Page is loading ...

^

AF

Installation

GRAA-IOM-1

Operation

Maintenance

Library

Service

Literature

P

roduct

Sec

t

ion

Air

Handling

Product

Make

-

Up

Air

Model

GRAA

,

GRBA

,

GRCA

,

GRDA

Literature

T

ype

I

nstallation

,

Operation

,

Maintenance

Sequence

^

Date

January

1995

File

No.

SV

-

AH

-

MUA

-

GRAA

-

IOM

-

1

-

1

95

Supersedes

Ne

w

Rooftop

Gas

Heating

,

Cooling

and

Ventilating

Unit

Sizes

100

MBh

-

1200

MBh

"

A

"

Design

Sequence

Since

the

Trans

Company

has

a

policy

of

continuous

product

improvement,

it

reserves

the

right

to

change

specifications

and

design

without

notice.

The

installation

and

servicing

of

the

equipment

referred

to

in

this

booklet

should

be

done

by

qualified,

experienced

technicians.

OAmerican

Standard

Company

1995

General

Information

Literature

Chang

e

History

GRAA

-

IOM

-

1

(January

1995

)

Original

issue

of

manual

describes

installation

of

GRAA,

GRBA,

GRCA,

GRDA

Rooftop

Gas

Heating,

Cooling

and

Ventilating

Units,

for

A

Design.

Warnings

and

Cautions

Notice

that

WARNINGS

and

CAUTIONS

appear

at

appropriate

intervals

throughout

this

manual.

Warnings

alert

installer,

owner,

operator

or

service

personnel

to

potential

hazards

that

could

result

in

personal

injury

or

death.

Cautions

are

provided

to

alert

personnel

to

conditions

which

could

result

in

damage

to

the

equipment

or

cause

property

damage.

Receiving

Instructions

Inspect

shipment

immediately

when

received

to

determine

if

any

damage

has

occurred

to

the

unit

during

shipment.

After

the

unit

has

been

uncrated,

check

for

any

visible

damage

to

the

unit.

If

any

damage

is

found,

the

consignee

should

sign

the

bill

of

lading

indicating

such

damage

and

immediately

file

claim

for

damage

with

the

transportation

company.

FOR

YOUR

SAFETY

:

If

you

smell

gas

:

1

.

Open

windows

.

2

.

Don

'

t

touch

electrical

switches

.

3

.

Extinguish

any

open

flame

.

4

.

Immediately

call

your

gas

supplier

.

FOR

YOUR

SAFETY:

The

use

and

storage

of

gasoline

or

other

flammable

vapors

and

liquids

in

open

containers

in

the

'

vicinity

of

this

appliance

is

hazardous.

WARNING:

Improper

installation,

adjustment,

alteration,

service

or

maintenance

can

cause

property

damage,

injury

or

death.

Read

the

installation,

operating

and

maintenance

instructions

thoroughly

before

installing

or

servicing

this

equipment.

Warnings

Approved

for

use

in

California

when

equipped

with

spark

ignition

.

Installer

Please

Note:

This

equipment

has

been

test

fired

and

inspected

.

It

has

been

shipped

free

from

defects

from

our

factory

.

However

,

during

shipment

and

instal

l

ation

,

problems

such

as

loose

wires,

leaks

or

loose

fasteners

may

occur.

It

is

the

installer

'

s

responsibility

to

inspect

and

correct

any

problems

th

a

t

may

be

found

.

Install,

operate

and

maintain

unit

in

accordance

with

manufacturer's

instructions

to

avoid

exposure

to

.,

fiP

P

R

OYED

fuel

substances

or

substances

from

incomplete

combustion

which

can

cause

death

or

serious

illness.

The

state

of

California

has

determined

that

these

substances

may

cause

cancer,

birth

defects,

or

other

reproductive

harm.

Model

Number

Description

(All

furnaces)

DIGIT

1

-

Gas

Heating

Equipment

G

=

G

as

DIGIT

2

-

Unit

Type

F =

Rooftop

D

uct

Furnace

R

=

R

oofto

p

H

eating

U

ni

t

S

=

Special

U

ni

t

T

y

p

e

DIGIT

3

-

Furnace

Type

A

=

S

t

a

ndard

T

e

m

p

R

ise

(

20

-6

0

D

eg.

F

)

LH

B

=

S

tandard

Te

m

p

R

ise

(

2

0-

60

Deg

.

F

)

RH

C

=

High

Temp

Rise

(60-90

Deg.

F)

LH

D

=

High

Tem

p

R

is

e

(60-90

De

g.

F

)

RH

E

=

B

lank

F

urnac e

S

l

ee

v

e

LH

G

= Blank

Furnace

Sleeve

RH

S

=

Special

Furnace

Type

DIGIT

4

-

Development

Sequence

A

=

F

irs

t

G

eneratio

n

DIGIT

5,6

-

Input

Capacity

Single

Furnace

10

=

100

MBh

Input

30

=

300

MBh

Input

15

=

150

MBh

Input

35

=

350

MBh

Input

20

=

200

MBh

Input

40

=

400

MBh

Input

25

=

250

MBh

x

Double Furnace

50

=

500

MBh

Input

70

=

700

MBh

Input

60

=

600

MBh

Input

80

=

800

MBh

Input

Triple

Furnace

12

=

1200

MBh

Input

SS

=Special

unit

DIGIT

7

-

Venting

Type

G

=

G

ravi

t

y

V

e

n

ting

P

=

P

ower

Ventin g

S

=

S

pecial

V

enting

DIGIT

9

-

Gas

Control

Option

(Intermittent

Pilot

Ignition)

A

=

Single-Stage

B

=

Two-Stage

C

=

Hydraulic

Modulating

(60-100)

D

=

Hydraulic

Modulating

(75-200)

E

=

Hydraulic

Modulating

W/Bypass

and

limit

(60-100)

F

=

Hydraulic

Modulating

W/Bypass

(75-200)

G

=

Electronic

Modulating

W/Room

T-Stat

H

=

Electronic

Modulating

W/Duct

T-Stat

J

=

Electronic

Modulating

W/Duct

T-Stat

and

Override

Room

Thermostat

K=

Electronic

Modulating

W/External

4-20

mA

Input

(Furnace

1)

L =

Electronic

Modulating

W/External

4-20

mA

Input

M=

Electronic

Modulating

W/External

0-10

VDC

Input

(Furnace

1)

N

=

Electronic

modulating

W/External

0-10

VDC

Input

P

=

VAV

Control

Two-Stage

R=

VAV

Control

Three-Stage

T

=

VAV

Control

Four-Stage

U

=

S-350

2

Stage

Modular

Electronic

Control

System

W

=

S-350

3

Stage Modular

Electronic

Control

System

X

=

S-350

4

Stage

Modular

Electronic

Control

System

Y

=

S-350

6

Stage

Modular

Electronic

Control

System

S

=Special

Gas

Control

DIGIT

13

-

Heat

Exchanger

Material

1

= Aluminized

S

teel

2

=

#

409

St

ainless

S

teel

(

F

i

r

s

t

Furn

a

ce

Only)

