Page is loading ...

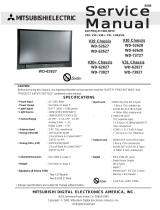

SERVICE MANUAL

BD-HP22SB

No. S49Y3BDHP22SB

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

SAFETY PRECAUTION

IMPORTANT SERVICE NOTES.........................i

Precautions for using lead-free solder ..............iii

CHAPTER 1. SPECIFICATIONS

[1] SPECIFICATIONS .........................................1-1

CHAPTER 2. OPERATION MANUAL

[1] PARTS NAMES..............................................2-1

CHAPTER 3. REMOVING OF MAJOR PARTS

[1] REMOVING OF MAJOR PARTS...................3-1

[2] EXTENSION CABLE CONNECTION DIA-

GRAM ............................................................3-3

[3] IMPORTANT SERVICE NOTICE...................3-3

[4] UPGRADING .................................................3-4

CHAPTER 4. TROUBLESHOOTING TABLE

[1] TROUBLESHOOTING TABLE....................... 4-1

CHAPTER 5. BLOCK DIAGRAM

[1] BLOCK DIAGRAM.........................................5-1

CHAPTER 6. PRINTED WIRING BOARD ASSEM-

BLIES

[1] MAIN PWB.....................................................6-1

[2] ANALOG PWB...............................................6-5

[3] POWER PWB ................................................6-7

[4] OPERATION-L PWB......................................6-9

[5] LCD PWB.....................................................6-10

CHAPTER 7. SCHEMATIC DIAGRAMS

[1] MAIN (1) CIRCUIT SCHEMATIC DIA-

GRAM............................................................7-1

[2] MAIN (2) CIRCUIT SCHEMATIC DIA-

GRAM............................................................7-2

[3] MAIN (3) CIRCUIT SCHEMATIC DIA-

GRAM............................................................7-3

[4] MAIN (4) CIRCUIT SCHEMATIC DIA-

GRAM............................................................7-4

[5] MAIN (6) CIRCUIT SCHEMATIC DIA-

GRAM............................................................7-5

[6] MAIN (7) CIRCUIT SCHEMATIC DIA-

GRAM............................................................7-6

[7] MAIN (8) CIRCUIT SCHEMATIC DIA-

GRAM............................................................7-7

[8] MAIN (9) CIRCUIT SCHEMATIC DIA-

GRAM............................................................7-8

[9] MAIN (11) CIRCUIT SCHEMATIC DIA-

GRAM............................................................7-9

[10] MAIN (12) CIRCUIT SCHEMATIC DIA-

GRAM..........................................................7-10

[11] POWER CIRCUIT SCHEMATIC DIA-

GRAM..........................................................7-11

[12] ANALOG CIRCUIT SCHEMATIC DIA-

GRAM..........................................................7-12

[13] LCD CIRCUIT SCHEMATIC DIAGRAM......7-13

[14] OPERATION-L CIRCUIT SCHEMATIC DI-

AGRAM .......................................................7-14

Parts Guide

TopPage

CONTENTS

BD-HP22SB

MODEL

BLU-RAY DISC PLAYER

In the interests of user-safety (Required by safety regulation in some countries) the set should be restored to its

original condition and only parts identical to those specified should be used.

BD-HP22SB

i

BDHP22SB

SAFETY PRECAUTION

IMPORTANT SERVICE NOTES

IMPORTANT SERVICE NOTES

This Player is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT label is located on

the rear cover.

This product contains a low power laser device. To

ensure continued safety do not remove any cover or

attempt to gain access to the inside of the product.

Refer all servicing to qualified personnel.

BD-HP22SB

ii

IMPORTANT SERVICE SAFETY PRECAUTION

WARNING

1. For continued safety, no modification of any circuit should be

attempted.

2. Disconnect AC power before servicing.

BEFORE RETURNING THE BD PLAYER (Fire &

Shock Hazard)

Before returning the BD player to the user, perform the following

safety checks:

3. Inspect all lead dress to make certain that leads are not pinched,

and check that hardware is not lodged between the chassis and

other metal parts in the receiver.

4. Inspect all protective devices such as non-metallic control knobs,

insulation materials, cabinet backs, adjustment and compartment

covers or shields, isolation resistor-capacitor networks, mechanical

insulators, etc.

5. To be sure that no shock hazard exists, check for leakage current in

the following manner.

Plug the AC cord directly into a 120 volt AC outlet.

Using two clip leads, connect a 1.5k ohm, 10 watt resistor paral-

leled by a 0.15

F capacitor in series with all exposed metal cabinet

parts and a known earth ground, such as electrical conduit or elec-

trical ground connected to an earth ground.

Use a n AC voltmeter having with 5000 ohm per volt, or higher, sen-

sitivity or measure the AC voltage drop across the resistor.

