SX1819T: Parts Breakdown & Operating Manual 04/19/10

Operating Instructions • Warning Information • Parts Break down

Rivet Capacity ..............................1/4"

Traction Power................ 3,960 ft. lbs.

Air Pressure ....................... 70-100 psi

Stroke Length ...............................3/4"

SX1819T

1/4" HEAVY

DUTY RIVET

GUN

Height .................................... 12-9/16"

Weight ...................................... 5.5 lbs

Minimum Hose Size ..............3/8" I.D.

Air Inlet ................................. 1/4" NPT

SPECIFICATIONS

•Alwaysreadinstructionmanualcarefully

beforeuse.

•Alwayswearsafetygoggles

(Userandbystanders).

•Alwayswearhearingprotection

(Userandbystanders).

•Avoidprolongedexposuretovibration.

•Alwaysdisconnectairsupplybeforeproceeding

withanyassemblyordisassemblyprocedures.

•Donotexceed100psimax.airpressure.

•Inspecthydraulicsectionpriortouse.

Donotuseifcracked.

•Alwaysfollowpropermaintenanceprocedures.

•Keepexhaustportpointedawayfromface.

Somedustcreatedbypowersanding,sawing,grinding,

drilling,andotherconstructionactivitiescontainschemicals

knowntocausecancer,birthdefectsorotherreproductive

harm.Someexamplesofthesechemicalsare:

• leadfromlead-basedpaints,

• crystallinesilicafrombricksandcement

andothermasonryproducts,and

• arsenicandchromiumfrom

chemically-treatedlumber.

Yourriskfromtheseexposuresvaries,dependingonhow

oftenyoudothistypeofwork.Toreduceyourexposureto

thesechemicals:workinawellventilatedarea,andworkwith

approvedsafetyequipment,suchasthosedustmasksthatare

speciallydesignedtofilteroutmicroscopicparticles.

WARNING

WARNING

SX1819T: Parts Breakdown & Operating Manual 2 04/19/10

WARNING!

FAILURE TO OBSERVE THESE WARNINGS

COULD RESULT IN INJURY.

This Instruction Manual Contains

Important Safety Information.

READ THIS INSTRUCTION MANUAL

CAREFULLY AND UNDERSTAND ALL

INFORMATION BEFORE OPERATING

THIS TOOL.

• Always operate, inspect and maintain this

toolin accordancewithAmericanNational

StandardsInstituteSafetyCodeofPortable

Air Tools (ANSI B186.1) and any other

applicablesafetycodesandregulations.

• For safety, top performance and maximum

durability of parts, operate this tool at 90

psi/6.2 bar max air pressure with 3/8"

diameterairsupplyhose.

• Alwayswearimpact-resistanteyeandface

protection when operating or performing

maintenance on this tool. Always wear

hearingprotectionwhenusingthistool.

• High sound levels can cause permanent

hearing loss. Use hearing protection as

recommended by your employer or OSHA

regulation.

• Keep the tool in efficient operating

condition.

• Operators and maintenance personnel

mustbephysicallyabletohandlethebulk,

weightandpowerofthistool.

• Airunderpressurecancausesevereinjury.

Never direct air at yourself or others.

Always turn off the air supply, drain hose

of air pressure and detach tool from air

supply before installing, removing or

adjusting any accessory on this tool, or

beforeperforminganymaintenanceonthis

tool.Failuretodosocouldresultininjury.

Whip hoses can cause serious injury.

Alwayscheckfordamaged,frayedorloose

hosesandfittings,andreplaceimmediately.

Donotusequickdetachcouplingsattool.

Seeinstructionsforcorrectset-up.

• Air powered tools can vibrate in use.

Vibration, repetitive motions or

uncomfortable positions over extended

periods of time may be harmful to your

handsandarms.Discontinueuseoftoolif

discomfort,tinglingfeelingorpain occurs.

Seekmedicaladvicebeforeresuminguse.

• Place the toolonthe workbeforestarting

the tool. Do not point or indulge in any

horseplaywiththistool.

• Slipping, tripping and/or falling while

operating air tools can be a major cause

of serious injury or death. Be aware of

excess hose left on the walking or

worksurface.

• Keep body working stance balanced and

firm. Do not overreach when operating

thetool.

• Anticipateandbealertforsuddenchanges

inmotionduring startupand operationof

anypowertool.