3

=

#409

Stainless

Steel

(All

Furnace

Sections)

4

=

#

3

21

S

t

a

inless

S

t

e

el

(

F

irst

F

ur

n

ac

e

O

nly)

5

=

#3

21 St

ainless

S

teel

(

A

ll

F

ur

na

ce

Sections)

6

=

#

4

09

S

tainless

S

teel

P

ackag

e

(

F

ir

s

t

Furnace

Only)

7

=

#409

S

tainless

St

eel

P

acka

ge

(

A

ll

F

urnace

S

ections)

8

=

#32

1

S

tainless

S

teel

P

acka

g

e(

F

irs

t

Furnace

Only)

9

=

#321

Stainless

Steel

P

acka

g

e(

A

ll

F

urnace

S

ec

t

ions)

S

=

Special

Heat

Exchanger

P

ackage

DIGIT

14

-

Rooftop

Arrangements

(Des

i

gnator

A

-

L

Assumes

Furnace

S

ecti

on

)

A

=

D

uct

Furnace

B

=

B

lower

(

S

tandard)

C

=

Blower

(Standard)

Plenum

D

=

B

lower

(Standard)

E

vaporative

C

oole

r

E

=

Blower

(Standard)

E

vaporativ

e

C

ooler/Plenum

G

=Blower

(High

CFM)

J

=

B

lower

(

H

igh

C

F

M

)/Plenum

K

=

B

lower

(

H

igh

C

F

M

)/

C

oolin

g

L

=

B

lower

(

H

igh

C

F

M

)/

C

o

o

lin

g

/

P

le

n

u

m

S

=

S

pecial

R

oofto

p

A

rr

a

ng

m

ent

DIGIT

8

-

Main

Power

Supply

A

=

115/60/1

E

=

230/60/3

B

=

208/60/1

F

=

460/60/3

C

=

230/60/1

G

=

575/60/3

D

=

208/60/3

S

=

Special

Main

Power

Supply

DIGIT

10

-

Design

Sequence

A

=

F

irst

D

esi

gn

DIGIT

11

-Design

Sequence

0

=

F

irst

D

esign

DIGIT

12

-

Fuel

Type

N

=

N

atural

Ga

s

P

=

LP

G

as

(

P

ropane)

L

=

N

a

t

ural

G

as

with

1

00%

L

ockout

S

=

S

pecial

F

uel

type

DIGIT

15

=

Roo

fto

p

H

eati

ng

Un

i

t

Motor

Selection

0

=

N

one

(Rooftop duct

furnace)

A

=

1/2

HP

w/contactor

B

=

3/4

HP

w/contactor

C

=

1

HP

w/contactor

D

=

1

1/2

HP

w/contactor

E

=

2

HP

w/contactor

F

=

3

HP

w/contactor

G

=

5

HP

w/contactor

H

=

1/2

HP

w/magnetic

starter

J

=

3/4

HP

w/magnetic

starter

K

=

1

HP

w/magnetic

starter

L

=

1

1/2

HP

w/magnetic

starter

N

=

2

HP

w/magnetic

starter

P

=

3

HP

w/magnetic

starter

Q

=

5

HP

w/magnetic

starter

R

=

7

1/2

HP

w/magnetic

starter

T

=

10

HP

w/magnetic

starter

U

=

15

HP

w/magnetic

starter

S

=

Special

Motor

1a

DIGIT

16

=

Motor

Speed

0

=

N

o

Selection

1

=

Single

Speed

ODP

1

800

RPM

2

=

Single

Speed

T

EF

C

180

0

R

PM

3

=Single

S

peed

H

igh

E

fficiency

ODP

1800

RPM

4

=

S

ingle

S

p

eed

H

igh

E

fficie

n

c

y

TEFC

1800

RPM

5

=

2S1

W

ODP

1800/900

RPM

6

=

2S2W

ODP

1800/1200

RPM

7

=

Special

M

o

t

o

r

Spee

d

&

S

tarter

DIGIT

17

=

Coil

Options

0

=

N

o

cooling

coil

selection

A

=

DX

coil,

4

R

ow,

Single

C

ircuit

B

=

DX

coil,

4

R

ow,

D

ual

C

ircui

t

C

=

DX

coil,

6

R

ow,

S

ingle

Circuit

D

=

DX

coil,

6

R

ow,

D

ual

C

ircuit

E

=

Chilled

W

ater

C

oil,

4

R

ow,

G

=

Chilled

Wa

t

er

Co

il,

6

R

ow,

S

=

Special

coil

DIGIT

18

=

Air

Inlet

Configuration

0

=

N

one

(

R

ooftop

duct

furnace)

1

=

Outside

Air(

OA

)

2

=

Outside

A

ir

W

/

A

ir

H

ood

3

=

R

etur

n

Air(

R

A)

4

=

Outside

An

d

R

eturn

A

ir

(

OA

/

RA

)

5

=

Outside

and

R

e

t

urn

Air

W

/

A

ir

H

ood

S

=

Special

A

ir

inlet

configu

r

a

t

io

n

DIGIT

19

=

Air

Control

& Damper

Arrangement

0

=

N

one

(

R

ooftop

duct

f

urnace)

A

=

O

u

t

side

Air

2

pos.

M

otor/

SR

B

=

R

eturn

Air

2

pos.

Mo

tor/

SR

C

=

OA

/

RA

2

p

os

S

R

D

=

OA

/

RA

M

o

d

M

i

r

.

W

/

M

ixe

d

A

ir

C

on

t

rol/

M

in.

P

o

t

E

=

O

A/

R

A

M

od

M

tr

W

/

M

ixe

d

A

ir

Control/Min

Pot/SR

G

=

OA

/

RA

M

od

Mi

r

W

/

M

ixed

A

ir

Co

ntr

o

l

H

=

O

A

/

RA

Mod

Mtr

W/Mixed

Air

Control/

SR

J

=

O

A/

RA

M

od

M

tr

W

/

M

i

n

P

o

t

K

=

OA/RA

Mod

Mtr

W/Min

P

ot/SR

L =

O

A

/

RA

M

od

Mtr

w

/

D

ry

B

ulb/

M

ixe

d

A

ir

C

o

n

trol/

M

in

P

ot

M

=

O

A/

RA

M

od

M

tr

w/

D

ry

B

ulb/

M

ixe

d

A

ir

C

ontrol/

M

in

P

ot/S

R

N

=

OA

/

R

A

M

od

Mi

r

w/

E

nthalpy

Co

n

trolled

E

conomizer/

SR

P

=

OA

/

RA

M

o d

M

tr

W

/

S

p

ac e

P

re

ss

ur

e

Controller

R

=

OA

/

RA

M

od

M

tr

W

/

S

-35

0

P

Proportional

Mixed

Air

Control/SR

T

=

OA

/

RA

M

tr.

