• Neverusethegeneratororanyofitspartsasastep.Stepping

ontheunitcanstressandbreakparts,andmayresultin

dangerousoperatingconditionsfromleakingexhaustgases,

fuelleakage,oilleakage,etc.

• Onelectricstartmodels,disconnectthePOSITIVE(+)battery

cablefromtheenginestarterORtheNEGATIVE(-)battery

cablefromthebatteryterminal,whicheveriseasier,before

transportingthegenerator.

NOTE:

Thisgenerator is equipped with a spark arrestor muffler. The

spark arrestor must bemaintained in effectiveworking order

by the owner/operator. In theState of California, a spark

arrestoris requiredby law (Section4442 of the California

PublicResources Code). Otherstates may havesimilar laws.

Federal lawsapply on federallands.

EXHAUST & LOCATIONHAZARDS

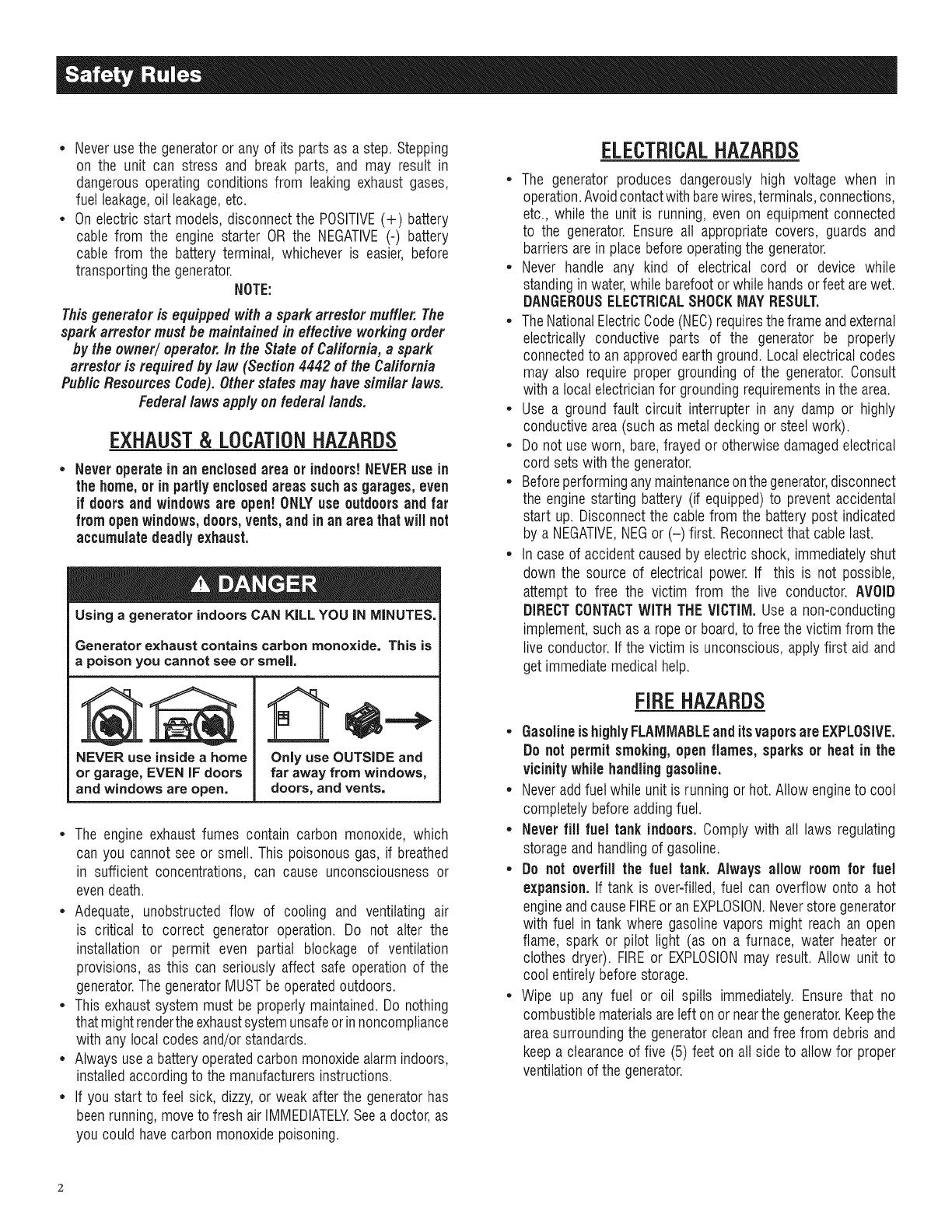

• Never operate in an enclosed areaor indoors!NEVERuse in

the home,or in partlyenclosedareas suchas garages, even

if doors and windowsare open! ONLYuse outdoors and far

fromopenwindows,doors, vents,andin anareathatwill not

accumulatedeadly exhaust.

