)

7

8. UnscrewCheckValvePlugfromsideofhead.Remove

CheckValveSpring,Guide,andBall.Asmallmagnetis

helpful.

9. IfCheckValveSeat(Figure10)isdamaged,contact

yourHUCKrepresentative.IfReliefValveSeatis

damaged,itcanberemovedasdescribedinstep10.

NOTE:Ifseatsareremoved,theymaynotbereused;

theymustbereplaced.

10. Relief ValVe Seat aSSembly RemoVal Note:Allpartsin

checkvalveholemustberemovedbeforePlug“A”

canberemoved.(Figs.1&10)UnscrewScrew“B”.

Inserta#10screwinthethreadofPlug“A”,andpull

toremove.Usingasmalldriftandhammer,fromrear

sideofhead,driveReliefValveSeatAssy(Fig.10)out

toward the front of the head.

11.PintailDeectorcanbepulledoffbarbedendatrear

ofHydraulicPullPiston.

12.UnscrewCylinderCapfromCylinder/Headusinga

1-3/4”open-endwrench.

13.(Fig.2)PlaceSpaceronHydraulicPullPiston,and

screwAssembly/DisassemblyBulletontopiston.Tap

orpresspistonassemblyoutofhead.This will push

out front and rear gland assemblies and wiper and

wiper housing.

14.(Fig.11)RemoveThrottleArmScrew;thenremove

ThrottleArm.PullThrottleValveoutofcylinder,and

removeSpring.

15.(Fig.10)Withasmallpunchandhammer,driveTrigger

PinfromtheHandle.RemoveCablePin.Removeball

endofCablefromThrottleArm(Fig.11),andpull

cable out of handle.

16.RemoveReservoirFillPlugfromhandle.(Fig.10)

17.(Fig.3)Holdtoolinvertedinvice.Unscrew3Cap

Screws with 5/32 hex key.

18. RemoveMuferEndCap,BottomExhaustGasket,

MuferandO-ring.

19. RemoveRetainingRingfromCylinderAssembly.Tap

Cylinder Head down into Cylinder Assembly for

easier removal of Retaining Ring.

20. ScrewCapScrewsintoCylinderHead,andcarefully

pryunderscrewstoremoveCylinderHead.(Figure3)

21. PushAirPistonallthewayintocylinderandlay

tool on its side. Hold Self-locking Nut with a 9/16

socketandextensionand,with7/64hexkey,unscrew

IntensierPistonScrew.

22. Turncylinderandhandleupsidedownandsecureina

vise.

23. GripSelf-lockingNutunderAirPistonwithpliersand

pullpistonandrodassemblyfromhandleandcylinder

assembly.

24. Witha13/8socketandextension,removeMain

Gland Assembly. Handle and cylinder will now

separate.

25. ToremovePolysealfromGlandAssembly,removethe

GlandAssemblyRetainingRingandSpacerrst.

26. Usingasoftdrift,pushIntensierPistonoutofhandle.

27. Toservicehandlesleeveandhandle,useablunt-

tippedpunchtogentlytapsleevefromtopofhandle

throughthebottom.Inspectsleevefordamageor

wear,andreplaceifnecessary.ServiceO-ringinside

handle bore.

Front Gland

Assembly

close-up

NOTE: Spacer must only be used for disassembly procedure

as it assists in pushing out Front Gland Assembly.

Note orientation

of polyseal

123111-1

Assembly

Bullet

123112-1

Spacer

HUCK

Figure 2

Muffler

EndCap

Bottom

Exhaust

Gasket

Muffler

O-Ring

Retaining

Ring

CapScrews

Use the screws

to pry out the

cylinder head.

Cylinder

Head

Assembly

Press air

piston

and piston

rod fully into

the air

Self-locking

Nut

Main Gland

Assembly

IntensifierPiston

Assembly (Must be

unscrewed from

handle-side of

piston rod.)

PistonRod

AirPiston

Assembly

HandleSleeve

Handle O-ring

Figure 3

Disassembly Procedure continued

256 Pneudraulic Installation Tool (HK1015)

8

Cleancomponentswithmineralspiritsorsimilarsolvent.