W

/External

0-

10

VDC

a

nd

4

-

20

m

AAn

alog

Inpu

t

/(

Ex

tern

a

l

In

pu

t)

U

=

OA

/

RA

M

tr.

W

/Exter

na

l

0

-

10

VDC

a

n

d

4

-

2

0

m

A

A

nalog

I

npu

t

/

SR

(

Exte

rnal

I

npu

t )

W

=

A

shrae

C

ycle

I

(

OA

/

RA

2

p

os,

w/warm-u

p

stat/

SR

X

=

Ashrae

C

ycle

I

I

(

OA

/

RA

M

o

d

W

/

W

arm-up

S

ta

t

/

M

ixe

d

A

ir/min

pot/S

R

Y

=

Ashrae

C

ycle

111(

O

A/RA

M

o

d

.

W/Warm-up

St

at/

M

ixed

Air/

SR

Z

=

M

anual

D

ampe

r

s

S

=

S

pecial

air

control

a

n

d

dam

p

er

a

r

r

ange

m

e

n

t

DIGIT

20

0

=

N

o

n

-

C

ali

fo

rnia

S

hi

pm

ent

1

=

California

Shipment

DIGIT

21

=

Miscellaneous

Options

A

=

O

rifice

s

For

E

lev

at

io

n

A

bov

e 2

000

F

e

et

(

S

pe

c

i

f

y

E

l

e

v a

ti

o

n)

B

=

1

2"

E

va

p

or

a

tive

M

e

d

i

a

C

=

M

ois

t

ure

E

limin at

ors

D

=

H

ori

zonta

l

R

eturn

E

=

I

nterlock

R

elay

-2

4V

C

oil

DPD

T

1

0

A

F

=

Fr

e

e

ze

s

t

at

G

=

Fa

n

T

i

m

e

D

elay

C

on

tr

ol

(

D

uc

t

F

urnac

e

Only)

H

=

R

etu

r

n

A

ir

Fir

e

sta

t

J= Supply

Air

Firestat

K

=

M

anual

B

lower

S

wi

t

ch

L

= 4

09

S

tainle

ss

S

teel

Furnace

D

rip

Pa

n

N

=

F

oil

F

ace

I

nsulation

P

=

Lo

w

Le

ak

Da

mpers

Q

=

C

logg

ed

Filter

S

witch

R

=

H

ig

h /L

ow

G

a

s

P

ress

u

re

L

i

m

i

t

S

wi

t

c

h

e

s

T

=

St

a

t

us

Indicat

o

r

La

m

ps

(

E

lec

cab

ine

t

)

V

=

Manu

al

Res

et

H

i

g

h

L

imi

t

Sw

i

tc

h

W

=Interl

o

ck

Re

lay

-

2

4/

1

15

V

Co

il

SPDT

10A

X

=

I

nt

e

rloc

k

R

elay

-

24

/1

1

5-

2

3

0V

Co

il

DPDT

1

0A

lb

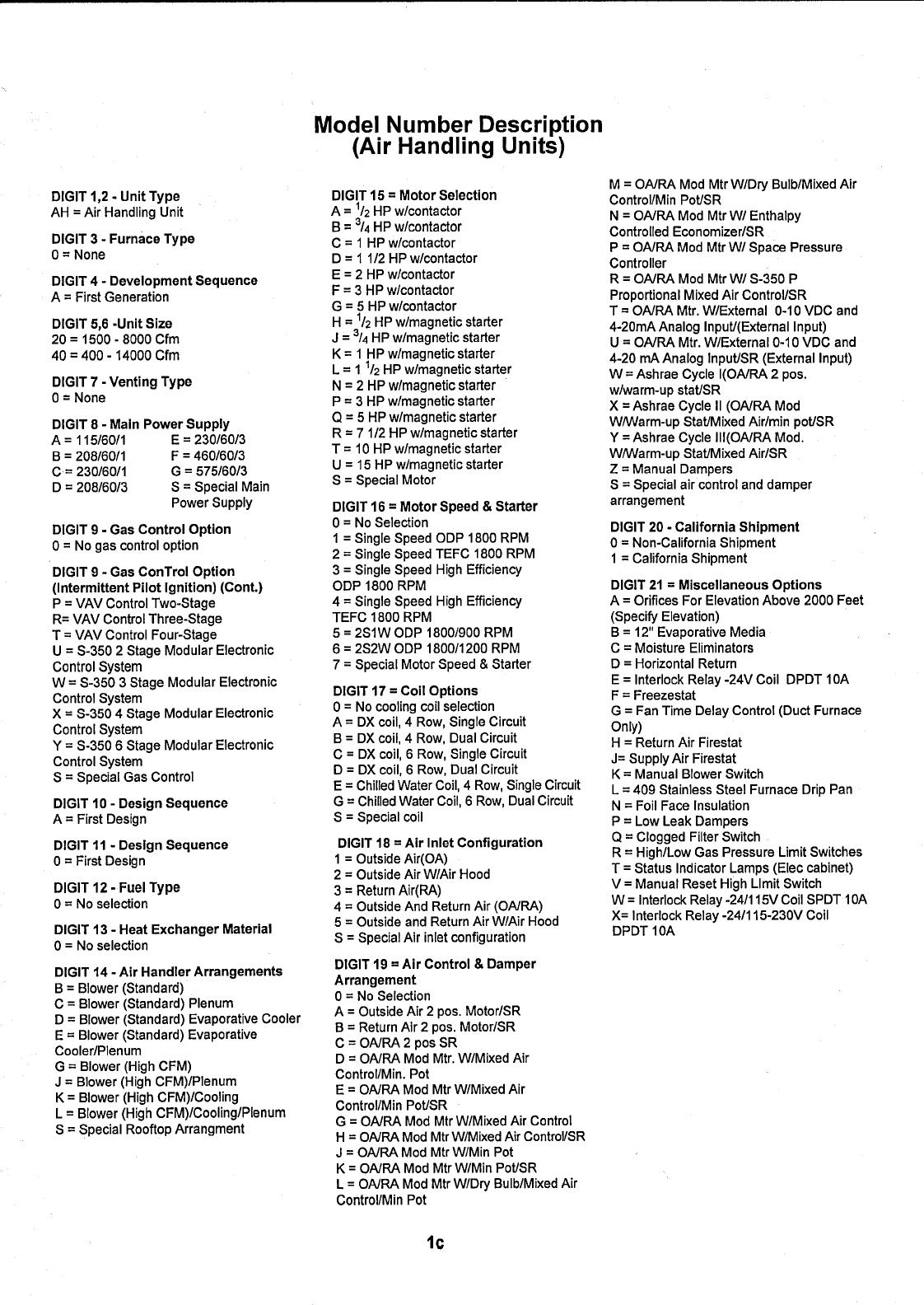

Model

Number

Description

(Air

Handling

Units)