• Donot carry tool by the hose.Protectthe

hosefromsharpobjectsandheat.

• Tool shaft may continue to rotate briefly

after throttle is released. Avoid direct

contact with accessories during and after

use. Gloves will reduce the risk of cuts

orburns.

• Keep away from rotating end of tool.

Do not wear jewelry or loose

clothing. Secure long hair. Scalping can

occur if hair is not kept away from tool

and accessories. Choking can occur if

neckwear is not kept away from tool

andaccessories.

• Donotexceed100psimaxairpressure.

• Always disconnect air supply before

proceeding with any assembly or

disassemblyprocedures.

• Keepexhaustportpointedawayfromface.

• Inspect the hydraulic section prior to use.

Donotuseifcracked.Contactthedistributor

forrepairorreplacement.

• Donotpoundonthenosepieceortheendof

theheadorforcetherivetintotheholeofthe

nosepieceasthiswilldamagethetool.

• Makesureallpartsarecorrectlyandsecurely

fastened.

• Always follow proper maintenance

procedures.

• Do not lubricate tools with flammable or

volatile liquids such as kerosene, diesel

orjetfuel.

• Donotforcetoolbeyonditsratedcapacity.

• Do not remove any labels. Replace any

damagedlabels.

• Use accessories recommended by

SunexTools®.

WARNING

SX1819T: Parts Breakdown & Operating Manual 3 04/19/10

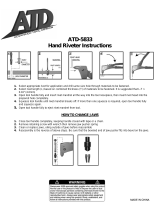

SX1819T

1/4" HEAVY DUTY RIVET GUN

DESCRIPTION

DESCRIPTION

DESCRIPTION

PART

NO.

PART

NO.

PART

NO.

REF.

NO.

REF.

NO.

REF.

NO.

QTY.

QTY.

QTY.