Using a generator indoors CAN KiLL YOU iN MINUTES.

Generator exhaust contains carbon monoxide. This is

a poison you cannot see or smell,

NEVER use insidea home

or garage, EVEN IF doors

and windows are open.

Only use OUTSIDE and

far away from windows,

doors, and vents.

• The engine exhaustfumes contain carbon monoxide, which

can you cannot see or smell. This poisonous gas, if breathed

in sufficient concentrations, can cause unconsciousnessor

evendeath.

• Adequate, unobstructed flow of cooling and ventilating air

is critical to correct generator operation. Do not alter the

installation or permit even partial blockage of ventilation

provisions, as this can seriously affect safe operationof the

generator.ThegeneratorMUSTbeoperatedoutdoors.

• This exhaustsystemmust be properlymaintained.Do nothing

that mightrendertheexhaustsystemunsafeorinnoncompliance

with any localcodes and/orstandards.

• Alwaysusea batteryoperatedcarbonmonoxidealarmindoors,

installedaccordingto themanufacturersinstructions.

• If you start to feet sick, dizzy,or weak after the generatorhas

beenrunning,moveto fresh air IMMEDIATELYSeea doctor,as

you couldhavecarbonmonoxidepoisoning.

ELECTRICALHAZARDS

• The generator produces dangerouslyhigh voltage when in

operation.Avoidcontactwith barewires,terminals,connections,

etc., while the unit is running,even on equipmentconnected

to the generator. Ensureall appropriate covers, guards and

barriersarein placebeforeoperatingthegenerator.

• Never handle any kind of electrical cord or device while

standinginwater,while barefootorwhile handsor feet arewet.

DANGEROUSELECTRICALSHOCKMAYRESULT.

• TheNationalElectricCode(NEC)requirestheframe andexternal

electrically conductive parts of the generator be properly

connectedto an approvedearthground.Local electricalcodes

may also require proper grounding of the generator.Consult

with a localelectricianfor groundingrequirementsinthearea.

• Use a groundfault circuit interrupter in any damp or highly

conductivearea(such as metaldecking or steelwork).

• Do not useworn, bare,frayed or otherwisedamagedelectrical

cord setswith the generator.

• Beforeperforminganymaintenanceonthegenerator,disconnect

the enginestarting battery (if equipped)to prevent accidental

start up. Disconnectthe cablefrom the batterypost indicated

by a NEGATIVE,NEGor (-) first. Reconnectthat cable last.

• In caseof accidentcausedby electricshock, immediatelyshut

down the source of electrical power. If this is not possible,

attempt to free the victim from the live conductor. AVOID

DIRECTCONTACTWITHTHEVICTIM, Use a non-conducting

implement,such asa rope or board,to freethevictim from the

live conductor.If the victim is unconscious,applyfirst aid and

getimmediatemedical help.

FIREHAZARDS

• GasolineishighlyFLAMMABLEand itsvaporsare EXPLOSIVE.

Do not permitsmoking,open flames, sparksor heat in the

vicinitywhilehandlinggasoline.

• Neveraddfuel whileunit isrunning or hot. Allow engineto cool

completelybeforeaddingfuel.

• Never fill fuel tank indoors, Comply with all laws regulating

storageand handlingof gasoline.

• Do not overfill the fuel tank. Always allow roomfor fuel

expansion. If tank is over=filled,fuel can overflow onto a hot

engineandcauseFIREor an EXPLOSION.Neverstoregenerator

with fuel in tank where gasolinevapors might reach an open

flame, spark or pilot light (as on a furnace, water heateror

clothes dryer). FIREor EXPLOSIONmay result. Allow unit to

cool entirelybeforestorage.

• Wipe up any fuel or oil spills immediately.Ensure that no

combustiblematerialsareleft on or nearthegenerator.Keepthe

areasurroundingthe generatorcleanandfree from debrisand

keepa clearanceof five (5) feet on all side to allow for proper

ventilationofthe generator.