Connect the resistor connection to all exposed metal parts having a

return to the chassis (antenna, metal cabinet, screw heads, knobs

and control shafts, escutcheon, etc.) and measure the AC voltage

drop across the resistor.

All checks must be repeated with the AC cord plug connection

reversed. (If necessary, a nonpolarized adaptor plug must be used

only for the purpose of completing these checks.)

Any reading of 0.75 Vrms (this corresponds to 0.5 mA rms AC.) or

more is excessive and indicates a potential shock hazard which

must be corrected before returning the monitor to the owner.

///////////////////////////////////////////////////////////////// //////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

SAFETY NOTICE

Many electrical and mechanical parts in BD player television have

special safety-related characteristics.

These characteristics are often not evident from visual inspection, nor

can protection afforded by them be necessarily increased by using

replacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics are

identified in this manual; electrical components having such features

are identified by " " and shaded areas in the Replacement Parts List

and Schematic Diagrams.

For continued protection, replacement parts must be identical to those

used in the original circuit.

The use of a substitute replacement parts which do not have the same

safety characteristics as the factory recommended replacement parts

shown in this service manual, may create shock, fire or other hazards.

///////////////////////////////////////////////////////////////// //////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Service work should be performed only by qualified service technicians who are thoroughly familiar with all safety checks and the

servicing guidelines which follow:

CAUTION: FO R CO NTIN UED PROTECTION

AGAINST A RISK OF FIRE REPLACE ONLY WITH

SAME TYP E FUSE .

F901 (250V 3.15A)

DVM

AC SCALE

1.5k ohm

10W

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

0.15

µ

F

TEST PROBE

BD-HP22SB

iii

Precautions for using lead-free solder

Employing lead-free solder

• “All PWBs” of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the PWBs and service manuals.

The alphabetical character following LF shows the type of lead-free solder.

Example:

Using lead-free wire solder

• When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire solder may cause dam-

age or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 °C, we recommend you to use a dedicated soldering

bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station or service branch in your area.

Soldering

• As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 °C which is higher than the conventional lead solder by 40 °C, and as it has poor

solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of time. However, Since the land may be

peeled off or the maximum heat-resistance temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the

steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on and off the power of the bit as

required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

• Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

L Fa

Indicates lead-free solder of tin, silver and copper.

L F a/a

Indicates lead-free solder of tin, silver and copper.

Part No. Description Code

ZHNDAi123250E J φ0.3mm 250g (1roll) BL

ZHNDAi126500E J φ0.6mm 500g (1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg (1roll) BM

BD-HP22SB

1 – 1

BDHP22SB

CHAPTER 1. SPECIFICATIONS

[1] SPECIFICATIONS

General

Power supply AC 100 - 240V, 50/60Hz

Power consumption (Normal) 25 W

Power consumption (Standby) 0.6 W (When "Quick Start" is set to "No")

Dimensions

Approx. 432 mm x 58 mm x 260 mm (W x H x D)

Weight Approx. 3.0 kg

Operating temperature 5°C to 35°C

Storage temperature -20°C to 55°C

Operating humidity 10 % to 80 % (no condensation)

TV systems PAL system/NTSC system

(The system recorded on the disc is output.)

Playback

Playable discs BD-ROM, BD-RE Dual Layer, BD-R Dual Layer,

DVD Video, DVD+RW/+R/-RW/-R Dual Layer (Video/VR format),

Audio CD (CD-DA), CD-RW/R (CD-DA, JPEG file format)

Input/Output

HDMI HDMI 19-pin standard connector (1080p 24Hz output)

HDMI

TM

(V.1.3 with x.v.Colour, Dolby TrueHD, DTS-HD Master Audio | Essential)

Component video output Output level:

Y: 1 Vp-p (75 ohms)

P

B

/C

B

,P

R

/C

R

: 0.7 Vp-p (75 ohms)

Jacks: RCA jack

Video output Output level: 1 Vp-p (75 ohms)

Jack: RCA-pin jack

Digital audio optical output Terminal: Square Optical terminal

Audio output Output level: 2 V rms (Output impedance: 1k ohms)

Jacks: RCA jack

USB input USB 2.0 High Speed (480Mbit/s) correspondence (for Local storage/Software

update)

ETHERNET 10BASE-T/100BASE-TX

Specifications are subject to change without notice.

BD-HP22SB

2 – 1

BDHP22SB

CHAPTER 2. OPERATION MANUAL

[1] PARTS NAMES

Main Unit (Rear)

Main Unit (Front)

Major Components

1

2

3

6 74 5

9

8 10

HDMI cable holder on the rear of the main

unit

This Player comes with a dedicated cable holder so that the HDMI

cable does not place direct weight and stress on the terminal. When

connecting the HDMI cable, be sure to pass the cable through the

cable holder and secure it.