1 RS819101 HydraulicSection 1

1A RS819108 PlungerRodGuide 1

1D RSOR1823 O-Ring 1

1E RSOR2227 O-Ring1

2 RSBR1217 Back-upRing 4

3 RSOR1217 O-Ring 4

4 RS721301 HydraulicPlunger 1

5 RSBR2431 Back-upRing 1

6 RSOR2431 O-Ring 2

7 RS721309 ReturnSpring 1

8 RS721112 RearGland1

8A RS214103 GuideTube 1

9 RSOR3034 O-Ring 1

10 RS214306 Nut 1

10A RSWW1317 WaveWasher 1

11 RS214308 Spring 1

12 RS214302 JawPusher 1

13 RS819303 Jaw"L" 2

14 RS819304 JawHousing 1

14A RS721305 JawHousingCoupler 1

15 RS819105 Head 1

15A RS819106 LockNut 1

16 RS721401 AirCylinderBody 1

17 RS918109 LockNut 1

17A RSOR2832 O-Ring 1

18 RS721502 PackingRing 1

18A RS721503 FrontHeadDisc 1

18B RS721504 RearHeadDisc 1

18C RSOR0509 O-Ring 1

18D RS918504 RearDisc 1

19 RS819501 PlungerRod 1

20 RSPW0512 Washer 1

21 RS508020 LockScrew 1

22 RS612505 BumperRing 1

22A RS819500 PistonAssy(incl.#18-#22) 1

23 RS721402 AirCylinderCap 1

23A RSOR8591 O-Ring 1

23B RSCH8084 RetainingRing 1

24 RS918207 ThrottleValve 1

25 RS656204 ThrottleValveSpring 1

26 RSOR1417 O-Ring 2

27 RS612206 ValvePlug 1

28 RS918200 ValveTubeAssy 1

28A RS918204 ValveTubeSpring 1

28B RS618605 BrassCollar 1

28C RSOR0914 O-Ring 1

28D RSOR0812 O-Ring 1

29 RS612611 Trigger 1

29A RS918602 Linkage 1

29B RS721603 RockerArm 1

29C RSSP3006 RollPin 2

29P RSSP3018 RollPin 2

30 RS612706 NosePiece3/16"(4.8mm) 1

RS612708 NosePiece1/4"(6.4mm) 1

31 RS922100 SwivelJointAssy

(incl.#31A-#31D) 1

31A RS92201S MaleInletBody 1

31B RS922A01 FemaleInletBody 1

31C RSCS1316 SnapRing 1

31D RSOR1015 O-Ring 2

32 RS612901 Deflector 1

33 RS612904 Multi-Wrench(A) 1

34 RS918905 Multi-Wrench(B) 1

35 RS721403 RubberBoot 1

15

30

12

11

26

28D

28

28B

28C

29C

29P

16

29B

31B

31C

31D

31D

31A

24

25

26

27

28A

29C

29A

29

29P

14A

10A

10

2

3

2

3

1

4

6

20

21

23A

23

23B

18C

19

17

17A

1D

1E

1A

3

2

3

2

22

35

18A

18

18B

18D

6

5

7

8A

9

8

32

33

34

15A

14

13

SX1819T: Parts Breakdown & Operating Manual 4 04/19/10

3. Jaw Opening Adjustment:

Toobtainthemaximumstrokeofthetool,properdistancesettingbetween

thejaw housingandtheheadisveryimportant.Firstloosen thelocknut.

A rivet is then inserted into the nosepiece which should be selected to

matchthe rivetsize to beset.While screwingor unscrewing thehead to

achievetheminimum opening ofthejaws,checkif the rivetmandrelcan

beremovedandinsertedfreely.Fastenthelocknutaftertheadjustment.

Maintenance...

1. Checkthetightnessoftheconnectionsbetweenthejawhousingcoupler,

nut,jawhousing,andthehydraulicplunger,thenosepiece,theheadand

thelocknut.

2. If the jaws show excessive wear and/or are dirty, follow the steps

providedintheservicingproceduressection.

Troubleshooting...

1. Rivet mandrel is gripped by the jaws but the rivet can not be set

and mandrel can not be bro ken:

CAUSE:Lowairpressureorlossofhydraulicfluid.

REMEDY:Increaseairpressureto7bar(100psi)maximumattool.Make

sureallfittingsincludingrearglandandheadaretight.Ifmalfunction

persists,callauthorizedSunexTools

®

warrantycenter.

2. Mandrel does not fit completely into nosepiece or fails to eject:

CAUSE:JawHousingdistanceincorrect.

REMEDY:Loosentheheadandchecktheratedstrokelength.

Ifshorter,searchforwornordamagedO-ringsandreplaceit.

CAUSE:Jawsaredirtyordamaged.

REMEDY:Cleanorreplacethejaws.

CAUSE:Fatiguedjawpusherspring.

REMEDY:Replacethejawpusherspring.

CAUSE:FatiguedReturnSpring.

REMEDY:Replacethereturnspring.

CAUSE:Airleakageinvacuumsystem.

REMEDY:Searchforwornordamagedsealsinthevacuumsystemand

replaceit.

3. Tool takes more than two strokes under ideal con di tions to set rivet

and break mandrel:

CAUSE:Lowairpressure.

REMEDY: IncreaseairpressurebutdoNOTexceed7bar(100psi)

attool.

CAUSE:LooseNosepieceorimpropersizeofnosepiece.

REMEDY: Tightennosepieceoruserightsize.

CAUSE:Rivetbodytoolongforthethicknessofthejoint.

REMEDY:Therivetbodyshouldbe3-6mmlongerthanthethicknessof

jointonly.

Ifmalfunctionpersists,callanauthorizedSunexTools

®

warrantycenter.

Air Supply...

Toolsofthisclassoperateonawiderangeofairpressures.Itisrecommended

thatairpressureofthesetoolsmeasures90psiatthetoolwhilerunningfree.

Higher pressure (over 90 psi;6.2 bar)raisesperformance beyondthe rated

capacity ofthe tool whichwill shorten toollife because of faster wear and

couldcauseinjury.

Alwaysuse clean,dryair.Dust,corrosivefumesand/or waterinthe air line

willcausedamagetothetool.Draintheairtankdaily.Cleantheairinletfilter

screenonatleastaweeklyschedule.Therecommendedhookupprocedurecan

beviewedinabovefigure.

The air inlet used for connecting air supply has standard 1/4" NPT. Line

pressureshouldbeincreasedtocompensateforunusuallylongairhoses(over

25feet).Minimumhosediametershouldbe3/8"I.D.andfittingsshouldhave

thesameinsidedimensionsandbetightlysecured.

Lubrication...

Lubricatetheairtoolwithqualityairtooloil.Ifnoairlineoilerisused,run1/2

ounceofairtooloilthroughthetoolbysquirtingoilintothetool'sairinletor

intothenearestconnectiontotheairinlet,reconnectingairsupply,andthen

runningtool.Donotusemorethan1/2ounceofoil,asoverfillingwillreduce

theperformanceofthetool.