Inspectforwear/damageandreplaceasnecessary.

Replaceallsealsofdisassembledcomponentsusing

ServicePartsKit,P/N256KIT.SmearLUBRIPLATE130AA

orPARKER-O-LUBEonringsandmatingpartstoease

assembly. Carefully assemble tool without damaging

O-rings,Quadrings,orBack-uprings.

1. (Figure4)InstallO-ringinsidehandle;thenpushsleeve

in handle until it bottoms on the chamfer.

2. Holdinghandleinvertedinavice,installtimingpin;

thenplaceaircylinderonhandlewithtimingpin

positionedinmatchinghole.AssembleMainGland

Assembly.Applyanti-seizecompound(p/n508183)to

glandthreads.Witha1-3/8inchsocketwrench,torque

it into the handle to 75-85 foot lbs.

3. Pushairpistonassemblyandpistonrodintoair

cylinderuntilitseatedinsideofaircylinder(Figure3).

4. Turntoolupright.AssembleIntensierPistonwith

O-RingandBack-upRings;thenapplyLoctite243to

intensierpistonscrewthreads,andcarefullypressin

fromtopofhandle.

5. Holding Self-locking Nut with 9/16 socket and

extension,screwintensierpistonontopistonrod

using7/64hexkey,andtorqueto180-190in.lbs.

6. Holdhandleinvisewithbottomup.PushCylinder

Head Assembly squarely into air cylinder. Install

Retaining Ring.

7. PositionO-RingandMuferoncenterofaircylinder.

PlaceBottomExhaustGasketonaircylinder.Place

MuferEndCapontopofGasket,andsecurewith3

CapScrewsusing5/32hexkey.

8. Turntoolupright.(Figure5)DropThrottleValveSpring

intoThrottleValveholeincylinder.PushThrottleValve,

withO-ringsinplace,intocylinder.

9. AssembleTrigger,Cable,andCablePin,andslideCable

into Handle. Align hole in Trigger with hole in Handle

andinstallTriggerPinwithahammerandpunch.

10. Slide Throttle Arm onto ball end of throttle cable.

Swingarmuntilendtsoverthrottlevalve.Attach

throttle arm Bushing and Screw to Throttle Arm.

Tighten with 5/32 hex key.

11.Ifairhoseassemblywasremoved,reinstallit.

12.IfReliefValveSeatAssyisbeingreplaced,pushPlug

“A”,withsealsinplace,intohead.InstallScrew“B”.

(Figure10)

13.CarefullydriveReliefValveSeatAssyinusingasoft

drift,withoutdamagingReliefValveBallsurface.

14.AssemblePullPistonwithnewseals.Lubricatewith

LUBRIPLATEorPARKERSUPER-O-LUBE.

15.ThreadAssemblyBulletontoPullPistonAssy.(Figure2)

NOTE:Spacernotneededduringassembly.Itspurpose

istopushoutthefrontglandduringdisassembly.

16.PushFrontGlandAssy,withallseals,Housing,and

Wiperinplace,overAssemblyBulletandontoPull

Piston.Pushentiregland/pistonassemblyintoHead.

17.(Figure10)InstallO-ringsandBack-upRingsonRear

GlandandpushcompleteassemblyintoHead.Screwin

CylinderCapandtighten.

18.(Figure10)InstallO-ring&Back-upRingonRelief

ValvePlug;theninstallBall,Guide,Sleeve,Spring,and

assembledReliefValvePlugintohead.

19. InstallO-ringonCheckValvePlug“D”,theninstall

Ball,Guide,Spring,andassembledCheckValvePlug

into head.

20.PushPintailDeectorontobarbedendofPullPiston.

21.(Figure10)PlaceO-ringsonBleedPlugs“C”&“E”and

screw assemblies into Handle and Cylinder Head.

22.(Figure10)InstallallO-ringsandBack-upRingsonPull

andReturnGlands.PushGlandAssembliesintohandle.

PushHeaddownonglands.