CAUTION

Do not pull on the HDMI cable when it is connected to the terminal, as

this can damage the terminal or cause a poor connection.

•

Press down on the tab and pull it towar ds you.

Pass the HDMI cable (commercially available) through the

cable holder.

Press in on the tab until it clicks into position.

1

2

3

Connect the HDMI cable to

the rear of the main unit while

providing some slack.

COMPONENT VIDEO OUT jacks

VIDEO output jack

2CH AUDIO output jacks

DIGITAL AUDIO OUT OPTICAL

terminal

ETHERNET terminal

BD STORAGE/SERVICE terminal

BD STORAGE

SERVICE for software

HDMI OUT terminal

HDMI cable holder (See below.)

Cooling fan

The cooling fan operates while the

power to the Player is on.

AC IN terminal

1

2

3

4

5

6

7

8

9

10

OPEN/CLOSE

Flap door

Disc tray

ON/STANDBY indicator

1

2

3

4

POWER

PLAY

STOP

PAUSE

5

6

7

8

AQUOS PURE MODE indicator

Remote control sensor

Front panel display

BD/DVD/CD mode indicator

9

10

11

12

HDMI cable

85

3

6 7 94

21

10 11 12

BD-HP22SB

2 – 2

Remote Control Unit

POWER

OPEN/CLOSE

AUDIO, SUBTITLE

Number buttons

REPEAT

SKIP/

SKIP/

PAUSE

PLAY

TOP MENU/TITLE LIST

Cursor buttons ( / / / ), ENTER

EXIT

A (Red), B (Green), C (Yellow), D (Blue)

(Lock) (See below.)

VIDEO OUTPUT RESET

DISPLAY

TV CONTROL buttons

FUNCTION

FWD

REV

STOP

POP-UP MENU

RETURN

PinP

SETUP

Keylock function

You can set the keylock to prevent accidental operations.

This function allows TVs compatible with AQUOS LINK to

also perform a Key Lock on the player.

Press and hold

(Lock) for more than 5 seconds.

Each time you perform this operation, the function is activated

or deactivated.

If you try to operate the Player while the keylock function is

set, “Hold” blinks on the front display panel to indicate that the

keylock function is set.

•

•

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

1

2

3

5

4

6

7

8

9

10

11

12

13

16

17

18

19

20

21

22

23

14

24

15

25

BD-HP22SB

3 – 1

BDHP22SB

CHAPTER 3. REMOVING OF MAJOR PARTS

[1] REMOVING OF MAJOR PARTS

1. Removing the tray cover

1. Eject the tray by open the Front door and inserting a pin into the

compulsory eject hole, then remove the Tray cover.

2. Removing the cabinet and the panel

1. Remove two screws and three screws from the Top cabinet.

2. Unhook claws of the Front panel and remove the Front panel.

3. Removing the BD drive

1. Disconnect the Power cable between the BD drive and Power

PWB.

Disconnect the SATA cable between the BD drive and Main PWB.

2. Remove three screws , four screws and remove the BD

drive upward.

4. Removing the front PWB

1. Disconnect the LCD FFC between the LCD PWB and MAIN PWB.

2. Remove three screws .

Insert

a pin

Tray cover

Front door

Top cabinet

2

1

1

Front panel

BD drive angle (Left)

BD drive

3

4

4

SATA cable

Power cable

Operation-L

PWB

LCD PWB

LCD FFC

5

5

BD-HP22SB

3 – 2

5. Removing the fan and the rear terminal board

1. Remove two screws .

2. Remove six screws .

3. Disconnect the fan cable connector and remove the Fan.

6. Removing each PWB

1. Disconnect the board to board connector from the Main PWB and

Analog PWB, then remove two screws .

Disconnect the board to board connector between the Main PWB

and Power PWB.

2. Remove two screws .

3. Remove three screws .

4. Remove the Insulation holder.

7

7

6

Rear terminal board

Fan

Insulation

holder

Power PWB

10

Main PWB

9

Analog PWB

8

BD-HP22SB

3 – 3

[2] EXTENSION CABLE CONNECTION DIAGRAM

[3] IMPORTANT SERVICE NOTICE

1. To replace the Main CBA, perform the items 9 - 12 of [4] Upgrading and confirm the version: it is necessary to upgrade with a disc to the latest ver-

sion if the CBA version is old.

2. The IC7201 and IC8505 cannot be replaced because they have the BD-playback key already written. Accordingly, the IC8502 that has the soft-

ware written together with the IC8505 cannot be replaced either. Keep also in mind that the IC8503 cannot be replaced either because of the

model information on it.