D

I

GIT

1

,

2

-

U

nit

T

y

p

e

A

H

=

Air

Handling

U

nit

DIGIT

3

-

Furnace

Type

0

=

N

one

DIGIT

4

-

De

v

elopment

Sequence

A

=

F

irst

G

eneration

DIGIT

5

,

6

-

Unit

Size

20

=

1500

-

8000

C

fm

4

0

=

400

-

14000

Cf

m

DIGIT

7

-

Vent

i

ng

Type

0 =

N

one

DIGIT

8

-

Main

Power

Supply

A

=

115/60/1

E

=

230/60/3

B

=

208/60/1

F

=

460/60/3

C

=

230/60/1

G

=

575/60/3

D

= 208/60/3

S

=

Special

Main

Power

Supply

D

I

GIT

9

-

Gas

Control

Option

0 =

N

o

gas

con

t

rol

optio n

DIGIT

9

-

Gas

ConTrol

Option

(Intermittent

Pilot

Ign

i

tion)

(Cont

.

)

P

=

VAV

C

ontrol

Two-

St

age

R

=

VA

V

Con

t

rol

T

hree-Stage

T

=

VAV

Control

F

our-Stage

U

=

S

-350

2

S

t

age

Modular

E

lectronic

Control

System

W

=

S

-350

3

Stage

M

odular

E

lectronic

C

ontrol

System

X

=

S-350

4

Stage

M

o

d

ular

E

lectronic

Control

System

Y

=

S-350

6

Stage

M

odular

E

lectronic

Control

System

S

=

Special

Gas

C

ontrol

D

I

GIT

10

-

Design

Sequence

A

=

Firs

t

D

esign

DIGIT

11

-

Design

Sequence

0

=

First

Design

DIGIT

12

-

Fuel

Type

0

=

No

selection

DIGIT

13

-

Heat

Exchanger

M

aterial

0

=

No

selection

DIGIT

14

-

Air

Handler

Arrangements

B

=

Blower

(Standard)

C

=

Blower

(Standard)

Plenum

D

=

Blower

(Standard)

Evaporative

Cooler

E

=

Blower

(Standard)

Evaporative

Cooler/Plenum

G

=Blower

(High

CFM)

J

=Blower

(High

CFM)/Plenum

K

=Blower

(High

CFM)/Cooling

L

=Blower

(High

CFM)/Cooling/Plenum

S

=Special

Rooftop

Arrangment

DIGIT

15

=

Motor

Selection

A

=

1/2

HP

w/contactor

B

=

3/4

HP

w/contactor

C

=

1

HP

w/contactor

D

=

1

1/2

HP

w/contactor

E

=

2

HP

w/contactor

F

=

3

HP

w/contactor

G

=

5

HP

w/contactor

H

=

1/2

HP

w/magnetic

starter

J

=

3/4

HP

w/magnetic

starter

K

=

1

HP

w/magnetic

starter

L

=

1

1/2

HP

w/magnetic

starter

N

=

2

HP

w/magnetic

starter

P

=

3

HP

w/magnetic

starter

Q

=

5

HP

w/magnetic

starter

R

=

7

1/2

HP

w/magnetic

starter

T

=

10

HP

w/magnetic

starter

U

=

15

HP

w/magnetic

starter

S

=

Special

Motor

DIGIT

16

=

Motor

Speed

&

Starter

0

=

N

o

Selection

1

=

S

ingle

S

peed

O

D

P

1800

RP

M

2

=

Single

Speed

T

EF

C

1

800

RPM

3

=

Single

Speed

High

Efficiency

O

DP

1800

RP

M

4

=

S

ingle

S

peed

High

E

fficiency

TEF

C

1800

R

P

M

5

=

2

S1

W

O

D

P

1

800/900

R

P

M

6 =

2S2W

ODP

1800/1200

RP

M

7

=

Special

Motor

Speed

&

Starter

DIGIT

17

=

Co

l

l

Options

0

=

N

o

co

o

ling

coil

selection

A

=

DX

coil,

4

R

ow,

Single

C

ircuit

B

=

DX

coil,

4

R

ow,

D

ual

C

ircuit

C

=

DX

coil,

6

R

ow,

Single

C

ircuit

D

=

DX

coil,

6

R

ow,

D

ual

Circui

t

E

=

C

hilled

Water

Coil,

4

R

ow,

S

ingle

C

ircuit

G

=

C

hilled

Water

C

oil,

6

R

ow,

D

ual

C

ircuit

S

=

Special

coil

D

IGIT

18

=

Air

Inlet

Configuration

1

=

Outside

Air(OA)

2 =

Outside

Air

W/Air

Hood

3

=

Return

Air(RA)

4 =

Outside

And

Return

Air

(OA/RA)

5

=

Outside

and

Return

Air

W/Air

Hood

S

=

Special

Air

inlet

configuration

DIGIT

19

=

Air

Control

&

Damper

Arrangement

0

=

N

o

S

election

A

=

Outside

Air

2

pos.

Mo

t

or/S

R

B

=

R

eturn

Air

2

p

os.

M

otor/S

R

C

=

OA/

RA

2

pos

S

R

D

=

OA/

RA

M

o

d

Mtr.

W/

M

ixed

Air

C

ontrol/

M

in.

P

ot

E

=

OA/

RA

Mod

M

t

r

W/Mixed

A

ir

C

ontrol/Min

P

ot/

SR

G

=

O

A/

RA

M

od

M

ir

W/Mixed

Air

C

ontrol

H

=

OA/R

A

M

od

M

tr

W/Mixe

d

Air

C

ontroVS

R

J

=

O

A/

R

A

M

od

M

tr

W/

M

in

P

o

t

K

=

OA/

R

A

M

od

M

tr

W/

M

in

P

ot/

SR

L =

O

A/R

A

M

o d

Mtr

W/D

ry

B

ulb/

M

ixed

Air

Co

n

tr

ol/

M

in

P

ot

M

=

OA/

R

A

M

od

M

tr

W/

D

ry

B

ulb/

M

ixed

A

ir

C

ontrol/

M

in

P

ot/

SR

N

=

O

A/

R

A

M

od

Mtr

W/

E

nthalpy

C

ontrolled

E

conomi

z

er/

SR

P

=

O

A/

R

A

M

od

M

t

r

W

/

S

pace

P

ressure

Controller

R

=

OA/

R

A

M

od

M

tr

W/

S-350

P

P

roportional

M

ixed

A

ir

C

ontrol/

SR

T

=

OA/R

A

M

tr.

