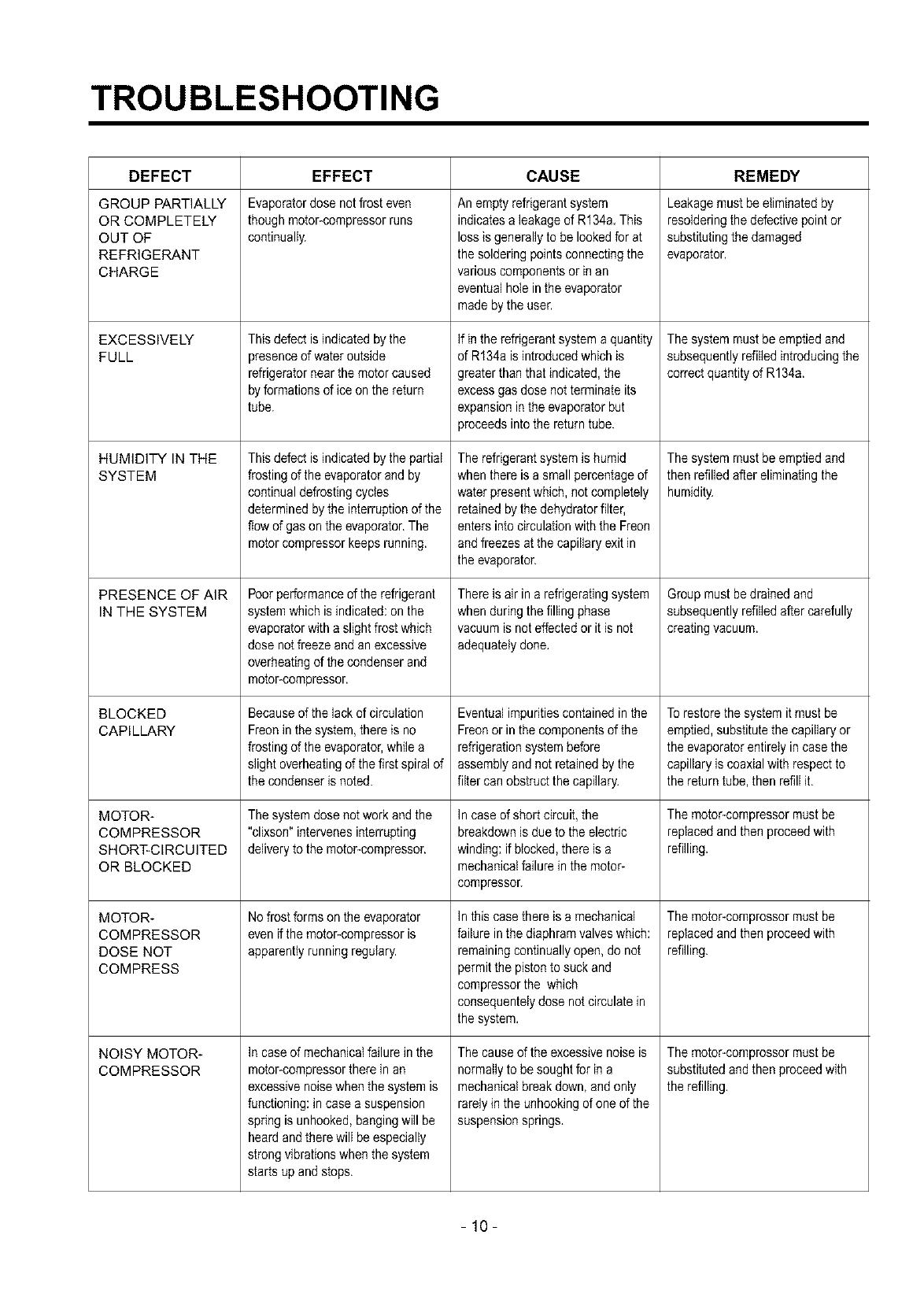

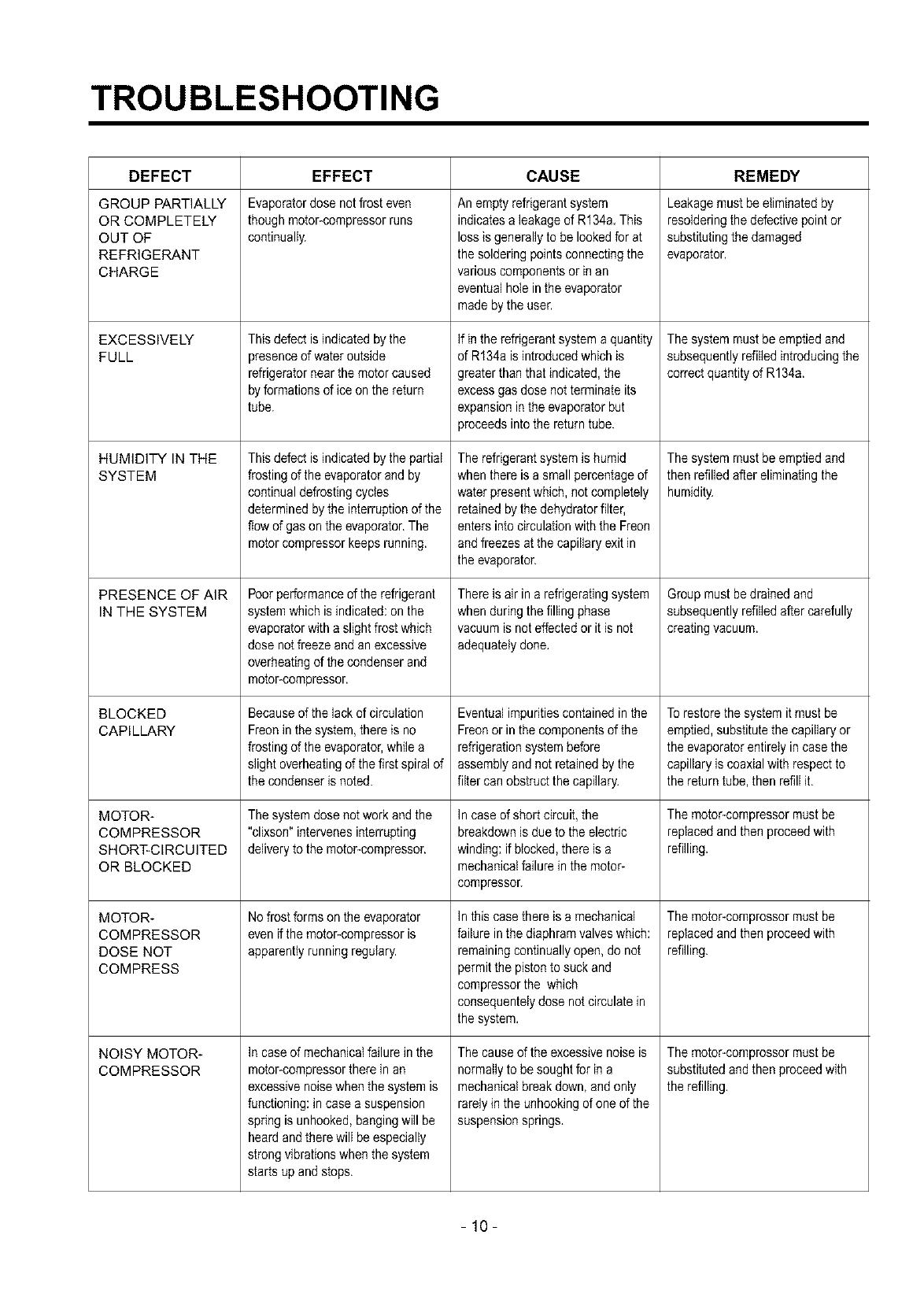

TROUBLESHOOTING

DEFECT EFFECT CAUSE REMEDY

GROUP PARTIALLY

OR COMPLETELY

OUT OF

REFRIGERANT

CHARGE

EXCESSIVELY

FULL

HUMIDITY IN THE

SYSTEM

PRESENCE OF AIR

IN THE SYSTEM

BLOCKED

CAPILLARY

MOTOR-

COMPRESSOR

SHORT-CIRCUITED

OR BLOCKED

MOTOR-

COMPRESSOR

DOSE NOT

COMPRESS

NOISY MOTOR-

COMPRESSOR

Evaporatordose notfrosteven

thoughmotoFcompressorruns

continually.