3. After replacing the E2PROM for front-end software (IC2505), perform Menu - Miscellaneous Settings - Reset Settings.

Parts Code Price Code Name/Description Pin

QCNW-E227WJPZ CL CN901 <=> SC9001, SC5601 <=> CN2301 23

QCNW-E573WJPZ AP P9002 <=> BD Drive 4

- - SATA Cable (Commercially available) CN7204 <=> BD Drive 7

㪪㪚㪐㪇㪇㪈

㪤㪘㪠㪥

㪧㪮㪙

㪦㪧㪜㪄㪣

㪧㪮㪙

㪘

㪪㪚㪐㪇㪈

㪝㪘㪥

㪚㪥㪐㪇㪉

㪧㪦㪮㪜㪩

㪧㪮㪙

㪚㪥㪉㪌㪇㪈

㪧㪐㪇㪉

㪣㪚㪛

㪧㪮㪙

㪪㪚㪈㪈㪇㪈

㪪㪚㪌㪍㪇㪈

㪘

㪚㪥㪐㪇㪈

㪘㪥㪘㪣㪦㪞

㪧㪮㪙

㪚㪥㪉㪊㪇㪈

㪙㪛

㪛㪩㪠㪭㪜

㪚

㪙

㪧㪐㪇㪇㪉

㪚㪥㪎㪉㪇㪋

A

B

C

㪨㪚㪥㪮㪄㪜㪉㪉㪎㪮㪡㪧㪱

㪍㪇㪇

㪘

㪚㪥㪐㪇㪈㹤㪪㪚㪐㪇㪇㪈

㪚㪥㪌㪍㪇㪈㹤㪚㪥㪉㪊㪇㪈

㪬㫊㪼㪻㩷㫀㫅㩷㫋㪿㪼㩷㪸㫍㫆㪹㪼

㫋㫎㫆㩷㫇㫀㪼㪺㪼㫊㪅㩷㩿㪉㪊㪧㫀㫅㪀

㪬㫊㪼㪻㩷㫀㫅㩷㫋㪿㪼㩷㪸㫍㫆㪹㪼

㫆㫅㪼㩷㫇㫀㪼㪺㪼㪅㩷㩿㪋㪧㫀㫅㪀

㪬㫊㪼㪻㩷㫀㫅㩷㫋㪿㪼㩷㪸㫍㫆㪹㪼

㫆㫅㪼㩷㫇㫀㪼㪺㪼㪅㩷㩿㪎㪧㫀㫅㪀

㪙

㪚

㪨㪚㪥㪮㪄㪜㪌㪎㪊㪮㪡㪧㪱

㪧㪐㪇㪇㪉㹤㪙㪛㩷㪛㪩㪠㪭㪜

㪌㪇㪇

㪪㪘㪫㪘㩷㪚㪸㪹㫃㪼㩷㩿㪚㫆㫄㫄㪼㫉㪺㫀㪸㫃㫃㫐㩷㪸㫍㪸㫀㫃㪸㪹㫃㪼㪀

㪚㪥㪎㪉㪇㪋㹤㪙㪛㩷㪛㪩㪠㪭㪜

BD-HP22SB

3 – 4

[4] UPGRADING

1. Press [Power] button to turn the switch on, then wait till the BD_LED changes from blinking to lit.

2. Press [Tray Open/Close] button to open the Tray, put the upgrade disc on the tray and close the tray.

3. The power automatically turns off. Then it turns on again and the upgrading with the disc will start.

4. During the upgrading, the mode indicator stays blinking in white as "V-up" message keeps blinking on LCD.

"NOW UPDATING DO NOT UNPLUG AC CORD" appears on the monitor screen.

And the version updating progress is expressed in %.

5. When upgrading with the disc is completed, the Tray automatically opens.

* If the front-end software was upgraded, the standby LED lights up halfway as well as the mode indicator starts blinking alternately in white and

blue.; the Tray will open after the upgrading is completed and the power will turn off. (Go to step 8.)

6. When the upgrading is completed, the following appears on the monitor screen.:

"SOFTWARE UPDATE IS COMPLETE"

If the version updating fails, "FAILED TO COMPLETE UPDATE RETRY SOFTWARE UPDATE" is displayed. Take out the disc, turn off the power

and take the procedure again starting from [1] above.

7. Remove the disc from the Tray and press any other button of the Main Unit than [Power], then the Tray will close and the power will automatically

turn off. (Confirm the power-off by stop of the Cooling Fan.)

* If [Power] button is pressed, the power will turn off with the Tray open.

8. Press [Power] button to turn the power on, then wait till the MODE INDICATOR changes from blinking to lit.

9. Press the [SETUP] button on the remote controller, and the menu screen shows up (if the wallpaper screen is used).

* There is no need to take this step, because just after the power is turned on, the menu screen shows up.

10.Select [SETTINGS] first and then [VERSION]. (Press the ENTER button.)

11.The version of the currently installed software appears on the monitor screen. Compare with the version of this updated software, make sure the

version is just the same. If the version id not updated, take the procedure again from Step [2].