W/External

0

-10

VDC

and

4-20mAAnalog

I

n

p

ut/(External

Inpu

t

)

U

=

O

A/

RA

M

t r

.

W/

E

xternal

0-10

VDC

an

d

4

-

2 0

m

A

Analog

Inpu

t

/

SR

(

E

xternal

I

npu

t

)

W

=

Ashrae

C

ycle

I(

O

A/

RA

2

pos.

w/warm-up

stat/

SR

X

=

Ashrae

C

ycle

I

I

(OA/

RA

M

o d

W/Warm-u

p

Stat/

M

ixed

Air/min

p

ot/

SR

Y

=

Ashrae

Cycle

III(OA/

R

A

Mod.

W/Warm-up

Stat/

M

ixed

Air/S

R

Z

=

M

anual

D

ampers

S

=

Special

air

control

and

damper

arrangement

DIGIT

20

-

California

Sh

i

pment

0

=

N

on-

C

alifornia

Shipment

1

=

C

alifornia

Shipmen

t

DIGIT

21

=

Miscellaneous

Options

A

=

O

rifices

F

or

E

levation

A

bove

2000

(Specify

E

levation)

B

=

12"

Evaporative

M

edia

C

=

Mois

t

ure

E

liminators

D

=

Horizontal

R

eturn

E

=

Interlock

R

elay

-2

4

V

C

oil

DPDT

1

F

=

Freezestat

G

=

Fan

T

ime

D

elay

C

ontrol

(

D

uc

t

F

ur

Only)

H

= Return

Air

Firestat

J=

Supply

Air Firestat

K

=

Manual

Blower

Switch

Feet

OA

ace

L

=

409

Stainless

Steel

Furnace

Drip

Pan

N

=Foil

Face

Insulation

P

=Low

Leak

Dampers

Q

=Clogged

Filter

Switch

R

=High/Low

Gas

Pressure

Limit

Switches

T

=Status

Indicator

Lamps

(Elec

cabinet)

V

=

Manual

Reset

High

Limit

Switch

W

=Interlock

Relay

-24/115V

Coil

SPDT

10A

X=

Interlock

Relay

-24/115-230V

Coil

DPDT

10A

1c

TABLE

OF

CONTENTS

1 .

RECEIVING &

PRE

-

INSTALLATION

INSTRUCTIONS

Access

Panel

Removal

...:................

3

Rigging

........

....

................3

Combustion

Air

Considerations

..............

3

Location

.....................

.......3

Mounting

/

Locations

.....................

3

II

.

GENERAL

REQUIREMENTS

.............

3

III

.

INSTALLATION

Installation

Clearances

....................

5

Mounting

on

Field

Furnished

Supports

........

5

Mounting

on

Roof

Curb

...................

6

Venting

...............:................6

Duct

Connections.......

...........

...

6

Gas

Piping

...........................6

Modulating

Gas

Control

..

..............

.

8

'Electrical

Connections

...

...............

9

DX

Coil

Equipped

Units

..................

10

Chilled

Water

Coil

Equipped

Units

..........

11

Evaporative

Cooling

Equipped

Units

.........

11

IV

.

OPERATION

General

Information

.....................

11

Gas

Control

System

.....

........

.

.....

11

Optional

Gas

Controls

...

'

..............

12

Air

Handling

Requirements

and

A

djustments

.

.

12

Lighting

........... ...........

13

Gas

Input

Adjustment....

..............

14

Pilot

Adjustment

........................

14

Primary

Air

Shutter

Adjustment

.............

14

Controls

..............................14

V

.

START

UP

...........

...............

15

VI

.

MAINTENANCE

......!

...............

16

VII

.

TROUBLESHOOTING

................

19

VII

I.

REP

L

ACEMENT

PARTS

..............

24

IX

.

SERVICE

NOTE

.....

.............

24

X

.

START

UP

SHEET

....................

25

The

following

terms

are

used

throughout

this

manual

to

bring

attention

to

the

presence

of

potential

hazards

or

to

important

information

concerning

the

product:

CAUTION:

Indicates

an

imminently

hazardous

situa-

tion

which,

if

not

avoided,

may

result

in

minor

injury

or

property

damage.

NOTE:

Used

to

notify

of

special

instructions

on

instal-

lation,

operation

or

maintenance

which

are

important

to

equipment

but

not

related

to

personal

injury

haz-

ards.

1 .

RECEIVING

INSTRUCTIONS

Inspect

shipment

immediately

when

received

to deter-

mine

if

any

damage

has

occurred

to

the

crate

during

ship-

ment.

After

the

unit

has

been

uncrated,

check

for

any

visible

damage

to

the

unit.

Check

motor

position

and

turn

blower

wheel

to

determine

if

damage

has

occurred

to

these

criti-

cal parts.

If

any

damage

is

found,

the

cosignee

should

sign

the

bill

of

lading

indicating

such

damage

and

immediately

file

claim

for

damage

with

transportation

company.

PRE

-

INSTALLATION

INSTRUCTIONS

W

he

n

the

u

nit

i

s

received

and

uncrated,

check

the

exter-

nal

data

plate

and

all

labels

on

the

unit

for

type

of gas,

electrica

l ,

and

operational

specifications

to confir

m

tha

t

t

hese

agree

with

those

at

point

o

f

installation.

If

the

unit

is

equipped

with

an

Outdoor

Duct

Furnace,

also

check

the

d

ata

plate

and

all

labels

located

inside

each

furnace.

Every

rooftop

unit

will

include

an

informational

packet

which

will

include

the

following:

The

blower

manual,

out-

door

duct

furnace

and

evaporative

cooler/cooling

coil

manuals

(if

applicable

to

the

unit

order),

wiring

diagram(s),

and

special

controls/data

sheets.

ACCESS

PANEL

REMOVAL

Each

access

panel

is

held

in

place

with

two

"grip"

latches.

To

remove

an

access

panel:

use

a

slotted

head

screw

dri-

ver

to turn

the

latch

screwhead

counter

clockwise.

Using

the

handle

provided,

push

the

panel

upwards.

Pull

the

bot-

tom

of

the

panel

out

and

lower

the

panel

to

disengage

it

from

the

top

lip.

To

replace

an

access

door

panel,

guide

-2-

the

panel

door

upwards

on

the

tracks,

and

push

up

into

the

top

lip,

swing

and

lower

the

panel

in

place

until

it

engages

with

the

bottom

panel.

Turn

the

screwhead

on

each

latch

clockwise.

The

screw

must

turn

freely

one

quarter

turn

before

resistance

is

felt

in

order

for

the

lock

to

engage.