23.Placetoolinavise,headdown,andinstall4Cap

Screws,andproceedtoFill&Bleedsectionofthis

manual.

Assembly

Handle shown

partially

transparent

for clarity.

Chamfers of

sleeveand

handle meet

here

O-ring inside

grooveinhandle

Sleevepushed

infromtopof

handle

Figure 4

TriggerPin

CablePin

Cable Assembly

Throttle Arm

Guard Screw

(notshown)

Throttle Arm

Spring

ThrottleValve

with 3 O-rings

inplace

Setscrew

Throttle Arm Guard

Throttle Arm

Bushing and Screw

Figure 5

256 Pneudraulic Installation Tool (HK1015)

9

EquipmentRequired:

-Shopairline90-100psimax.

- Air regulator

-FillBottle(Fig.7,suppliedwith

tool)

- Fill Tool 112465

-Largeatbladescrewdriver

- Stall Nut 120824

- Nose assembly

-Fasteners(Optional)

Preparation:

1. Installairregulatorinairline,

andsetpressureto20-40psi.

2. FillbottlealmostfullofDEXRONIII-ATF(automatic

transmissionuid).NOTE: Rell tool only when red line on

plunger drops below the red line on the reservoir housing

or when tool is rebuilt.

FORPARTSIDENTIFICATION,SEEFIGURES10AND11.

STEP1:ScrewFillToolintoReservoirPlunger,pullPlungerinto

ReservoirHousingandlockFillToolinfullforwardpositionby

tiltinghandle(longsidetouchingtool)andlockinginplace.

(Figure8)

STEP2:RemoveReliefandCheckValvePlugs,Guides,Springs

andBallsfromportsinhead.ReinstallPlugandSleeveinheadin

ReliefValveport(frontoftool).

STEP3: Screw retaining nut onto Head Assembly. Screw Stall

NutontoHydraulicPistonandtightentoensurefullthread

engagement. Back off Retaining Nut until it engages Stall Nut.

Check that Hydraulic Piston is all the way forward and locked with

Retaining Nut and with (or without) Stall Nut.

STEP4:AttachthetoolairsourcemomentarilytoseatAirPiston

atbottomofAirCylinder,thendisconnecttool.With Reservoir

Fill port facing up, lay tool on

its side.

STEP5: Install Fill Bottle in

ReservoirFillport.(Figure9)

STEP6:Connecttooltoshopair

20to40psi.Cycletool20-30

times,watchforairbubbles

escapingfromthetoolinto

bottle.(Youmayrockthetoolto

freetrappedairinthetool.)Do

not allow the air to re-enter the

tool.Whencyclingtool,alwaysholdbottleupasshowninFigure

10topreventdrawinginairfromemptypartofbottle.

STEP7:Whenairbubblesnolongerappearinbottle,removeFill

BottleandreplacetheReservoirFillPlugwhile tool is lying on

its side.

STEP8:InstalltheCheckValveBall,GuideandSpring.Replace

theCheckValvePlug.

STEP9:Turntoolsofrontofheadfacesyou.Priortoremoving

ReliefValvePlug,usinga3/32Allenwrench,backoutsetscrew

insideoftheplugapproximately1/2turncounterclockwise.

ThisensuresthatthePistonwillremaininfull-forwardposition.

RemovetheReliefValvePlug,installBall,Guide,Sleeveand

Spring,andreplacetheplug.

STEP10:UnlockFillToolandcheckReservoirredline.Cyclethe

tool the with Stall Nut attached and Retaining Nut locked in the

full-forwardposition(“DeadStall”).Reservoirshouldnotdrop

belowtheredlineontheReservoirhousing.

STEP11:Re-lockthelltool.Laytoolonitssideandremove

ReservoirFillPlug.TopoffReservoirbyplacingafewdropsof

oilinholeandwaitingforairbubblestoescape.Pushapinora

scribeintoholetocheckfortrappedairbubbles.ReplacePlug.

STEP12:UnlocktheFillToolandcycletoolasinstep10.