12.Press [Power] button to turn the power off. (Confirm the power-off by stop of the cooling fan.)

NOTE: Do not unplug the AC cord during version updating.

* The version updating cannot be made on the menu screen. Make the wallpaper onscreen.

Monitor: "CANNOT UPDATE. FINISH PLAYBACK OR EDIT AND SET A DISC"

Consult with your Services Company as we cannot provide the upgrading software.

Start

Turn the power on.

Open the tray,

put the upgrade disc and

close the tray

The power automatically

turns off. Then, the power

turns on automatically and

the upgrading starts.

Monitor:

"NOW UPDATING

DO NOT UNPLUG AC CORD"

ex.

غغغع

غغ

20%

The tray opens

automatically.

Upgrading completed

No

Yes

Monitor:

"SOFTWARE UPDATE IS

COMPLETE"

Remove the disc and turn

the power off.

Remove the disc and turn

the power off.

Turn the power on and

confirm the version.

End

Restart

Upgrading successful. Upgrading unsuccessful.

Monitor:

"FAILED TO COMPLETE

UPDATE

RETRY SOFTWARE

UPDATE"

BD-HP22SB

4 – 1

BDHP22SB

CHAPTER 4. TROUBLESHOOTING TABLE

[1] TROUBLESHOOTING TABLE

1. MAIN UNIT

The main PWB circuit doesn't function when the power is turned ON.

The power does not become ON.

Is the level of pin (6) of SC9101 at Low?

The power becomes OFF.

Check the POWER pwb. Check the

IC9001, 9002, 9003, 9004, 9005

and their peripheral circuits.

YES

NO

NO

NO

Is the fan turning on when the power

is turned ON?

Check the fan, fan power and their

peripheral circuits.

YES

YES NO

YES

YES

FLOW CHART No.1

NO

Are AT_9V, AT_5V, SUB_PC-8V,

SUB_PC_5V supplied to SC9101?

Check the power PWB.

YES

NO

Is 1.05V supplied to TL9019 and TL9016,

3.3V to TL9017, 1.8V to TL9018 and

TL9020 respectively?

Check the IC9001, 9002, 9003, 9004, 9005

and their peripheral circuits.

YES

NO

Is the level of pin (14) of CN5601 at High? Check R5626 and the analog PWB.

YES

NO

Is 27MHz detected at R7326? Check X7201 and its peripheral circuits.

YES

NO

Does pin (1) of CN7203 turn to High and

Low on start-up?

Check IC7802, IC7803, IC7804, IC7805,

IC8502, IC8505 and their peripheral

circuits.

Check IC7201 and its peripheral circuits.

The drive doesn't function normally.

Are 12V and 5V supplied to the drive?

Check the power PWB, BD_12V, BD_5V and their peripheral

circuits.

NO

YES

Is the SATA cable connected CN8102 and drive certainly?

Check the connection of CN8102 and drive.

NO

YES

Pin 2, 3, 5, 6 of CN8102 occasionally turn to low.

Check the peripheral circuits of CN7201.

NO

YES

Check the drive.

FLOW CHART No.2

BD-HP22SB

4 – 2

No video signal output from the main PWB.

Is video signal input into each terminal of SC5601?

1) S-VIDEO and COMPOSIT OUTPUT TERMINALS

2 pins (SUB_YOUT), 4 pins (SUB_COUT)

2) D-VIDEO TERMINAL

6 pins (MAIN_YOUT), 8 pins (MAIN_PBOUT),

10 pins (MAIN_PROUT)

NO

YES

Is video signal input into the base of transistor for each buffer?

1) S-VIDEO and COMPOSIT OUTPUT TERMINALS

Q5604, Q5605

2) D-VIDEO TERMINAL

Q5601, Q5602, Q5603

Check SUB_PC_5V line.

Check SC5601.

YES

NO

Check IC7201.

FLOW CHART No.3

No audio signal output from the main PWB

Is audio signal input into terminal of each connector?

1) 2ch analog audio connection

Pins (12) (MAIN_L) and (14) (MAIN_R) of SC5601.

YES

NO

Is there output from DAC?

1) 2ch analog audio connection

Check pins (9) and (10) of IC5606.

Check the peripheral circuits of SC5602.

Check the ANALOG pwb.

YES

NO

Is 5V supplied to pin (13) and -8V to pin (11) of IC5606

respectively?

Check the peripheral circuits of IC5602.

NO

Replace IC5606.

YES

YES

Is any digital signal input into pins (1) - (4) of the IC5606?

Check the peripheral circuits of IC7201.

Check the line between each resistor and IC5606.

YES

NO

NO

Is any digital signal detected at each resistor of R7304 to

7315?

FLOW CHART No.4

BD-HP22SB

4 – 3

No video and audio signal output from HDMI terminal.

Replace the TV set (cable) and reconfirm.

Still no video and audio output?