If

latch

does

not

hold,

turn

screw

counter-clock-

wise

several

turns

and

repeat

the

above

procedure.

RIGGING

Rig

unit

using

either

belt

or

cable

slings.

Use

spreader

bars

to

protect

the

top

of

the

unit

when

it

is

lifted.

See

fig-

ure

1.

On

units

with

a

total

length of

less

than

104"

(2642

mm),

excluding

evaporative

cooler,

two

holes are

provided

in

the

base

rail

on

each

side

of

the

unit.

Slide

pipes

beneath

the

unit

through

these

holes

and

attach

rigging

to

pipes

for

lifting

the

unit.

On

units

with

a

total

length

of

a

104"

(2642

mm)

or

greater,

excluding

evaporative

cooler,

lifting

lugs

attached

to

the

base

rail

are

provided.

Attach

rigging to

lugs

for

lifting

the

unit.

For

distance

between

lifting

lugs

and

total

unit

lengths,

refer

to

original

Submittal

Sheets

supplied

specified

for

the

unit.

Also

see

Center

of

Gravity

and

Weights

Sections

in

this

manual.

COMBUSTION

AIR

CONSIDERATIONS

The

presence

of

chlorine

vapors

or

other

corrosive

vapors

in

the

combustion

air

supply

for

gas-fired

heating

equip-

ment

presents

a

potential

corrosive

hazard.

Chlorine

will,

when

exposed

to

flame,

precipitate

from

the

compound

(usually

freon

or

degreaser

vapors)

and

go

into

solution

with

any

condensation

that

is

present

in

the

heat

exchang-

er or

associated

parts.

The

result

is

hydrochloric

acid

which

will

readily

attack

all

metals,

including

300

grade

stainless

steel.

Care

should

be

taken

to

separate

these

vapors

from

the

combustion

process.

This

may

be

done

by

wise

location

of

the

unit

with

regard

to

exhausters

or

prevailing

wind

direction.

LOCATION

Before

placing

roofto

p

unit

in

its

permanent

location,

make

certain

that

the

roof

is

capable

of

carrying

the

additional

load

of

this

equipment.

Check

the

unit

weight

given

at

the

end

of

this

manual.

Refer

to

Figure

2

for

required

clearances

to

combustible

material.

Figure

1

USE

SPRE

A

D

T

O

PREVE

N

TI

T

O

U

N

I

USE SPRE

A

DE R

BAR

T

O

PRE V

E

N

T

DAMAGE

T

O

UN

IT

MOUNTING/

LOCATIONS

These

units

are

suitable

for

installation

on

combustible

flooring.

Single,

double

and

triple

duct

furnace

only

models

have

base

rails

which

can

be

mounted

either

on

solid

planking

or

steel

channels.

All

other

units

installed

on

field

furnished

supports

must

use

the

recommended

method

shown

in

Mounting

on

Field

Furnished

Supports

or

equivalent.

Roof

curb

kits

for

rooftop

units

are

shipped

unassembled.

Included

with

the

roof

curb

kit

are

insulated

or

uninsulated

curb

rails,

bolts

and

screws

needed

for

assembly,

sealant,

a

roll

of

self-adhering

rubber

gasketing,

and

installation

instructions.

Roof

insulation,

cant

stripping,

flashing,

roof

felts,

caulking,

and

nails

must

be

furnished

by

the

installer.

See

separate

roof

curb

specifications.

II

.

GENERAL

REQUIREMENTS

-3-

The

venting

is

an

integral

part

of

the

unit

and

must

not

be

altered

in

the

field.

The

Natural

Vented

units

are

equipped

with

a

ventcap

which

is

designed

for

natural

draft

venting.

Air

for

combustion

enters

the

base

of

the

vent

cap

through

a

protective

grill

and

products

of

com-

bustion

are

discharged

at

the

upper

section

of

the vent

cap.

CAUTION

:

Insure

that

all

power

sources

conform

to

th

e

un

i

t

requirements

or

damage

to

the

unit

may

result

Installation

must

be

made

in

accordance

with

local

codes,

or

in

the

absence

of

local

codes,

with

the

latest

edition

of

ANSI

Standard

Z223.1

(N.F.P.A.

No.

54)

National

Fuel

Gas

Code.

All

of

the

AN

SI

and

N

FPA

Standards

referred

to

in

these

installation

instructions

are

those

that

were

applicable

at

the time

the

design

was

certified.

The

ANSI

Standards

are

available

from

the

American

Gas

Association,

1515

Wilson

Blvd.,

Arlington,

Virginia

22209.

The

NFPA

Standards

are

available

from

the

N

ational

Fire

Protection

Association,

Batterymarch

Park,

Quincy,

MA

02269.

If

installed

in

Canada,

the

installation

must

conform

with

local

building

codes,

or

in

the

absence

of

local

building

codes,

with

the

current

CAN/CGA-B149.1

or

B149.2

"Installation

Codes

for

Gas

Burning

Appliances

and

Equipment'.

T

hese

outdoor

duct

furnaces

have

been

designed

for

and

certified

to

comply

with

CAN/CGA

2.8.

These

units

have

been

designed

cert

i

f

i

ed

for

outdoor

u

se

only

,

and

may

be

located

on

the

roof of

the

building

or

at

any

convenient

location

external

to

the

building

to

be

heated.

This

vent

cap

is

shipped

in

a

separate

carton

and

should

be

installed

per

the

Venting

section

of

the

Outdoor

Rooftop

Gas-Fired Duct

Furnace

Installation

and

Service

Manual.

The

Power

Vented

unit

has

a

induced

draft

venting

system.

The

combustion

air

inlet

and

prod-

ucts

of

combustion

discharge

grills

are

located

in

the

upper

section

of

the

Duct

Furnace

side

access

panel.

A

pilot

burner

plate

is

provided

in

the

Duct

Furnace

for

access

to

the

pilot

burner

and

ignition

system

without

removing

the

burner

drawer.

Clearance

between

the

external

unit

and

any

obstruction

must be

sufficient

for

proper

servicing

of

pull

out

burner

drawer.

See

Figure

2

for

this

clearance.

These

units

are

certified

for

operation

on

either

natural

or

propane

gases.

If

a

unit

is

to

be

installed

at

an

altitude

exceeding

2000

feet

(610

m)

above

sea

level,

Berate

the

unit

input

of

each

duct

furnace

by

4%

for

each

1000

feet

(305

m)

above

sea

level.

Special

main

burner

gas

orifices

are

required

for

installations

above

2000

feet

(610

m).

In

Canada,

if

unit

is

to

be

installed

at altitudes

of

2000

feet

(610

m)

to

4500

feet

(1372

m),

each

duct

furnace

must

have

the

main

burners

re-orificed to

give

90%

of

the

normal

altitude

input

rating.