Operation...

When the Lever/Trigger is depressed, the throttle valve is moved down off

its seat bythe valve tube. Air enters the bottom ofthe air cylinder, forcing

thepistonassemblyup.Asthepistonassemblyrises,theplungerrodforces

hydraulic fluid in to the upper part of the hydraulic section, retracting the

hydraulicplunger. Meanwhile, thejawsgripthemandreloftherivet, pulling

untiltherivetissetandbreakingthemandrelintheprocess.

Whentheleverisreleased,thethrottlevalveresetsandshutsofftheairsupply.

Thevalvetubespringthenliftsthevalvetubeandexhauststheairthroughout

thehollowofthevalvetube.Thereturnspringreturnsthehydraulicplungerto

itsoriginalposition.Thisopensthejaws,releasesthemandrel,andretractsthe

pistonassemblybacktoitsoriginalstaticsite.

Servicing Procedures...

1. Changing Nosepieces:

Hookupthetooltotheairlineanddepressthelever.Whilecontinuingtohold

theleverdown,usethemaintenancetooltoremovetheunwantednosepiece

andtightenthenewnosepieceinplaceagain.Whentheleverisreleasedand

thetoolisatrest,acircularopeningshouldbevisiblewhenlookingthrough

thehydraulicsectionfromtherearglandtothenosepiece.

2. Cleaning and Changing of the Jaws:

Disconnect the tool from the air line and then remove the head with the

maintenancetool. Hold thejawhousingcouplerfirmlyandremovethe jaw

housing. Clean the jaws with either a steel brush or solvent. If excessive

wearisapparent,replacethemwithnewjaws.Beforereassembling,applya

thincoatofoiltotheslidingsurfaceofthejaws.Reassemblethetoolinthe

reverseorderwhilemakingsurethatthechamferedendofthejawpusheris

incontactwiththejawsproperly.

Operating Instructions • Warning Information • Parts Break down

SX1819T: Parts Breakdown & Operating Manual 5 04/19/10

Limited Warranty...

SUNEX INTERNATIONAL, INC. WARRANTS TO ITS CUSTOMERS THAT THE COMPANY’S SUNEX TOOLS

®

BRANDED

PRODUCTS ARE FREE FROM DEFECTS IN WORKMANSHIP AND MATERIALS.

Sunex International, Inc. will repair or replace its Sunex Tools

®

branded products which fail to give satisfactory service due to defective workmanship

or materials, based upon the terms and conditions of the following described warranty plans attributed to that specific product. This product carries a

ONE-YEARwarranty.Duringthiswarrantyperiod,SunexTools

®

willrepairorreplaceatouroptionanypartorunitwhichprovestobedefectiveinmaterialor

workmanship.

Other important warranty information...

Thiswarrantydoesnotcoverdamagetoequipmentortoolsarisingfromalteration,abuse,misuse,damageanddoesnotcoveranyrepairsorreplacementmade

byanyoneotherthanSunexTools

®

oritsauthorizedwarrantyservicecenters.TheforegoingobligationisSunexTools

®

soleliabilityunderthisoranyimplied

warrantyandundernocircumstancesshallwebeliableforanyincidentalorconsequentialdamages.

Note: Somestatesdonotallowtheexclusionorlimitationofincidentalorconsequentialdamages,sotheabovelimitationorexclusionmaynotapplytoyou.

ReturnequipmentorpartstoSunexTools

®

,oranauthorizedwarrantyservicecenter,transportationprepaid.Becertaintoincludeyournameandaddress,

evidenceofthepurchasedate,anddescriptionofthesuspecteddefect.

Ifyouhaveanyquestionsaboutwarrantyservice,pleasewritetoSunexTools

®

.Thiswarrantygivesyouspecificlegalrightsandyoumayalsohaveotherrights

whichvaryfromstatetostate.RepairkitsandreplacementpartsareavailableformanyofSunexTools

®

productsregardlessofwhetherornottheproductis

stillcoveredbyawarrantyplan.

SHIPPING ADDRESS: Sunex Tools • 315 Hawkins Rd. • Travelers Rest, SC 29690

MAILING ADDRESS: Sunex Tools • P.O. Box 1233 • Travelers Rest, SC 29690

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

/