YES

NO

Is level of R4218 higher than 2V?

Is the level of pin (5) of IC4203 at least 5V?

Defective TV set or cable. Or, check the contact of soldered

connector of SC4201.

NO

NO

Are output voltages of IC4201 as 1.0V, IC4203 as 5V,

IC4206 as 3.3V OK?

Check the IC4201, IC4203 and IC4206 or peripheral circuits.

NO

YES

Is the data line functioning (Hi/Low)?

Check IC7802, IC7803, IC7804, IC7805, IC8502, IC8505 and

their peripheral circuits.

Replace IC7201.

Or rewrite the main software.

NO

YES

FLOW CHART No.5

No audio signal output from the Optical and Coaxial terminal.

Is there digital audio signal at R5669?

YES

NO

Check the IC7201 and their peripheral circuits.

Check the J5601 and CN5602 and the peripheral circuits.

FLOW CHART No.6

The software cannot be updated by using the USB memory terminal. Or any BD-LIVE-enabled titles cannot be enjoyed.

Replace the USB memory with new one, and check again.

Does the USB function properly?

YES

USB memory defective.

NO

NO

Is 5V supplied to pin (1) of CN4802?

Are output voltages pin (1) of

IC4804 as 5V?

Is pin (4) of IC4804 at "Low" level?

NO

Check the Power PWB.

YES

Is 5V supplied to pin (5) of IC4804? Replace IC4804.

Check or replace the peripheral

circuits of IC4802.

Check the contact of soldered

connectors.

NO

Check the contact of soldered

connector of CN4802.

YES

YES

YES

NO

YES

Is signal input into pins (2)/(3) of CN4802?

Check the L4803.

Check the pins (101)/(102) of CN4802 and

thier peripheral circuits.

NO

FLOW CHART No.7

BD-HP22SB

4 – 4

2. ANALOG UNIT

No picture appears with the component or composite signal.

Is the video signal outputted from the component or

composite terminal J2401?

YES

NO

* Is the component output sent to the component

terminal if selected?

Select the component output with the remote controller.

Hold down the HDMI button on the remote controller.

CP-oP: Component output

H-oP: HDMI output

Mount C2301, C2306, C2313, C2317 and C2320 in place.

If no signal comes in, replace IC2301.

(When the 5V signal is fed to pins (7) and (21) of IC2301.)

Are pins (2) (composite) and (13) (component output mute) of

IC2301 at "H" level? ("H": Mute)

Disconnect the output coupling capacitors C2305, C2314, C2318

and C2321. If no signal comes out of the IC, replace this IC.

Check the connected cable and its connection tightness.

Check also the input of connected TV set.

Disconnect CN2302.

Is there the signal at each terminal of SC5601?

Check the PMUTE1, PMUTE2

and F_MUTE lines.

Check IC2301 and its

peripheral circuits.

Or replace IC2301 as required.

NO

YES

Is the video signal inputted to the component or composite

terminal J2401?

Check each terminal.

Check the line between IC2301 and each terminal.

NO

YES

Are there the following input signals at the CN2302 terminals?

Ԙ Component

pin (6)MAIN_Y

pin (8)MAIN_PB

pin (10)MAIN_PR

ԙ Composite

pin (2)SUB_Y

pin (4)SUB_C

MAIN FLOW CHART No.3

NO

NO

NO

YES

YES

YES NO

YES

Are there the following input signals at the IC2301 terminals?

Ԙ Component

pin (8)CY_IN

pin (10)CB_IN

pin (12)CR_IN

ԙ Composite

pin (1)C_IN

pin (3)Y_IN

Are there the following output signals at the IC2301 terminals?

Ԙ Component

pin (20)CY_OUT

pin (17)CB_OUT

pin (15)CR_OUT

Ԛ Composite

pin (25)V_OUT

Check the line between CN2302 and IC2301.

NO

Check the SUB_PC_5V line.

Is the SUB_PC_5V signal fed to pins (7) and (21) of IC2301?

NO

YES

YES

FLOW CHART No.1

BD-HP22SB

4 – 5

3. OPERATION/LCD UNIT

The reproduced audio signal does not come from each audio output terminal.

Is the audio signal outputted from J2401?

YES

NO

Check the pattern up to J2401.

Check the connected cable and its connection tightness.

Check also the input of connected TV set or amplifier.

Disconnect CN2302. Is there the audio signal at SC5601?

Does the mute circuit function?

Is the audio signal inputted to J2401?

Check the mute circuit and the F_MUTE and AUDIOMAINMUTE

signal lines. Muting occurs when both the F_MUTE and

AUDIOMAINMUTE signals are at "H" level.

YES

NO

Are there the following input audio signals at CN2302?

pin (12)AUD_MAIN_L

pin (14)AUD_MAIN_R

MAIN FLOW CHART No.4

NO

NO

YES

YES

Check the pattern up to R2212 and R2213.