If

the

unit

was

ordered

from

the

factory

for

high

altitude

operation

,

confirm

input

rating

.

See

Gas

Input

Adjustment

.

re

2A

,a

.

ow•

.

3

125

(

8

)

3

g

<.x)

-4-

Figure

2B

18"

(457

mm)

A

I

R

FLOW

(45

7

mm)

Blower

c

0

U

0

U

U

W

Duct

Furnace

I

Duct

F

urnace

D3

8

6 5

F*

"`

Refer

to

Outdoor

Duct

Furnace

Manual

for

spec

i

fic

clearances

.

Supply

Plenum

16"--

.

(457

mm)

If

a

single,

double

or

triple

duct

furnace

only

unit

is

III

.

INSTALLATION

connected

to

a

return

air

duct

or

any

other

inlet air

restriction,

the

appliance

shall

be

installed

on

the

positive

pressure

side

of

the

air

circulating

blower.

Installation

must

conform

with

local

building

codes

or

in

the

absence

of

local

codes

with

the

National

Fuel

Gas

Code

ANSI

Z223

.

1

latest

edi

-

t

i

on

.

A

heat

loss

study

and

a

complete

layout

of

the

sys-

tem

should

be

made

first.

When

locating

the

unit

in

its

permanent

location,

make

certain

that

the

roof

is

capable

of

carrying

the

additional

load

of

the

equipment.

Check

the

unit

net

weights

section

of

this

manual

.

Make

certain

that

clearances

are

provided

for

ser-

vice,

minimum

clearance

to

combustible

material

and

to

venting

cap.

See

figure

2

for

this

information.

Ducts

connected

to

units

which

do

not

have

either

a

blower

section

or

a supply

plenum

must

have

a

removable

access

panel

in

the

duct,

which

is

con-

nected

to

a

duct

furnace.

The

duct

openings

shall

be

accessible

when

the

unit

is

installed

in

service

and

shall

be

of

such

size that

smoke

or

reflected

light

may

be

observed

inside

the

casing

to

indicate

the

presence

of

leaks

in

the

heating

element.

The

covers

for

the

panels

shall

be

attached

in

such

manner

as

to

prevent

leaks.

Ducts

exposed

to

the

outdoors

must

be

insulated

and

sealed

to

prevent

water

from

enter-

ing

either

the

unit

or

building

through

the

duct.

CAUTION:

Remove

wooden

shipping

support

from

beneath

blower

housing

of

Blower

Section

to

prevent

possible

unit

damage

or

improper

unit

operation

(if

applicable).

INSTALLATION

CLEARANCES

Minimum

clearances

to

combustible

material

are

shown

on

the

unit

data

plate.

It

is

important

that

clearances

be

maintained

for

servicing

the

unit

(refer

to

Submittal

Insert

for

service clearances),

and

that

minimum

clearances

are

provided

from

the

unit

(including

vent

cap,

if

Natural

Vent

model)

to

com-

bustible

material.

Clearances

around

the

outside

air

hood

(if

unit

is

so

equipped)

must

be

unobstructed.

See

Figure

2.

MOUNTING

ON

FIELD

FURNISHED

SUPPORTS

Single,

double,

triple

duct

furnace

only

models

have

base

rails

which

are

suitable

for

mounting

either

directly

on

solid

planking

or

steel

channels.

N

ever

install

the

unit

on

a

soft

roof

where

the

rails

could

sink,

reducing

clearance

between

the

bottom

panel

and

the

roof,

or

cause

damage

to

the

roofing surface.

All

other

models

must

use

the

following

method

or

an

equivalent

when

unit

supports

are

field

furnished:

Each

section

of

the

Rooftop

unit

must

be

supported,

which

includes

supports

located

at

both ends.

If

the

unit

consists

of

a

High

CFM

Blower

section,

a

DX

Coil,

a

Duct

Furnace

and

a

Supply Plenum,

five

sup-

ports

are

required.

See

Figure

3.

-5-

3

Suppo

rt

m

us

t

clear

return

a

i

r

o

penin

g

a

n

d

f

i

t

Ins

i

de

b

ase

rai

l

f

la

n

g e

.

See

Figures

4

&

13

for

this

dimension.

Support

must

fit

inside

base

rail

f

lang

e

s.

MOUNTING

ON

ROOF

CURB

Assemble

and

install

roof

curb

per

Roof

Curb

Installation

Instructions.

See

Figures

4

&

13

for

roof

opening

sizes,

distance

between

openings

and

unit

relationship

to

roof

curb.

VENTINGt

All

venting

installations

shall

be

in

accordance

with

the

latest

edition

of

Part

7

,

"Venting

of

Equipment",

of

the

National

Fuel

Gas

Code,

ANSI

Z223.1-1992

(or

the

latest

edition),

or

applicable

provisions

of

local

building

codes.

The

Natural

Vente

d

u

nits'...

are

equipped

with

a

vent

cap

which

is

designed

for

n

atural

draft

venting.

Air

for

combustion

enters the

base

of

the

vent

cap

through

a

protective

grill

and

produc

t

s

of

combustion

are

dis-

charged

at

the

upper

section

of

the

vent

cap.

t

Th

i

s

ve

nt

c

a

p

i

s

sh

i

pped

in

a

separate

carton

and

s

hould

be

installed

per

the

Venting

section

of

the

Outdo

or

Rooftop

Gas

-

F

i

red

Duct

Fu

r

na

c

e

In

s

t

a

lla

ti

on and

Service

Manual

.

The

Power

Vented

unit

has

a

induced

draft

venting

system.

The

combustion

air

inlet

and

products

of

combustion

discharge

louvers

are

located

in

the

upper

section

of

the

Duct

Furnace

side

access

panel.

Never

locate

these

units

in

an

area

where

the

flue

products

discharge

outlet

may

be

directed

at

any

fresh

air

vents.

See

the

Outdoor

Rooftop

Gas-Fired

Duct

Furnace

Installation

and

Service

M

anual

for

installation

and

servicing

requirements.

DUCT

CONNECTIONS

All

ductwork

must

be

properly

supported

so

that

no

strain

is

put

on

the

unit.

Do

not

alter

or

bend

the

dis-

charge

duct

flanges

supplied

on

your

furnace/air

handler.

Ducts

connected

to

units

which

do

not

have

either

a

blower

section

or

a

supply

plenum

must

have

a

removable

access

panel

in

the

duct

which

is

con-

nected

to

a

duct

furnace.

The

duct

openings

shall

be

accessible

when

the

unit

is

installed

in

service,

and

shall

be

of

such

size

that

smoke

or

reflected

light

may

be

observed

inside

the

casing

to

indicate

the

presence

of

leaks

in

the

heating

element.