This defectisindicatedbythe

presenced wateroutside

refrigeratornearthe motorcaused

byformationsof ice onthe return

tube.

This defectisindicatedbythe partial

frosting ofthe evaporatorand by

continualdefrostingcycles

determinedby the interruptionof the

flow ofgas onthe evaporator.The

motorcompressorkeepsrunning.

Poorperformanceofthe refrigerant

systemwhich is indicated:onthe

evaporatorwitha slightfrostwhich

dosenot freezeand anexcessive

overheatingof thecondenserand

motor-compressor.

Becauseof thelack of circulation

Freonin the system,thereis no

frosting ofthe evaporator,while a

slightoverheatingofthe first spiralof

the condenseris noted.

The systemdose notwork andthe

"clixson" intervenesinterrupting

deliverytothe motorraompressor.

Nofrostformson the evaporator

evenifthe motor-compressoris

apparentlyrunningregulary.

Incaseof mechanicalfailurein the

motor-compressorthere in an

excessivenoisewhenthe system is

functioning:incaseasuspension

spring isunhooked,bangingwill be

heardand therewill be especially

strong vibrationswhen the system

startsup and stops,

An emptyrefrigerantsystem

indicatesaleakageof R134a This

lossis generallyto belookedfor at

the soldering pointsconnectingthe

variouscomponentsor in an

eventualhole inthe evaporator

madeby the user.

Ifinthe refrigerantsystema quantity

of R134aisintroducedwhichis

greaterthanthat indicated,the

excessgas dosenot terminate its

expansionin the evaporatorbut

proceedsintothe returntube.

The refrigerantsystemis humid

when there isa small percentageof

waterpresentwhich,notcompletely

retainedbythe dehydratorfilter,

enters into circulationwiththe Freon

andfreezes atthe capillaryexitin

the evaporator.

There isair inarefrigeratingsystem

when duringthe fillingphase

vacuum isnot effectedor it is not

adequatelydone.

Eventualimpuritiescontainedin the

Freonor inthe componentsofthe

refrigerationsystembefore

assemblyandnot retainedbythe

filter canobstructthe capillary.

Incaseof shortcircuit,the

breakdownis dueto the electric

winding:if blocked,thereis a

mechanicalfailurein the motor-

compressoE

Inthiscasethereisa mechanical

failurein the diaphramvalveswhich:

remainingcontinuallyopen, do not

permitthe pistonto suck and

compressorthe which

consequenteIydosenot circulatein

the system.

The causeofthe excessivenoise is

normailytobe soughtfor in a

mechanicalbreak down,and only

rarelyin theunhookingofone of the

suspensionsprings.

Leakagemustbeeliminated by

resolderingthe defectivepoint or

substitutingthe damaged

evaporator.

Thesystemmustbe emptiedand

subsequentlyrefilledintroducingthe

correctquantityof R134a.

Thesystemmustbe emptiedand

thenrefilledafter eliminatingthe

humidity.

Groupmustbedrainedand

subsequentlyrefilledaftercarefully

creatingvacuum.

Torestorethe systemit mustbe

emptied,substitutethe capillaryor

the evaporatorentirelyin casethe

capillaryis coaxialwith respectto

the returntube,thenrefillit.

Themotor-compressormustbe

replacedandthenproceedwith

refilling.

Themotor-comprossormustbe

replacedandthenproceedwith

refilling.

Themotor-comprossormustbe

substitutedandthenproceedwith

the refilling.

-10-