NO

Check each terminal.

YES

FLOW CHART No.2

The remote controller does not function.

The main unit controls function, but the remote controller

controls fail to function.

YES

YES

Check the line between pin (1) of RMC1201 and pin (25) of IC2504.

Check the remote control codes 1, 2 and 3.

Using the remote controller, is the "L" pulse signal outputted

from pin (1) of RMC1201?

Is the "L" pulse signal inputted to pin (25) of IC2504?

Replace RMC1201 or the remote control receiver.

NO

NO

Is the remote control code as specified?

NO

YES

Is the 5V voltage applied to pin (3) of the RMC1201 remote

control receiver?

Check the AT_5V line.

NO

YES

Check IC2504. Replace it as required.

YES

FLOW CHART No.1

BD-HP22SB

4 – 6

The LCD display fails to light up.

Is the LCD unit cracked or otherwise damaged?

NO

NO

Check all the signal lines between SC1101 and IC1101.

Replace LCD1101.

Are there the following inputs to the following pins: 5V at pin

(37), LCD_RST at pin (36), LCD_CS at pin (42), LCD_CLK at

pin (43) and LCD_DATA at pin (44), all on IC1101?

Are there the following outputs from the following pins: 5V at

pin (8), LCD_CS at pin (11), LCD_DATA at pin (18),

LCD_CLK at pin (9) and LCD_RST at pin (12), all on SC1101?

Check IC1101 and its peripheral circuits. Or replace IC1101 as

required.

YES

YES

Check the connection between SC2501 and CN1101.

YES

Is the display-designated SEG or COM signal inputted to

LCD1101?

YES

Replace LCD1101.

YES

NO

Are the signals outputted from pins (1 thru 17, 33, 34 and 35)

of IC1101?

Check the pattern between IC1101 and LCD1101.

YES

NO

Are there the following inputs to the following pins: 5V at pin

(14), LCD_CS at pin (11), LCD_DATA at pin (13), LCD_CLK

at pin (12) and LCD_RST at pin (10), all on SC2501?

NO

Check the following signal flows:

LCD_DATA; Pin (1) of IC2504 to pin (13) of CN2502

LCD_CLK; Pin (2) of IC2504 to pin (12) of CN2502

LCD_RST; Pin (3) of IC2504 to pin (10) of CN2502

LCD_CS; Pin (47) of IC2504 to pin (11) of CN2502

Check also IC2504 and its peripheral circuits.

NO

Is the 5V signal fed to pin (14) of SC2501?

NO

Check the SUB_PC_5V line.

FLOW CHART No.2

The LCD backlight fails to light up.

Is the "H" voltage applied at the non-base-connected side of

Q1107 on R1138?

NO

NO

Check the pattern between pin (13) of SC1101 and R1138.

Is the "H" potential outputted from pin (40) (LED_BL_LCD) of

IC2504?

Check IC2504 and its peripheral circuits.

Or replace IC2504 as required.

Check the line between pin (40) of IC2504 and pin (9) of SC2501.

YES

Is the "H" potential applied at pin (13) (BL_LCD) of SC1101?

YES

Check Q1107, LED and the current-limiting resistor.

YES

NO

Is the "H" potential applied at pin (9) (BL_LCD) of SC2501?

Check the FFC between SC1101 and SC2501.

YES

NO

FLOW CHART No.3

BD-HP22SB

4 – 7

The LED power indicator fails to light up.

Is the power as specified?

YES

NO

Check each transistor, LED and the current-limiting resistor.

Is there the "H" potential at pin (18) (LED_STBY) or pin (17)

(LED_PON) of SC2504?

Is the "H" potential outputted from pin (53) (LED_STBY) or pin

(51) (LED_PON) of IC2504?

Check the FFC between SC1101 and SC2501.

YES

Check the line between IC2504 and SC2501.

YES

Is the "H" potential applied at the base of Q1111 or Q1112?

YES

POWER FLOW CHART No.1 or POWER FLOW CHART No.3

NO

NO

Check IC2504 and its peripheral circuits. Or replace IC2504 as

required.

NO

Is there the "H" potential at pin (4) (LED_STBY) or pin (5)

(LED_PON) of SC1101?

Check the line between SC1101 and the base of each transistor.

YES

NO

FLOW CHART No.4

The LED mode display indicator fails to light up.

* White LED: Blinking while the disc is being loaded.

Lights up when the disc has been recognized.

* Blue LED: While the disc is being played back.

Is the "H" potential applied at the base of Q1104 or Q1105?

NO

NO

Check the line between SC1101 and the base of each transistor.

Is there the "H" potential output from the following pins in each

mode: Pin (54), (LED_BD_MODE), pin (57) (LED_DVD_

MODE), pin (55) (LED_BD_PLAY) or pin (58) (LED_DVD_

PLAY), all on IC2504?