The

covers

for

the

panels

shall

be

attached

in

such

a

manner

as

to

prevent

leaks.

Ducts

exposed

to

the

outdoors

must

be

insulated

and

sealed

to

prevent

water

from

either

the

unit

or

building

through

the

duct.

If

a

single,

double

or

triple

duct

furnace

only

unit

is

connected

to

a

return

air

duct,

or

any

other

inlet

air

restriction,

the

appliance

shall

be

installed

on

the

positive

pressure

side

of

the

air

circulating

blower.

When

connecting

return

air

duct

to

Standard

or

High

CFM

cabinets,

attach

duct

to

return

air

opening

flange

when

no

dampers

are

used.

Otherwise,

if

dampers

are

used,

attach

return

air

duct

around

col-

lar

at

bottom

of

damper

assembly. Also

refer

to

the

Submittal

Data

Sheets

specified

for

your

unit.

When

connecting

supply

air

duct

to

Supply

Plenum,

attach

duct

to

supply

air

opening

flange

when

no

dampers

are used.

Otherwise,

if

dampers

are used,

attach

supply

air

duct

around

collar

at

bottom

of

damper

assembly.

Refer

to

the

Figure

13.

GAS

PIPING

tt

All

gas

piping

must

be

installed

in

accordance

with

local

codes.

It

is

required

that

a

ground

union

be

installed

adjacent

to

the

gas

valve

of

each

duct

fur-

nace,

and

a

ground

union

be

installed

just

external

of

each

duct

furnace

for

unit

servicing.

On

vertical

runs,

a

drip

leg

should

be

provided

upstream

of

any

con-

trol

manifold.

A

gas

shutoff

valve

should

be,

or

may

be

required

by

local

codes,

installed

upstream

of

the

external

ground

union

for

each

duct

furnace.

A

1/8

inch

N.P.T.

plugged

tapping,

accessible

for

test

gauge

connection,

must

be

installed

immediately

upstream

of

the

unit

gas

supply

connection.

tt

For

complete

Gas

Piping

installation,

see

Outdoor

Rooftop

Gas-Fired

Duct

Furnace

Installation

and

Service

Manual.

It

is

recommended

that

the

gas

piping

not

be

installed

through

the

bottom

of

the

duct

furnace

bot-

tom

panel.

If

piping

must

penetrate

the

duct

furnace

bottom

panel,

it

must

be

sealed

to

prevent

water

leakage.

Gas

piping

must

be

installed

to

allow

for

removal

of

burner

drawer

for

unit

maintenance.

Refer

to

Figure

2.

-6-

Figure

4

CURB

SPECIFICATIONS

*

ROOF

OPENINGS

UNIT

TYPE

UTJ

"RT,

PVOrAH

"

CAPAC

I

TY

DIMENSION

[

CA]

'

R

E

TURN

SUPPLY

26

00

AIR

B*

AIR

10/

1

5

(660)

OP

E

NING

OPENING

37

.

00

20/25/50

(940)

30

/

35

/

60170

48

.

^

(1219)

40

/

80/12

53

.

50

(1359)

20

.

875

A*

20

.

875

ALL

DIMENSIONS

SHOWN

HAVE

BEEN

(530) (530)

CALCULATED

TO

INCLUDE

A

ONE

(1)

INCH

CLEARANCE

AROUND

RETURN

AND

SUPPLY

DUCTS

.

**

U

ROOFTOP

z

ARRANGEMENT

1

[RA]

LL

C,

E

J

J

^

z

L

UNIT

TYPE[

UTJ

"AT

orPV"

UNIT

SPECIFICATIONS

(REFERENCES)

CAPACITY

BLOWER

COIL

SUPPLY

DIMENSION

[CA]

STD.

HIGH

CFM

PLENUM

A"

10

-

40

^

.

J

50.85

(1292)

20

-

40

87.04

(2211)

10

-

40

113.

0

2

(2871)

UMT

TYPE!

LIT)

AH

"

BLOWER

[

R

A

I

[CA]

ST

'

D

.

HI

COI

L

SUPPLY

A

20 24

.

859

N,R

or

40

(631)

20

^

.

J

61

.

047

T

or

40

(1551)

W

20

.

J

^

.

J

87

.

035

or

40

(2211)

C

,

E

50

-80

76.

84

(

1

952)

113.02

J

M

5

0

-

80

(

2

871

)

139.01

L

50

-

80

(353

1

)

J

^

12

^

.^

1

39.01

(35

31

)

• '

ROO

FT

OP

ARR

A

NG

E

ME

NTS

[

RA

]

B,

D

,

G,

K,

M

,

P

,

S

& U

ARE

WITHOUT

A

S

UPP

L

Y

P

L

EN

U

M

;

U

SE

THE

SA

M

E

RE

TUR

N

A

IR

D

IME

N

SIO

N

S

F

O

R

THES

E

UNITS

R

OOFTO

P

O

PE N

I

N

GS.

REFE

R

TO

U

N

I

T

SUB

M

I

TTA

LS

FO

R

M

OR

E

D

E

TA

IL.

UNIT

4

.

00

(102)

RUBBER

GASK

ET

1

2

.

00

(3

0

5)

ROOF

U

NI

T

BASE

R

A

IL

F

L

AN

GE

WI

T

H

C

URB

CAP

1

.

00

NAI

L

NAILER

(WOOD

STRIP)

CANT

FELT

DIMENSIONS

ARE

IN

INCHES

D

I

MENSIONS

IN

()

ARE

IN

MM

.

.

375

(10)

CLEARANCE

SHOULD

BE

MAINTAINED

ON

EACH

SIDE

TO

INSURE

PROPER

INSTALLATION

.

-7-

CAUTION

:

Do

not

over

-

tighten

the

inlet

gas

pip-

ing

at

unit

gas

valve

or

stresses

that

could

crack

the

valve

may

result

.

The

gas

line

should

be

supported

so

that

no

strain

is

placed

on

the

unit.

Pipe

compounds

which

are

not

soluble

to

liquid

petroleum

gases

must

be used

on

threaded

joints.

The

appliance

and

its

individual

shutoff

valve

must

be

disconnected from

the

gas

supply

piping

system

during

any

pressure

testing

of that

system

at

test

pressures

in

excess

of

1/2

psig

(3.5

kPa).

The

appliance

must

be

isolated

from

the

gas

supply

piping

system

by

closing

the

individual

manual

shut-

off

valve

during

any

pressure

testing

of

the

gas

sup-

ply

piping

system

at

test

pressures

equal

to

or

less

than

1/2

psig

(3.5

kPa).

;

For

additional

gas

piping information,

including

pipe

sizing

and

drip

leg

installation,

refer

to

Outdoor

Rooftop

Gas-Fired

Duct

Furnace

Installation

and

Service

Manual.

For

additional

piping