Reservoirmaydropslightly.Ifso,repeatstep11until,whenthe

FillToolhandleistouched,ithasnopressureagainstitandit

dropsoutofthelockposition,andtheReservoirPlungerdoes

notdropwhentooliscycled.NOTE:Thisusuallyrequires3to4

timestoppingoff.

STEP13:RemoveFillToolandStallNut.Installanoseassembly

andpullseveralfastenerstotestfunction.

WARNING: Avoid contact with hydraulic uid.

Hydraulic uid must be disposed of in accordance

with Federal, State and Local Regulations.

120337 Fill Bottle Assy

120336

Fill Bottle

120004Cap

Fill Point

Figure 7

WARNING: Air pressure MUST be set to 20 to 40 psi

to prevent possible injury from high pressure spray.

If Check Valve Plug is removed, Fill Bottle must be in

place before cycling tool.

(Check Valve port)

Install Fill Bottle here

Reservoir

FillPlug

CheckValvePlug

Relief

Valve

Plug

Red line indicator

120824 Stall Nut

112465 Fill Tool

(Shown in LOCK

position.)

Retaining Nut

Reservoir

Housing

Figure 8

Fill Bottle

shown in

Reservoir

Fill Port

Figure 9

Fill and Bleed

WARNING: Failure to re-lock Fill Tool will result in oil

being ejected from the head under pressure during

the topping off of the Reservoir. Severe personal

injury may result.

256 Pneudraulic Installation Tool (HK1015)

10

505864

Spring(2)

112403Housing/SpacerAssy

contains Housing 125546

and Spacer 123848

501408

QUADRing

112405Reservoir

Plunger

120129 Screw “B”

501082Back-upRing

502929 Ball

111067 Guide

100874Spring

120204Plug“A”

104293BleedPlugAssy“C”

508481 Setscrew

505446 O-Ring

111079BleedPlugAssy“D”

104293BleedPlugAssy“E”

117824

Retaining Nut

506160Polyseal

(Note orientation)

110670

Stop

130244

ThrottleLever(Trigger)

125643

Cable Assembly

130938Handle&

SleeveAssembly

505496CablePin

500621TriggerPin

126082 Front Gland Assy

(Gland not sold separately)

126087

PintailTube

505894

Wiper

114530Plug

501082Back-upRing

505446 O-Ring

505863Spring

120127Sleeve

120128 Ball Guide

505120

Relief

ValveBall

501082Back-upRing

505446 O-Ring

130254ReliefValveSeat&SealsAssembly

(Relief Valve Seat not sold separately.

Assemble/disassemble through front of head only)

501082Back-upRing

Check Valve Seat

(Reservoir Fill Plug)

(Relief Valve Plug)

(Check Valve Plug)

130267

Sleeve

508518

O-ring

123138

Wiper

Housing

130609 Hydraulic

PullPistonAssembly

(Piston not sold separately)

124209

Deflector

112491CylinderCap

(Torque to 36-66 ft. lbs.)

126086 Rear Gland Assembly

(Gland not sold separately)

113253Back-upRing

505887 O-Ring

129944Polyseal

(Note orientation)

126088Back-upRing

500823 O-Ring

113251

Back-upRing

500851 O-Ring

113251

Back-up

Ring

126098 Cylinder / Head

590517HUCKYearofMfrSticker

590240 WARNING Sticker*

*NOTE: Stickers must remain on tool and readable at all times. If stickers become

worn, damaged, or if they are missing, they must be ordered and replaced.

500101

Screw(4)

130244

ThrottleLever(Trigger)

500101

Screw(4)

SECTION A-A

Rotated 90° CCW

112502

Return Gland Assembly

500776

O-Ring

501084

Back-upRing

(Gland not sold

separately)

501082

Back-up

Ring

500778 O-Ring

500776

O-Ring

(Gland not sold

separately)

501082

Back-up

Ring

508518

O-Ring

131055

Pull Gland Assembly

A

A

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew

114530Plug

(Relief Valve Plug)

505864

Spring(2)

100874Spring

508481 Setscrew