Check IC2504 and its peripheral circuits. Or replace IC2504

as required.

Check the line between IC2504 and SC2501.

YES

Is there the "H" potential at pin (18) (LED_BD_MODE) or pin

(17) (LED_BD_PLAY) of SC1101?

YES

Check each transistor, LED and the current-limiting resistor.

YES

NO

Is there the "H" potential at pin (5) (LED_MODE_R) or pin (4)

(LED_PLAY_R) of SC2504?

Check the FFC between SC1101 and SC2501.

YES

NO

FLOW CHART No.5

BD-HP22SB

4 – 8

4. ETHER UNIT

A button fails to work.

Is the button switch contact and tightness as specified?

YES

YES

Check the line between each button and IC2504. Or check the

pull-up resistor at pin (74) or (75) of IC2504. (R2578, R2507)

Is the control voltage properly applied at pin (74) (KEY_EJCT)

and pin (75) (KEY_STBY) of IC2504? (While the relevant

button is held down, the "H" level changes to "L" level.)

NO

Check the relevant switch. Replace it as required.

NO

Check IC2504 and its peripheral circuits. Or replace IC2504

as required.

FLOW CHART No.6

Internet connection impossible with Ether terminal.

Still malfunctioning even by replacing the cable.

NO

YES

Is any signal input into pins (1)/(2)/(4)/(5) of the J7001?

Check the J7001 contact.

Cable defective.

YES

NO

Is any signal input into pins (28)/(29)/(31)/(32) of the IC7001?

Check the peripheral circuits of J7001.

YES

Check or replace the peripheral circuits of X7001 and R7024.

NO

Check the peripheral circuits of FB7001, FB9004 and IC9002.

NO

YES

Is 50MHz clock detected at pin (14) of IC7001?

Is 3.3V supplied to pins (7)/(25)/(30)/(33)/(35) of IC7001?

YES

Check or replace the peripheral circuits of IC7201.

YES

Is any signal input into the R7004 - 7012?

YES

Check or replace the peripheral circuits of IC7001.

NO

Is 50MHz clock detected of R7027?

NO

Check or replace the peripheral circuits of IC7201.

YES

FLOW CHART No.1

BD-HP22SB

4 – 9

5. POWER UNIT

Power does not come ON.

Is the fuse working properly?

If the fuse still blows after replacement, refer to "The fuse blows" in

the FLOW CHART No.2.

Does the power come back if the power cable is unplugged

and plugged again after several seconds?

Is a part of primary circuit causing leaks, short-circuit or open circuit

(L901, L902, D901, T901, IC901, C911 and their peripheries)?

Check D954, L953, C960 and C963 of the AT_5V line.

YES

NO

Check the power failure detection circuit (IC2508 and its periphery).

NO

NO

NO

Is AT_5V line working normally?

Is voltage normal at lines AT_14V, BD_12V, AT_9V, BD_5V,

SUB_PC_5V, AT_-12V and SUB_PC_-8V?

Check each rectifier circuit and SW circuit of the secondary circuit.

YES

YES

YES

Is pin (19) of IC2504 at "H" level?

NO

FLOW CHART No.1

The fuse blows.

Is a part of primary circuit causing leaks, short-circuit or open

circuit (L901, L902, D901, T901, IC901, C911 and their

peripheries)?

Check if the rectifier diode and the circuit are causing short-circuit in

each rectifier circuit of the secondary circuit. (D952, D953, D954,

D955)

Case(1)

Case(2)

FLOW CHART No.2

The power does not come ON from power OFF status.

Is AT_5V line working normally?

Check the rectifier circuit of AT_5V and if there is a short-circuit in

the secondary circuit side.

Check the function of Microcomputer in IC2504 and its peripheral

circuits.

When the Power key (S1201) is pressed, is pin (75) of IC2504

at "L" level?

YES

NO

NO

NO

Is pin (59) of IC2504 at "H" level?

Is ST_5V output?

Check the line between S1201 a nd IC2504.

NO

Check the SUB_PC_5V circuits (Q9501 and its periphery).

YES

YES

Is pin (76) of IC2504 at "H" level?

NO

Check the peripheral circuits of IC2504.

YES

Is the DRIVE_P-CON(H) line at "H" level?

NO

Check Q912 and the peripheral circuits.

YES

Are BD_12V and BD_5V output?

NO

Check the BD_12V and BD_5V circuits (Q904, Q913, etc.).

YES

Check or replace the peripheral circuits of IC2504.

YES

FLOW CHART No.3

Buzzing sound is generated near the power circuit.

Check if the rectifier diode and the circuit are causing short-circuit, or if the shunt regulator circuit is defective, in each rectifier circuit of the

secondary circuit (around D952, 953, 954, 955 and 951).

FLOW CHART No.4

/